What Is a Die Cutting Machine?

A die cutting machine is your go-to tool for creating intricate designs with precision. Whether you're working with paper, fabric, or leather, this machine transforms materials into custom shapes and patterns effortlessly. It’s a favorite among crafters, scrapbookers, and even industries like packaging and textiles. The ability to cut cleanly and consistently makes it invaluable for both personal projects and professional applications. With advancements like digital and laser technologies, these machines now offer unmatched versatility, catering to your creative and functional needs.

Key Takeaways

Die cutting machines are essential tools for creating precise shapes from various materials, making them popular among crafters and professionals alike.

Understanding the difference between manual and digital die cutting machines can help you choose the right one based on your crafting needs and budget.

Die cutting machines save time and reduce material waste, allowing for efficient production of multiple identical pieces, which is especially beneficial for businesses.

These machines offer versatility, enabling you to cut a wide range of materials, from paper to leather, and even thin metal sheets, enhancing your creative possibilities.

Before purchasing a die cutting machine, assess your specific needs, including the types of materials you'll use and the scale of your projects.

Reading reviews and seeking recommendations can provide valuable insights into the performance and reliability of different die cutting machines.

Investing in a die cutting machine can elevate your crafting experience, making complex projects easier and more enjoyable.

How Does a Die Cutting Machine Work?

Die cutting machines operate by applying pressure to a material, forcing it against a sharp-edged die to create precise shapes. This process can be as simple as turning a crank or as advanced as using software to guide a blade. Whether you're crafting at home or working in an industrial setting, understanding how these machines function can help you make the most of their capabilities.

The Basics of Die Cutting

At its core, die cutting involves using a die—a specialized tool with a sharp edge—to cut materials into specific shapes. You place the material, such as paper or fabric, on a cutting plate, then position the die on top. The machine applies pressure, either manually or electronically, to push the die through the material. This creates clean, consistent cuts every time.

Some machines also offer embossing features, which add raised designs to your projects. This versatility makes die cutting machines essential for creating everything from greeting cards to intricate fabric patterns. With the right dies, you can cut through a variety of materials, including leather, vinyl, and even thin metal sheets.

Manual vs. Digital Mechanisms

Manual die cutting machines rely on your physical effort to operate. You turn a crank or handle to feed the material and die through the machine. These machines are straightforward, durable, and often more affordable. They're perfect for beginners or those who enjoy hands-on crafting.

Digital die cutting machines, on the other hand, use software to control the cutting process. Think of them as printers, but instead of ink, they use a blade to cut designs. You connect the machine to a computer or use cartridges with preloaded designs. This setup allows for greater precision and the ability to repeat designs effortlessly. Digital machines are ideal for complex projects or when you need to cut multiple items quickly.

Both types have their strengths. Manual machines offer simplicity and reliability, while digital machines provide advanced features and customization. Choosing between the two depends on your needs, budget, and the type of projects you plan to tackle.

Types of Die Cutting Machines

Die cutting machines come in various types, each designed to meet different needs and preferences. Whether you're a hobbyist or a professional, understanding these options can help you choose the right tool for your projects.

Manual Die Cutting Machines

Manual die cutting machines are straightforward and reliable. You operate them by turning a crank or handle, which applies pressure to cut materials using pre-made dies. These machines are perfect if you enjoy hands-on crafting or prefer a simple setup. They don’t require electricity or software, making them portable and easy to use anywhere.

One of their key advantages is affordability. Manual machines are often more budget-friendly, making them a great choice for beginners or those who only need basic cutting capabilities. However, they do require physical effort and can be slower compared to digital options. If you’re working on small-scale projects or enjoy the tactile experience of crafting, a manual die cutting machine might be your ideal match.

