What Machine to Laser Cut Wood for Beginners

Choosing what machine to laser cut wood is a crucial step that can transform your woodworking journey. As a beginner, you need a tool that balances ease of use, safety, and performance. Laser cutting wood offers precision and versatility in design, making it ideal for crafting unique woodworking project ideas. Understanding what machine to laser cut wood, such as CO2 lasers or diode lasers, can help reduce material wastage and allow you to explore the advantages of laser cut wood. Whether you're learning how to laser cut wood at home or diving into tutorials, starting with the best laser engravers for wood ensures success. A step-by-step guide will help you unlock your creative potential.

Key Features to Look for in a Beginner-Friendly Laser Cutter

When selecting a laser cutter as a beginner, focusing on specific features ensures a smooth and rewarding experience. These features not only simplify the learning process but also enhance the quality of your wood projects.

Ease of Use

A beginner-friendly laser cutter should prioritize simplicity in its design and operation. Machines like the LaserPecker LX1 are perfect examples, offering intuitive controls and straightforward setup. Look for models with user-friendly software that allows you to create designs without a steep learning curve. Many beginner machines come with pre-installed templates or easy-to-follow instructions, making it easier for you to start crafting woodworking projects right away.

Additionally, features like touchscreen interfaces or wireless connectivity can further streamline the process. For instance, school laser cutters often include simple apps that help students and beginners quickly grasp the basics of laser cutting.

Safety Features

Safety is a critical factor when working with laser cutting machines. A reliable laser cutter should include built-in safety mechanisms to protect you during operation. Features such as automatic shut-off, protective covers, and ventilation systems are essential. The MONPORT ONYX 55W Desktop CO2 Laser Engraver, for example, offers a protective enclosure that minimizes exposure to the laser beam, ensuring a safer environment for beginners.

Proper ventilation is equally important, especially when cutting wood, as certain types can release harmful fumes. Always follow safety guidelines provided by the manufacturer to avoid risks. Machines designed for home use, like the OMTech K40+, often come equipped with exhaust systems to maintain air quality.

Affordability

For beginners, affordability plays a significant role in choosing the right laser cutter. You want a machine that balances cost with functionality. The Monport 40W Desktop Laser Engraver is an excellent choice, offering precision and accuracy at a budget-friendly price. Affordable options like this allow you to explore laser cutting without a significant financial commitment.

While affordability is important, avoid compromising on essential features like safety and precision. Investing in a reliable machine ensures better results for your wood projects and reduces the likelihood of costly repairs or replacements in the future.

Compatibility with Wood Types

When choosing a laser cutter, you need to ensure it works well with the types of wood you plan to use. Not all machines handle every wood type effectively, so understanding compatibility is essential for achieving clean cuts and detailed engravings.

Softwoods like basswood or pine are beginner-friendly options. These woods cut easily and produce consistent results. Machines such as the LaserPecker LX1 excel at handling softwoods, making them ideal for small-scale projects or home crafting. Their precision and efficiency allow you to experiment with various designs without worrying about uneven cuts.

For hardwoods like oak or walnut, you need a more powerful laser cutter. The MONPORT ONYX 55W Desktop CO2 Laser Engraver offers the strength and precision required for denser materials. Its versatility ensures you can work on intricate designs while maintaining high-quality results. This machine also includes autofocus, which adjusts the laser beam for optimal performance on different wood thicknesses.

Plywood presents unique challenges due to its layered construction. A reliable option like the OMTech K40+ handles plywood effectively, ensuring smooth edges and minimal charring. This machine’s user-friendly features make it a great choice for hobbyists exploring more complex materials.

"Understanding the grain direction of the wood is crucial, as it can affect the quality and appearance of the cut." – Expert Tip

For beginners, starting with softwoods helps build confidence and skills. As you gain experience, you can explore hardwoods and plywood with machines designed for those materials. Always check the manufacturer’s specifications to confirm compatibility with your chosen wood type.

Types of Laser Cutting Machines for Beginners

When starting your journey in laser cutting and engraving, understanding the types of machines available is essential. Each type offers unique features and capabilities, making it easier to match the machine to your needs and skill level. Below, you’ll find an overview of the most common laser cutting machines suitable for beginners.

CO2 Lasers

CO2 lasers are among the most popular choices for beginners. These machines use a gas mixture, primarily carbon dioxide, to generate a powerful laser beam. They excel at cutting and engraving wood, offering precision and versatility for various projects. CO2 lasers work well with softwoods like pine and basswood, which are ideal for beginners due to their smooth cutting properties.

