Why Laser Metal Cutting Machines Are Vital for Industries

Laser cutting machines have become a cornerstone of modern manufacturing. These machines deliver unmatched precision and efficiency, enabling you to achieve intricate designs with minimal errors. Their ability to handle diverse materials and thicknesses makes them indispensable across industries like automotive, aerospace, and electronics. Fiber laser cutting machines, in particular, stand out for their speed and adaptability, revolutionizing production processes. By integrating advanced technology, such as automation, these machines ensure consistent quality while reducing waste. If you wonder what is laser metal cutting machine technology, it’s the key to staying competitive in today’s fast-paced manufacturing landscape.

What is Laser Metal Cutting Machine?

Definition and Functionality

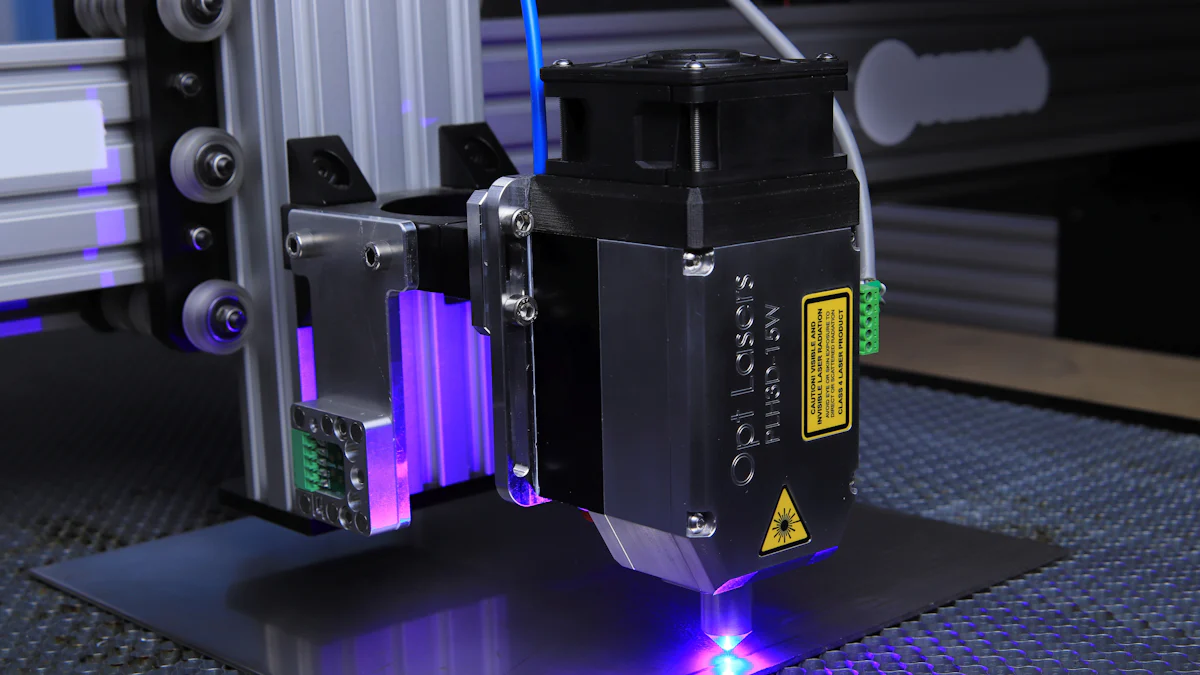

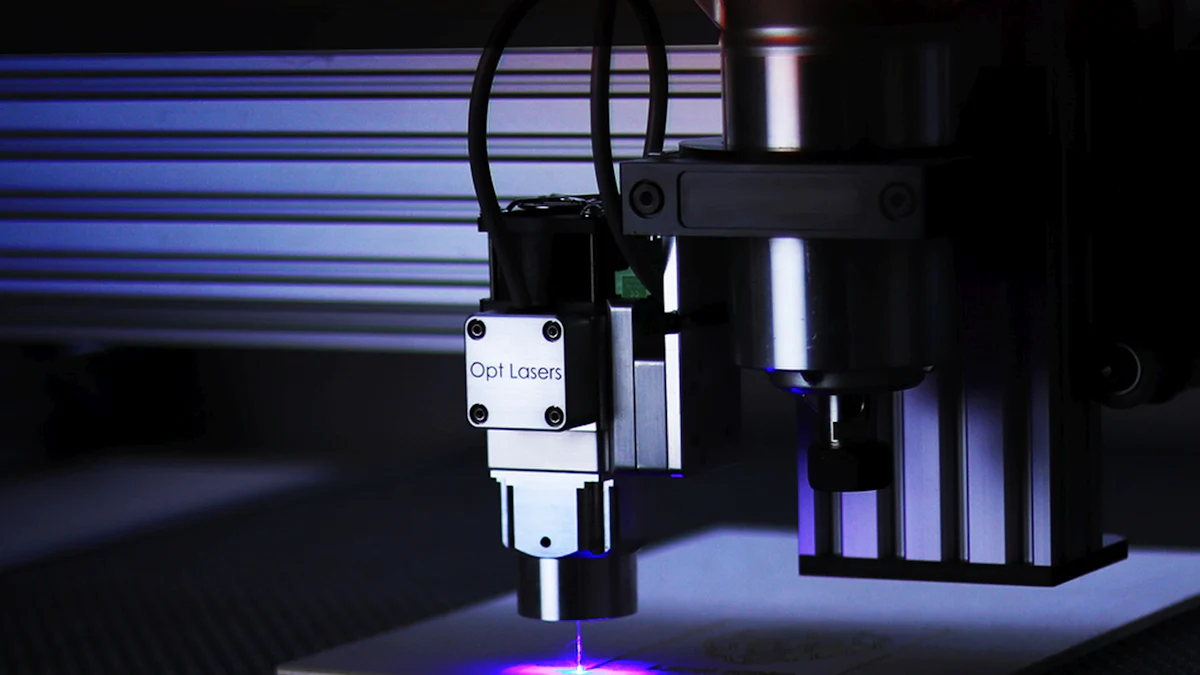

A laser metal cutting machine is a highly advanced tool designed to cut through materials with exceptional precision. It operates by directing a concentrated, high-powered laser beam onto the surface of the material. This beam generates intense heat, causing the material to melt, burn, or vaporize along the designated path. The process leaves behind clean, sharp edges without requiring additional finishing.

These machines often incorporate fiber lasers, CO2 lasers, or Nd:YAG lasers, each tailored for specific applications. For instance, fiber lasers excel in cutting metals like steel and aluminum, while CO2 lasers are versatile enough to handle non-metal materials such as wood and plastics. The integration of Computer Numerical Control (CNC) systems allows you to input digital designs, ensuring every cut matches your exact specifications. This combination of precision and automation makes laser metal cutting machines indispensable for creating intricate patterns and complex geometries.

