Who Invented Laser Cutting Machine

Have you ever wondered who invented laser cutting machines? The journey begins with the brilliance of multiple inventors. Theodore Maiman made history in 1960 by creating the first operational laser, a groundbreaking step in harnessing light for practical use. Just a few years later, Kumar Patel revolutionized the field with his invention of the CO2 laser in 1964, making industrial applications more efficient. Visionaries like Marshall Jones and Gordon Gould pushed the boundaries further, transforming lasers into powerful tools for precision cutting. Their combined efforts shaped the technology that powers industries today.

The Foundations of Laser Technology

Albert Einstein's Theoretical Contributions

Have you ever thought about where the story of lasers truly begins? It all started in 1917 when Albert Einstein introduced the concept of stimulated emission of radiation. This idea explained how atoms could release energy in the form of light when triggered by external photons. Einstein’s theory wasn’t just revolutionary—it became the backbone of modern laser technology. Without his groundbreaking work, the idea of amplifying light into a focused beam wouldn’t exist.

Einstein’s insights revealed how light interacts with atomic structures. He showed that this interaction could amplify electromagnetic radiation, paving the way for what we now call light amplification by stimulated emission of radiation. This principle is the very mechanism that powers every laser today. His work didn’t just stop at theory; it inspired generations of scientists to explore the practical applications of light.

“The history of laser cutting began back in 1917 when Albert Einstein came up with the theory of ‘stimulated emission of radiation,’ the principle behind the modern laser.”

Einstein’s contributions remind us that even the most advanced technologies often have their roots in pure scientific curiosity.

Theodore Maiman and the First Operational Laser

Fast forward to 1960, and you’ll find Theodore Maiman making history. He built the first working laser, turning Einstein’s theoretical ideas into a tangible reality. Using a synthetic ruby crystal, Maiman created a device that could emit a concentrated beam of light. This invention wasn’t just a scientific milestone—it was a game-changer.

Maiman’s laser demonstrated how light could be controlled and focused with incredible precision. This breakthrough laid the foundation for countless innovations, from medical devices to industrial tools. The first working laser wasn’t just a machine; it was a glimpse into the future of technology.

What made Maiman’s invention so special? It wasn’t just the science—it was the possibilities. His laser showed the world that light could be more than illumination. It could be a tool, a weapon, or even a means of communication. Maiman’s work proved that Einstein’s theories weren’t just ideas—they were the keys to unlocking a new era of innovation.

Early Applications of Laser Technology

Once Maiman introduced the laser, the world quickly realized its potential. Early applications focused on scientific research and industrial uses. Lasers became essential tools for measuring distances, analyzing materials, and even performing surgeries. Their ability to produce precise, high-energy beams of light made them invaluable.

One of the first industrial uses of lasers was cutting and drilling. Engineers discovered that lasers could cut through materials like metal and diamond with unmatched accuracy. This marked the beginning of laser cutting technology, which would later revolutionize manufacturing.

Lasers also found their way into communication systems. Scientists used them to transmit information over long distances, laying the groundwork for modern fiber-optic networks. These early applications proved that lasers weren’t just a scientific curiosity—they were a practical solution to real-world problems.

From Einstein’s theories to Maiman’s invention, the journey of laser technology shows how curiosity and innovation can change the world. The ability to harness light has transformed industries, improved lives, and opened doors to endless possibilities.

Gordon Gould: A Visionary in Laser Development

Early Life and Education

Have you ever wondered what shapes a visionary mind? Gordon Gould, born in 1920 in New York City, grew up with a natural curiosity about science. His fascination with physics and engineering led him to pursue higher education at Columbia University. There, he studied under some of the most brilliant minds of the time, which fueled his passion for innovation.

Gould’s academic journey wasn’t just about earning degrees. It was about exploring ideas that could change the world. His early exposure to cutting-edge research laid the groundwork for his future contributions to laser technology. You can imagine how those formative years shaped his determination to push boundaries and challenge conventional thinking.

Coining the Term "Laser" and Foundational Work

Did you know that the word "laser" itself owes its existence to Gordon Gould? In 1957, Gould coined the term "LASER," which stands for Light Amplification by Stimulated Emission of Radiation. This wasn’t just a catchy acronym. It captured the essence of a groundbreaking technology that would soon revolutionize industries.

Gould didn’t stop at naming the technology. He also outlined its potential applications in a notebook, which included ideas for cutting, welding, and even medical uses. His vision extended far beyond the lab. He saw lasers as tools that could transform everyday life. This foresight made him a true pioneer in the field.

“Gould’s notebook became a blueprint for the future of laser technology, showcasing his ability to think ahead of his time.”

His foundational work wasn’t just theoretical. It was practical and forward-thinking, setting the stage for the development of laser cutting machines and other innovations.

