What Is a Cutting Machine and What Are Its Uses

A can cutting machine is a versatile tool designed to slice through materials like paper, fabric, metal, and wood with precision. These machines play a vital role in industries by enhancing productivity and ensuring accuracy. For instance, the global CNC metal-cutting machine market reached a value of USD 86.59 billion in 2022 and is projected to grow at a rate of 5.5% annually. This growth reflects their increasing demand in sectors such as automotive manufacturing, where industrialization and supportive government policies drive their application.

Key Takeaways

- Cutting machines are essential tools across various industries, enhancing productivity and precision in tasks like manufacturing, crafting, and construction.

- Understanding the different types of cutting machines—mechanical, die cutting, digital, and specialized—helps you select the right tool for your specific needs. Choosing a cutting machine, consider factors such as material compatibility, precision requirements, and your budget to ensure optimal performance.

- Regular maintenance, including cleaning and inspecting blades, is crucial for keeping your cutting machine in top condition and extending its lifespan.

- Emerging trends in cutting technology, such as automation and eco-friendly practices, are shaping the future of the industry, making machines more efficient and sustainable. Investing in high-precision cutting machines, like laser or CNC machines, can significantly improve the quality of your projects, especially in professional settings.

- For crafting enthusiasts, user-friendly machines like Cricut offer endless creative possibilities, making it easy to produce intricate designs at home.

Types of Cutting Machines

Cutting machines come in various types, each designed to meet specific needs. Understanding these categories helps you choose the right tool for your projects.

Mechanical Cutting Machines

Overview of mechanical cutting methods

Mechanical cutting machines rely on physical force to slice through materials. These machines use sharp blades or tools to remove material and create precise shapes. They are widely used in industries where durability and straightforward operation are essential.

Common examples like saws, shears, and guillotines

- Saws: These tools cut through wood, metal, or plastic with toothed blades. Circular saws and band saws are common examples.

- Shears: Shears are ideal for cutting sheet metal or fabric. They use two blades that move past each other to make clean cuts.

- Guillotines: Guillotine cutters are perfect for slicing large sheets of paper or metal. They deliver straight, accurate cuts with minimal effort.

Die Cutting Machines

Explanation of die cutting and its applications

Die cutting machines use pre-shaped dies to cut materials into specific forms.

Examples of manual and automatic die cutters

- Manual die cutters: These machines require you to operate them by hand. They are suitable for small-scale projects like crafting or scrapbooking.

- Automatic die cutters: Automatic models handle larger workloads. They can cut through materials like fabric, rubber, and even sheet metal with precision and speed.

"Die cutting machines can perform through cutting, which separates designs completely from the material stock. This feature makes them invaluable for industries like packaging."

Digital Cutting Machines

Overview of digital cutting technology

Digital cutting machines use advanced technology to achieve high precision. These machines often integrate with design software, enabling you to create intricate patterns and shapes. They are versatile and suitable for a wide range of materials.

Examples like laser cutters, Cricut machines, and CNC machines

Laser cutters use focused laser beams to cut materials like metal, wood, and acrylic.

- Cricut machines: Cricut machines are popular among crafters. They cut paper, vinyl, and fabric with ease, making them perfect for DIY projects.

- CNC machines: CNC (Computer Numerical Control) machines automate cutting processes. They are commonly used in manufacturing to produce complex parts with high accuracy.

Each type of cutting machine serves a unique purpose. Whether you need a can cutting machine for crafting or a laser cutter for industrial use, understanding these options ensures you make an informed choice.

Specialized Cutting Machines

Overview of waterjet cutting machines and their uses

Waterjet cutting machines use a high-pressure stream of water, often mixed with abrasive materials like garnet, to cut through a wide range of materials. These machines operate at pressures between 20,000 PSI and 100,000 PSI, delivering precise cuts without causing thermal damage. This makes them ideal for materials sensitive to heat, such as ceramics, titanium, and certain types of steel.