Importance in Modern Manufacturing

In modern manufacturing, laser metal cutting machines play a pivotal role in enhancing productivity and quality. Their ability to deliver precise cuts ensures minimal material waste, which is crucial for cost-effective production. Unlike traditional cutting methods, these machines can handle a wide range of materials and thicknesses, making them versatile tools for industries like automotive, aerospace, and electronics.

The non-contact nature of laser processing reduces wear and tear on equipment, leading to lower maintenance costs and longer machine lifespans. Additionally, the speed and accuracy of these machines significantly improve production timelines. You can achieve faster turnaround times without compromising on quality, which is essential in today’s competitive manufacturing landscape.

Moreover, laser metal cutting machines align seamlessly with advanced technologies such as automation and robotics. This integration allows for streamlined operations, enabling you to scale production efficiently. By adopting this technology, you not only meet the demands of modern manufacturing but also position your business for long-term growth and sustainability.

Unparalleled Precision and Quality

High-Quality Results

Laser cutting machines deliver exceptional results that set them apart from traditional cutting methods. Their ability to achieve high-level precision ensures that every cut meets exact specifications, producing high-quality parts consistently. Unlike mechanical cutting, laser processing eliminates physical contact with the material, reducing the risk of contamination or damage. This non-contact approach also prevents warping, even when working with delicate or thin materials.