Patent Battles and Legal Challenges

Gould’s journey wasn’t without obstacles. Have you ever faced a challenge that tested your resolve? For Gould, it was a decades-long battle over patents. Despite his early contributions, he struggled to gain recognition and legal rights for his work. His patent applications faced delays, and others claimed credit for similar inventions.

The legal battles weren’t just about ownership. They were about the value of innovation. Gould’s persistence paid off in the 1970s, when he finally secured patents for his contributions to laser technology. These patents became incredibly valuable, as lasers had already started to impact various industries.

The delays, however, had an unexpected benefit. They allowed laser technology to spread into multiple fields, from manufacturing to medicine. Gould’s struggle highlighted the importance of protecting intellectual property while also fostering innovation.

“The debate over whether Gould invented the laser remains unresolved, but his contributions to its development are undeniable.”

Gould’s story is a testament to resilience and vision. His work didn’t just shape the technology. It inspired others to explore its possibilities, proving that innovation often comes with challenges worth overcoming.

Kumar Patel and the CO2 Laser Breakthrough

Development of the CO2 Laser at Bell Labs

Imagine a world where cutting through tough materials like steel or aluminum was slow and inefficient. That’s the challenge Kumar Patel tackled in 1964 while working at Bell Labs. He didn’t just improve laser technology—he transformed it. Patel invented the carbon dioxide (CO2) laser, a groundbreaking innovation that quickly became the most powerful continuously operating laser of its time.

Patel’s approach was revolutionary. Instead of relying on solid-state materials like ruby crystals, he developed a gas laser using a mixture of carbon dioxide, nitrogen, and helium. This unique combination allowed the CO2 laser to produce a high-energy beam that operated more efficiently than earlier designs. It wasn’t just powerful—it was practical. The CO2 laser could run continuously, making it ideal for industrial applications.

“The CO2 laser wasn’t just an invention; it was a leap forward in efficiency and versatility.”

Patel’s work didn’t stop at creating the laser. He also explored its potential uses, setting the stage for its adoption in industries worldwide. His invention wasn’t just a scientific achievement—it was a tool that would reshape manufacturing and beyond.

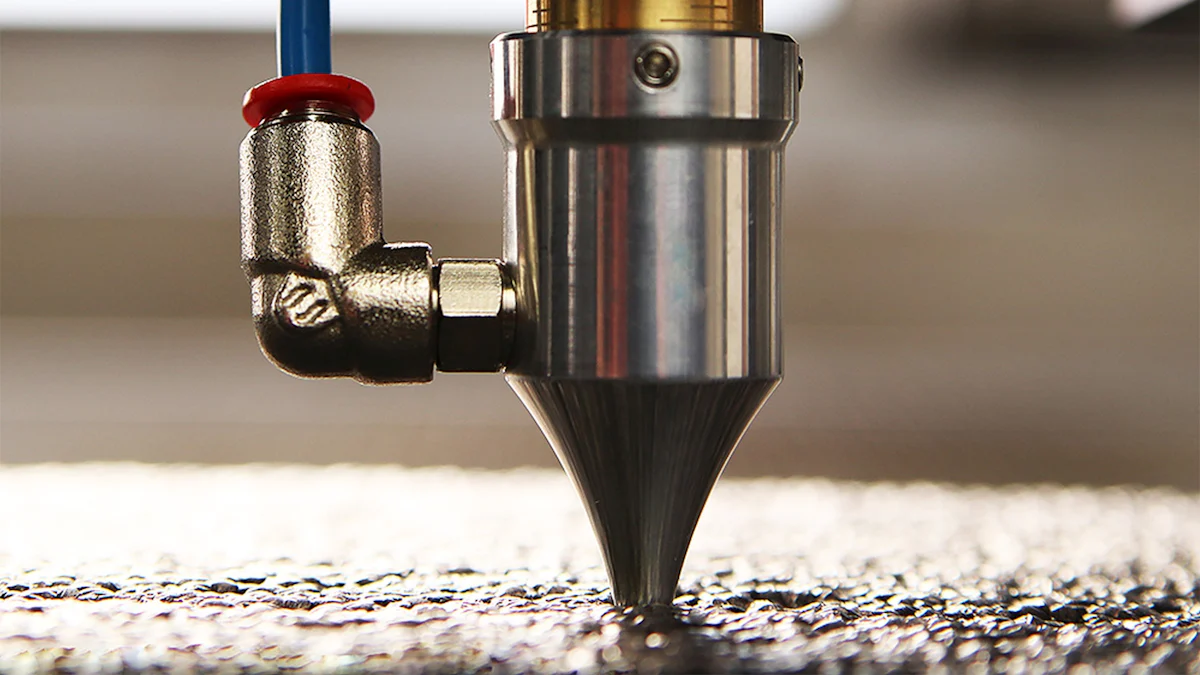

Impact of the CO2 Laser on Industrial Applications

You might wonder, what made the CO2 laser so impactful? Its ability to cut through a wide range of materials with precision and speed changed the game for industries. Before Patel’s invention, cutting processes were slower and less accurate. The CO2 laser introduced a new level of efficiency, especially in fields like metalworking and manufacturing.