Digital Die Cutting Machines

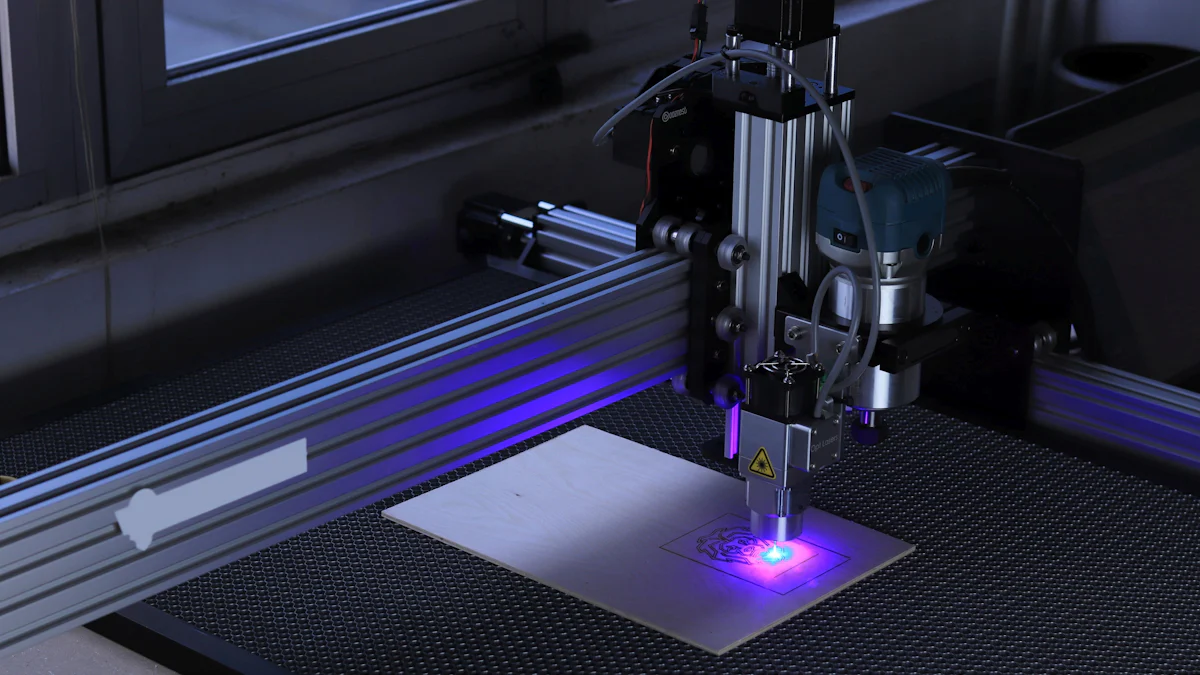

Digital die cutting machines take precision and versatility to the next level. These machines use software to guide a blade or laser, allowing you to create intricate designs with ease. You can connect them to a computer or use cartridges loaded with pre-designed templates. This setup makes it simple to repeat designs or customize patterns to suit your needs.

Unlike manual machines, digital ones handle complex projects effortlessly. They cut faster and with greater accuracy, making them ideal for large-scale tasks or detailed work. While they tend to be more expensive, their advanced features and time-saving capabilities often justify the investment. If you’re looking for a tool that offers flexibility and efficiency, a digital die cutting machine is worth considering.