You can rely on waterjet cutters for intricate designs and clean edges. They are widely used in industries like aerospace, construction, and manufacturing. For example, they excel at cutting stone, granite, and even delicate fabrics. Their versatility allows you to handle diverse projects with ease, whether you're working with hard metals or softer materials.

"Waterjet cutting machines provide unmatched precision and versatility, making them indispensable for industries requiring high-quality results."

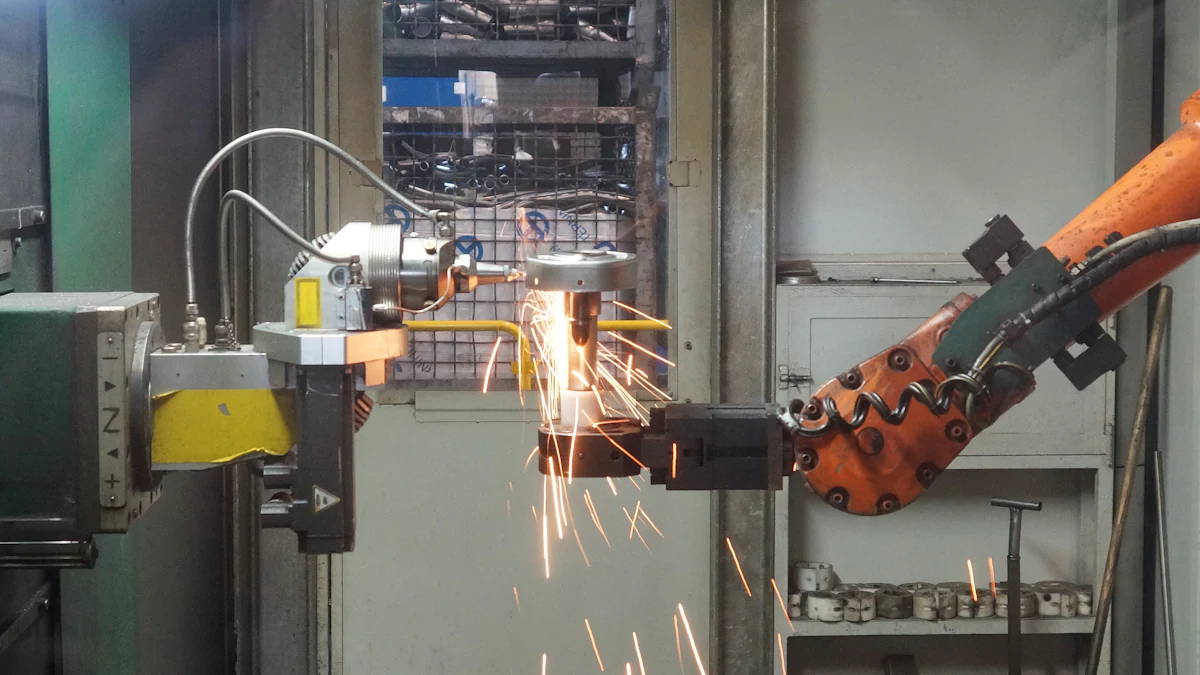

Examples of plasma cutters for metalworking

Plasma cutters use a stream of ionized gas, or plasma, to cut through electrically conductive materials. These machines are perfect for cutting thick metals like steel, aluminum, and copper. The plasma arc melts the material, while the high-speed gas blows away the molten metal, creating smooth and precise cuts.

You’ll find plasma cutters particularly useful in metalworking industries, including automotive and construction. They offer fast cutting speeds and are easy to operate, making them a popular choice for both professionals and hobbyists. Handheld plasma cutters are great for smaller tasks, while CNC plasma systems handle large-scale projects with precision.

Key benefits of plasma cutters include:

- Speed: They cut through thick metals quickly, saving time on large projects.

- Precision: Plasma cutters deliver clean edges, reducing the need for additional finishing.

- Versatility: They work on a variety of metals, from stainless steel to aluminum.