Industrial lasers powered by Patel’s design became essential tools for cutting, welding, and engraving. They could handle materials like stainless steel, aluminum, and even non-metals such as wood and plastic. This versatility made the CO2 laser a staple in factories and workshops around the globe.

The CO2 laser wasn’t just about speed. It also reduced costs. By improving energy efficiency and minimizing waste, it offered a more economical solution for businesses. Patel’s invention didn’t just make processes faster—it made them smarter.

“The CO2 laser set the standard for industrial lasers, proving that innovation could drive both performance and affordability.”

Today, you’ll find CO2 lasers in countless applications, from automotive manufacturing to medical device production. Patel’s work didn’t just solve a problem—it opened doors to new possibilities. His invention remains a cornerstone of modern industrial lasers, proving that one breakthrough can change everything.

Marshall Jones: Innovator in Laser Cutting Machines

Early Life and Career

Have you ever wondered what drives someone to revolutionize an entire industry? For Marshall Jones, it was a mix of curiosity, determination, and a passion for solving problems. Born in 1941 in Louisiana, Jones grew up in a time when opportunities for African Americans in science and engineering were limited. Despite these challenges, he pursued his education with relentless focus. He earned degrees in mechanical engineering, eventually completing his Ph.D. at the University of Massachusetts Amherst.

Jones didn’t just stop at academic achievements. He began his career at General Electric (GE) in the 1970s, where he quickly made a name for himself. His early work focused on developing advanced manufacturing techniques. You can imagine how his innovative mindset and technical expertise set the stage for groundbreaking contributions to laser technology. Jones wasn’t just an engineer; he was a trailblazer who believed in pushing boundaries.

“Marshall Jones’ journey reminds us that perseverance and vision can overcome even the toughest barriers.”

Pioneering High-Power Lasers for Cutting and Welding

When you think about cutting-edge technology, lasers probably come to mind. But did you know that Marshall Jones played a pivotal role in making lasers practical for industrial use? In the late 1970s, Jones pioneered the development of fiber-optic laser beam delivery systems. This innovation allowed lasers to become powerful enough to cut through tough materials like steel, titanium, and nickel-based alloys. His work didn’t just improve laser performance—it transformed how industries approached manufacturing.

Jones’ innovations weren’t limited to cutting. He also developed methods for welding and drilling with lasers, enabling manufacturers to work with materials at multiple angles. This versatility made lasers indispensable in industries like automotive and aerospace. Companies like Ford and Lockheed Martin adopted his technologies to create more efficient and precise products.

“Jones’ fiber-optic laser systems didn’t just cut through metal—they cut through the limitations of traditional manufacturing.”

His contributions laid the foundation for modern industrial laser welding and cutting. Today, his work continues to influence everything from car production to the creation of medical devices.

Overcoming Technical Challenges in Industrial Applications

Have you ever faced a problem so complex it seemed unsolvable? That’s the kind of challenge Marshall Jones tackled in his career. Early laser systems were bulky, inefficient, and difficult to integrate into industrial settings. Jones addressed these issues head-on by inventing novel methods to make lasers more practical and user-friendly.

One of his most significant breakthroughs was the development of fiber-optic systems. These systems made it easier to deliver laser beams with precision, even in challenging environments. By overcoming technical hurdles, Jones made lasers more accessible to industries worldwide. His work didn’t just solve problems—it opened doors to new possibilities.

Jones also invented techniques for welding dissimilar metals, a feat that had long puzzled engineers. This innovation expanded the range of materials that could be used in manufacturing, making processes more versatile and cost-effective. His ability to think outside the box turned obstacles into opportunities.

“Marshall Jones didn’t just innovate—he redefined what was possible in industrial laser applications.”

His contributions earned him a place in the National Inventors Hall of Fame, a testament to his lasting impact on technology and industry. Jones’ legacy isn’t just about the machines he helped create. It’s about the way he inspired others to see challenges as opportunities for innovation.

Recognition and Awards

When you think about groundbreaking contributions to technology, recognition often follows. For Marshall Jones, his work didn’t just earn accolades—it reshaped industries. His innovations in laser technology, particularly in fiber-optic laser beam delivery systems, revolutionized manufacturing processes. These systems made lasers powerful enough to cut through tough materials like steel, titanium, and nickel-based alloys. They also enabled welding and drilling at multiple angles, which transformed how industries approached production.

Jones’ achievements didn’t go unnoticed. He received numerous awards for his pioneering work. One of his most notable honors was his induction into the National Inventors Hall of Fame. This recognition celebrated his role in advancing industrial laser applications. His inventions became essential tools for companies like Ford and Lockheed Martin, proving their value in creating efficient and precise products.