Specialized Die Cutting Machines

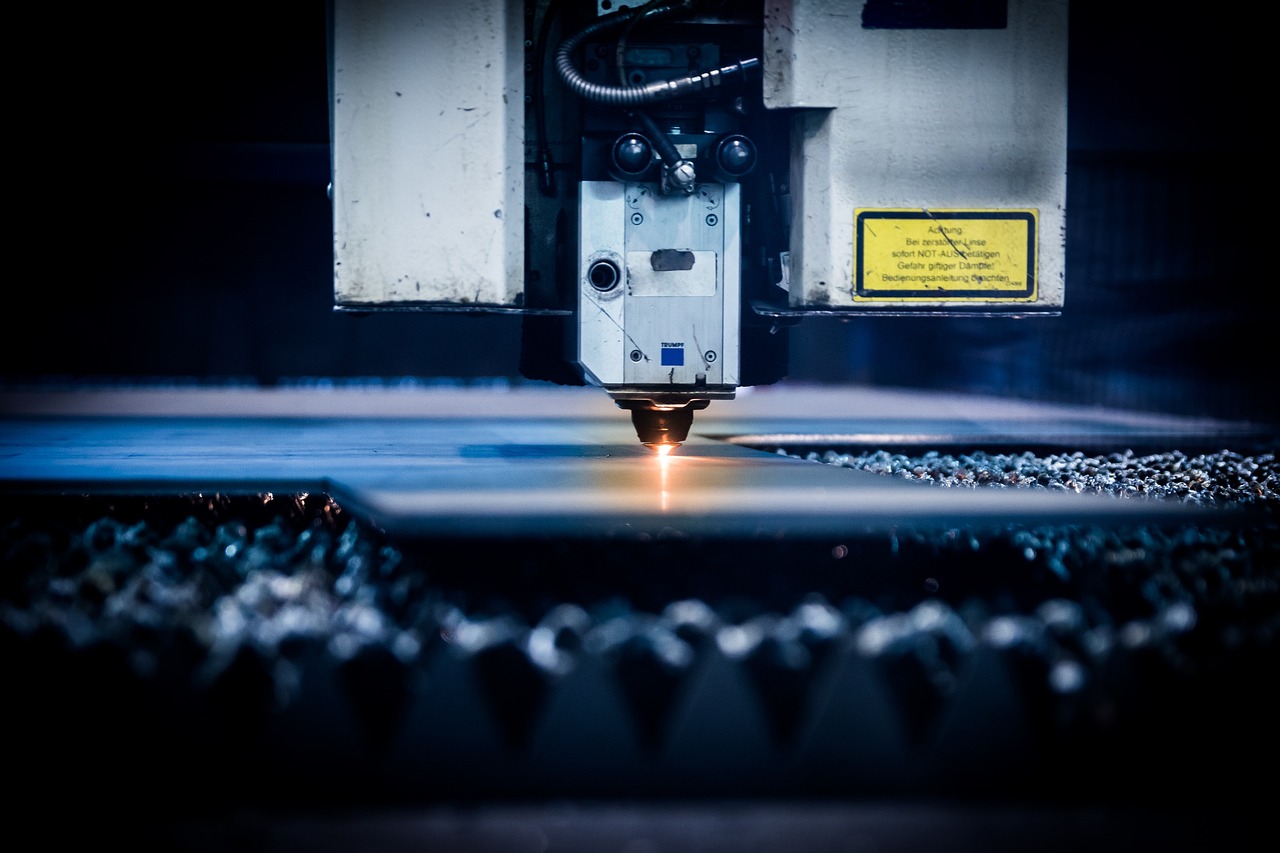

Specialized die cutting machines cater to specific materials or industries. For example, some machines are designed exclusively for cutting fabric, leather, or even thin metal sheets. These machines often include unique features tailored to their intended use, such as stronger blades or larger cutting areas.

Industries like packaging, textiles, and education frequently rely on specialized machines for their precision and durability. If your projects involve unique materials or require heavy-duty performance, exploring these specialized options can ensure you get the best results.

Pro Tip: Before purchasing any die cutting machine, think about the materials you’ll work with most often. This will help you decide whether a manual, digital, or specialized machine is the right fit for your needs.

Common Uses of a Die Cutting Machine

Die cutting machines have become indispensable tools across various fields. Whether you're a crafter, a business owner, or an educator, these machines open up endless possibilities for creativity and functionality.

Crafting and DIY Projects

If you love crafting, a die cutting machine can transform your projects. It allows you to cut intricate shapes and designs that would be nearly impossible with scissors or craft knives. You can create custom greeting cards, scrapbook embellishments, gift tags, and even home décor items. For quilters, these machines simplify cutting fabric into precise geometric shapes, saving time and ensuring accuracy.

Die cutting also adds a professional touch to your DIY creations. For example, you can use it to emboss patterns on paper or create layered designs for invitations. The versatility of materials—like cardstock, vinyl, leather, and thin wood—means you can experiment with different textures and finishes. Whether you're making personalized T-shirts, stickers, or decorative signs, a die cutting machine helps bring your ideas to life.

Fun Fact: Many crafters call their die cutting machine their "best friend" because it makes repetitive tasks easier and more enjoyable.

Commercial and Industrial Applications

In the commercial world, die cutting machines play a vital role in manufacturing and packaging. Businesses use them to produce custom labels, packaging designs, and promotional materials. For instance, companies in the printing industry rely on die cutting to create unique stationery items like business cards, folders, and envelopes.

Industries like textiles and leather goods also benefit from specialized die cutting machines. These machines handle heavy-duty materials and produce consistent results, making them ideal for large-scale production. Whether you're cutting protective films for book covers or shaping leather for handbags, a die cutting machine ensures precision and efficiency.

Pro Tip: If you're running a business, investing in a die cutting machine can save costs in the long run by reducing manual labor and material waste.

Educational and Professional Settings

Die cutting machines are not just for crafting and business—they're also valuable in educational and professional environments. Teachers use them to create engaging classroom materials, such as bulletin board decorations, flashcards, and interactive learning aids. These machines make it easy to cut letters, shapes, and patterns that enhance visual learning.

