What is Laser Cutting Machine? Top 3 Types Compared

A laser cutting machine is a powerful tool that uses a focused beam of light to cut materials with precision. So, what is a laser cutting machine's primary function? It slices through various materials like metal, wood, and plastic, creating intricate designs and shapes. The demand for these machines has surged, especially in industries like automotive and aerospace, due to their ability to produce high-quality components. In 2023, the U.S. market for laser cutting machines was valued at USD 1.32 billion, reflecting their crucial role in modern manufacturing.

Overview of Laser Cutting Technology

Basic Principles of Laser Cutting

How laser cutting works

You might wonder how laser cutting achieves such precision. The process involves directing a high-powered laser beam onto the material you want to cut. This beam melts, burns, or vaporizes the material, creating a clean edge. The laser's movement is controlled by a computer, allowing for intricate designs and patterns. This technology excels in producing detailed cuts without the need for physical contact with the material.

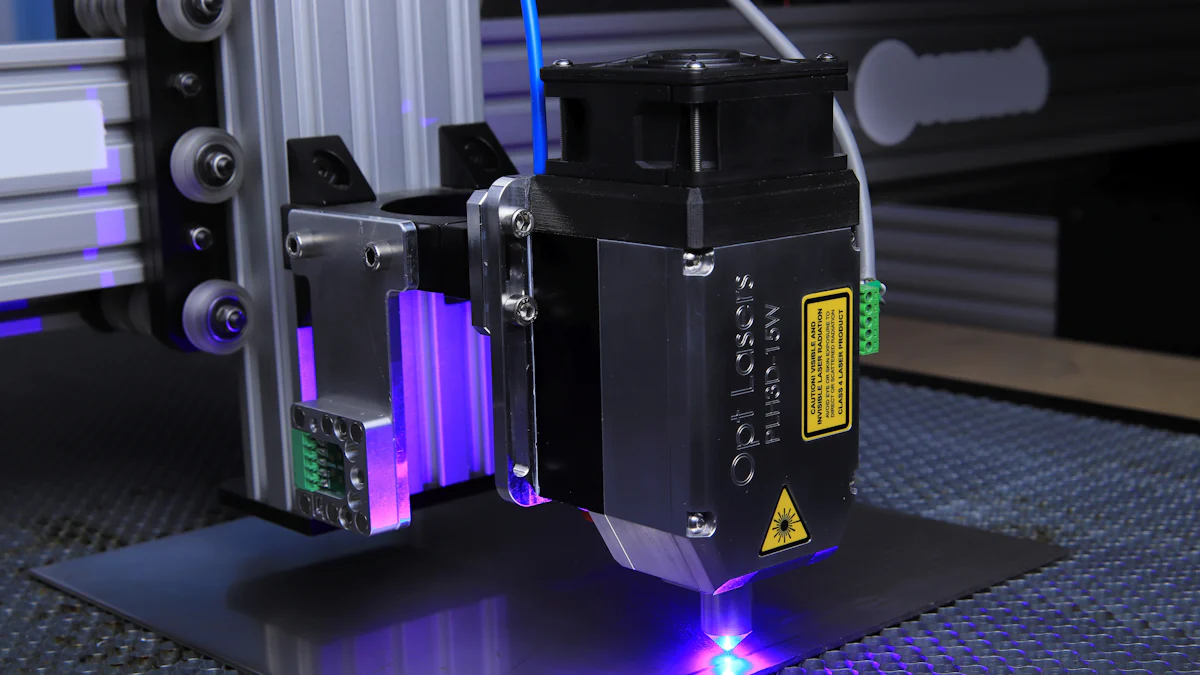

Key components of a laser cutting machine

A laser cutting machine consists of several essential components. The laser resonator generates the laser beam. Mirrors or fiber optics guide the beam to the cutting head. The cutting head focuses the beam onto the material. A motion control system ensures precise movement of the cutting head, while a cooling system prevents overheating. These components work together to deliver accurate and efficient cuts.

Advantages of Laser Cutting

Precision and accuracy

Laser cutting stands out for its precision and accuracy. You can achieve intricate cuts with minimal material waste. The laser's fine focus allows for detailed designs that other cutting methods struggle to replicate. This precision reduces the need for post-processing, saving you time and effort.