“Marshall Jones’ contributions to laser technology have left an indelible mark on modern manufacturing.”

Beyond industry recognition, Jones’ work inspired countless engineers and scientists. His ability to solve complex problems, like welding dissimilar metals, showcased his innovative mindset. These breakthroughs didn’t just improve existing technologies—they opened new possibilities for future advancements. His legacy continues to influence fields like metal additive manufacturing and industrial laser welding.

Marshall Jones’ story reminds us that innovation isn’t just about creating something new. It’s about solving real-world problems and making a lasting impact. His awards and recognition stand as a testament to his vision, perseverance, and unmatched contributions to laser technology.

The Evolution of Laser Cutting Machines

The First Production-Oriented Laser Cutting Machine (1965)

In 1965, the world witnessed a groundbreaking moment in manufacturing. Western Electric introduced the first production-oriented laser cutting machine. This machine wasn’t just a technological marvel; it was a game-changer for industries. Designed specifically to cut holes in diamond dies, it showcased the incredible precision and power of lasers. You can imagine how revolutionary this was for manufacturers who had struggled with traditional cutting methods.

This early laser cutting machine used a ruby laser, which emitted a concentrated beam of light. The beam could cut through materials with unmatched accuracy. For the first time, industries had a tool that combined speed, precision, and efficiency. This innovation marked the beginning of a new era in manufacturing, where lasers became indispensable tools.

“The introduction of the first laser cutting machine in 1965 set the stage for decades of innovation in industrial applications.”

The success of this machine inspired further research and development. Engineers and scientists began exploring ways to enhance laser technology, leading to advancements that would transform industries worldwide.

Advancements in Precision and Efficiency

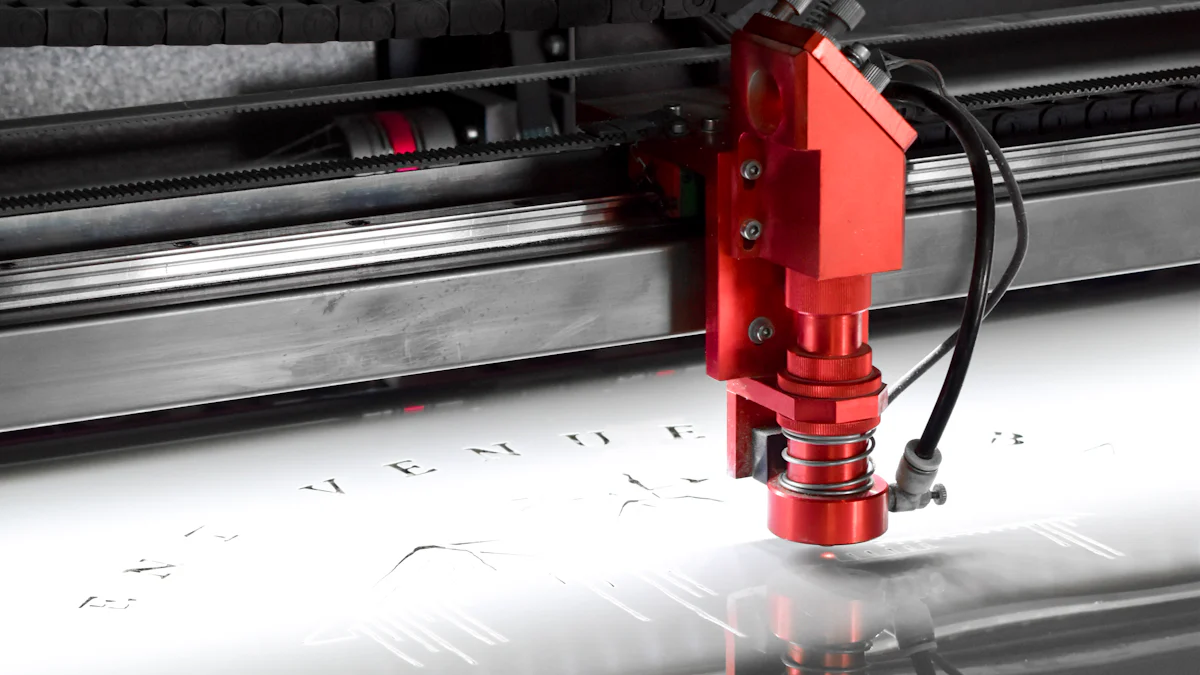

As laser technology evolved, so did its capabilities. Early machines were groundbreaking, but they had limitations. Over time, engineers focused on improving precision and efficiency. You’ve probably noticed how modern manufacturing demands perfection. Lasers became the answer to these demands.

One major advancement was the development of computer numerical control (CNC) systems. These systems allowed lasers to follow precise patterns, making intricate cuts possible. Imagine creating complex designs with pinpoint accuracy—lasers made it a reality. CNC technology also reduced human error, ensuring consistent results every time.