The advanced technology behind laser cutting machines allows you to create clean edges without requiring additional finishing. This feature not only saves time but also enhances the overall quality of the final product. Whether you are cutting metals, plastics, or composites, the results remain uniform and flawless. By using laser cutting, you can meet the stringent demands of industries like aerospace and electronics, where precision and reliability are paramount.

Intricate Designs and Minimal Errors

When it comes to intricate designs, laser cutting machines excel in delivering unmatched accuracy. The concentrated laser beam can cut complex patterns and shapes with ease, enabling you to produce designs that would be challenging or impossible with traditional methods. This capability is particularly valuable in industries requiring detailed components, such as jewelry or automotive manufacturing.

The integration of Computer Numerical Control (CNC) systems further enhances precision cutting. By inputting digital designs, you can ensure that every piece matches the intended dimensions without deviation. This level of control minimizes errors, reducing material waste and optimizing production efficiency. Additionally, laser cutting machines can handle a wide range of materials and thicknesses, giving you the flexibility to tackle diverse projects with confidence.

Compared to conventional cutting methods, laser cutting offers several advantages:

- Tight tolerance cutting for superior accuracy.

- Reduced material waste through optimized utilization.

- The ability to cut materials that are difficult to process mechanically.

These benefits make laser cutting machines indispensable for achieving unparalleled precision and quality in modern manufacturing.

Efficiency and Safety in Manufacturing

Faster Production Times

Laser cutting machines significantly enhance your production speed. These machines operate with remarkable precision, allowing you to complete tasks faster than traditional methods. The high-powered laser beam cuts through materials efficiently, reducing the time required for each project. This speed ensures that you can meet tight deadlines without compromising on quality.

By adopting laser cutting, you streamline your manufacturing process. The advanced technology minimizes manual intervention, enabling you to focus on other critical aspects of production. This improvement in cutting speed and efficiency directly boosts your overall productivity. Whether you are working on large-scale projects or intricate designs, laser cutting machines help you achieve faster turnaround times.

Additionally, the ability to handle diverse materials and thicknesses in a single setup eliminates the need for frequent adjustments. This versatility further reduces delays, ensuring a seamless workflow. Faster production times not only improve your operational efficiency but also position your business as a reliable partner in the competitive manufacturing landscape.

Reduced Downtime and Maintenance

Laser cutting machines are designed with durability and reliability in mind. Their non-contact nature minimizes wear and tear, resulting in minimal maintenance requirements. Unlike traditional cutting tools, these machines do not rely on physical force, which reduces the risk of mechanical failures. This feature ensures that you experience minimal downtime during operations.

The integration of advanced technologies, such as automated diagnostics, allows you to identify potential issues before they escalate. Regular maintenance becomes more manageable, ensuring that your machines remain in optimal condition. This proactive approach enhances your productivity by preventing unexpected disruptions.

Moreover, the precision of laser processing reduces material waste, which contributes to smoother operations. Clean cuts and consistent performance eliminate the need for rework, saving both time and resources. By investing in laser cutting machines, you ensure a reliable and efficient manufacturing process with minimal downtime.