One of the key advantages of CO2 lasers is their ability to handle a wide range of materials, including plywood and hardwoods. For example, birch and bamboo plywood cut reliably with these machines, making them excellent options for crafting ideas like custom signs or intricate designs. Machines like the Glowforge Basic provide user-friendly interfaces and pre-installed settings, ensuring a smooth learning curve for first-time users.

"CO2 lasers are versatile tools that deliver clean cuts and detailed engravings, making them a favorite for wood laser engraving projects."

If you’re looking for a machine that balances power and ease of use, CO2 lasers are a solid choice. They allow you to experiment with different wood types while maintaining high-quality results.

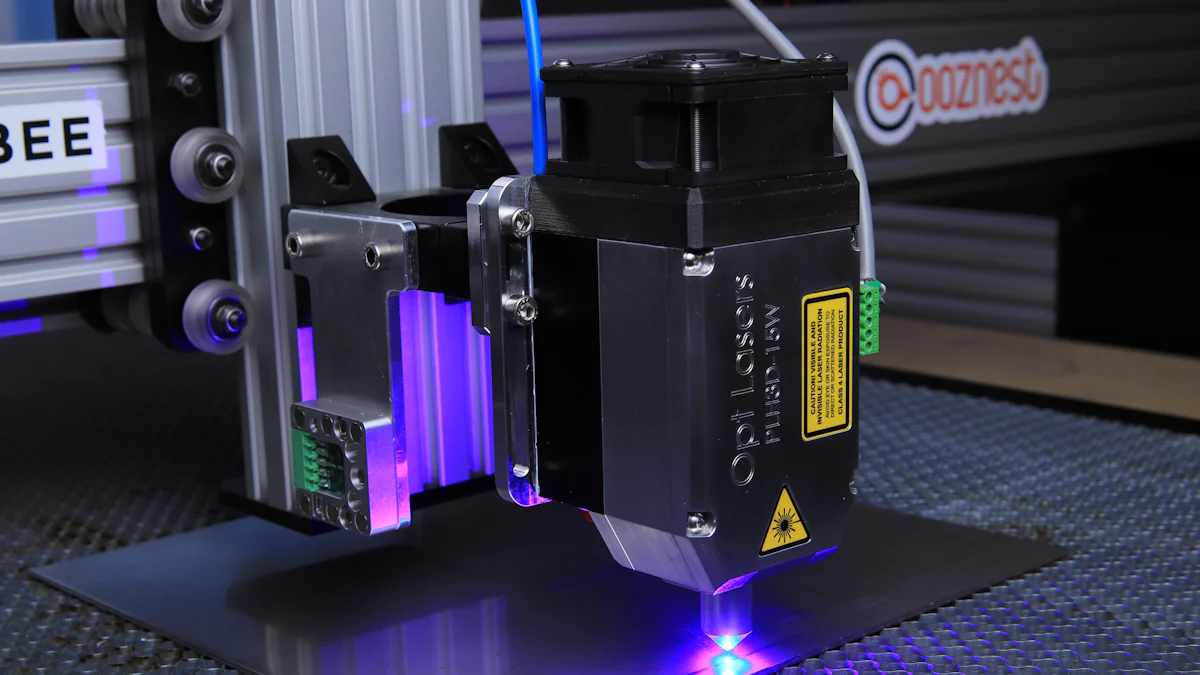

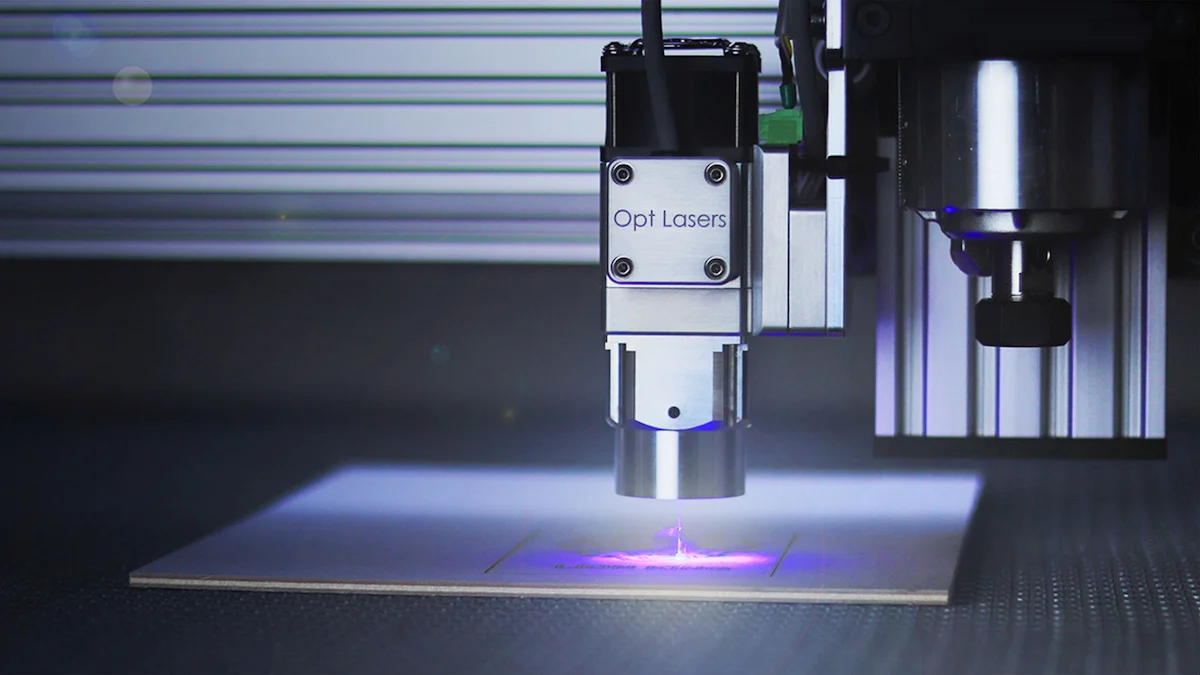

Diode Lasers

Diode lasers are compact and affordable, making them perfect for hobbyists and beginners. These machines use semiconductor technology to produce a focused laser beam. While they are less powerful than CO2 lasers, diode lasers are excellent for wood laser engraving and light cutting tasks. They work best with softwoods and thin plywood, allowing you to create detailed designs without excessive material wastage.

A major benefit of diode lasers is their portability and low maintenance requirements. Machines like the xTool D1 Pro are beginner-friendly, offering intuitive controls and compatibility with various design software. These lasers are ideal for small-scale projects, such as personalized coasters or decorative ornaments, where precision and detail matter most.

Diode lasers also consume less energy, making them an eco-friendly option for home use. Their affordability allows you to explore laser cutting and engraving without a significant financial investment.

Fiber Lasers

Fiber lasers are less common for wood projects but still worth mentioning. These machines use optical fibers to amplify the laser beam, resulting in high precision and speed. While fiber lasers are primarily designed for cutting metals, some models can handle wood engraving tasks with exceptional accuracy.

