What Machine Used to Cut Plastic Laser Best?

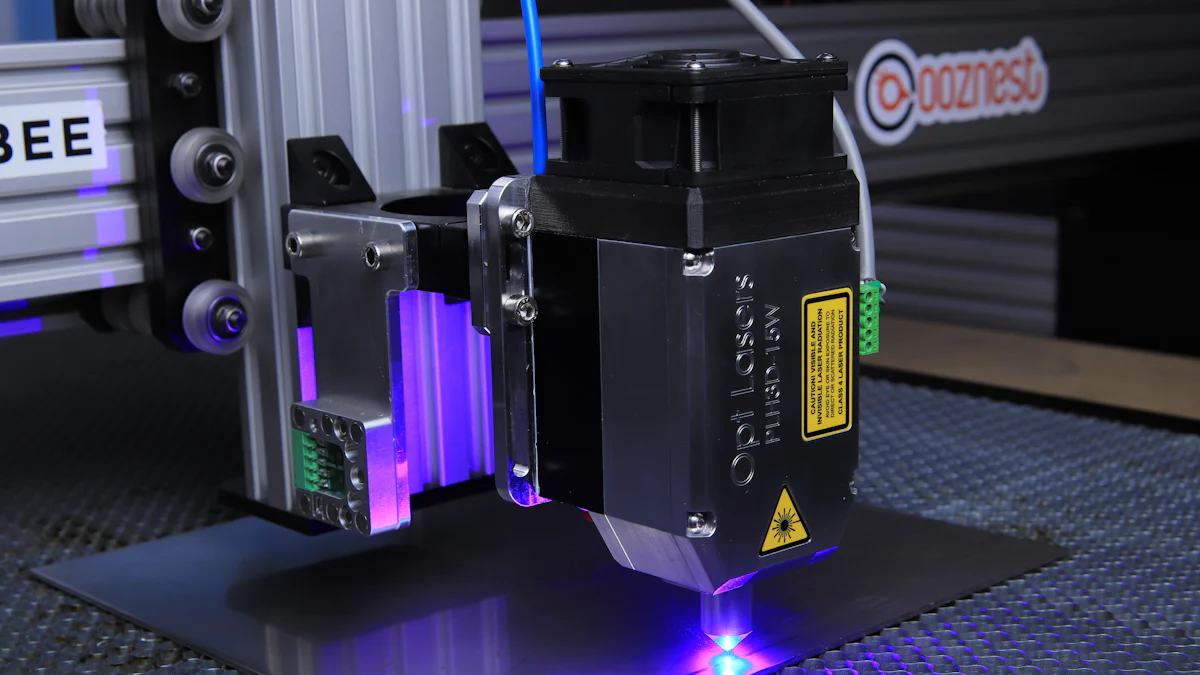

When considering what machine used to cut plastic laser, precision and efficiency make laser cutting the top choice for working with plastics. Machines like the Epilog Fusion Edge, Trotec Speedy 400, Glowforge Pro, and OMTech MF1220-50 are specifically designed to deliver exceptional results. These laser cutters excel at processing various plastics, such as acrylic and polycarbonate, offering clean edges and unparalleled accuracy. With advanced features like high-powered lasers and versatile work areas, they are perfect for intricate designs as well as large-scale projects. Whether you're crafting custom creations or managing production tasks, these machines set the standard for cutting plastic with lasers.

