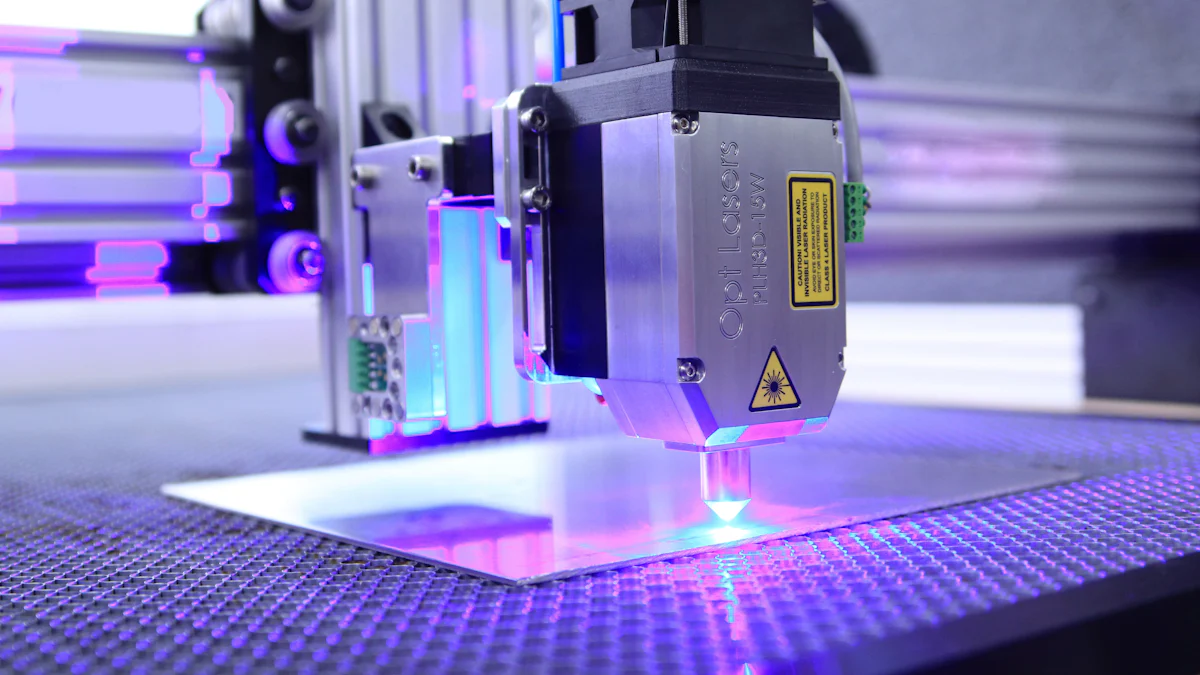

What is a CO2 Laser Cutting Machine?

A CO2 laser cutting machine stands as a marvel of modern technology, offering you the ability to cut or engrave materials with unmatched precision and efficiency. This device utilizes a high-intensity laser beam generated from carbon dioxide gas. The global market for these machines was valued at USD 7.12 billion in 2023, reflecting their growing importance across various industries. As you explore what is CO2 laser cutting machine, you'll discover its role in revolutionizing manufacturing processes. With its capability to handle intricate designs, this machine has become indispensable in today's fast-paced production environments.

Understanding the Working Principle of CO2 Laser Cutting

To grasp the intricacies of a CO2 laser cutting machine, you must first understand its working process. This machine uses a carbon-dioxide laser to cut materials with precision. The process involves several key steps and components that work together seamlessly.

How CO2 Lasers Cut Materials

Laser Generation and Amplification

In a CO2 laser cutting machine, the laser generation begins with a gas-filled tube containing a mixture of carbon dioxide, nitrogen, and helium. When electricity passes through this tube, it excites the gas molecules, creating a high-intensity laser beam. This beam is then amplified to increase its power, making it capable of cutting through various materials. The carbon-dioxide laser emits energy at a wavelength of 10,600 nm, which many materials absorb effectively, especially those containing water.

