What Is YAG Laser Cutting Machine Used For

YAG laser cutting machines, often referred to as what is yag laser cutting machine, redefine precision in modern manufacturing. You can rely on these machines for intricate cutting, engraving, and welding tasks across industries. Their ability to handle diverse materials, from metals like stainless steel and aluminum to ceramics and plastics, ensures unmatched versatility. With their high energy output and precise control, they excel in producing accurate results, even for complex designs. Industries such as automotive, aerospace, medical, and electronics benefit significantly from these machines. Their role in creating high-quality components and products makes them indispensable in today’s competitive market.

Industries Benefiting from YAG Laser Cutting Machines

YAG laser cutting machines have revolutionized various industries by offering unmatched precision and versatility. Their ability to handle intricate tasks with high accuracy makes them indispensable in modern manufacturing. Below, you will discover how these machines are transforming key sectors.

Automotive Industry

High-precision cutting and welding of automotive components.

In the automotive industry, precision is critical. YAG laser cutting machines excel at cutting and welding components like engine brackets, body panels, and exhaust systems. These machines ensure that every part meets the exact specifications required for optimal vehicle performance. Their ability to deliver clean cuts and strong welds enhances the durability and functionality of automotive components.

Engraving intricate designs for vehicle interiors and exteriors.

Customization plays a significant role in automotive design. YAG lasers allow you to engrave intricate patterns and designs on both interior and exterior surfaces. Whether it’s decorative trims or branding elements, these machines enable manufacturers to achieve detailed and aesthetically pleasing results.

Aerospace Industry

Cutting lightweight metals and alloys for aircraft manufacturing.

The aerospace industry demands lightweight yet durable materials. YAG laser cutting machines are ideal for cutting metals like aluminum and titanium alloys, which are essential for aircraft manufacturing. Their precision ensures that every cut meets the stringent requirements of aerospace applications, reducing material waste and improving efficiency.

Precision shaping of heat-resistant materials for aerospace applications.

Aerospace components often require materials that can withstand extreme temperatures. YAG lasers excel at shaping heat-resistant materials, such as turbine blades and engine casings. These machines provide the accuracy needed to create components that ensure safety and performance in high-stress environments.

Medical Industry

Producing surgical instruments and medical implants with exceptional accuracy.

In medical device manufacturing, precision is non-negotiable. YAG laser cutting machines produce surgical tools and implants with exceptional accuracy. Their ability to handle delicate materials ensures that each instrument meets the highest standards of quality and safety.

Cutting and welding small medical devices like stents and catheters.

YAG lasers are indispensable for creating small, intricate medical devices. They can cut and weld stents, catheters, and other components with micron-level precision. This capability supports advancements in minimally invasive procedures and improves patient outcomes.

Electronics Industry

YAG laser cutting machines play a vital role in the electronics industry, where precision is paramount. You can rely on these machines to handle delicate tasks with unmatched accuracy.

Cutting circuit boards, semiconductor materials, and thin metals with micron-level precision.

In electronics manufacturing, YAG lasers excel at cutting circuit boards, semiconductor materials, and thin metals. These machines deliver micron-level precision, ensuring that every cut meets the exact specifications required for high-performance electronic devices. Whether you are working on microchips or printed circuit boards, YAG lasers provide the accuracy needed to maintain functionality and reliability.

Engraving and marking components for traceability and branding.

Traceability and branding are essential in the electronics sector. YAG laser cutting machines allow you to engrave serial numbers, logos, and other identifying marks on components. This capability ensures that parts remain traceable throughout their lifecycle while also supporting branding efforts. The precision of YAG lasers guarantees clear and durable markings, even on small or intricate surfaces.

Jewelry and Fashion Industry

The jewelry and fashion industry benefits greatly from the precision and versatility of YAG laser cutting machines. These machines enable you to create intricate designs and achieve exceptional craftsmanship.

Creating intricate designs and detailed components for jewelry.

YAG lasers are perfect for crafting detailed and intricate designs in jewelry. You can use them to cut and shape precious metals like gold, silver, and platinum with remarkable accuracy. Whether you are designing rings, necklaces, or bracelets, these machines help you achieve fine details that elevate the quality of your creations.

Engraving and cutting precious metals for fashion accessories.