Why Laser Cutting is Effective for Plastics

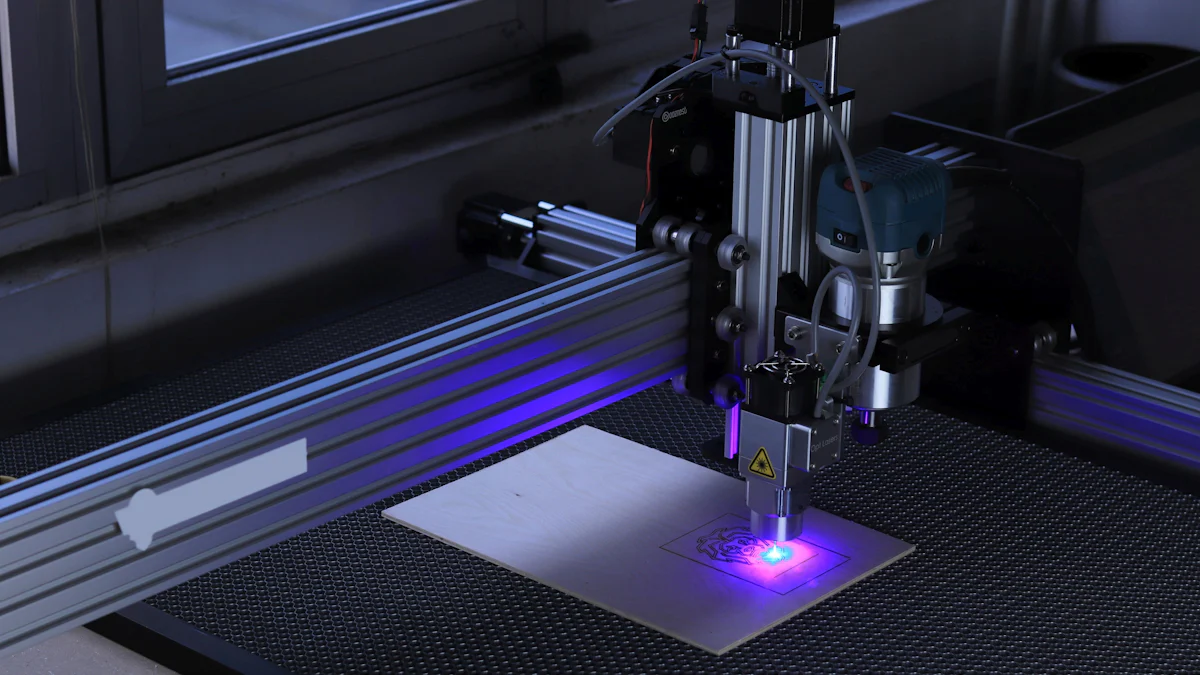

Laser cutting has become a go-to method for working with plastics. Its precision, speed, and versatility make it an excellent choice for both hobbyists and professionals. Whether you're crafting intricate designs or producing large-scale parts, laser cutting ensures high-quality results every time.

Benefits of Laser Cutting for Plastics

Precision and clean edges

Laser cutting delivers unmatched precision. The focused laser beam allows you to create intricate patterns and detailed cuts without any rough edges. Unlike traditional cutting methods, which can leave burrs or uneven surfaces, laser cutting produces smooth, polished edges. This makes it ideal for projects where aesthetics and accuracy matter most.

Versatility for different plastic types

One of the standout features of laser cutting is its ability to handle a wide range of plastics. From acrylic to polycarbonate, the process adapts seamlessly to various materials. You can even work with specialized plastics like Kapton or ABS. This versatility ensures that no matter the type of plastic you're using, laser cutting can meet your needs.

Speed and efficiency for production

Time is often a critical factor in any project. Laser cutting excels in this area by offering fast processing speeds. The technology minimizes material waste and reduces lead times, making it perfect for both small-scale and large-scale production. Whether you're creating prototypes or final products, laser cutting keeps your workflow efficient.

Types of Plastics Commonly Cut with Lasers

Acrylic (PMMA)

Acrylic is one of the best plastics for laser cutting. It melts cleanly under the laser beam, resulting in smooth, glossy edges. This makes it a popular choice for signage, displays, and decorative items. Laser cutting acrylic also allows for precise engraving, adding another layer of customization to your projects.

Polycarbonate (PC)

Polycarbonate is another plastic that works well with laser cutting. Known for its durability and impact resistance, it’s often used in industrial applications. While it requires careful handling due to its tendency to discolor under high heat, a properly calibrated laser cutter can achieve excellent results.

Polyethylene (PE) and Polypropylene (PP)

These plastics are lightweight and versatile, making them suitable for a variety of uses. Laser cutting handles them with ease, ensuring clean cuts without melting or warping. They are commonly used in packaging, automotive parts, and household items.