For beginners, fiber lasers may not be the first choice due to their higher cost and complexity. However, if you plan to expand your skills into mixed-material projects, investing in a fiber laser could be beneficial. These machines excel at creating intricate patterns and designs, making them suitable for advanced woodworking ideas.

Fiber lasers are best suited for professionals or those looking to transition from hobbyist to business-level production. Their ability to deliver consistent results across various materials makes them a versatile addition to any workshop.

"Fiber lasers offer unmatched precision, making them ideal for detailed engraving tasks on wood and other materials."

Recommended Models for Beginners

Glowforge Basic (CO2 Laser)

The Glowforge Basic stands out as an excellent choice for beginners exploring what machine to laser cut wood. This CO2 laser cutter offers a user-friendly experience with its intuitive design and cloud-based software. You can easily upload your designs and let the machine handle the rest. Its precision ensures clean cuts and detailed engravings, making it ideal for softwoods like basswood or pine.

One of its key features is its versatility. The Glowforge Basic works well with various materials, including wood, acrylic, and leather. This flexibility allows you to experiment with different projects while maintaining high-quality results. Additionally, its compact size makes it suitable for home use, fitting seamlessly into small workspaces.

Safety is another highlight of this model. The built-in ventilation system helps manage fumes, ensuring a safer environment for you. If you’re looking for a reliable and efficient CO2 laser cutter, the Glowforge Basic provides a great starting point for your woodworking journey.

xTool D1 Pro (Diode Laser)

The xTool D1 Pro is a diode laser cutter designed with beginners in mind. Its affordability and ease of use make it a popular choice for hobbyists learning what machine to laser cut wood. This machine excels at engraving fine details, making it perfect for creating intricate designs on softwoods and thin plywood.