Fashion accessories often require unique and personalized touches. YAG laser cutting machines allow you to engrave names, patterns, or logos on precious metals, adding value to your products. You can also cut metals into custom shapes, enabling you to produce one-of-a-kind pieces that stand out in the competitive jewelry market.

Construction Industry

In the construction industry, YAG laser cutting machines provide the precision and efficiency needed to handle demanding applications. These machines help you shape and cut materials for various structural and architectural purposes.

Shaping steel and aluminum components for building frames and structural supports.

YAG lasers are ideal for shaping steel and aluminum components used in building frames and structural supports. You can achieve clean and precise cuts, ensuring that each piece fits perfectly into the overall structure. This precision reduces material waste and enhances the stability of the final construction.

Cutting materials for architectural designs and construction projects.

Architectural designs often require intricate patterns and unique shapes. YAG laser cutting machines enable you to cut materials like metal panels and decorative elements with high accuracy. Whether you are working on modern facades or custom interior designs, these machines help you bring creative visions to life while maintaining structural integrity.

Advertising Industry

YAG laser cutting machines have transformed the advertising industry by enabling the creation of visually appealing and customized promotional materials. These machines provide the precision and flexibility needed to meet the unique demands of branding and marketing.

Creating customized signage and promotional materials.

In advertising, standing out is essential. YAG laser cutting machines allow you to craft customized signage with intricate details and unique designs. Whether you need to create large outdoor signs or small indoor displays, these machines deliver clean and precise cuts. You can work with a variety of materials, including metals, plastics, and composites, to produce durable and eye-catching promotional items. The ability to cut complex shapes and patterns ensures that your signage aligns perfectly with your brand's identity and message.

Engraving logos and designs for branding purposes.

Branding requires attention to detail, and YAG laser cutting machines excel in this area. You can engrave logos, slogans, and intricate designs on various surfaces with exceptional clarity. These machines ensure that every engraved element is sharp and professional, enhancing the overall quality of your branding materials. Whether you are working on metal plaques, acrylic displays, or promotional gifts, YAG lasers provide the precision needed to leave a lasting impression. Their versatility makes them an invaluable tool for creating branded items that resonate with your audience.