ABS and other engineering plastics

ABS is a favorite for engineering and prototyping due to its strength and flexibility. Laser cutting ABS allows for precise shaping and detailing, making it ideal for creating custom parts. Other engineering plastics, like Kapton, also benefit from laser cutting's precision and efficiency.

"CO2 laser systems offer ultra-high precision and contactless cutting for plastic processing, minimizing waste." – Eurolaser

Laser cutting stands out as a reliable and effective method for working with plastics. Its ability to deliver clean edges, adapt to different materials, and maintain efficiency makes it a top choice for professionals and hobbyists alike.

Top Recommended Laser Cutting Machines for Plastics

When deciding on what machine used to cut plastic laser, you’ll want to explore the best options available. Below, we’ve highlighted some of the top laser cutting machines that deliver exceptional performance for plastic materials. Each machine offers unique features, making it easier for you to find one that fits your needs.

Epilog Fusion Edge

Features and specifications

The Epilog Fusion Edge combines advanced technology with user-friendly features. It comes equipped with a high-speed servo motor, a 120 IPS engraving speed, and a precise CO2 laser system. The machine supports a wide range of materials, including acrylic and polycarbonate. Its touchscreen interface and built-in camera make setup and alignment straightforward.

Pros and cons

Pros:

- Exceptional precision for intricate designs.

- High-speed operation for faster production.

- Easy-to-use software for beginners and professionals.

Cons:

- Higher price point compared to other models.

- Limited cutting depth for thicker plastics.

Ideal use cases

The Epilog Fusion Edge is perfect for small businesses and hobbyists working on detailed projects. It excels in creating custom signage, decorative items, and prototypes.

Trotec Speedy 400

Features and specifications

The Trotec Speedy 400 is a powerhouse in the world of laser cutting. It features a robust CO2 laser with up to 120 watts of power, allowing it to cut through thicker plastics like acrylic and ABS. Its patented InPack Technology™ ensures durability by protecting sensitive components from dust and debris. The large working area of 39 x 24 inches makes it suitable for larger projects.

Pros and cons

Pros:

- High power for cutting thicker materials.

- Large cutting area for versatile applications.

- Durable design with minimal maintenance needs.

Cons:

- Bulky size may not fit smaller workspaces.

- Higher upfront cost.

Ideal use cases

The Trotec Speedy 400 is ideal for industrial applications and large-scale production. It’s a great choice for businesses needing to cut and engrave plastics for signage, packaging, or automotive parts.

Glowforge Pro

Features and specifications

The Glowforge Pro stands out for its ease of use and innovative features. It includes a dual-laser setup, autofocus, and a macro camera for precise alignment. The web-based app simplifies the cutting process, allowing you to view the cutting surface and adjust settings effortlessly. However, it requires an internet connection to operate and an additional filtration system for indoor use.

Pros and cons

Pros:

- User-friendly interface with intuitive controls.

- Compact design suitable for small spaces.

- Regular software updates enhance functionality.

Cons:

- Limited cutting power compared to industrial-grade machines.

- Requires internet connectivity and extra filtration equipment.

Ideal use cases

The Glowforge Pro is perfect for small businesses and DIY enthusiasts. It’s great for crafting personalized items, such as jewelry, home décor, and small-scale prototypes. However, if you need to cut thicker plastics or handle heavy-duty tasks, you might want to consider alternatives like the OMTech machines.

These machines represent some of the best options for laser cutting plastics. Whether you’re looking for precision, power, or ease of use, there’s a machine tailored to your needs. By understanding their features and capabilities, you can confidently choose what machine used to cut plastic laser for your projects.

OMTech MF1220-50

Features and specifications

The OMTech MF1220-50 stands out as a powerful and versatile laser cutting machine. It features a 50-watt CO2 laser, which provides enough power to cut through thicker plastics like acrylic and ABS with ease. The machine offers a spacious 12" x 20" cutting area, giving you plenty of room to work on larger projects or multiple smaller pieces at once. Its advanced control panel allows for precise adjustments, ensuring you get the exact results you need. Additionally, the OMTech MF1220-50 supports a wide range of materials, making it a reliable choice for various applications.