In professional settings, graphic designers and interior decorators use die cutting machines to create prototypes, mock-ups, and custom designs. For example, a designer working on a yearbook project can use a die cutting machine to produce uniform shapes and layouts. This tool streamlines the creative process and ensures high-quality results.

Did You Know? Many schools and offices keep a die cutting machine on hand because it simplifies tasks and encourages creativity among students and staff.

Benefits of Using a Die Cutting Machine

Die cutting machines bring a world of advantages to your creative and professional projects. Whether you're crafting at home or working in an industrial setting, these machines can elevate your work in ways you might not have imagined.

Precision and Consistency

One of the biggest benefits of using a die cutting machine is its ability to deliver precise and consistent results. Imagine trying to cut dozens of identical shapes by hand. It’s not only time-consuming but also nearly impossible to achieve the same level of accuracy. A die cutting machine ensures every cut is clean and uniform, no matter how intricate the design. This precision is especially valuable when working with detailed patterns or materials like fabric and leather. You can trust the machine to handle the hard work while you focus on your creative vision.

Quick Tip: If you’re working on a project that requires multiple identical pieces, a die cutting machine will save you from the frustration of uneven cuts.

Time and Cost Efficiency

Time is precious, and a die cutting machine helps you save plenty of it. Instead of spending hours cutting shapes manually, you can let the machine do the job in minutes. For example, if you’re creating wedding invitations or custom labels, the machine can cut hundreds of pieces in a fraction of the time it would take by hand. This efficiency doesn’t just save time—it also reduces material waste. The machine’s precision minimizes errors, so you won’t need to redo cuts or throw away ruined materials.

In professional settings, this time-saving feature translates to cost efficiency. Businesses can produce high-quality products faster, which boosts productivity and lowers labor costs. Whether you’re a small business owner or a hobbyist, the machine’s ability to streamline your workflow makes it a worthwhile investment.

Did You Know? Many industries rely on die cutting machines to meet tight deadlines and maintain consistent quality in their products.

Versatility and Creativity

A die cutting machine isn’t just a tool—it’s a gateway to endless creative possibilities. These machines can cut a wide range of materials, from paper and vinyl to leather and thin metal sheets. This versatility allows you to experiment with different textures and designs, bringing your ideas to life in ways you never thought possible. Whether you’re making custom T-shirts, intricate scrapbook layouts, or decorative home items, the machine adapts to your needs.

The variety of dies and templates available further enhances your creative freedom. You can choose from pre-made designs or create your own, giving you complete control over your projects. For beginners, the simplicity of using pre-designed dies makes crafting more accessible. For experienced users, the ability to customize designs opens up new levels of artistic expression.

Fun Fact: Some crafters say their die cutting machine feels like an extension of their imagination, turning even the wildest ideas into reality.

Choosing the Right Die Cutting Machine

Selecting the perfect die cutting machine can feel overwhelming, especially with so many options available. By focusing on your specific needs and understanding the features that matter most, you can make a confident choice. Let’s break it down step by step.

Assessing Your Needs

Start by thinking about how you’ll use the machine. Are you crafting for fun, running a small business, or working on large-scale projects? Your purpose will guide your decision. For example, if you’re a hobbyist, a manual machine might suit your needs. On the other hand, professionals often prefer digital machines for their speed and precision.

Consider the materials you’ll work with most often. Some machines handle paper and cardstock well, while others are designed for tougher materials like leather or fabric. If you plan to cut a variety of materials, look for a versatile machine that can adapt to different projects.

Also, think about the size of your projects. Machines come in various sizes, from compact models for small crafts to larger ones for industrial tasks. If space is limited, a portable machine might be the best fit. However, if you need to cut bigger designs, a larger machine with a wider cutting area will save you time and effort.

Pro Tip: Make a list of your top priorities—materials, project size, and frequency of use. This will help you narrow down your options quickly.

Comparing Features and Costs

Once you know your needs, compare the features of different machines. Manual machines are simple and budget-friendly, but they require physical effort. Digital machines, while more expensive, offer advanced features like software integration and automatic cutting. Decide which type aligns with your goals.

Pay attention to additional features like embossing capabilities, cutting speed, and ease of use. Some machines come with built-in designs or allow you to upload custom templates. These extras can enhance your creative experience and save time.

Cost is another important factor. Basic manual machines often cost less than $100, while advanced digital models can exceed $600. Don’t just focus on the upfront price—consider the long-term value. A slightly pricier machine with better features might save you money in the long run by reducing material waste and increasing efficiency.