Interaction with Material

Once the laser beam is generated, it interacts with the material you want to cut. The beam heats the material to its ignition point, causing it to melt or vaporize. This process allows the laser to penetrate the material and follow a programmed path, cutting or engraving according to your design. The efficiency of this interaction depends on the laser cutting parameters, such as power and speed, which you can adjust to achieve the desired results.

The Role of Optics and Motion Systems

Focusing the Laser Beam

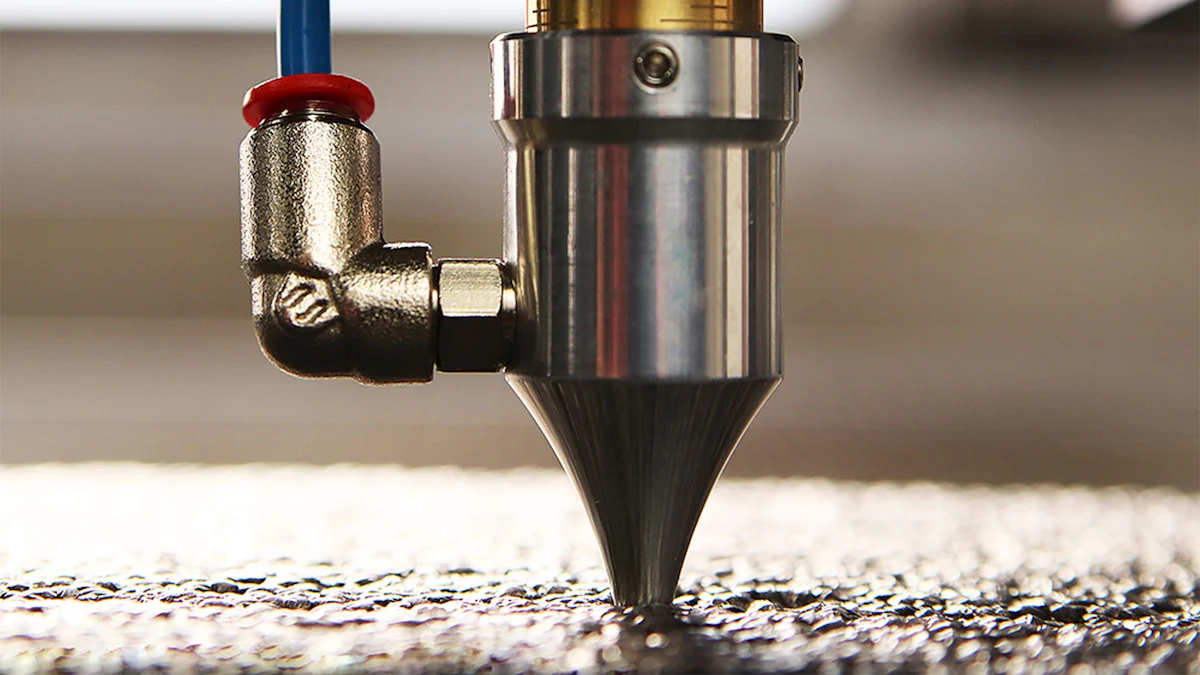

The optics system in a CO2 laser cutting machine plays a crucial role in focusing the laser beam. Lenses and mirrors direct and concentrate the beam onto a small spot on the material's surface. This focused beam ensures precise cuts and minimizes the heat-affected zone, enhancing the quality of the cut. Research indicates that low power CO2 laser cutting improves cut quality by reducing surface roughness and the heat-affected zone.

Movement and Precision Control

The motion system, often controlled by CNC (computer numerical control), ensures that the laser follows the exact path needed for cutting. This system allows for intricate designs and precise cuts, making CNC laser cutting a preferred choice in many industries. The movement and precision control are vital components of the working process of a laser cutting machine, enabling you to achieve high-quality results efficiently.