Another highlight is its durability. The machine is built with high-quality components designed to withstand heavy use. This makes it a great option for both hobbyists and professionals who need a dependable tool for their laser cutting tasks. Unlike some other machines, it doesn’t require constant internet connectivity, which adds to its convenience.

Pros and cons

Pros:

- High laser power for cutting thicker plastics.

- Large cutting area for versatile project sizes.

- Durable construction for long-term use.

- Works offline, offering flexibility in different environments.

- Affordable compared to other high-performance laser cutters.

Cons:

- Slightly steeper learning curve for beginners.

- Requires proper ventilation due to fumes from cutting plastics.

Ideal use cases

The OMTech MF1220-50 is perfect for professionals and small businesses that need a reliable machine for cutting and engraving plastics. It excels in creating custom signage, industrial parts, and intricate designs. If you’re working on projects that involve thicker plastics or require high precision, this machine delivers exceptional results. Its affordability also makes it a great choice for those looking to invest in a high-quality laser cutter without breaking the bank.

When deciding on what machine used to cut plastic laser, the OMTech MF1220-50 offers a balance of power, precision, and value. Whether you’re crafting prototypes, producing decorative items, or handling industrial tasks, this machine can meet your needs effectively.

Factors to Consider When Choosing a Laser Cutting Machine for Plastics

When selecting the right laser cutting machine for plastics, you need to evaluate several key factors. These considerations ensure that your machine delivers the performance and results you expect, whether you're working on intricate designs or large-scale projects.

Power and Wattage

Importance of power for cutting thicker plastics

The power of a laser cutting machine directly impacts its ability to cut through thicker plastics. Machines with higher wattage, such as the OMTech MF1220-50, which boasts a robust 50W CO2 laser, excel at handling dense materials like acrylic and ABS. A higher-powered laser ensures clean cuts without requiring multiple passes, saving you time and maintaining the quality of your work. If you frequently work with thicker plastics, prioritize machines with at least 50 watts of power.

Matching power to material type

Not all plastics require the same laser power. For thinner materials like polyethylene or polypropylene, a lower-wattage machine may suffice. However, for tougher plastics like polycarbonate or engineering-grade materials, higher wattage is essential. Matching the laser power to the type of plastic you’re working with ensures optimal results and prevents damage to the material.

Precision and Cutting Area

Importance of precision for intricate designs

Precision is crucial when creating detailed designs or working on projects where accuracy matters. Laser cutting machines like the Epilog Fusion Edge and Glowforge Pro are known for their exceptional precision, making them ideal for intricate patterns and fine engravings. A precise machine minimizes errors and ensures your final product meets your expectations.

Choosing the right cutting area size for your needs

The size of the cutting area determines the scope of your projects. Machines like the Trotec Speedy 400, with its expansive 39 x 24-inch workspace, are perfect for larger projects or batch production. On the other hand, compact machines like the Glowforge Pro are better suited for smaller spaces and projects. Consider the scale of your work and choose a machine with a cutting area that aligns with your requirements.

Material Compatibility

Ensuring the machine supports the plastics you work with

Not all laser cutting machines are compatible with every type of plastic. For example, CO2 lasers are the ideal choice for cutting most plastics, including acrylic and ABS, due to their ability to produce clean and precise cuts. Machines like the OMTech MF1220-50 support a wide range of materials, making them versatile tools for various applications. Always verify that the machine you choose can handle the specific plastics you plan to work with.

Avoiding materials that release harmful fumes

Some plastics, such as PVC, release toxic fumes when cut with a laser. These fumes can damage your machine and pose health risks. Ensure that the materials you use are safe for laser cutting. Additionally, invest in a machine with proper ventilation or an external filtration system to maintain a safe working environment.

By carefully considering these factors, you can select a laser cutting machine that meets your needs and delivers high-quality results. Whether you're working with the best plastics for laser cutting or exploring new materials, the right machine will make all the difference in your projects.

Budget and Maintenance Costs

Balancing upfront costs with long-term value

When choosing a laser cutting machine, the initial price tag might feel overwhelming. However, it’s essential to think beyond the upfront cost. A high-quality machine, like the OMTech MF1220-50, offers exceptional value over time. Its robust 50W laser output and durable construction ensure consistent performance for years. While it may cost more initially than entry-level options, its ability to handle thicker plastics and diverse projects makes it a worthwhile investment.