Versatility of Laser Cutting Machines

Handling Various Materials and Thicknesses

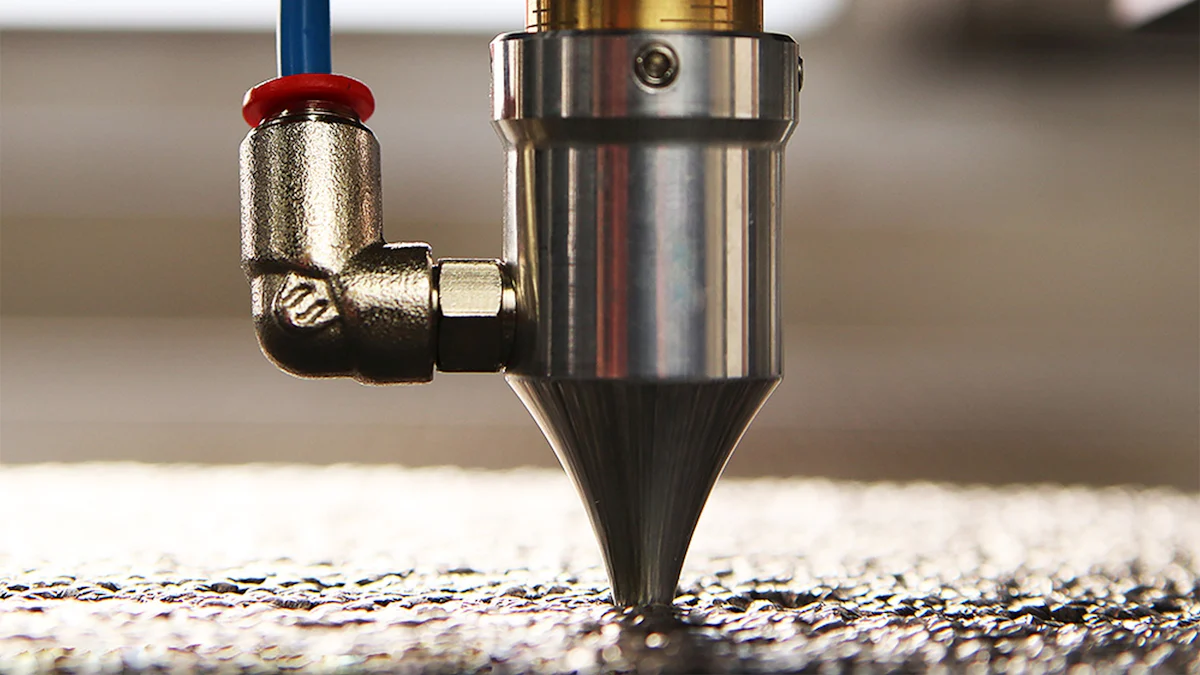

Laser cutting machines excel in their ability to process a wide range of materials. Whether you work with metals like steel, aluminum, or brass, or non-metals such as plastics, wood, or glass, these machines deliver precise results. Their adaptability allows you to handle everything from cutting thin sheets to thick plates with ease. This versatility makes them an essential tool in industries that require diverse material applications.

The advanced technology behind laser processing ensures clean cuts regardless of the material's thickness or density. For example, in metalworking shops, laser cutting is commonly used to shape sheet metal, rods, pipes, and tubes. This capability eliminates the need for multiple tools, streamlining your operations and reducing costs. Additionally, the non-contact nature of laser cutting minimizes material stress, preserving the integrity of even fragile or delicate materials.

By using laser cutting machines, you can achieve consistent results across various projects. This reliability is crucial for industries like aerospace and automotive, where precision and quality are non-negotiable. Whether you need intricate designs or straightforward cuts, these machines adapt to your requirements, ensuring efficiency and accuracy every time.

Applications Across Multiple Industries

Laser cutting machines have revolutionized manufacturing by serving a broad spectrum of industries. In the automotive sector, they play a pivotal role in crafting intricate components and customizations. From engine parts to interior detailing, laser cutting ensures precision and consistency, meeting the high standards of this competitive industry.

In the aerospace industry, laser cutting machines are indispensable for fabricating lightweight yet durable components. The ability to cut complex geometries with tight tolerances makes them ideal for producing parts used in aircraft and spacecraft. Similarly, in the agricultural sector, laser cutting is used to create machinery components like spreaders, chassis, and grain movement parts, enhancing the efficiency of farming equipment.

The food and beverage industry also benefits from laser cutting technology. It is instrumental in manufacturing machinery parts and packaging solutions that meet strict hygiene and safety standards. Beyond these sectors, laser cutting finds applications in shipbuilding, electronics, art, and even fashion. Its ability to handle diverse materials and deliver precise results makes it a versatile tool across industries.

By integrating laser cutting machines into your operations, you gain the flexibility to cater to various market demands. Their efficiency and adaptability not only improve production timelines but also position your business as a leader in innovation and quality.

Cost-Effectiveness of Laser Cutting Machines

Long-Term Savings and ROI

Investing in laser cutting machines offers significant long-term savings. These machines reduce the need for multiple tools by handling various materials and thicknesses with precision. This versatility eliminates the expense of purchasing and maintaining separate equipment for different tasks. You can rely on one machine to perform a wide range of operations, streamlining your manufacturing process and cutting costs.

