What is a CO2 Laser Cutting Machine and Its Applications

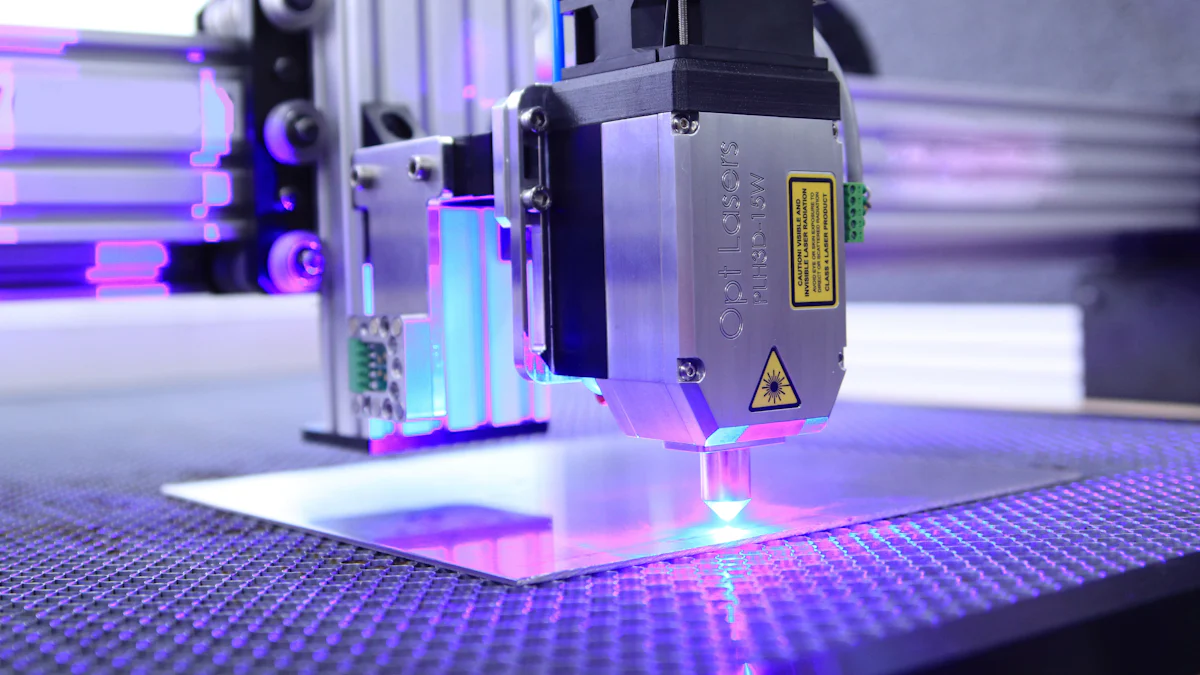

A CO2 laser cutting machine is a powerful tool designed to cut, engrave, and mark materials with exceptional precision. So, what is a CO2 laser cutting machine? It uses a focused laser beam generated by carbon dioxide gas to achieve clean and accurate results. This type of laser cutting machine stands out for its ability to handle a wide range of non-metallic materials, such as wood, acrylic, and plastics, making it highly versatile. Industries rely on these machines for their efficiency and adaptability, whether in manufacturing, creative design, or commercial applications. Its precision and speed make it an essential tool for modern production processes.

What is a CO2 Laser Cutting Machine and How Does It Work?

A CO2 laser cutting machine operates with remarkable precision and efficiency, making it a vital tool in various industries. To understand how it works, you need to explore its key components and the technology behind its operation.

Key Components of a CO2 Laser Cutting Machine

A CO2 laser cutting machine relies on several essential components to deliver accurate and clean results:

Laser tube for generating the laser beam

The laser tube serves as the core of the machine. It generates a high-powered laser beam using a carbon dioxide gas mixture. This beam is the primary energy source that interacts with the material to cut or engrave it.

Mirrors and lenses for directing and focusing the beam

Mirrors and lenses guide the laser beam from the tube to the cutting area. These components ensure the beam remains focused and concentrated, allowing it to achieve precise cuts. Proper alignment of these parts is crucial for optimal performance.