Quick Tip: Look for bundles that include dies, embossing folders, or other accessories. These can add value and help you get started right away.

Reading Reviews and Seeking Recommendations

Before making a final decision, take some time to read reviews. Customer feedback can give you insight into a machine’s performance, durability, and ease of use. Look for patterns in the reviews—if multiple users mention the same issue, it’s worth considering.

Ask for recommendations from friends, crafting communities, or online forums. People who’ve used a die cutting machine can share valuable tips and advice. They might even suggest brands or models you hadn’t considered.

Retailers like Amazon and Walmart often feature customer reviews alongside product listings. These reviews can help you weigh the pros and cons of each option. Don’t forget to check out video tutorials or demonstrations to see the machine in action.

Did You Know? Many crafters recommend starting with a beginner-friendly machine and upgrading later as your skills and needs evolve.

By assessing your needs, comparing features, and gathering feedback, you’ll find a die cutting machine that fits your projects perfectly. Whether you’re crafting for fun or tackling professional tasks, the right machine will make your creative journey smoother and more enjoyable.

A die cutting machine is more than just a tool; it’s your partner in creativity and precision. Whether you’re crafting for fun or working on professional projects, this machine simplifies complex tasks and delivers consistent results. By understanding how it works and exploring its types and benefits, you can confidently choose the one that fits your needs. From cutting intricate shapes to embossing unique designs, the possibilities are endless. With the right machine, you’ll unlock new levels of efficiency and creativity, making every project a masterpiece.

FAQ

Do you need a machine to use cutting dies?

Yes, you’ll need a die cutting machine to use cutting dies effectively. These machines use a combination of rollers and cutting plates to apply pressure, allowing you to cut your chosen material with precision. Without the machine, it’s nearly impossible to achieve the same level of accuracy and consistency.

How do I choose the right die cutting machine?

Choosing the right die cutting machine depends on your needs. Think about the materials you’ll work with and the types of projects you plan to create. For example, if you want intricate designs or need to cut tougher materials like leather, you might prefer a digital machine. If you’re working on simpler projects, a manual machine could be a better fit. Consider whether you need features like embossing or software compatibility as well.

What’s the difference between manual and digital die cutting machines?

Manual machines rely on physical effort. You turn a crank to apply pressure and cut the material. They’re simple, portable, and great for beginners. Digital machines, on the other hand, use software to guide the cutting process. They’re faster, more precise, and ideal for complex or large-scale projects. Your choice depends on your budget and the level of customization you need.

Can a die cutting machine cut all materials?

Die cutting machines can handle a wide range of materials, but not all machines are equally versatile. Most can cut paper, cardstock, and vinyl. Some advanced models can cut fabric, leather, and even thin metal sheets. Always check the machine’s specifications to ensure it supports the materials you plan to use.

Do die cutting machines require special maintenance?

Die cutting machines are generally low-maintenance. Keep the cutting plates clean and replace them when they show signs of wear. For digital machines, ensure the software stays updated. Regularly check the blades and replace them if they become dull. Proper care will keep your machine running smoothly for years.

Are die cutting machines beginner-friendly?

Absolutely! Many die cutting machines are designed with beginners in mind. Manual machines are especially easy to use, as they don’t require any technical knowledge. Digital machines might have a learning curve, but most come with user-friendly software and tutorials to help you get started.

Can I use any dies with my machine?

Not all dies are compatible with every machine. Some machines work with specific brands or types of dies. Before purchasing new dies, check your machine’s compatibility guidelines. Using the wrong dies could damage your machine or result in poor-quality cuts.

What should I consider when buying a die cutting machine?

When shopping for a die cutting machine, focus on these key factors:

Type of machine: Decide between manual and digital based on your needs.

Materials: Ensure the machine can handle the materials you’ll use most often.

Features: Look for extras like embossing, software integration, or portability.

Budget: Compare prices and consider long-term value over upfront cost.

Can I use a die cutting machine without electricity?

Yes, manual die cutting machines don’t require electricity. They operate using a crank or handle, making them portable and convenient for crafting on the go. Digital machines, however, do need electricity to function.

Are there any safety tips for using a die cutting machine?

To stay safe while using a die cutting machine, follow these tips:

Keep your fingers away from the rollers and blades.

Use the machine on a stable surface to prevent accidents.

Store sharp tools, like blades, out of reach of children.

Follow the manufacturer’s instructions for proper use and maintenance.

Pro Tip: Always double-check your setup before starting a project to avoid mistakes or injuries.