Whether you need to cut intricate designs or handle heavy-duty tasks, plasma cutters provide a reliable solution for your metalworking needs.

Uses of Cutting Machines Across Industries

Cutting machines have revolutionized various industries by offering precision, efficiency, and versatility.

Manufacturing and Industrial Applications

Cutting metals, plastics, and other materials for production

In manufacturing, cutting machines play a critical role in shaping raw materials into finished products. You can use them to cut metals, plastics, and other materials with high precision. For instance, laser cutters excel at creating intricate designs on thinner materials, while plasma cutters handle thicker metals like steel and aluminum. These machines ensure consistent quality, which is essential for mass production.

Examples of industries like automotive, aerospace, and packaging

Packaging companies use die cutting machines to create custom shapes for boxes and containers.

"Automated plasma cutting systems offer precise cuts, high-quality results, and increased productivity, making them indispensable in industrial applications."

Crafting and DIY Projects

Cutting paper, fabric, and vinyl for creative projects

For crafting enthusiasts, cutting machines open up endless possibilities. You can use them to cut paper, fabric, and vinyl for projects like scrapbooking, card-making, and home décor. Cricut machines, a popular choice among crafters, allow you to create intricate patterns with ease. These machines integrate with design software, enabling you to bring your creative ideas to life.

Examples of tools like Cricut machines for crafting

Crafting tools like Cricut machines and manual die cutters are perfect for small-scale projects. They are user-friendly and versatile, making them ideal for beginners and professionals alike. Whether you are designing custom stickers or cutting fabric for quilts, these machines help you achieve professional-quality results.

"Cutting machines can be used to create a wide range of products, including stickers, die cuts, and custom vinyl stickers."

Construction and Engineering

Cutting materials like wood, stone, and concrete

In construction and engineering, cutting machines handle tough materials like wood, stone, and concrete. Waterjet cutters are particularly effective for cutting stone and granite without causing heat damage. Saws and laser cutters are also widely used for precise cuts in wood and other building materials. These tools ensure accuracy and reduce waste, which is crucial in large-scale projects.

Examples of tools like saws, waterjet cutters, and laser cutters

Construction professionals rely on a variety of cutting machines. Circular saws and band saws are common for woodworking tasks. Waterjet cutting machines excel at cutting complex shapes in materials like ceramics and titanium. Laser cutters are ideal for detailed work on thinner materials. Each tool serves a specific purpose, helping you complete projects efficiently and effectively.

"Waterjet cutting machines deliver precise cuts without thermal damage, making them ideal for materials like ceramic, titanium, and stone."

Textile and Fashion Industry

Cutting fabrics and patterns for clothing production

In the textile and fashion industry, cutting machines play a pivotal role in transforming raw fabric into precise patterns for clothing production. These machines ensure accuracy and consistency, which are essential for creating high-quality garments. You can use cutting machines to slice through various fabrics, from delicate silks to heavy-duty denim, without compromising the material's integrity.

Modern fabric cutting machines utilize advanced technologies to streamline the cutting process. For example, laser cutters deliver intricate designs with unmatched precision, making them ideal for high-end fashion pieces. On the other hand, waterjet cutting machines excel at cutting fabrics without causing heat damage, preserving the material's texture and quality. These tools allow you to achieve clean edges and detailed patterns, even on complex designs.

"Waterjet cutting machines deliver precise cuts without thermal damage, making them perfect for delicate fabrics and intricate patterns."

Examples of fabric cutting machines used in mass production

For mass production, specialized fabric cutting machines ensure efficiency and scalability. Here are some examples of machines commonly used in the textile industry:

- Automatic fabric cutting machines: These machines use computer-controlled systems to cut multiple layers of fabric simultaneously. They are perfect for large-scale production, reducing manual labor and increasing output.

- Laser fabric cutters: Laser cutters are widely used for their precision and ability to handle intricate designs. They are particularly effective for cutting synthetic fabrics, as the laser seals the edges, preventing fraying.