CO2 laser cutting technology has revolutionized the way materials are processed. By understanding the working principle of these machines, you can appreciate their capabilities and the precision they bring to various applications.

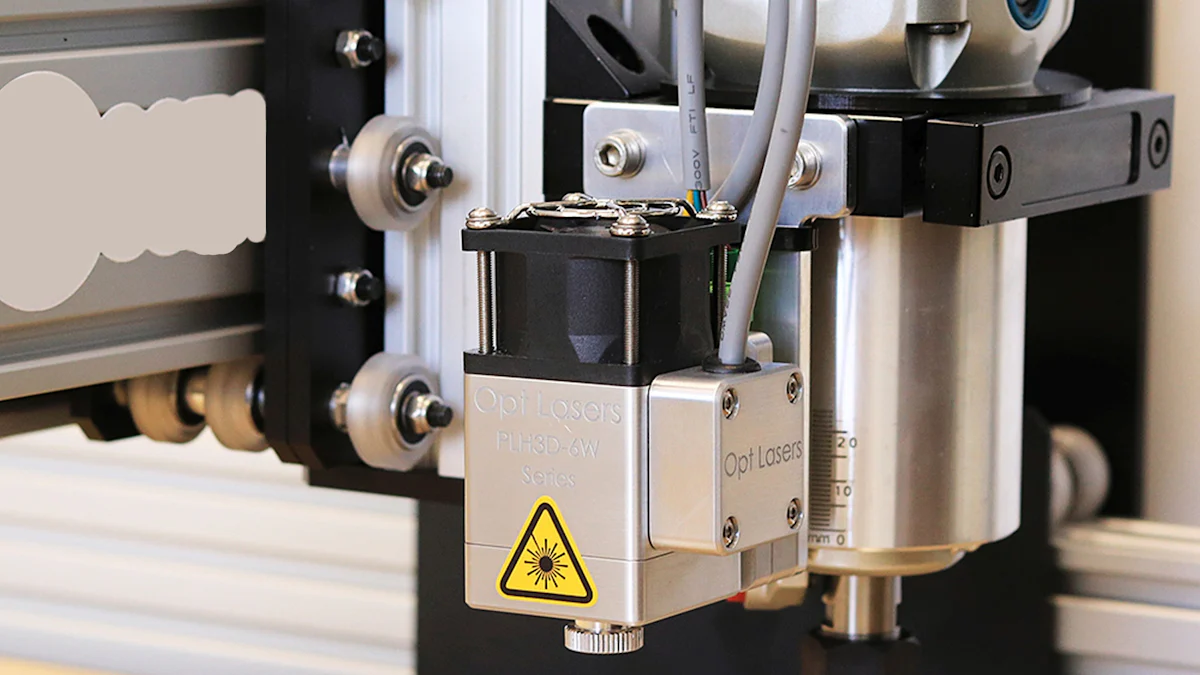

Key Components of a CO2 Laser Cutting Machine

Understanding the main components of a laser cutting machine helps you appreciate its functionality and efficiency. Each part plays a crucial role in ensuring precise and effective cutting or engraving.

Laser Tube

The laser tube serves as the heart of the CO2 laser cutting machine. It contains a mixture of carbon dioxide, nitrogen, and helium gases. When electricity excites these gases, they generate a powerful laser beam. This beam can penetrate and cut through various materials with precision. The quality and lifespan of the laser tube significantly impact the machine's performance. Regular maintenance ensures that the laser tube operates at optimal levels, providing consistent results.

Mirrors and Lenses

Mirrors and lenses guide and focus the laser beam onto the material's surface. Mirrors reflect the beam along the desired path, while lenses concentrate it into a fine point. This focused beam allows for intricate cuts and detailed engravings. Proper alignment of mirrors and lenses is essential for maintaining accuracy. You should regularly check and adjust these components to ensure the laser beam remains sharp and precise.