Versatility in material cutting

Laser cutting offers remarkable versatility. You can cut a wide range of materials, including metals, plastics, wood, and textiles. This flexibility makes laser cutting suitable for various industries, from automotive to fashion. The ability to handle different materials without changing tools enhances efficiency and reduces costs.

"Laser cutting offers advantages like high precision, no material contamination, high speed, unlimited 2D complexity, a wide variety of materials, and applications."

Types of Laser Cutters

Understanding the different types of laser cutters is crucial for selecting the right machine for your needs. Each type has unique features and applications, making them suitable for various tasks.

CO2 Laser Cutters

CO2 laser cutters are among the most popular types of lasers for cutting. They use a gas mixture, primarily carbon dioxide, to produce a laser beam. These machines excel in cutting non-metal materials like wood, acrylic, and fabric.

Features of CO2 lasers

CO2 lasers operate by exciting a gas mixture to emit light. This light is then amplified to create a powerful laser beam. The beam's wavelength makes it ideal for cutting organic materials. CO2 laser cutters are known for their ability to produce smooth edges and intricate designs.

Advantages and typical applications

You will find CO2 laser cutters advantageous due to their versatility and precision. They are perfect for engraving and cutting detailed patterns. Industries such as signage, textiles, and woodworking frequently use these machines. Their ability to handle a variety of materials without changing tools enhances productivity.

Fiber Laser Cutters

Fiber laser cutters are renowned for their efficiency and precision, especially in metal cutting. They use a solid-state laser, which is generated through a seed laser and amplified within a glass fiber.

Characteristics of fiber lasers

Fiber lasers offer high power density, making them suitable for cutting metals like steel and aluminum. They have a compact design and require less maintenance compared to other laser types. The beam quality of fiber lasers ensures precise cuts with minimal waste.

Benefits and common uses

You will appreciate fiber laser cutters for their speed and accuracy. They are ideal for industrial applications, including automotive and aerospace manufacturing. These machines can cut through thick metals quickly, reducing production time and costs. Their ability to etch and engrave adds to their versatility.

Nd:YAG Laser Cutting Machines

Nd:YAG laser cutting machines use a crystal as the laser medium. They are less common than CO2 and fiber lasers but offer unique advantages in specific applications.

Properties of Nd:YAG lasers

Nd:YAG lasers produce a beam with a shorter wavelength, allowing for precise cutting and engraving. They are effective for applications requiring high accuracy, such as in the electronics and medical device industries.

Strengths and typical scenarios of use

You will find Nd:YAG lasers beneficial for tasks that demand precision and detail. They excel in engraving and marking metals and ceramics. Their ability to produce fine details makes them suitable for intricate designs and patterns.

Comparison of the Top 3 Types

When choosing a laser cutting machine, understanding the differences in cost, efficiency, and precision is crucial. Each type of laser cutter offers unique benefits that cater to specific needs.

Cost

Initial investment and maintenance costs

The initial investment for laser cutting machines varies significantly. CO2 laser cutters generally have a lower upfront cost compared to fiber laser cutters and Nd:YAG laser cutting machines. However, fiber lasers often provide better long-term value due to their durability and lower maintenance requirements. You might find that Nd:YVO lasers, a variant of Nd:YAG, also offer competitive pricing for specialized applications. Maintenance costs can add up over time, so consider the longevity and reliability of each machine type.

Efficiency

Speed and energy consumption

Efficiency in laser cutting involves both speed and energy consumption. Fiber laser cutters excel in speed, especially when cutting metals, making them ideal for high-volume industrial applications. They also boast high energy efficiency, consuming less power than traditional CO2 lasers while delivering superior performance. Although CO2 lasers are slower, they remain effective for non-metal materials. Nd:YAG lasers offer precision in cutting but may require more energy, impacting overall efficiency. Despite higher energy consumption, the net power usage can be more efficient depending on the processing time.

Precision

Accuracy and detail level

Precision remains a hallmark of laser cutting technology. Fiber lasers lead in precision, providing exceptional accuracy and detail, particularly in metal cutting. This precision ensures high-quality cuts with minimal waste. CO2 lasers also deliver quality results, especially for intricate designs on non-metal materials. Nd:YAG lasers shine in applications requiring extreme precision, such as electronics and medical devices. Their ability to produce fine details makes them indispensable for tasks demanding high-quality outcomes.