- Die cutting machines: Die cutters are ideal for repetitive tasks, such as cutting identical shapes or patterns. They are commonly used in the production of uniforms and other standardized garments.

Each of these machines offers unique benefits, allowing you to choose the best option based on your production needs. Whether you're crafting custom designs or producing garments in bulk, fabric cutting machines provide the tools you need to succeed in the competitive world of fashion.

"Laser fabric cutters not only ensure precision but also prevent fraying, making them indispensable for synthetic materials in the fashion industry."

How to Choose the Right Cutting Machine

Selecting the right cutting machine ensures efficiency and precision in your projects.

Material Compatibility

Importance of matching the machine to the material

Choosing a machine that matches the material you work with is crucial for achieving clean and accurate cuts.

"Different industries require different precision levels and types of cuts, leading to a variety of cutting machines such as laser cutters, plasma cutters, waterjet cutters, and mechanical saws."

Examples of materials and suitable machines

Here are some examples to guide your choice:

- Metal: Plasma cutters and laser cutters are excellent for cutting metals like steel and aluminum.

- Fabric: Die cutting machines and laser fabric cutters work well for textiles.

- Wood: Mechanical saws and laser cutters are ideal for woodworking projects.

- Stone or Concrete: Waterjet cutters handle these materials with precision and without causing thermal damage.

Matching the machine to your material ensures durability, efficiency, and high-quality results.

Precision and Accuracy

Why precision matters for specific applications

Precision plays a vital role in industries where accuracy impacts the final product's quality. For instance, in the aerospace sector, even minor inaccuracies can compromise safety. Similarly, crafting intricate designs for DIY projects requires machines capable of detailed cuts. A machine with high precision minimizes errors and reduces material waste, saving time and resources.

Examples of high-precision cutting machines

Some cutting machines stand out for their precision:

- Laser cutters: These machines deliver unmatched accuracy, making them suitable for engraving and intricate designs.

- CNC machines: CNC (Computer Numerical Control) machines automate cutting processes with exceptional precision, often used in manufacturing complex parts.

- Waterjet cutters: These machines provide clean edges without heat distortion, perfect for delicate materials.

Investing in a high-precision machine ensures consistent results, especially for professional or large-scale projects.

Cost and Budget Considerations

Balancing cost with functionality

When choosing a cutting machine, balancing your budget with the machine's functionality is essential. High-end machines often offer advanced features like automation and software integration, but they come at a premium price. On the other hand, budget-friendly options may lack certain capabilities but still meet basic needs. Assess your requirements carefully to avoid overspending on unnecessary features.

Examples of budget-friendly vs. high-end machines

Here’s a comparison to help you decide:

- Budget-friendly options: Manual die cutters and entry-level Cricut machines are affordable and suitable for small-scale projects.

- High-end machines: Industrial laser cutters and CNC machines offer advanced features like automation and high precision, making them ideal for large-scale or professional use.

"Industrial die cutters are versatile and can cut sheet metal quickly and efficiently, allowing metal fabricators to incorporate them into production lines."

By evaluating your needs and budget, you can find a cutting machine that delivers value without compromising on performance.

Additional Factors to Consider

Machine size and workspace requirements

When selecting a cutting machine, you need to evaluate the available workspace and the machine's dimensions. Larger machines often require dedicated areas, making them suitable for industrial or professional settings. Compact models, on the other hand, fit well in smaller spaces, such as home workshops or crafting rooms.

Consider the type of projects you plan to undertake. For instance:

- Industrial die cutters: These machines are typically large and demand significant space. They are ideal for manufacturing environments where high-volume production occurs.

- Cricut machines: These compact devices are perfect for personal use. They fit easily on a desk or table, making them convenient for crafting enthusiasts.

- Waterjet cutters: These machines often require additional space for water tanks and drainage systems. They are better suited for workshops with ample room.

"Choosing a machine that aligns with your workspace ensures smooth operation and prevents unnecessary adjustments to your setup."