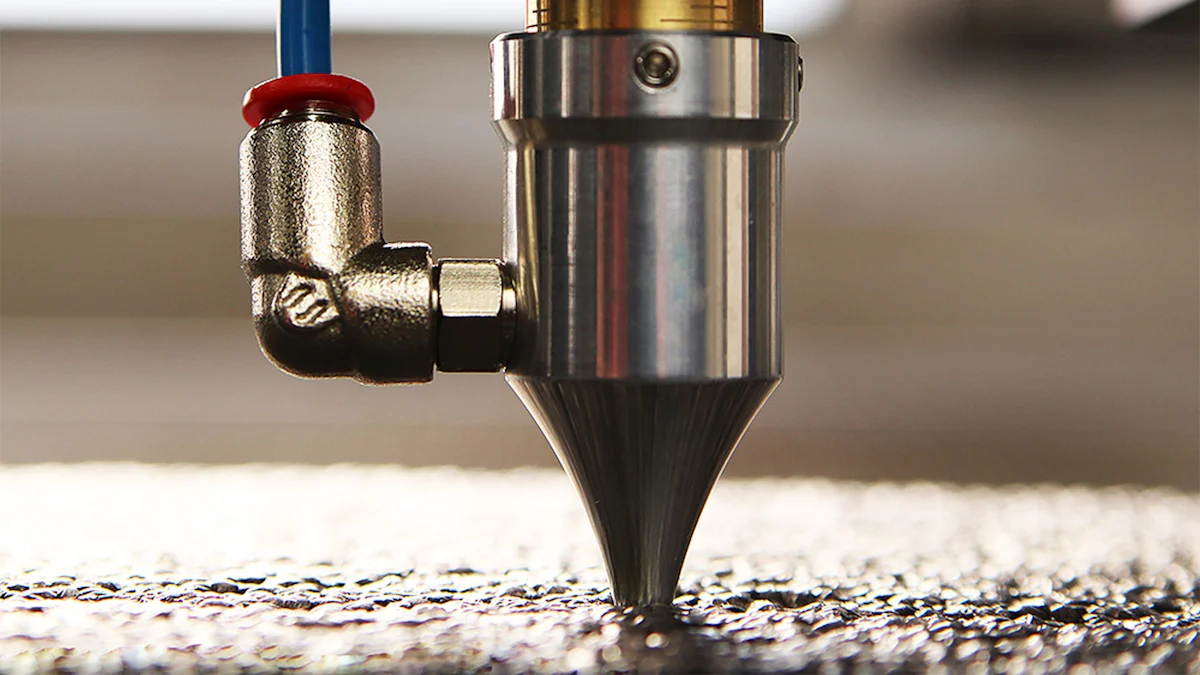

Cutting bed for material placement

The cutting bed provides a stable surface for placing materials. It holds the material securely during the cutting process, ensuring accuracy and preventing movement. The bed design often includes features like honeycomb patterns to minimize reflections and improve airflow.

The Technology Behind CO2 Laser Cutting

The operation of CO2 laser cutting combines advanced technology with precision engineering. Here’s how it works:

Interaction of the CO2 laser beam with materials

The laser beam interacts with the material by heating, melting, or vaporizing it at the point of contact. The high-energy density of the beam ensures clean cuts with smooth edges. As the beam moves across the material, it removes layers to create intricate designs or patterns.

Role of computer-aided design (CAD) in guiding the machine

Computer-aided design (CAD) software plays a critical role in controlling the machine. You can create detailed designs and upload them to the machine’s control system. The system then guides the laser beam along the programmed path, ensuring precise execution of your design.

By combining these components and technologies, a CO2 laser cutting machine delivers exceptional results. Whether you’re working on industrial projects or creative designs, this machine offers the precision and versatility needed to bring your ideas to life.

Applications of CO2 Laser Cutting Machines

CO2 laser cutters have revolutionized various fields with their precision and adaptability. These machines cater to a wide range of needs, from industrial production to creative artistry. Let’s explore the diverse applications of CO2 laser cutters and how they can enhance your projects.