Another leap forward came with the introduction of high-power lasers. These lasers could cut through thicker materials, such as steel and titanium, without compromising speed or accuracy. Industries like automotive and aerospace quickly adopted these advancements, using lasers to create parts with unparalleled precision.

“Advancements in laser technology didn’t just improve manufacturing—they redefined what was possible.”

Efficiency also improved. Modern lasers consume less energy while delivering more power. This not only reduces costs but also minimizes environmental impact. Today, laser cutting machines are faster, more reliable, and more versatile than ever before.

Modern Laser Cutting Technologies: Fiber Lasers and CO2 Lasers

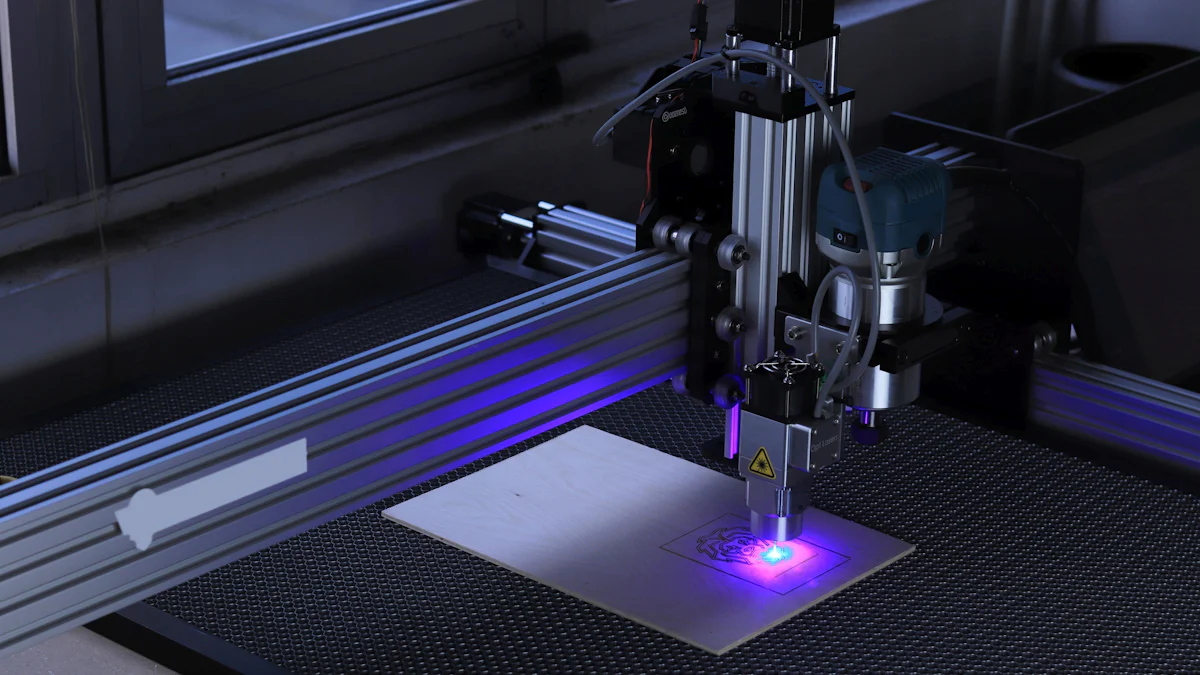

When you think about modern laser cutting, two technologies stand out: fiber lasers and CO2 lasers. Each has unique strengths, making them suitable for different applications.

Fiber lasers represent the latest in laser technology. They use optical fibers to amplify light, producing a highly focused beam. This makes them ideal for cutting metals like stainless steel and aluminum. Fiber lasers are incredibly efficient, requiring less maintenance and energy compared to older systems. Their speed and precision make them a favorite in industries that demand high performance.

CO2 lasers, on the other hand, have been around longer but remain highly effective. They use a gas mixture, including carbon dioxide, to generate the laser beam. CO2 lasers excel at cutting non-metal materials, such as wood, plastic, and glass. Their versatility makes them a popular choice for creative and artistic applications.

“Fiber lasers and CO2 lasers showcase how far laser technology has come, offering solutions for a wide range of needs.”

Both technologies continue to evolve. Researchers are exploring ways to combine their strengths, creating hybrid systems that offer even greater flexibility. The integration of automation and artificial intelligence is also pushing the boundaries of what laser cutting machines can achieve.

From the first production-oriented machine to today’s advanced systems, the evolution of laser cutting technology highlights the power of innovation. These machines have transformed industries, proving that progress is always possible when creativity meets determination.

Integration with Automation and AI

Imagine a world where laser cutting machines think and act almost like humans. That’s the reality today, thanks to automation and artificial intelligence (AI). These technologies have taken laser cutting to a whole new level, making it faster, smarter, and more efficient than ever before.