Before purchasing, measure your workspace and compare it with the machine's specifications. This step helps you avoid overcrowding and ensures efficient workflow.

Ease of use and software compatibility

Ease of use plays a crucial role in maximizing the potential of your cutting machine. Machines with intuitive controls and user-friendly interfaces save time and reduce the learning curve. For beginners, straightforward operation is essential to avoid frustration and errors.

Modern cutting machines often integrate with design software, allowing you to create intricate patterns and designs. Compatibility with popular software like Adobe Illustrator or CorelDRAW enhances your creative possibilities. For example:

- CNC machines: These machines rely on advanced software to automate cutting processes. They are ideal for professionals who require precision and efficiency.

- Laser cutters: Many laser cutting machines come with proprietary software. Ensure the software is compatible with your computer system and supports the file formats you use.

- Cricut machines: These devices connect seamlessly with Cricut Design Space, a user-friendly platform for crafting projects.

"Software compatibility ensures that your cutting machine integrates smoothly into your workflow, enabling you to focus on creativity rather than technical challenges."

When evaluating ease of use, look for features like touchscreens, pre-programmed settings, and clear instructions. These elements simplify operation and enhance your overall experience.

Maintenance and Care for Cutting Machines

Proper maintenance ensures your cutting machine operates efficiently and lasts longer. By following a regular care routine, you can avoid costly repairs and maintain optimal performance.

Regular Cleaning and Inspection

Importance of keeping the machine clean

Keeping your cutting machine clean is essential for maintaining its functionality. Dust, debris, and residue from materials can accumulate over time, affecting the machine's precision and performance. For example, laser cutting machines may lose accuracy if dirt obstructs the laser beam. Similarly, mechanical cutting machines can experience wear and tear when debris builds up around the blades or moving parts.

A clean machine not only performs better but also ensures safety during operation. Neglecting cleanliness can lead to overheating, dull blades, or even mechanical failure. Regular cleaning helps you avoid these issues and keeps your machine running smoothly.

"A well-maintained cutting machine delivers consistent results and reduces the risk of unexpected breakdowns."

Tips for regular maintenance

To keep your cutting machine in top condition, follow these maintenance tips:

- Clean after every use: Remove dust, scraps, and residue from the machine's surface and components. Use a soft brush or cloth for delicate parts.

- Lubricate moving parts: Apply appropriate lubricants to gears, bearings, and other moving components to reduce friction and wear.

- Inspect blades and tools: Check for signs of dullness or damage. Sharp blades ensure precise cuts and prevent material wastage.

- Check alignment: Ensure that cutting tools, such as dies or lasers, remain properly aligned for accurate results.

- Follow manufacturer guidelines: Refer to the user manual for specific cleaning instructions and recommended maintenance schedules.

By incorporating these practices into your routine, you can extend the lifespan of your cutting machine and maintain its efficiency.

Replacing Parts and Upgrades

When to replace blades, dies, or other components

Over time, certain parts of your cutting machine will wear out and require replacement. Blades, dies, and other cutting tools lose their sharpness with repeated use, leading to uneven cuts and reduced precision. For instance, industrial die cutting machines may need new dies after extensive use in high-volume projects. Similarly, fabric cutting machines benefit from replacing worn-out blades to maintain clean and accurate cuts.

You should replace parts when you notice:

- Dull or damaged blades: These can tear or fray materials instead of cutting cleanly.

- Misaligned dies: Misalignment affects the consistency of shapes and patterns.

- Reduced performance: If the machine struggles to cut through materials it previously handled with ease, it’s time to inspect and replace components.

Regularly monitoring your machine's performance helps you identify when replacements are necessary, ensuring uninterrupted operation.

Examples of upgrades for better performance

Upgrading your cutting machine can enhance its capabilities and adapt it to new challenges. Modern advancements offer features that improve precision, speed, and versatility. Here are some examples:

- Advanced blades: Upgrade to high-performance blades designed for specific materials, such as titanium-coated blades for cutting tough fabrics or metals.