Cutting Bed and Motion Control System

The cutting bed provides a stable platform for materials during the cutting process. It supports various materials, from wood to plastics, ensuring they remain in place. The motion control system, often governed by computer numerical control (CNC), directs the laser's movement. This system allows for precise control over the cutting path, enabling complex designs and patterns. By understanding the main components of a laser cutting machine, you can optimize its use for diverse applications.

Cooling System

The cooling system in a CO2 laser cutting machine plays a vital role in maintaining optimal performance. As you operate the machine, the laser tube generates significant heat. Without proper cooling, this heat can damage the laser tube and other components, reducing the machine's efficiency and lifespan.

-

Functionality: The cooling system dissipates heat from the laser tube, ensuring it remains at a stable temperature. This stability is crucial for consistent laser output and precision in cutting or engraving tasks.

-

Types of Cooling Systems:

- Water Cooling: Most CO2 laser cutting machines use water cooling systems. Water circulates around the laser tube, absorbing excess heat and preventing overheating. You must regularly check the water level and quality to ensure effective cooling.

- Air Cooling: Some smaller or less powerful machines might use air cooling systems. Fans or blowers help disperse heat, but this method is generally less efficient than water cooling.

-

Maintenance Tips:

- Regularly inspect the cooling system for leaks or blockages. These issues can lead to inadequate cooling and potential damage.

- Ensure the water used in the cooling system is clean and free from impurities. Contaminated water can cause scaling or corrosion, affecting the system's efficiency.

- Monitor the temperature of the laser tube during operation. If you notice any unusual temperature spikes, investigate immediately to prevent damage.

By understanding and maintaining the cooling system, you can enhance the longevity and performance of your CO2 laser cutting machine. Proper cooling ensures that the machine operates efficiently, allowing you to achieve precise and high-quality results in your cutting and engraving projects.

Benefits of CO2 Laser Cutting Machines

CO2 laser cutting machines offer numerous benefits that make them a preferred choice in various industries. Understanding these advantages can help you appreciate the value they bring to modern manufacturing and design.

Precision and Accuracy

CO2 laser cutting machines excel in delivering exceptional precision and accuracy. The laser beam's ability to focus on a small spot size allows you to cut intricate designs and achieve a workpiece with ultrafine precision. This precision ensures that each cut is clean and smooth, reducing the need for additional finishing processes. You can rely on these machines to produce high-quality parts consistently, enhancing the overall quality of your production.

Versatility in Material Cutting

One of the significant advantages of laser cutting is its versatility. CO2 laser cutting technology can handle a wide range of materials, including wood, plastics, ceramics, and even some metals. This versatility allows you to work with different materials without needing multiple machines. Whether you're cutting a delicate design on acrylic or engraving patterns on wood, a CO2 laser cutting machine provides the flexibility you need to meet diverse production requirements.

Efficiency and Speed

Efficiency and speed are crucial in any production environment, and CO2 laser cutting machines deliver on both fronts. The cutting process is fast and efficient, allowing you to complete projects quickly without compromising on quality. The CNC system ensures precise control over the cutting path, enabling high production speed and reducing material waste. With a CO2 laser cutting machine, you can enhance your production performance and meet tight deadlines with ease.

Limitations of CO2 Laser Cutting Machines

While CO2 laser cutting machines offer numerous advantages, they also come with certain limitations that you should consider before investing in this technology.

Material Limitations

CO2 laser cutting machines excel at cutting non-metallic materials like wood, acrylic, and plastics. However, they face challenges when dealing with metals, especially thicker ones. The laser's wavelength, which is ideal for non-metals, doesn't interact as effectively with metals. If your projects primarily involve metal cutting, you might need to explore alternative technologies like fiber lasers. Despite these limitations, CO2 lasers remain versatile for a wide range of non-metallic applications.

Initial Cost and Maintenance

Investing in a CO2 laser cutting machine requires a significant initial outlay. The cost includes not only the machine itself but also the necessary accessories and setup. Additionally, maintaining the machine can be costly. Regular maintenance is crucial to ensure optimal performance and longevity. You need to replace components like the laser tube and mirrors periodically. While the initial cost and maintenance might seem high, the machine's efficiency and precision can offset these expenses over time.