Portability is a significant advantage of the xTool D1 Pro. Its lightweight design allows you to move it easily, making it convenient for home workshops. The machine also supports various design software, giving you the freedom to create custom projects without limitations.

Energy efficiency is another benefit of this diode laser. It consumes less power compared to CO2 lasers, reducing operational costs. If you’re new to laser cutting and want a cost-effective option, the xTool D1 Pro offers precision and reliability for small-scale projects.

OMTech 40W (CO2 Laser)

The OMTech 40W is a powerful CO2 laser cutter that combines affordability with performance. This machine is well-suited for beginners who want to explore what machine to laser cut wood without breaking the bank. Its 40W laser provides enough power to cut through softwoods, hardwoods, and even plywood with ease.

One of its standout features is its durability. The OMTech 40W is built to handle frequent use, making it a reliable option for long-term projects. It also includes safety features like an exhaust system to manage fumes and maintain air quality in your workspace.

This model offers a balance between functionality and cost, making it an excellent choice for beginners. Whether you’re crafting decorative items or experimenting with complex designs, the OMTech 40W delivers consistent results. Its user-friendly interface ensures a smooth learning curve, helping you build confidence in your laser cutting skills.

"Choosing the right laser cutter can transform your woodworking experience. Start with a model that matches your needs and skill level."

Tips for Getting Started with Your First Machine

Setting Up Your Laser Cutter

Setting up your laser cutter correctly is the first step to ensuring smooth operation and achieving great results. Begin by choosing a well-ventilated workspace. Proper ventilation is essential when laser cutting wood, as it helps remove fumes and prevents the buildup of harmful particles. Position your machine on a stable surface to avoid vibrations during operation.

Next, prepare the laser cutter by following the manufacturer’s instructions. Machines like the Glowforge and OMTech 40W come with detailed setup guides that simplify the process. Connect the power supply and ensure all cables are securely attached. If your machine includes a built-in camera, like the Glowforge, calibrate it to align your designs accurately.

Before starting your first laser cutting project, run a test cut on scrap materials. This step helps you adjust the settings for optimal performance. For example, softwoods like basswood may require lower power settings, while hardwoods need more intensity. Testing ensures clean cuts and prevents material wastage.

"Always double-check the alignment of your laser beam and the focus settings before cutting. Proper alignment ensures precision and reduces errors."

Safety Guidelines for Laser Cutting Wood

Safety should always be your top priority when working with laser cutters. Follow these safety guidelines to protect yourself and your workspace:

-

Wear Protective Gear: Use safety goggles designed for laser cutting to shield your eyes from the laser beam. Even machines with protective enclosures, like the OMTech 40W, require extra caution.

-

Monitor the Machine: Never leave the laser cutter unattended while it’s running. Wood is flammable, and unattended operation increases the risk of fire. Keep a fire extinguisher nearby as a precaution.

-

Ensure Proper Ventilation: Cutting wood releases fumes that can be harmful if inhaled. Machines like the xTool D1 Pro and Glowforge include exhaust systems, but you should still work in a well-ventilated area or use an external ventilation setup.

-

Inspect Materials: Avoid using treated or painted wood, as these materials can release toxic fumes when cut. Stick to natural woods like basswood or pine for your first laser cutting project.

-

Follow Manufacturer Guidelines: Each machine has specific safety features and operational requirements. Adhering to the provided instructions minimizes risks and ensures a safe experience.

"Safety is not optional. Taking precautions protects you and enhances the longevity of your machine."

Maintenance and Care

Regular maintenance keeps your laser cutter in top condition and ensures consistent results. Start by cleaning the lens and mirrors after every use. Dust and residue from materials can accumulate and affect the laser’s performance. Use a soft, lint-free cloth and a cleaning solution recommended by the manufacturer.

Check the ventilation system frequently. Machines like the OMTech 40W and Glowforge rely on exhaust systems to manage fumes. Clean the filters and ducts to maintain airflow and prevent blockages. A well-maintained ventilation system also reduces the risk of fire.

Inspect the laser tube or diode periodically. Over time, these components may wear out and require replacement. Refer to the manufacturer’s instructions for guidance on replacing parts. For example, the xTool D1 Pro offers easy access to its components, making maintenance straightforward.