Cheaper machines might save you money at first, but they often lack the power and precision needed for professional results. They may also wear out faster, leading to frequent replacements. By investing in a reliable machine upfront, you reduce the risk of downtime and avoid the hassle of constant repairs. This approach saves you money in the long run and ensures your projects maintain a professional standard.

Considering maintenance and operational expenses

Owning a laser cutting machine involves more than just the purchase price. Maintenance and operational costs play a significant role in your overall budget. Machines like the OMTech MF1220-50 are designed with durability in mind, reducing the need for frequent repairs. Its high-quality components can withstand heavy use, making it a dependable choice for both hobbyists and professionals.

To keep your machine running smoothly, regular maintenance is crucial. Cleaning the laser lens, checking the alignment, and ensuring proper ventilation are simple tasks that prevent costly repairs. Additionally, consider the cost of consumables like replacement parts or filters. Machines with efficient designs, such as the OMTech MF1220-50, minimize these expenses by using durable materials and requiring fewer replacements.

Energy consumption is another factor to consider. Laser cutting machines with higher wattage, while powerful, may use more electricity. Balancing power needs with energy efficiency helps you manage operational costs without compromising performance. For example, the OMTech MF1220-50 delivers powerful cutting capabilities while maintaining reasonable energy usage, making it a cost-effective option for long-term use.

By carefully evaluating both upfront and ongoing costs, you can choose a machine that fits your budget and meets your needs. A well-maintained laser cutter not only saves money but also ensures consistent, high-quality results for every project.

Recommended Laser Cutting Services for Plastics

If you’re not ready to invest in a laser cutting machine or need professional-grade results, laser cutting services can be a fantastic option. These services give you access to high-end equipment and skilled professionals who specialize in working with plastics. Let’s explore some of the top companies and the benefits of using their expertise.

Top Companies Specializing in Laser Cutting for Plastics

Ponoko: Overview and services offered

Ponoko is a well-known name in the laser cutting industry. They offer a wide range of services, including cutting and engraving plastics like acrylic, polycarbonate, and ABS. Ponoko’s platform allows you to upload your designs, choose your materials, and receive your finished product quickly. Their focus on precision and customization makes them a favorite for creative projects like signage, prototypes, and decorative items.

"Ponoko’s streamlined process ensures high-quality results with minimal effort on your part."

Pololu: Overview and services offered

Pololu specializes in laser cutting and engraving services tailored for engineering and prototyping needs. They excel at handling intricate designs and small-scale projects. Pololu works with various plastics, including engineering-grade materials, and offers quick turnaround times. Their expertise in precision cutting makes them a go-to choice for tech enthusiasts and professionals looking to create detailed components.

Laser Cutting Inc.: Overview and services offered

Laser Cutting Inc. stands out for its industrial-grade capabilities. They handle large-scale projects and work with a wide variety of plastics. Whether you need custom parts for automotive applications or detailed engravings for promotional items, Laser Cutting Inc. delivers reliable results. Their advanced machinery ensures clean cuts and consistent quality, even for complex designs.

Benefits of Using Professional Laser Cutting Services

Access to high-end machines without purchasing

Professional services let you use state-of-the-art laser cutting machines without the need to buy one yourself. Companies like Ponoko and Laser Cutting Inc. use advanced CO2 lasers capable of cutting through thick plastics with precision. This access allows you to achieve professional results without the upfront cost of owning a machine.

Expertise in handling different plastic materials

Working with plastics requires knowledge of material properties and laser settings. Professional services bring this expertise to the table. For example, Pololu’s team understands how to handle delicate materials like polycarbonate or engineering plastics without causing discoloration or warping. Their experience ensures your project turns out exactly as you envisioned.

Cost-effectiveness for small-scale projects

If you only need occasional laser cutting, hiring a service is often more cost-effective than purchasing a machine. Services like Ponoko offer affordable pricing for small orders, making them ideal for hobbyists or businesses testing new designs. You save on maintenance, operational costs, and the learning curve associated with operating a laser cutter.