"Laser cutting offers precision, cutting speed, convenience, scalability, and cost savings at a relatively small price premium over other solutions."

Material Compatibility

Understanding the material compatibility of laser cutting machines is crucial for selecting the right tool for your projects. Each type of laser cutter excels in cutting specific materials, making them suitable for various applications and supported materials.

Types of materials each machine can cut

-

CO2 Laser Cutters: You will find CO2 laser cutters ideal for non-metal materials. They excel in cutting wood, acrylic, fabric, and leather. These machines are perfect for applications and supported materials in industries like signage, textiles, and woodworking. Their ability to produce smooth edges and intricate designs makes them a popular choice for creative projects.

-

Fiber Laser Cutters: Fiber laser cutters are your go-to option for metal cutting. They handle materials like steel, aluminum, and brass with ease. These machines are highly efficient and precise, making them suitable for industrial applications and supported materials in sectors such as automotive and aerospace. Their speed and accuracy reduce production time and costs, enhancing overall efficiency.

-

Nd:YAG Laser Cutting Machines: Nd:YAG lasers are versatile and effective for both metal and non-metal materials. They are particularly useful for applications requiring high precision, such as electronics and medical devices. You can use them for engraving and marking metals, ceramics, and plastics. Their ability to produce fine details makes them indispensable for intricate designs and patterns.

"Laser cutting offers precision, cutting speed, convenience, scalability, and cost savings at a relatively small price premium over other solutions."

In summary, laser cutting machines offer remarkable capabilities across various materials, providing unmatched precision and versatility. You can choose from CO2, fiber, and Nd:YAG laser cutters, each excelling in different applications. When selecting the right machine, consider your specific needs. For non-metal materials, CO2 lasers are ideal. If you focus on metal cutting, opt for fiber lasers. For tasks requiring high precision, Nd:YAG lasers are your best choice. Understanding these differences ensures you maximize efficiency and achieve the best results in your projects.

FAQ

What is a laser cutting machine?

A laser cutting machine uses a focused beam of light to cut materials with precision. You can use it to slice through various materials like metal, wood, and plastic, creating intricate designs and shapes.

How does laser cutting work?

Laser cutting works by directing a high-powered laser beam onto the material you want to cut. This beam melts, burns, or vaporizes the material, creating a clean edge. A computer controls the laser's movement, allowing for intricate designs and patterns.

What are the main types of laser cutters?

The main types of laser cutters include CO2 Laser Cutters, Fiber Laser Cutters, and Nd:YAG Laser Cutting Machines. Each type has unique features and applications, making them suitable for various tasks.

Which materials can each type of laser cutter handle?

- CO2 Laser Cutters: Ideal for non-metal materials like wood, acrylic, fabric, and leather.

- Fiber Laser Cutters: Best for metal materials such as steel, aluminum, and brass.

- Nd:YAG Laser Cutting Machines: Versatile for both metal and non-metal materials, including ceramics and plastics.

What factors should I consider when choosing a laser cutter?

When choosing a laser cutter, consider factors like material compatibility, work area, laser power, precision, speed, automation, maintenance, cooling, and gas assist. These factors help you select the right machine for your specific needs.

How do CO2 and fiber lasers differ in terms of cost?

CO2 laser cutters generally have a lower upfront cost compared to fiber laser cutters. However, fiber lasers often provide better long-term value due to their durability and lower maintenance requirements.

Why is precision important in laser cutting?

Precision is crucial because it ensures high-quality cuts with minimal waste. You achieve intricate designs and detailed patterns that other cutting methods struggle to replicate, reducing the need for post-processing.

Can laser cutting machines engrave as well as cut?

Yes, laser cutting machines can engrave as well as cut. You can use them to etch and mark materials, adding versatility to their applications.

What industries benefit most from laser cutting technology?

Industries like automotive, aerospace, signage, textiles, and electronics benefit significantly from laser cutting technology. These machines produce high-quality components and intricate designs efficiently.

How does laser cutting contribute to cost savings?

Laser cutting offers cost savings through high precision, cutting speed, and versatility. You reduce material waste and production time, enhancing overall efficiency and lowering costs.

See Also

Understanding Laser Cutting Machines And Their Various Types

A Comprehensive Guide To Laser Cutting Machine Costs

Exploring Different Types Of Laser Cutting Technologies