Where to Buy Gold Laser Cutting Machine Maintenance Tips

Maintaining your gold laser cutting machine is essential to ensure its longevity and consistent performance. Proper maintenance not only keeps the machine running smoothly but also prevents costly repairs and downtime. By following regular maintenance routines, you can optimize the machine's efficiency and extend its lifespan. If you're wondering where to buy gold laser cutting machine models that are durable and reliable, it's important to research trusted suppliers. Additionally, reliable maintenance tips are readily available through trusted sources like manufacturer manuals, professional service providers, and online communities. These resources equip you with the knowledge to care for your machine effectively, ensuring it operates at peak performance for years to come.

Why Regular Maintenance is Crucial

Regular maintenance plays a vital role in ensuring your gold laser cutting machine operates efficiently and remains reliable over time. By dedicating time to proper upkeep, you can avoid unexpected issues and maximize the machine's potential.

Preventing Costly Repairs

Neglecting maintenance often leads to expensive repairs. When components wear out or fail due to lack of care, the repair costs can quickly add up. Regularly inspecting and cleaning your machine helps you identify minor issues before they escalate into major problems. For example, keeping the lenses and mirrors clean ensures precise laser focusing, which prevents damage to other parts. Additionally, replacing worn parts like belt drives and bearings on time avoids sudden breakdowns that could halt your operations. Preventive maintenance saves you money by reducing the need for emergency repairs.

Ensuring Optimal Performance

A well-maintained machine consistently delivers optimal performance. Daily cleaning and lubrication of moving parts reduce friction and wear, allowing the machine to function smoothly. Proper alignment checks ensure precision cutting, which directly impacts the quality of your work. Monitoring the cooling system and maintaining the laser generator daily also contribute to stable performance. Machines with regular maintenance experience fewer interruptions, enabling you to meet deadlines and maintain productivity. By following a maintenance routine, you ensure your machine operates at its best every day.

Extending Machine Lifespan

Maintenance directly contributes to an extended lifespan for your laser cutting machine. Regular lubrication prevents frictional wear, while cleaning debris from the machine bed reduces strain on its components. Keeping the machine in a well-ventilated area helps regulate temperatures, protecting sensitive parts from overheating. Preventive care safeguards your investment by reducing wear and tear over time. A machine that receives consistent attention lasts longer, providing you with reliable service for years. Proper maintenance not only preserves the machine but also enhances its value.

Key Maintenance Tips for Gold Laser Cutting Machines

Proper maintenance ensures your laser cutting machine operates efficiently and lasts longer. By following these essential tips, you can keep your equipment in top condition and avoid unexpected breakdowns.

Daily Inspection and Cleaning

Performing a daily inspection is vital for identifying potential issues early. Check the machine’s components for signs of wear or damage. Pay close attention to the lenses and mirrors, as dirt or debris can affect laser precision. Clean these parts carefully using a soft, lint-free cloth to maintain accurate laser focusing. Additionally, remove any debris from the machine bed and working area to prevent interference with operations. A clean machine not only performs better but also reduces the risk of long-term damage.

Lubrication of Moving Parts

Lubricating moving parts is a simple yet effective way to extend the lifespan of your laser cutting machine. Apply lubricant to components like bearings, rails, and drive belts regularly. This reduces frictional wear and ensures smooth operation. Use high-quality lubricants recommended by the manufacturer to achieve the best results. Neglecting lubrication can lead to increased wear and tear, which may cause costly repairs. By making lubrication a routine task, you enhance the machine’s performance and reliability.

Maintaining the Cooling System

The cooling system plays a critical role in regulating the temperature of your laser cutting machine. Monitor the quality and level of the circulating water in the laser tube daily. Replace the water periodically to prevent contamination, which can impact the machine’s efficiency. Ensure the cooling system operates within the recommended temperature range to protect sensitive components from overheating. Keeping the machine in a well-ventilated area further supports temperature regulation. A properly maintained cooling system safeguards your equipment and ensures consistent performance.