The durability of laser cutting machines ensures a longer lifespan compared to traditional cutting tools. Their non-contact nature minimizes wear and tear, reducing repair and replacement expenses. Over time, this reliability translates into a higher return on investment (ROI). By producing high-quality parts consistently, you can meet customer demands without incurring additional costs for rework or material waste.

Additionally, the speed of laser cutting enhances productivity. Faster production times allow you to complete more projects within the same timeframe, increasing your revenue potential. The combination of reduced operational costs and improved output makes laser cutting machines a cost-effective solution for modern manufacturing.

Energy Efficiency and Reduced Waste

Laser cutting machines operate with remarkable energy efficiency. Unlike traditional cutting methods, which often consume excessive power, laser processing uses focused energy to achieve precise cuts. This targeted approach minimizes energy waste, lowering your utility bills and contributing to a more sustainable operation.

The precision of laser cutting also reduces material waste. Traditional methods often result in uneven cuts or excess scrap, but laser cutting ensures optimal material utilization. You can achieve clean, accurate cuts that maximize the use of raw materials. This efficiency not only saves money but also aligns with environmentally conscious manufacturing practices.

By adopting laser cutting machines, you contribute to a cleaner and more sustainable production process. The reduced waste and energy consumption reflect positively on your business, showcasing your commitment to efficiency and environmental responsibility. These benefits further enhance the cost-effectiveness of laser cutting technology, making it an essential tool for industries focused on quality and sustainability.

Integration with Modern Manufacturing Technologies

Automation and Robotics

Automation has transformed the way you approach manufacturing, and laser cutting machines are no exception. By integrating automation into laser cutting, you can achieve higher efficiency and precision in your operations. Automated systems allow these machines to perform repetitive tasks without manual intervention, reducing errors and increasing productivity. For instance, in industries like automotive, automation enhances production capacities by streamlining processes and ensuring consistent quality.

Robotics further amplifies the capabilities of laser cutting machines. Robotic arms equipped with laser cutters can handle complex tasks, such as cutting intricate patterns or working on hard-to-reach areas. This combination of robotics and laser processing ensures that you can tackle challenging projects with ease. Additionally, automated loading and unloading systems minimize downtime, enabling you to maintain a seamless workflow in modern workshops.

The integration of automation also improves workplace safety. By reducing the need for manual handling, you lower the risk of accidents and injuries. This not only protects your workforce but also ensures uninterrupted operations. Automation in laser cutting is not just a trend; it is a necessity for staying competitive in today’s fast-paced manufacturing environment.

Compatibility with CAD/CAM Systems

Laser cutting machines excel in their compatibility with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems. These systems allow you to create precise digital designs and translate them directly into cutting instructions. By using CAD/CAM software, you can ensure that every cut aligns perfectly with your specifications, eliminating guesswork and reducing material waste.

This compatibility streamlines modern workshop workflows. You can easily modify designs, test prototypes, and implement changes without disrupting production. For example, in industries like aerospace and electronics, where precision is critical, CAD/CAM integration ensures flawless execution of intricate designs. This level of accuracy is difficult to achieve with traditional methods.

Moreover, CAD/CAM systems enhance the versatility of laser cutting machines. You can work with various materials and thicknesses while maintaining consistent quality. This adaptability makes these machines indispensable for modern workshop workflows, where diverse projects require quick adjustments and reliable results.

By integrating CAD/CAM systems, you also improve collaboration within your team. Designers and operators can work together seamlessly, ensuring that the final product meets both aesthetic and functional requirements. This synergy not only boosts efficiency but also positions your business as a leader in innovation and quality.

Environmental Benefits of Laser Cutting

Eco-Friendly Operations

Laser cutting machines contribute significantly to eco-friendly manufacturing practices. These machines operate with remarkable precision, which minimizes material waste. Unlike traditional cutting methods that often leave behind excess scrap, laser cutting ensures optimal material utilization. This efficiency reduces the demand for raw materials, helping you conserve resources and lower your environmental footprint.

The energy efficiency of laser cutting machines further enhances their eco-friendly nature. By using focused laser beams, these machines consume less energy compared to conventional cutting tools. This targeted energy use not only reduces operational costs but also decreases carbon emissions. As a result, adopting laser cutting technology aligns your manufacturing processes with sustainable practices.