Key Laser Cutting Applications of YAG Machines

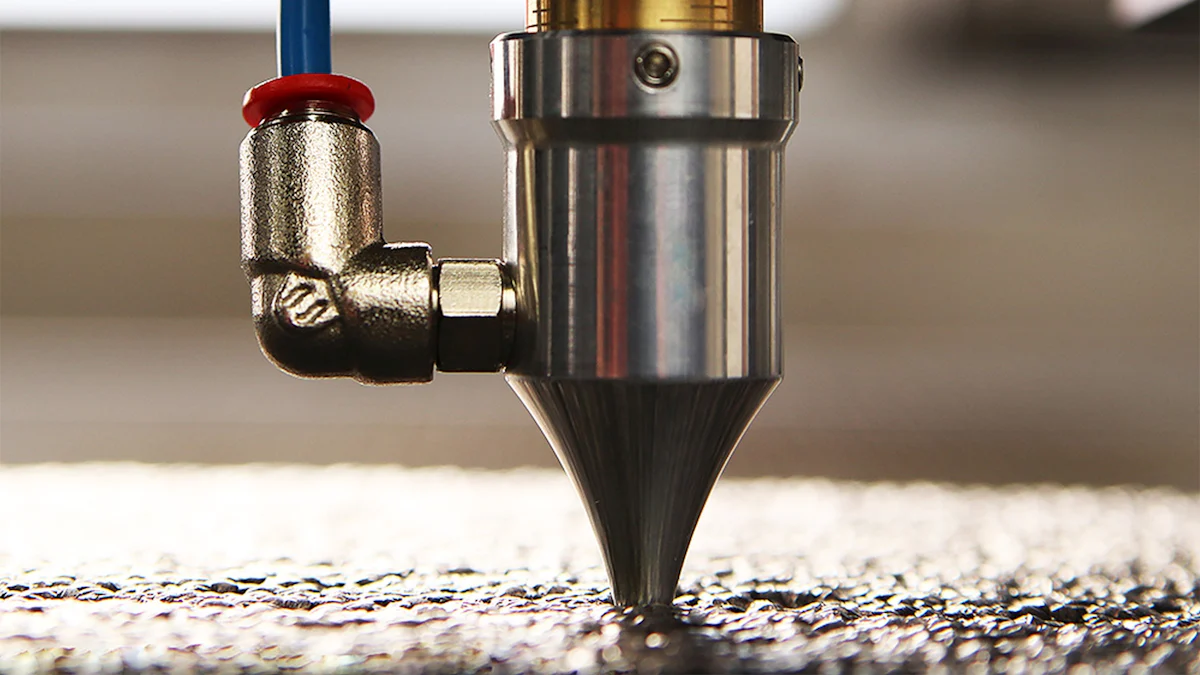

YAG laser cutting machines have become essential tools in modern manufacturing. Their ability to deliver precise results across various tasks makes them invaluable for industries requiring accuracy and efficiency. Below, you will explore the most common applications of these machines and how they enhance production processes.

Precision Cutting

Cutting complex shapes and patterns with minimal material waste.

YAG laser cutting machines excel at precision cutting, allowing you to create intricate shapes and patterns with remarkable accuracy. This capability is especially useful in industries like automotive, medical, and defense, where every millimeter matters. The focused laser beam ensures clean cuts, reducing material waste significantly. Whether you are working with metals, plastics, or ceramics, these machines help you achieve optimal results while conserving resources.

Achieving high accuracy in cutting thin or delicate materials.

When handling thin or delicate materials, maintaining accuracy becomes critical. YAG lasers provide the control needed to cut fragile materials without causing damage. For example, in electronics manufacturing, these machines can cut thin metals and semiconductor materials with micron-level precision. This level of accuracy ensures that components meet strict quality standards, enhancing the reliability of the final product.

Engraving and Marking

Engraving serial numbers, logos, and designs on various materials.

Engraving is one of the most versatile laser cutting applications. YAG lasers allow you to engrave serial numbers, logos, and intricate designs on a wide range of materials, including metals, plastics, and ceramics. This capability is vital for industries like defense and shipbuilding, where traceability and branding are essential. The engraved marks remain durable and clear, even under harsh conditions, ensuring long-term visibility.

Marking components for traceability and branding purposes.

Traceability plays a crucial role in many industries. YAG laser cutting machines enable you to mark components with unique identifiers, such as barcodes or QR codes. These markings help track products throughout their lifecycle, improving supply chain management. Additionally, you can use these machines to add branding elements, enhancing the visual appeal of your products while maintaining functionality.

Prototyping and Customization

Creating prototypes for product development.

Prototyping is a key step in product development, and YAG lasers make this process faster and more efficient. You can use these machines to create prototypes with precise dimensions and intricate details. This capability allows you to test designs and make adjustments before moving to mass production. Industries like textile and shipbuilding benefit greatly from this application, as it reduces development time and costs.

Customizing products with unique designs and features.

Customization has become a major trend in modern manufacturing. YAG laser cutting machines empower you to personalize products with unique designs and features. Whether you are engraving names on jewelry or cutting custom shapes for defense equipment, these machines provide the flexibility needed to meet diverse customer demands. Their ability to handle various materials ensures that you can deliver high-quality, tailored solutions across multiple sectors.

Advantages of YAG Laser Cutting Machines

YAG laser cutting machines offer a range of advantages that make them indispensable in modern manufacturing. Their ability to deliver precise results, handle diverse materials, and enhance productivity sets them apart from traditional methods. Below, you will explore the key benefits of using laser cutters and how they can transform your operations.

High Precision and Accuracy

Ability to cut intricate designs with minimal errors.

YAG laser cutting machines excel in achieving high precision. You can rely on them to cut intricate designs with remarkable accuracy. The focused laser beam ensures clean and sharp edges, reducing the chances of errors. This level of precision is essential for industries like automotive and aerospace, where even the smallest deviation can impact performance.

Suitable for applications requiring tight tolerances.

When your projects demand tight tolerances, YAG laser cutting technology delivers exceptional results. These machines maintain consistent accuracy, ensuring that every cut meets exact specifications. Whether you are working on delicate electronics or robust construction materials, you can trust these machines to meet your requirements without compromise.

Material Versatility

Compatible with metals, ceramics, plastics, and more.

The versatility of laser cutting machines allows you to work with a wide range of materials. From metals like stainless steel and aluminum to ceramics and plastics, these machines handle them all with ease. This compatibility makes them suitable for diverse industries, including medical, jewelry, and advertising.