Daily Maintenance of the Laser Generator

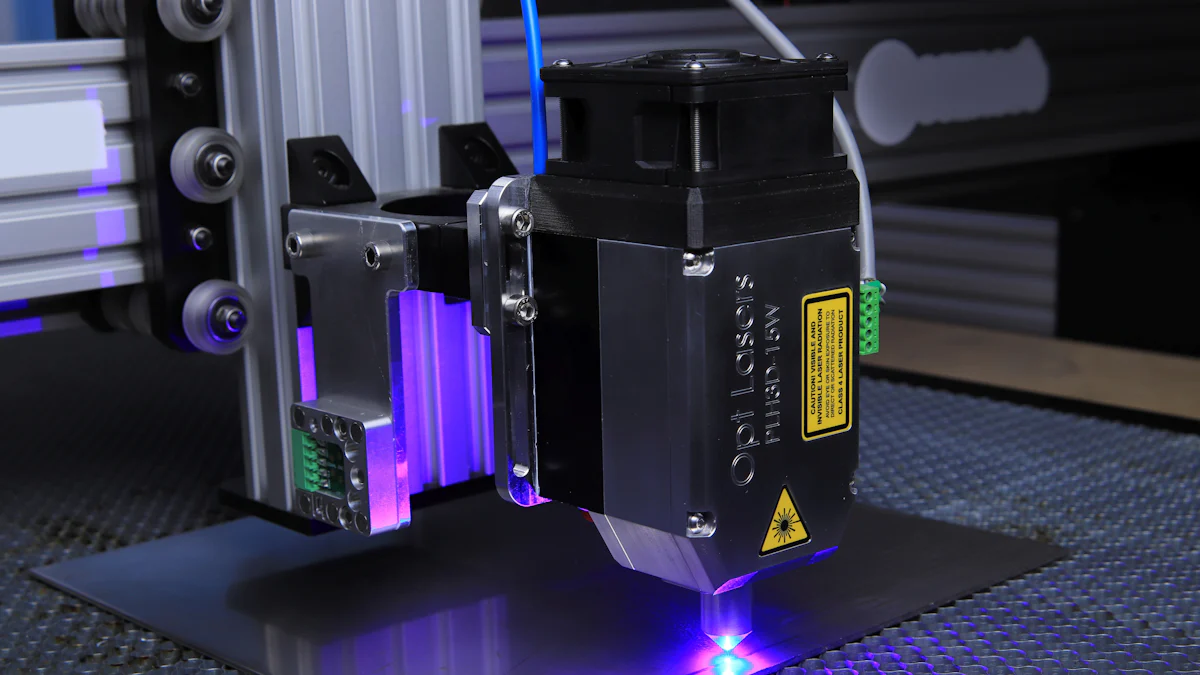

Performing daily maintenance of the laser generator is essential to keep your gold laser cutting machine running efficiently. The laser generator serves as the core of your machine, and its proper upkeep ensures consistent performance and precision. Start by inspecting the generator for any visible signs of wear or damage. Check for dust accumulation or debris around the generator, as these can interfere with its functionality. Use a soft, dry cloth to clean the surface and ensure no contaminants affect its operation.

Monitor the generator’s power output daily. Fluctuations in power can indicate underlying issues that need immediate attention. Keep an eye on the cooling system connected to the generator. Ensure the water levels are adequate and the circulating water remains clean. Contaminated water can reduce the generator’s efficiency and lead to overheating. Replace the water periodically to maintain optimal conditions.

Additionally, follow the manufacturer’s guidelines for maintaining the laser generator. These instructions often include specific cleaning techniques and recommended tools. By dedicating a few minutes each day to this routine, you can prevent potential problems and extend the lifespan of your machine’s most critical component.

Scheduling Professional Servicing

While daily maintenance is crucial, scheduling professional servicing is equally important to ensure your machine operates at its best. Professional technicians have the expertise to identify and address issues that may not be visible during routine checks. Plan for servicing at least once or twice a year, depending on the frequency of your machine’s use.

During professional servicing, experts will inspect the internal components, calibrate the machine, and replace worn-out parts. They will also perform advanced diagnostics to detect hidden problems. This level of care helps prevent unexpected breakdowns and ensures your machine continues to deliver high-quality results.

Choose a reputable service provider with experience in maintaining gold laser cutting machines. Look for providers who use genuine parts and follow industry standards. Regular professional servicing not only enhances the machine’s performance but also gives you peace of mind knowing your equipment is in capable hands.