Additionally, laser cutting eliminates the need for harmful chemicals or lubricants often required in traditional cutting methods. This absence of toxic substances ensures cleaner operations, making it safer for both the environment and your workforce. By choosing laser cutting machines, you actively support greener production methods while maintaining high-quality results.

Cleaner and Safer Work Environments

Laser cutting machines create cleaner and safer work environments by reducing contamination and improving air quality. The non-contact nature of laser cutting eliminates physical wear on tools, which prevents the release of debris or particles into the workspace. This feature ensures a cleaner environment, especially when working with delicate or hazardous materials.

The precision of laser cutting also reduces the need for secondary finishing processes, such as grinding or sanding, which often generate dust and noise. By minimizing these additional steps, you maintain a quieter and healthier workspace. This improvement not only benefits your employees but also enhances overall operational efficiency.

Moreover, laser cutting machines produce minimal waste, which simplifies cleanup and disposal processes. The reduced material wastage and absence of chemical byproducts contribute to a safer and more sustainable workplace. By integrating laser cutting into your operations, you prioritize the well-being of your team while adhering to environmentally responsible practices.

Laser cutting machines have become indispensable in modern manufacturing. Their precision, efficiency, and versatility allow you to produce high-quality products while reducing waste and improving productivity. These machines not only streamline operations but also support sustainable practices, making them a vital tool for industries aiming to innovate and stay competitive. By investing in laser cutting technology, you ensure faster production, cost savings, and long-term sustainability. Whether you work in automotive, aerospace, or electronics, these machines empower you to meet the demands of today’s dynamic manufacturing landscape.

FAQ

What are laser cutting machines used for?

Laser cutting machines are used to cut, engrave, or shape materials with high precision. You can use them in industries like automotive, aerospace, electronics, and even art. They handle tasks such as creating intricate designs, cutting metal sheets, or producing components for machinery.

How do laser cutting machines work?

These machines use a focused laser beam to generate intense heat. The heat melts, burns, or vaporizes the material along a specific path. This process creates clean and precise cuts without physical contact. You can control the cutting process using digital designs through CNC systems.

What materials can you cut with laser cutting machines?

You can cut a wide range of materials, including metals like steel, aluminum, and brass. Non-metals such as plastics, wood, glass, and even fabrics are also compatible. The machine’s versatility allows you to work with materials of varying thicknesses and densities.

Are laser cutting machines safe to use?

Yes, laser cutting machines are designed with safety in mind. They include features like enclosed cutting areas, automated systems, and safety interlocks. These features protect you from exposure to the laser beam and reduce the risk of accidents.

How do laser cutting machines improve manufacturing efficiency?

Laser cutting machines enhance efficiency by reducing production times and minimizing errors. Their speed and precision allow you to complete tasks faster. Additionally, their ability to handle diverse materials in one setup eliminates the need for frequent adjustments, streamlining your workflow.

Do laser cutting machines require a lot of maintenance?

No, these machines require minimal maintenance. Their non-contact nature reduces wear and tear, which lowers the need for frequent repairs. Automated diagnostics also help you identify potential issues early, ensuring smooth operations.

Can laser cutting machines handle intricate designs?

Yes, laser cutting machines excel at creating intricate designs. The focused laser beam can cut complex patterns with high accuracy. By using CNC systems, you can ensure that every design matches your specifications perfectly.

Are laser cutting machines cost-effective?

Yes, they are cost-effective in the long term. These machines reduce material waste, lower energy consumption, and eliminate the need for multiple tools. Their durability and efficiency also provide a high return on investment by improving productivity and reducing operational costs.

What industries benefit the most from laser cutting machines?

Industries like automotive, aerospace, electronics, and manufacturing benefit significantly. These machines are also valuable in sectors like agriculture, shipbuilding, and even fashion. Their versatility makes them essential across various fields.

How do laser cutting machines support sustainability?

Laser cutting machines support sustainability by minimizing material waste and energy consumption. They use focused energy for precise cuts, reducing excess scrap. Additionally, they eliminate the need for harmful chemicals, making your operations more environmentally friendly.

See Also

Understanding The Functionality Of Laser Cutting Machines

Maximizing Efficiency With Laser Cutting Machines

The Process Behind Cutting Metal As Thin As Paper