Automation allows laser cutting machines to perform repetitive tasks without constant human supervision. You can program these machines to follow precise instructions, ensuring consistent results every time. For example, in a factory setting, automated laser cutters can handle large-scale production runs with minimal downtime. This not only saves time but also reduces errors, giving you flawless cuts on every piece.

AI, on the other hand, brings intelligence into the mix. With AI, laser cutting machines can analyze data, learn from past operations, and even make decisions. Imagine a machine that adjusts its settings based on the material it’s cutting or predicts maintenance needs before a breakdown occurs. That’s the power of AI. It transforms laser cutters into adaptive tools that improve over time.

“AI-driven laser cutting systems are revolutionizing manufacturing by combining precision with adaptability.”

The integration of these technologies has also made laser cutting more accessible. User-friendly interfaces and smart software mean you don’t need to be an expert to operate these machines. AI algorithms guide you through the process, suggesting optimal settings and detecting potential issues. This makes laser cutting technology approachable for businesses of all sizes.

Here’s how automation and AI are reshaping laser cutting:

- Enhanced Precision: Machines equipped with AI can detect and correct deviations in real-time, ensuring perfect cuts.

- Increased Efficiency: Automation speeds up production while reducing waste, saving you both time and resources.

- Predictive Maintenance: AI monitors machine performance and alerts you to potential problems, preventing costly downtime.

- Customization at Scale: Automated systems allow for mass production of custom designs, meeting unique customer demands effortlessly.

Dr. Marshall Jones, a pioneer in laser technology, played a significant role in making these advancements possible. His work on fiber-optic laser beam delivery systems laid the groundwork for integrating lasers with modern technologies. Recognized with awards like the Coolidge Award and the GE ICON award, Jones’ contributions continue to inspire innovation in the field.

The combination of automation and AI doesn’t just make laser cutting more efficient—it makes it smarter. Whether you’re in manufacturing, design, or even healthcare, these advancements open up endless possibilities. The future of laser cutting is here, and it’s powered by intelligence and precision.

Applications and Impact of Laser Cutting Technology

Laser cutting technology has reshaped industries and sparked creativity in ways you might not expect. Its precision and versatility have made it a go-to tool for everything from manufacturing to artistic expression. Let’s explore how this incredible technology impacts various fields and why it’s so valuable.

Industrial Applications

Automotive and Aerospace Industries

In the automotive and aerospace sectors, laser cutting has become a game-changer. You’ve probably seen how cars and airplanes demand parts with extreme precision. Laser cutting delivers that accuracy, ensuring components fit perfectly every time. Since the 1960s, industries like these began adopting laser technology to streamline production. By the 1980s, gas laser cutting had become widespread, with over 20,000 industrial laser cutters in use globally.

For automotive manufacturers, lasers simplify cutting complex shapes in materials like steel and aluminum. This precision reduces waste and speeds up production. In aerospace, where safety is critical, lasers cut lightweight yet durable materials like titanium. The introduction of 3D laser cutting in 1979 further expanded possibilities, allowing engineers to create intricate designs for aircraft and spacecraft components.

“Laser cutting didn’t just improve manufacturing—it revolutionized it, making processes faster, safer, and more efficient.”

Electronics and Medical Device Manufacturing

Think about the tiny circuits inside your smartphone or the intricate tools used in surgeries. Laser cutting plays a vital role in creating these. Its ability to cut with microscopic precision makes it ideal for electronics and medical devices. Manufacturers use lasers to shape delicate materials like silicon wafers for semiconductors or to craft surgical instruments with unmatched accuracy.

In medical device production, lasers ensure tools meet strict hygiene and safety standards. For example, they can cut stainless steel without leaving burrs, which reduces the risk of contamination. This level of precision has made lasers indispensable in producing life-saving equipment.

Creative and Artistic Uses

Jewelry and Fashion Design

Laser cutting isn’t just for factories—it’s also a favorite among designers. In jewelry making, lasers help you achieve intricate patterns that would be nearly impossible by hand. Whether it’s engraving a delicate design on a ring or cutting fine details into a pendant, lasers make it happen with ease.

Fashion designers also love using lasers to create unique patterns on fabrics. Imagine a dress with precise, laser-cut lacework or a leather jacket with custom engravings. These techniques allow designers to push boundaries and bring their creative visions to life.

Architectural and Decorative Projects

Have you ever admired a beautifully designed building or a stunning piece of home décor? Chances are, laser cutting played a part in its creation. Architects use lasers to cut precise models and intricate designs for structures. This helps them visualize projects and refine details before construction begins.

In decorative arts, lasers enable you to craft custom pieces like wall panels, light fixtures, and furniture. The precision of laser cutting ensures every detail is flawless, whether it’s a geometric pattern or an elaborate floral design. This technology has opened up endless possibilities for artists and architects alike.