Where to Find Reliable Maintenance Tips

Finding reliable maintenance tips for your gold laser cutting machine ensures you can keep it in excellent condition. Accessing trustworthy sources equips you with the knowledge to handle routine care and address potential issues effectively. Below are some of the best places to find dependable guidance.

Manufacturer Manuals and Guides

Manufacturer manuals and guides serve as your primary resource for maintenance information. These documents provide detailed instructions tailored to your specific machine model. You can find step-by-step procedures for cleaning, lubricating, and inspecting components. Manufacturers often include troubleshooting sections to help you identify and resolve common problems.

“Always refer to the manufacturer’s manual for accurate maintenance practices. It is the most reliable source for understanding your machine’s requirements.” – Advice from a cosmetic laser technician.

Keep the manual in an accessible location for quick reference. If you misplace it, visit the manufacturer’s website. Many companies offer downloadable versions of their manuals. Following these guides ensures you perform maintenance tasks correctly, reducing the risk of errors that could damage your machine.

Professional Service Providers

Professional service providers offer expert advice and hands-on assistance for maintaining your gold laser cutting machine. These technicians possess specialized knowledge and experience, enabling them to address complex issues that may go unnoticed during routine checks. Scheduling regular servicing with professionals ensures your machine receives thorough care.

When selecting a service provider, choose one with a proven track record in handling gold laser cutting machines. Look for companies that use genuine replacement parts and follow industry standards. During servicing, professionals inspect internal components, calibrate the machine, and replace worn-out parts. Their expertise helps you maintain optimal performance and avoid costly repairs.

“Technicians can identify hidden issues and provide solutions that extend the lifespan of your equipment.” – Insight from a laser technician interview.

Online Resources and Communities

Online resources and communities offer a wealth of information on maintaining your gold laser cutting machine. Blogs, forums, and video tutorials provide practical tips and demonstrations. Websites dedicated to laser cutting often feature maintenance checklists and troubleshooting guides. These resources allow you to learn from the experiences of other users.

Joining online communities connects you with individuals who share similar interests. Industry forums enable you to ask questions, share insights, and receive advice from experienced users. Platforms like YouTube host instructional videos that visually guide you through maintenance tasks. Always verify the credibility of online sources to ensure the information is accurate and reliable.

“Engaging with online communities helps you stay updated on the latest maintenance techniques and best practices.”

By leveraging these resources, you gain valuable insights into maintaining your machine effectively. Combining knowledge from manuals, professionals, and online platforms ensures you have a comprehensive understanding of proper care.

Additional Resources for Maintenance

Recommended Blogs and Websites

Exploring blogs and websites dedicated to laser cutting machines can provide you with valuable insights into proper maintenance practices. Many of these platforms share step-by-step guides, troubleshooting tips, and expert advice tailored to specific machine models. For instance, websites like Boss Laser’s official page offer detailed instructions on cleaning, lubrication, and calibration. These resources help you understand how to maintain your machine effectively and avoid common pitfalls.

Additionally, some blogs focus on industry trends and innovations, keeping you informed about the latest tools and techniques. Regularly visiting these sites ensures you stay updated on best practices. Look for blogs that emphasize practical advice and actionable steps, as these are often the most beneficial for maintaining the quality and performance of your equipment.

“Reading trusted blogs and websites equips you with the knowledge to handle maintenance tasks confidently.”

Industry Forums and Communities

Joining industry forums and online communities connects you with other laser cutting machine users. These platforms allow you to exchange ideas, ask questions, and learn from the experiences of others. Forums often feature discussions on common maintenance challenges and their solutions. By participating in these conversations, you gain practical tips that can enhance your machine’s performance.

Communities on platforms like Reddit or specialized industry forums provide a space for sharing insights and troubleshooting advice. Many users post detailed guides or videos demonstrating maintenance techniques. Engaging with these groups helps you build a network of support, ensuring you always have access to reliable information.

“Active participation in forums and communities fosters learning and helps you discover innovative ways to maintain your machine.”