Lubricate moving parts, such as rails and belts, to ensure smooth operation. Use a lubricant recommended by the manufacturer to avoid damaging the machine. Regularly check for loose screws or bolts and tighten them as needed.

"Consistent maintenance not only extends the life of your laser cutter but also ensures high-quality results for your woodworking projects."

By setting up your machine properly, following safety guidelines, and maintaining it regularly, you can enjoy a seamless laser cutting experience. These steps help you build confidence and create stunning woodworking projects with ease.

Selecting the right laser cutting machine is essential for a successful start to your woodworking journey. A beginner-friendly machine with features like ease of use, safety, and compatibility can simplify your learning process and boost your confidence. By taking the first step and choosing a reliable laser cutter, you open the door to endless creative possibilities. The right machine transforms laser cutting into an enjoyable and rewarding experience, allowing you to craft unique designs with precision. Start today and unlock your potential in the world of laser cutting.

FAQ

What is the best type of laser cutter for beginners?

CO2 lasers are often the best choice for beginners. These machines provide precision and versatility, making them ideal for cutting and engraving wood. They handle softwoods like basswood with ease and can also work on plywood and hardwoods. CO2 lasers, such as the Glowforge Basic, offer user-friendly features that simplify the learning process.

"CO2 lasers deliver clean cuts and detailed engravings, making them a favorite for wood projects."

Can I use a laser cutter at home?

Yes, you can use a laser cutter at home. Many beginner-friendly models, like the xTool D1 Pro and OMTech 40W, are designed for home use. Ensure your workspace has proper ventilation to manage fumes. Choose a compact machine that fits your space and follow all safety guidelines to create a safe environment.

What types of wood are best for laser cutting?

Softwoods, such as basswood and pine, are the best options for beginners. These woods cut easily and produce consistent results. For more advanced projects, you can experiment with hardwoods like oak or walnut. Always check your machine’s specifications to ensure compatibility with the wood type you plan to use.

How much does a beginner laser cutter cost?

Beginner laser cutters range from $300 to $3,000, depending on the features and capabilities. Diode lasers, like the xTool D1 Pro, are more affordable and start at the lower end of this range. CO2 lasers, such as the Glowforge Basic, tend to be more expensive but offer greater versatility and power.

Is laser cutting wood safe?

Laser cutting wood is safe when you follow proper precautions. Use safety goggles to protect your eyes and ensure your workspace has adequate ventilation. Machines with built-in safety features, like the OMTech 40W, provide added protection. Never leave the machine unattended while it’s running, and keep a fire extinguisher nearby.

"Safety is essential when working with laser cutters. Always follow the manufacturer’s guidelines to minimize risks."

Do I need special software to design for laser cutting?

Yes, most laser cutters require design software to create cutting or engraving patterns. Many machines come with compatible software, such as Glowforge’s cloud-based platform. You can also use popular design tools like Adobe Illustrator or Inkscape. Ensure the software supports your machine’s file format.

How thick can a laser cutter cut wood?

The cutting thickness depends on the machine’s power. For example, a 40W CO2 laser can cut wood up to 6 mm thick, while a 100W laser can handle up to 10 mm. Always refer to your machine’s specifications to determine its cutting capacity.

How do I maintain my laser cutter?

Regular maintenance ensures your laser cutter performs well. Clean the lens and mirrors after each use to remove dust and residue. Check the ventilation system and clean filters to maintain airflow. Inspect moving parts, such as belts and rails, and lubricate them as needed. Follow the manufacturer’s instructions for replacing worn components.

"Consistent maintenance extends the life of your laser cutter and ensures high-quality results."

Can I engrave other materials besides wood?

Yes, many laser cutters can engrave materials like acrylic, leather, and glass. Machines like the Glowforge Basic offer versatility, allowing you to experiment with different materials. Always check your machine’s compatibility before starting a new project.

What should I consider before buying a laser cutter?

When choosing a laser cutter, focus on ease of use, safety features, and compatibility with your preferred materials. Affordability is also important, especially for beginners. Models like the xTool D1 Pro and OMTech 40W balance cost and functionality, making them excellent options for starting your laser cutting journey.

See Also

Guidelines for Selecting the Best Wood Cutting Machine

Is CNC Technology Effective for Wood Cutting?

Effective Techniques for Operating a Laser Cutter