- Software integration: Many laser cutting machines and CNC machines now support advanced design software. Upgrading to compatible software allows you to create intricate patterns with ease.

- Automation features: Adding automated systems to industrial die cutting machines can increase efficiency in mass production.

- Specialized tools: Equip your machine with tools tailored to unique tasks, such as embossing dies for cardboard die cutting machines or rotary blades for craft cutting machines.

"Upgrades not only improve performance but also expand the range of materials and projects your cutting machine can handle."

Investing in replacements and upgrades ensures your cutting machine stays relevant and efficient, meeting the demands of both current and future projects.

Future Trends in Cutting Machine Technology

Advancements in Automation

Overview of automated cutting systems

Automation is transforming the cutting machine industry by introducing systems that operate with minimal human intervention. Automated cutting systems streamline production processes, reduce errors, and enhance efficiency. These systems rely on advanced technologies like sensors, robotics, and computer programming to execute precise cuts. You can program these machines to handle repetitive tasks, ensuring consistent results every time.

For example, CNC (Computer Numerical Control) machines represent a significant leap in automation. These machines follow pre-programmed instructions to cut materials with exceptional accuracy. Multi-axis CNC systems allow you to create complex designs by moving the cutting tool in multiple directions. This capability makes them ideal for industries like aerospace and automotive manufacturing, where precision is critical.

"Automated cutting systems not only improve productivity but also reduce material waste, making them a cost-effective solution for businesses."

Examples of AI-powered cutting machines

Artificial intelligence (AI) is further enhancing automation in cutting machines. AI-powered systems analyze data in real-time to optimize cutting processes. These machines can adjust cutting speed, pressure, and angles based on the material's properties, ensuring flawless results. For instance, AI-integrated laser cutters can detect irregularities in materials and adapt their settings to maintain precision.

Some cutting machines now feature predictive maintenance powered by AI. These systems monitor the machine's performance and alert you when components need servicing or replacement. This proactive approach minimizes downtime and extends the machine's lifespan.

Key examples of AI-powered cutting machines include:

- AI-enhanced CNC machines: These machines use machine learning algorithms to improve cutting accuracy over time.

- Smart laser cutters: These devices adjust their focus and intensity automatically for optimal performance.

- Robotic cutting arms: Equipped with AI, these arms can perform intricate cuts in hard-to-reach areas.

By embracing AI-powered cutting machines, you can achieve higher efficiency, reduced costs, and superior quality in your projects.

Sustainability and Eco-Friendly Cutting

Importance of sustainable practices

Sustainability is becoming a priority in the cutting machine industry. As environmental concerns grow, adopting eco-friendly practices helps reduce your carbon footprint. Sustainable cutting methods minimize waste, conserve energy, and use environmentally safe materials. These practices not only benefit the planet but also align with consumer demand for greener products.

For instance, traditional cutting methods often generate excess material waste. In contrast, modern cutting machines, like waterjet cutters, use precise techniques to maximize material usage. Additionally, energy-efficient machines consume less power, lowering operational costs and environmental impact.

"Sustainable practices in cutting technology contribute to a healthier planet while meeting the growing demand for eco-conscious solutions."

Examples of eco-friendly cutting technologies

Several cutting technologies now focus on sustainability. These innovations help you achieve your goals without compromising environmental responsibility. Here are some examples:

- Waterjet cutting machines: These machines use water and abrasives to cut materials without producing harmful emissions. They also recycle water, reducing waste.

- Laser cutters with energy-saving modes: Many modern laser cutters feature energy-efficient settings that reduce power consumption during operation.

- Biodegradable cutting materials: Some machines now support cutting biodegradable materials, such as plant-based plastics, which decompose naturally over time.

- Electric-powered cutting machines: Unlike gas-powered alternatives, electric machines produce fewer emissions and operate more quietly.

By choosing eco-friendly cutting technologies, you can contribute to sustainability while maintaining high-quality results. These advancements ensure that cutting machines remain both innovative and environmentally responsible.