Companies Offering Expert Advice

Reaching out to companies specializing in laser cutting machines is another excellent way to access expert advice. Reputable providers like Boss Laser not only sell high-quality machines but also offer comprehensive support for maintenance. Their technicians can guide you through essential tasks such as optical cleaning, belt tensioning, and lubrication. They also provide professional servicing to address complex issues.

Many companies include maintenance guidelines on their websites or offer customer support to answer your questions. Some even provide downloadable manuals and video tutorials. Partnering with a trusted company ensures you receive accurate information and high-quality service, helping you maintain your machine’s longevity and efficiency.

“Consulting experts ensures your machine receives the care it needs to deliver consistent, high-quality results.”

Regular maintenance is the cornerstone of ensuring your gold laser cutting machine delivers optimal performance and stands the test of time. By dedicating consistent effort to upkeep, you prevent costly repairs, maintain precision, and extend the machine's longevity. Trusted resources like manufacturer manuals, professional services, and online communities provide invaluable guidance for effective care. Prioritize these practices to keep your equipment running smoothly and efficiently. Remember, a well-maintained machine not only enhances productivity but also safeguards your investment for years to come.

FAQ

What are the benefits of regular maintenance for a gold laser cutting machine?

Regular maintenance offers numerous advantages. It extends the lifespan of your machine, enhances performance, and ensures consistent, high-quality cuts. Maintenance also reduces downtime by identifying potential issues early, saving you from costly repairs. Additionally, it improves safety by keeping the machine in optimal working condition.

“Preventive maintenance safeguards your investment and ensures reliable operation over time.”

How often should I perform maintenance on my laser cutting machine?

You should perform daily maintenance tasks, such as cleaning and inspecting components, to keep your machine in top condition. Schedule professional servicing at least once or twice a year, depending on usage. Regular checks ensure your machine operates efficiently and prevents unexpected breakdowns.

Why is lubrication important for laser cutting machines?

Lubrication minimizes frictional wear on moving parts like bearings and rails. This ensures smooth operation and extends the lifespan of your machine. Neglecting lubrication can lead to increased wear and tear, resulting in costly repairs and reduced performance.

“Regular lubrication is essential for maintaining the longevity and effectiveness of laser cutters.”

How can I ensure the cooling system functions properly?

Monitor the circulating water in the cooling system daily. Replace the water periodically to prevent contamination, which can affect efficiency. Keep the machine in a well-ventilated area to regulate temperatures and protect sensitive components from overheating.

What should I do if my machine’s performance starts to decline?

Start by inspecting key components like lenses, mirrors, and the laser generator. Clean these parts to remove dirt or debris that may affect performance. Check for worn-out parts, such as drive belts or bearings, and replace them promptly. If the issue persists, consult a professional technician for a thorough inspection.

Are manufacturer manuals reliable for maintenance guidance?

Yes, manufacturer manuals are your most reliable source for maintenance instructions. They provide detailed, step-by-step procedures tailored to your specific machine model. These guides also include troubleshooting tips to help you address common issues effectively.

“Always refer to the manufacturer’s manual for accurate maintenance practices.”

Can I rely on online resources for maintenance tips?

Online resources, such as blogs, forums, and video tutorials, can be valuable for learning maintenance techniques. However, verify the credibility of the source before following their advice. Trusted platforms and industry experts often provide accurate and practical guidance.

How do I choose a professional service provider for my machine?

Select a service provider with experience in maintaining gold laser cutting machines. Look for companies that use genuine replacement parts and follow industry standards. A reputable provider will offer thorough inspections, calibrations, and advanced diagnostics to ensure your machine operates at its best.

What are the risks of neglecting maintenance?

Neglecting maintenance can lead to costly repairs, reduced performance, and shorter machine lifespan. Dirt and debris can affect laser precision, while worn-out parts may cause sudden breakdowns. Regular upkeep prevents these issues and ensures your machine remains reliable.

How does preventive maintenance save costs?

Preventive maintenance identifies potential problems before they escalate into major issues. By addressing minor wear and tear early, you avoid expensive repairs and downtime. This proactive approach keeps your machine running efficiently and saves money in the long run.

“Preventive care not only conserves the lifespan of your equipment but also saves time and resources.”

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Comparative Analysis of Laser Cutting Machine Prices

Guidelines for Selecting an Ideal Water Jet Cutter