Environmental and Economic Benefits

Laser cutting doesn’t just enhance creativity and efficiency—it’s also better for the planet and your wallet. Traditional cutting methods often produce a lot of waste, but lasers minimize this by focusing energy only where it’s needed. This precision reduces material waste and lowers production costs.

Energy efficiency is another advantage. Modern laser systems consume less power while delivering high performance. This means businesses can save on energy bills while reducing their carbon footprint. Additionally, the durability of laser machines means fewer replacements and repairs, which further cuts costs.

“Laser cutting combines precision with sustainability, proving that innovation can benefit both industries and the environment.”

From reducing waste to saving energy, laser cutting technology offers solutions that are both practical and eco-friendly. It’s a win-win for businesses and the planet.

Laser cutting has come a long way since its early days in the 1960s. Whether it’s shaping the future of industries or inspiring artistic creations, its impact is undeniable. This technology doesn’t just cut materials—it cuts through limitations, opening up new possibilities for innovation and creativity.

The Legacy of Laser Cutting Technology

Contributions of Inventors to Science and Industry

The story of laser cutting technology is a testament to the brilliance and determination of its inventors. Each one left an indelible mark on science and industry. From Theodore Maiman’s creation of the first operational laser to Kumar Patel’s groundbreaking CO2 laser, these pioneers didn’t just invent tools—they redefined what was possible. Their work laid the foundation for modern manufacturing, medicine, and even art.

Marshall Jones, a trailblazer in industrial laser applications, revolutionized how industries approached cutting and welding. His innovations in fiber-optic laser delivery systems made it possible to cut through tough materials with precision. His contributions earned him a place in the national inventors hall of fame, a recognition that celebrates those who have changed the world through their ingenuity. Similarly, Gordon Gould’s vision and persistence in coining the term "laser" and outlining its potential applications inspired countless advancements.

These inventors didn’t just create machines; they opened doors to new possibilities. Their work continues to inspire engineers, scientists, and creators to push boundaries. The legacy of these innovators reminds us that curiosity and determination can lead to breakthroughs that shape entire industries.

“The contributions of these inventors extend far beyond their lifetimes, influencing everything from manufacturing processes to artistic expression.”

Impact on Modern Manufacturing and Creativity

Laser cutting technology has transformed modern manufacturing. Its precision and efficiency have made it a cornerstone in industries like automotive, aerospace, and electronics. You’ve likely benefited from products made possible by lasers, whether it’s the car you drive or the smartphone in your pocket. By enabling faster production and reducing waste, lasers have set new standards for quality and sustainability.

Beyond manufacturing, lasers have sparked creativity in unexpected ways. Artists and designers use laser cutting to craft intricate jewelry, fashion pieces, and architectural models. This technology allows creators to bring their most ambitious ideas to life with unmatched detail. Imagine a sculptor using a laser to carve delicate patterns into metal or a fashion designer creating custom lacework for a runway show. Lasers make these visions a reality.

The impact doesn’t stop there. Laser technology has also improved accessibility for small businesses and hobbyists. Affordable laser cutting machines empower individuals to start their own ventures, from crafting custom home décor to producing personalized gifts. This democratization of technology has fueled innovation at every level.

“Laser cutting bridges the gap between functionality and artistry, proving that technology can be both practical and inspiring.”

Future Trends in Laser Cutting Technology

The future of laser cutting technology looks brighter than ever. Advancements in automation and artificial intelligence are driving the next wave of innovation. Imagine a laser cutting machine that adjusts its settings automatically based on the material it’s working with. AI systems are already optimizing cutting processes, reducing waste, and improving precision. These smart machines are transforming manufacturing into a more efficient and sustainable industry.

Automation is also paving the way for lights-out manufacturing, where factories operate without human intervention. This approach increases production speeds and reduces errors, allowing businesses to meet growing demands with ease. Robotics and machine learning are further enhancing the capabilities of laser cutting machines, enabling them to handle complex tasks with minimal supervision.

Fiber lasers, known for their speed and efficiency, are becoming the go-to choice for cutting harder materials like titanium and composites. Researchers are also exploring hybrid systems that combine the strengths of fiber and CO2 lasers. These innovations promise to expand the range of materials that lasers can handle, opening up new possibilities for industries like aerospace and medical device manufacturing.

“The fusion of laser technology with AI and automation is revolutionizing manufacturing, making it smarter, faster, and more adaptable.”

As these advancements unfold, the role of laser cutting in personalized production will grow. Businesses will use lasers to create custom products at scale, meeting unique customer needs without sacrificing efficiency. This shift will not only improve customer satisfaction but also redefine how we think about mass production.

The legacy of laser cutting technology is still being written. With each new development, this remarkable tool continues to shape the future of industries and creativity alike. Whether you’re an engineer, artist, or entrepreneur, the possibilities are endless.