Cutting machines are essential tools that bring precision and efficiency to various industries and creative projects. From mechanical saws to advanced digital systems, each type serves unique purposes, ensuring you find the right fit for your needs. Their applications span manufacturing, crafting, construction, and fashion, showcasing their versatility. When selecting a cutting machine, consider factors like material compatibility, precision, and budget to make an informed choice. Whether you need a can cutting machine for crafting or industrial use, exploring these tools can unlock endless possibilities for your projects.

FAQ

What is a cutting machine?

A cutting machine is a tool designed to slice, shape, or engrave materials like paper, fabric, metal, and wood. These machines use various technologies, such as mechanical blades, lasers, or waterjets, to achieve precise cuts. You can find them in industries like manufacturing, crafting, and construction.

How do I choose the right cutting machine for my needs?

To choose the right cutting machine, consider the material you plan to cut, the level of precision required, and your budget. For example:

- Laser cutters work well for intricate designs on wood, acrylic, and metal.

- Waterjet cutters handle heat-sensitive materials like ceramics and titanium.

- Cricut machines are ideal for crafting projects involving paper, vinyl, or fabric.

Matching the machine to your project ensures better results and efficiency.

What materials can cutting machines handle?

Cutting machines can handle a wide range of materials, including:

- Metals: Steel, aluminum, and copper.

- Fabrics: Cotton, silk, and synthetic textiles.

- Wood: Plywood, MDF, and hardwood.

- Plastics: Acrylic and PVC.

- Stone: Granite and marble.

Always check the machine's specifications to ensure compatibility with your chosen material.

Are cutting machines suitable for beginners?

Yes, many cutting machines are beginner-friendly. Devices like Cricut machines and manual die cutters come with user-friendly interfaces and straightforward instructions. These machines often include pre-programmed settings, making them easy to operate even if you’re new to cutting projects.

How do cutting machines improve production efficiency?

For instance, automated systems like CNC machines streamline repetitive tasks, ensuring smoother workflows.

What role does AI play in modern cutting machines?

Artificial intelligence (AI) optimizes cutting processes by adjusting parameters like speed and pressure in real time. AI-powered machines also predict maintenance needs, reducing downtime. According to McKinsey & Company, AI could generate up to $2 trillion in value annually in manufacturing and supply chains, highlighting its transformative impact.

How do I maintain my cutting machine?

Regular maintenance keeps your cutting machine in top condition. Follow these steps:

- Clean the machine after every use to remove dust and debris.

- Lubricate moving parts to reduce wear and tear.

- Inspect blades or tools for dullness and replace them when necessary.

- Check alignment to ensure accurate cuts.

Proper care extends the machine’s lifespan and ensures consistent performance.

Can cutting machines be eco-friendly?

Yes, many cutting machines now incorporate eco-friendly features. For example:

- Waterjet cutters recycle water during operation.

- Laser cutters often include energy-saving modes.

- Machines compatible with biodegradable materials support sustainable practices.

These advancements help you reduce waste and lower your environmental impact.

What industries benefit the most from cutting machines?

Cutting machines are essential in industries like:

- Manufacturing: For shaping metals, plastics, and other materials.

- Textile and Fashion: For cutting fabrics and patterns.

- Construction: For slicing wood, stone, and concrete.

- Crafting: For creating intricate designs on paper, vinyl, and fabric.

Their versatility makes them valuable across diverse fields.

Are there any future trends in cutting machine technology?

Future trends include advancements in automation and sustainability. Automated systems, such as AI-powered CNC machines, improve precision and reduce material waste. Eco-friendly technologies, like waterjet cutters and energy-efficient laser systems, align with growing environmental concerns. These innovations ensure cutting machines remain efficient and responsible.

See Also

Exploring The Cost And Varieties Of Cutting Machines

Understanding The Functionality Of Die Cutting Machines

An Overview Of CNC Cutting Machines And Their Variants