Effective for both hard and soft materials.

YAG laser cutting machines adapt seamlessly to both hard and soft materials. You can cut through tough metals or delicate fabrics without damaging the material. This adaptability highlights the versatility of laser cutting, enabling you to tackle various projects with confidence and efficiency.

Efficiency and Speed

Faster cutting speeds compared to traditional methods.

YAG laser cutting technology significantly enhances productivity by offering faster cutting speeds. You can complete tasks in less time compared to traditional cutting methods. This speed advantage allows you to meet tight deadlines and handle high-volume production with ease.

Reduced production time and increased output.

By reducing production time, YAG laser cutting machines help you achieve increased efficiency and productivity. The precise and clean cuts minimize the need for additional finishing processes, saving you valuable time. This streamlined workflow boosts your overall output, making your operations more cost-effective and competitive.

The benefits of using laser cutters extend beyond precision and speed. Their versatility and ability to handle various materials make them an essential tool in industries ranging from automotive to construction. By incorporating YAG laser cutting machines into your processes, you can achieve increased efficiency and productivity while maintaining the highest standards of quality.

Minimal Material Waste

Clean cuts with minimal heat-affected zones.

YAG laser cutting machines deliver clean and precise cuts, ensuring minimal impact on the surrounding material. The focused laser beam generates a concentrated heat zone, which prevents unnecessary thermal damage to adjacent areas. This feature is especially beneficial when working with delicate or heat-sensitive materials. You can rely on these machines to maintain the integrity of your materials, reducing the risk of warping or discoloration. By preserving the quality of the material, you achieve better results and reduce the need for additional finishing processes.

Reduced waste due to precise cutting capabilities.

Precision is a hallmark of YAG laser cutting machines. Their ability to cut with exceptional accuracy minimizes material waste. Every cut aligns perfectly with your design specifications, leaving no room for errors or excess material removal. This efficiency not only saves resources but also lowers production costs. Whether you are working on intricate designs or large-scale projects, you can maximize material usage and reduce scrap. By optimizing your material consumption, you contribute to sustainable manufacturing practices while maintaining high-quality output.

YAG laser cutting machines have become indispensable tools across various industries. Their precision and versatility make them essential for creating intricate designs and high-quality components. You can rely on their ability to handle diverse materials, from metals to ceramics, ensuring efficient and accurate results. These machines play a pivotal role in sectors like automotive, medical, and electronics, driving innovation and enhancing productivity. As laser cutting technology continues to evolve, you can expect these machines to unlock new applications and redefine manufacturing standards, solidifying their place in modern production processes.

FAQ

What is a YAG laser cutting machine?

A YAG laser cutting machine uses a Yttrium Aluminum Garnet crystal as its laser medium. It produces a highly focused beam of light that can cut, engrave, or weld materials with exceptional precision. These machines are widely used in industries like automotive, aerospace, medical, and electronics due to their ability to handle diverse materials such as metals, plastics, and ceramics.