Safety Considerations

Operating a CO2 laser cutting machine involves certain safety risks. The high-intensity laser beam can cause severe injuries if not handled properly. You must follow strict safety protocols to protect yourself and others. This includes wearing appropriate protective gear and ensuring the machine is in a well-ventilated area. Additionally, the cutting process can produce harmful fumes, especially when working with certain materials. Implementing proper ventilation systems is essential to maintain a safe working environment. By adhering to safety guidelines, you can minimize risks and ensure a secure operation.

Understanding these limitations helps you make informed decisions about using CO2 laser cutting machines. While they offer remarkable benefits, being aware of their constraints ensures you can maximize their potential safely and effectively.

Applications of CO2 Laser Cutting Technology

CO2 laser cutting technology has transformed various industries by offering precise and efficient solutions for material processing. Understanding the diverse applications of CO2 laser cutting can help you appreciate its impact on modern manufacturing and design.

Industrial Manufacturing

In industrial manufacturing, CO2 laser cutting machines play a crucial role. You can use them to cut and engrave materials with high precision, which is essential for producing complex components. These machines excel in creating intricate designs and patterns on materials like plastics, wood, and textiles. The ability to automate the cutting process with CNC systems enhances productivity and reduces human error. By incorporating CO2 laser cutting into your manufacturing processes, you can achieve consistent quality and meet tight production deadlines.

Art and Design

The art and design industry benefits significantly from the versatility of CO2 laser cutting technology. Artists and designers use these machines to create detailed and intricate pieces that would be challenging to achieve manually. You can cut and engrave various materials, such as acrylic, leather, and paper, to bring your creative visions to life. The precision of CO2 laser cutting allows you to experiment with complex patterns and designs, expanding the possibilities for artistic expression. Whether you're crafting custom jewelry or designing unique home decor, CO2 laser cutting offers the flexibility and accuracy you need.

Medical Device Fabrication

In the medical field, CO2 laser cutting technology is invaluable for fabricating medical devices. You can use it to produce components with the precision required for medical applications. The ability to cut and engrave materials like plastics and ceramics ensures that medical devices meet strict quality standards. CO2 laser cutting machines enable you to create intricate parts for devices such as surgical instruments and diagnostic equipment. By utilizing this technology, you can enhance the quality and reliability of medical devices, contributing to improved patient care.

The applications of CO2 laser cutting extend across various industries, showcasing its versatility and efficiency. By understanding these applications, you can leverage the technology to enhance your projects and achieve superior results.

Automotive Industry

CO2 laser cutting technology has made significant strides in the automotive industry. You can use these machines to cut and engrave various components with precision and efficiency. This capability is crucial for producing parts that meet the high standards required in automotive manufacturing.

1. Precision in Component Manufacturing

In the automotive sector, precision is paramount. CO2 laser cutting machines allow you to achieve this precision by cutting intricate designs and patterns on materials like plastics and textiles. This precision ensures that each component fits perfectly, reducing the need for additional adjustments or modifications. By using CO2 laser cutting, you can maintain the quality and consistency of automotive parts, which is essential for vehicle safety and performance.

2. Versatility in Material Processing

The versatility of CO2 laser cutting machines makes them ideal for the automotive industry. You can work with a wide range of materials, including plastics, rubber, and composites. This flexibility allows you to produce various components, from interior panels to engine parts, without needing multiple machines. The ability to switch between materials quickly enhances production efficiency and reduces downtime.

3. Efficiency and Speed in Production

Efficiency and speed are critical in the fast-paced automotive industry. CO2 laser cutting machines deliver on both fronts, allowing you to complete projects quickly without compromising on quality. The CNC system ensures precise control over the cutting path, enabling high production speed and reducing material waste. With CO2 laser cutting, you can meet tight production deadlines and increase your output.