The journey to understanding who invented laser cutting machine reveals a collaborative effort that changed the world. Visionaries like Theodore Maiman, Kumar Patel, Gordon Gould, and Marshall Jones each played a pivotal role in shaping this groundbreaking technology. Their invention revolutionized industries by introducing unmatched precision and efficiency. Today, laser cutting machines power everything from automotive manufacturing to intricate artistic designs. As advancements in automation and AI continue to evolve, the legacy of these pioneers ensures that laser cutting remains at the forefront of innovation, driving progress across industrial and creative fields.

FAQ

What is laser cutting technology?

Laser cutting technology uses a high-powered laser beam to cut, engrave, or shape materials with precision. The laser focuses intense energy on a specific area, melting, burning, or vaporizing the material. This process allows you to achieve intricate designs and clean edges, making it ideal for industries like manufacturing, automotive, and even creative arts.

Who invented the first laser cutting machine?

The first production-oriented laser cutting machine was introduced in 1965 by Western Electric. It was designed to cut holes in diamond dies using a ruby laser. This innovation marked the beginning of laser cutting as a practical tool for industrial applications.

How has laser cutting evolved over time?

Laser cutting has come a long way since the 1960s. Early machines were limited in power and precision. Over the years, advancements like CO2 lasers, fiber lasers, and computer numerical control (CNC) systems have made the technology faster, more efficient, and highly accurate. Today, laser cutting integrates automation and artificial intelligence, pushing the boundaries of what’s possible.

“The evolution of laser cutting technology highlights its journey from a niche tool to a cornerstone of modern manufacturing.”

What are the main types of laser cutting machines?

The two most common types of laser cutting machines are fiber lasers and CO2 lasers:

- Fiber lasers: These are highly efficient and excel at cutting metals like stainless steel and aluminum. They require less maintenance and deliver faster results.

- CO2 lasers: These are versatile and work well with non-metal materials like wood, plastic, and glass. They are often used in creative and artistic applications.

Each type serves different purposes, so your choice depends on the material and application.

What industries benefit the most from laser cutting?

Laser cutting plays a vital role in several industries:

- Automotive and aerospace: It ensures precision in cutting parts like steel and titanium for vehicles and aircraft.

- Electronics: It helps create intricate circuits and components for devices like smartphones.

- Medical devices: It produces surgical tools and implants with unmatched accuracy.

- Creative arts: Designers use it for jewelry, fashion, and architectural projects.

Its versatility makes it indispensable across these fields.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers several advantages over traditional methods:

- Precision: Lasers can make intricate cuts with minimal errors.

- Speed: The process is faster, especially for complex designs.

- Versatility: It works on a wide range of materials, from metals to plastics.

- Efficiency: Lasers reduce waste and energy consumption, making them more eco-friendly.

Traditional methods often struggle to match the accuracy and efficiency of laser cutting.

What are the environmental benefits of laser cutting?

Laser cutting minimizes waste by focusing energy only where it’s needed. This precision reduces material loss during production. Modern laser systems also consume less energy, lowering their carbon footprint. Additionally, their durability means fewer replacements, which further reduces environmental impact.

“Laser cutting combines innovation with sustainability, proving that advanced technology can benefit both industries and the planet.”

Can laser cutting machines handle custom designs?

Yes, laser cutting machines excel at creating custom designs. With the help of CNC systems, you can program the machine to follow precise patterns. This capability makes it perfect for producing unique items like personalized gifts, intricate jewelry, or custom architectural models. Whether for mass production or one-of-a-kind creations, laser cutting delivers exceptional results.

What advancements are shaping the future of laser cutting?

The future of laser cutting lies in automation and artificial intelligence. AI-powered systems can analyze data, adjust settings, and even predict maintenance needs. Automation enables lights-out manufacturing, where factories operate without human intervention. Researchers are also exploring hybrid laser systems that combine the strengths of fiber and CO2 lasers, expanding their capabilities.

“The integration of AI and automation is transforming laser cutting into a smarter, faster, and more adaptable technology.”

Is laser cutting technology accessible for small businesses?

Absolutely! Modern laser cutting machines come in various sizes and price ranges, making them accessible to small businesses and hobbyists. Compact and affordable models allow you to create custom products, from home décor to personalized gifts. This accessibility empowers entrepreneurs to innovate and compete in diverse markets.

Why is laser cutting considered revolutionary?

Laser cutting has revolutionized industries by offering unmatched precision, efficiency, and versatility. It has transformed manufacturing processes, reduced waste, and opened doors to creative possibilities. From automotive production to artistic expression, laser cutting continues to push boundaries and redefine what’s possible.

“Laser cutting isn’t just a tool—it’s a game-changer that has reshaped how we create and innovate.”

See Also

Understanding Laser Cutting Machines And Their Various Types

A Simple Explanation Of How Laser Cutting Machines Operate

The Functionality Of CNC Laser Cutting Machines Explained

A Comprehensive Guide To Laser Cutting Machine Costs

The Role Of Laser Cutting Machines In Industrial Applications