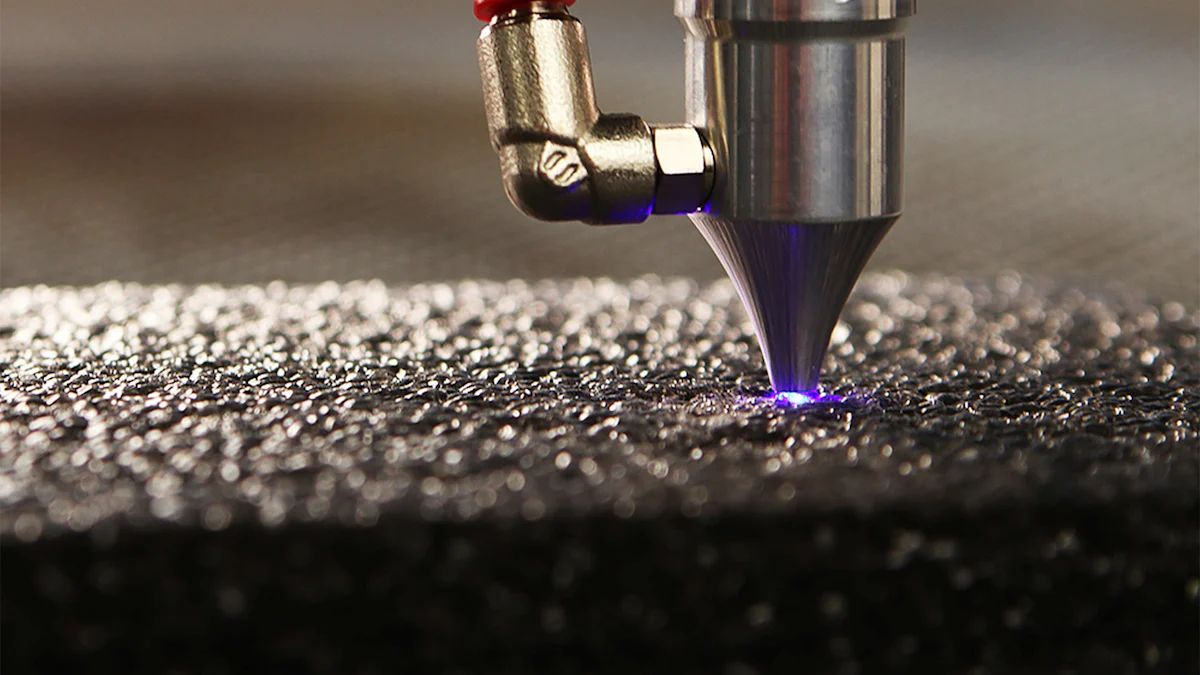

How does a YAG laser cutting machine work?

The machine generates a high-energy laser beam by exciting the YAG crystal with a light source. This beam is then directed onto the material, where it melts, vaporizes, or removes the targeted area. The process ensures clean and precise cuts with minimal heat-affected zones, making it ideal for intricate designs and delicate materials.

What materials can you cut with a YAG laser?

You can cut a wide range of materials, including:

- Metals like stainless steel, aluminum, and titanium.

- Plastics and polymers.

- Ceramics and glass.

- Precious metals like gold and silver.

The versatility of YAG lasers allows you to work with both hard and soft materials, making them suitable for various applications.

Why is YAG laser cutting preferred over traditional methods?

YAG laser cutting offers several advantages over traditional methods:

- High precision: Achieves intricate designs with minimal errors.

- Efficiency: Cuts faster, reducing production time.

- Minimal waste: Produces clean cuts with little material loss.

- Versatility: Works on a variety of materials, from metals to plastics.

These benefits make YAG lasers a superior choice for modern manufacturing.

What industries benefit the most from YAG laser cutting machines?

Industries that rely on precision and efficiency benefit the most, including:

- Automotive: For cutting and welding vehicle components.

- Aerospace: For shaping lightweight and heat-resistant materials.

- Medical: For producing surgical tools and implants.

- Electronics: For cutting circuit boards and marking components.

- Jewelry: For crafting intricate designs in precious metals.

Each industry leverages the unique capabilities of YAG lasers to enhance production quality.

Are YAG laser cutting machines safe to use?

Yes, YAG laser cutting machines are safe when used correctly. They come equipped with safety features like enclosed workspaces and protective shields to prevent laser exposure. Always follow the manufacturer’s guidelines and wear appropriate safety gear, such as laser safety glasses, to ensure safe operation.

Can YAG lasers handle delicate materials?

Absolutely. YAG lasers excel at cutting thin and delicate materials with high accuracy. Their small heat-affected zone minimizes the risk of damage, making them ideal for applications like electronics manufacturing and medical device production.

How do YAG lasers minimize material waste?

YAG lasers produce clean and precise cuts, reducing the need for additional finishing processes. Their focused beam ensures that only the targeted area is affected, leaving surrounding material intact. This precision helps you maximize material usage and lower production costs.

What makes YAG lasers efficient for prototyping?

YAG lasers allow you to create prototypes quickly and accurately. Their ability to cut intricate shapes and patterns ensures that your designs are precise, enabling you to test and refine products before mass production. This efficiency saves time and reduces development costs.

How do YAG lasers contribute to sustainable manufacturing?

By minimizing material waste and reducing energy consumption, YAG lasers support sustainable manufacturing practices. Their precision ensures optimal use of resources, while their efficiency lowers production time and energy usage. These factors make them an eco-friendly choice for modern industries.

See Also

Understanding The Functionality Of Laser Cutting Machines

Exploring The Operation Of Fiber Laser Cutters

An Overview Of Laser Cutting Machines And Their Varieties