4. Challenges and Considerations

While CO2 laser cutting offers numerous benefits, you should be aware of certain challenges. These machines require significant power consumption, leading to higher operational costs. Regular maintenance is also necessary to ensure optimal performance. Additionally, CO2 lasers may not be suitable for cutting very thick metals or highly reflective materials. Understanding these limitations helps you make informed decisions about using CO2 laser cutting in your automotive projects.

By leveraging CO2 laser cutting technology, you can enhance the quality and efficiency of automotive manufacturing. This technology offers the precision and versatility needed to produce high-quality components, contributing to the advancement of the automotive industry.

CO2 laser cutting machines have revolutionized modern manufacturing and design. Their precision and versatility make them indispensable across various industries. From automotive to medical device fabrication, these machines offer unmatched capabilities. You can rely on them for intricate designs and efficient production. The laser cutting technology has evolved since the 1970s, becoming a crucial part of industries like aerospace and consumer electronics. With CNC systems, you achieve high-quality results consistently. As you explore the diverse applications, you'll find that a laser cutting machine is a valuable asset in today's fast-paced production environments.

FAQ

What is a CO2 laser cutting machine?

A CO2 laser cutting machine uses a high-intensity laser beam generated from carbon dioxide gas to cut or engrave materials. This technology allows you to achieve precise and intricate designs on various materials, making it a valuable tool in many industries.

How does a CO2 laser cutting machine work?

The machine generates a laser beam by exciting a mixture of carbon dioxide, nitrogen, and helium gases. This beam then focuses on the material's surface, heating it to the point where it melts or vaporizes. You can control the laser's path using CNC systems, ensuring precise cuts and engravings.

What materials can a CO2 laser cutting machine process?

CO2 laser cutting machines excel at cutting non-metallic materials such as wood, acrylic, plastics, and textiles. While they can handle some metals, they are not ideal for cutting thicker or highly reflective metals. For such applications, you might consider alternative technologies like fiber lasers.

Why is CNC important in laser cutting?

CNC, or computer numerical control, plays a crucial role in laser cutting by directing the laser's movement. It allows you to achieve precise and consistent cuts by following programmed paths. This automation enhances productivity and reduces errors in the cutting process.

What are the benefits of using CO2 laser cutting machines?

These machines offer several advantages, including high precision, versatility in material processing, and efficiency. You can rely on them for intricate designs and fast production, making them indispensable in industries like automotive, art, and medical device fabrication.

Are there any limitations to CO2 laser cutting machines?

Yes, CO2 laser cutting machines have some limitations. They struggle with cutting thick metals and require significant initial investment and maintenance. Additionally, you must follow strict safety protocols to prevent injuries and manage harmful fumes during operation.

How has CO2 laser technology impacted the automotive industry?

CO2 laser technology has revolutionized automotive manufacturing by providing precise and efficient solutions for cutting and engraving components. You can produce high-quality parts with intricate designs, enhancing vehicle safety and performance.

What safety measures should you take when operating a CO2 laser cutting machine?

To ensure safety, always wear protective gear and operate the machine in a well-ventilated area. Implement proper ventilation systems to manage harmful fumes, and regularly inspect the machine for any issues that could compromise safety.

Can CO2 laser cutting machines be used for artistic purposes?

Absolutely! Artists and designers use CO2 laser cutting machines to create detailed and intricate pieces. You can experiment with various materials and designs, expanding your creative possibilities and bringing your artistic visions to life.

How has laser cutting technology evolved over the years?

Laser cutting technology has significantly evolved since the 1960s. It has become a critical tool in industries like aerospace, automotive, and manufacturing. The advancements in laser technology have improved precision, efficiency, and versatility, making it an essential part of modern production processes.

See Also

Understanding Laser Cutting Machines And Their Various Types

The Functionality Of CNC Laser Cutting Machines Explained

A Simple Explanation Of How Laser Cutting Works