Using professional laser cutting services gives you the flexibility to focus on your designs while leaving the technical work to the experts. Whether you’re creating prototypes, custom products, or industrial parts, these services provide a hassle-free way to achieve high-quality results.

Laser cutting offers a precise, fast, and versatile way to work with plastic materials. Machines like the Epilog Fusion Edge, Trotec Speedy 400, Glowforge Pro, and OMTech MF1220-50 stand out as top choices, each catering to different needs and budgets. When selecting a machine, focus on factors like power, precision, and material compatibility to ensure it aligns with your projects. If purchasing a machine feels overwhelming, professional services like Ponoko, Pololu, and Laser Cutting Inc. provide access to high-end equipment and expertise, making them an excellent alternative for achieving professional results.

FAQ

What types of plastics can laser cutting machines handle?

Laser cutting machines work with a wide variety of plastics. Common materials include acrylic (PMMA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), and ABS. Some machines can also process specialized plastics like Kapton or Delrin. Always check the machine's compatibility with your chosen material to ensure optimal results.

Is laser cutting safe for all plastics?

Not all plastics are safe for laser cutting. For example, PVC releases harmful fumes when cut, which can damage the machine and pose health risks. Always verify the material's safety before starting a project. Machines with proper ventilation or external filtration systems, like the Glowforge Pro, help maintain a safe working environment.

How do I choose the right laser cutting machine for my needs?

Focus on key factors like power, precision, cutting area size, and material compatibility. For intricate designs, prioritize machines with high precision, such as the Epilog Fusion Edge. If you work with thicker plastics, opt for a machine with higher wattage, like the OMTech MF1220-50. Consider your project size and budget to find the best fit.

Can I use professional laser cutting services instead of buying a machine?

Yes, professional services are a great alternative if you don’t want to invest in a machine. Companies like Ponoko, Pololu, and Laser Cutting Inc. offer access to high-end equipment and expert handling of various plastics. These services are cost-effective for small-scale projects or occasional needs.

"Ponoko’s streamlined process ensures high-quality results with minimal effort on your part."

What are the benefits of using professional laser cutting services?

Professional services provide several advantages:

- Access to advanced machines without purchasing.

- Expertise in handling different plastic materials.

- Cost-effectiveness for small or one-time projects. For instance, Pololu specializes in intricate designs and small-scale projects, while Laser Cutting Inc. excels in large-scale production with quick turnarounds.

How precise are laser cutting machines?

Laser cutting machines deliver exceptional precision, often achieving accuracy within 0.003 mm. This level of detail ensures clean edges and intricate designs. Machines like the Trotec Speedy 400 and Epilog Fusion Edge are known for their high precision, making them ideal for professional-grade projects.

Do laser cutting machines require regular maintenance?

Yes, regular maintenance is essential to keep your machine running smoothly. Tasks include cleaning the laser lens, checking alignment, and ensuring proper ventilation. Machines like the OMTech MF1220-50 are built with durable components, reducing the need for frequent repairs and minimizing operational costs.

Can I cut thick plastics with a laser cutter?

Yes, but you’ll need a machine with sufficient power. For example, the OMTech MF1220-50 features a 50W CO2 laser, which can handle thicker plastics like acrylic and ABS. Higher wattage ensures clean cuts without multiple passes, saving time and maintaining quality.

Are laser cutting machines suitable for beginners?

Some machines are beginner-friendly, like the Glowforge Pro, which offers an intuitive interface and web-based app for easy operation. However, more advanced models, such as the OMTech MF1220-50, may have a steeper learning curve. Choose a machine that matches your skill level and gradually build your expertise.

What makes laser cutting better than traditional cutting methods?

Laser cutting offers unmatched precision, speed, and versatility. Unlike traditional methods, it produces smooth, polished edges without burrs or rough surfaces. It also minimizes material waste and handles intricate designs effortlessly. Whether you’re a hobbyist or a professional, laser cutting ensures high-quality results every time.

See Also

Is CNC Cutting Acrylic Superior to Laser Cutting?

Understanding Laser Cutting Machines and Their Varieties

Best 10 Precision Machines for Cutting Acrylic