Industrial Applications

Manufacturing and prototyping

In manufacturing, CO2 laser cutters excel at creating precise components. You can use them to cut intricate shapes or patterns in materials like wood, acrylic, and plastics. Their ability to produce consistent results makes them ideal for prototyping. Whether you’re developing a new product or refining an existing design, these machines ensure accuracy and efficiency.

Automotive and aerospace industries

The automotive and aerospace sectors rely on CO2 laser cutters for their precision and speed. You can use these machines to create lightweight components, engrave identification marks, or cut non-metallic materials used in interiors. Their ability to handle complex designs ensures they meet the high standards required in these industries.

Creative and Artistic Applications

Custom engraving for gifts and décor

CO2 laser cutters open up endless possibilities for personalized creations. You can engrave names, messages, or intricate designs on materials like wood, leather, or acrylic. This makes them perfect for crafting unique gifts or decorative items. Whether it’s a custom plaque or a beautifully engraved keepsake, these machines bring your ideas to life.

Jewelry design and intricate patterns

For jewelry makers, CO2 laser cutters provide unmatched precision. You can create detailed patterns and designs that would be difficult to achieve by hand. From delicate pendants to intricate earrings, these machines allow you to experiment with various materials and styles, elevating your craftsmanship.

Commercial and Retail Applications

Signage and advertising

In the commercial world, CO2 laser cutters play a vital role in creating eye-catching signage. You can cut or engrave logos, letters, and designs on materials like acrylic or wood. Their precision ensures clean edges and professional finishes, making your signs stand out in any setting.

Packaging and product design

CO2 laser cutters also shine in packaging and product design. You can use them to create custom packaging solutions that reflect your brand’s identity. From intricate cutouts to engraved logos, these machines help you add a personal touch to your products, enhancing their appeal to customers.

CO2 laser applications span across industries, offering solutions for both functional and creative needs. Whether you’re working in manufacturing, design, or retail, these machines provide the tools to achieve exceptional results.

Best Materials for CO2 Laser Cutters

CO2 laser cutting machines are incredibly versatile, capable of working with a wide range of materials. Understanding the best materials for CO2 laser cutters ensures you achieve optimal results in your projects. Below, we’ll explore the most suitable materials, their unique properties, and those you should avoid.

Organic Materials

Wood, plywood, and MDF

Wood is one of the most popular materials for CO2 laser cutting. Its high carbon content allows the laser to cut cleanly and efficiently. You can use it for creating intricate designs, furniture components, or decorative items. Plywood and MDF (medium-density fiberboard) are also excellent choices. These engineered woods offer consistent density, making them ideal for precise cuts and engravings. Wood laser cutting is perfect for crafting detailed patterns or custom wooden products.

Leather and textiles

Cutting and engraving leather with a CO2 laser cutter opens up endless possibilities for creating custom designs. You can use it to craft wallets, belts, or decorative leather pieces. Textiles, including fabrics like cotton, felt, and polyester, are also well-suited for laser cutting. Cutting textiles with a CO2 laser ensures clean edges without fraying, making it a preferred method for fashion design, upholstery, and custom fabric projects.

Synthetic Materials

Acrylic and plastics

Acrylic is one of the best materials for CO2 laser cutters due to its smooth cutting properties and polished finish. Cutting acrylic allows you to create signage, display cases, and decorative items with professional results. Plastics, including polycarbonate and PETG, are also compatible with CO2 lasers. Cutting plastics requires precise settings to avoid melting or warping, but the results are worth the effort. You can even produce custom plastic parts for industrial or creative applications.

Rubber and foam

Rubber and foam are excellent choices for CO2 laser cutting. You can use rubber to create custom stamps, gaskets, or seals. Foam materials, such as EVA foam, are ideal for packaging, crafts, or protective inserts. The laser’s precision ensures clean cuts, even in intricate designs, making these materials highly versatile.

Materials Not Suitable for CO2 Laser Cutting

Metals and reflective surfaces

Metals are among the materials to avoid for CO2 laser cutting. The longer wavelength of CO2 lasers makes them ineffective for cutting metals like aluminum or steel. Reflective surfaces, such as polished metals, can also damage the laser machine by reflecting the beam back into its components.

Hazardous materials like PVC

PVC (polyvinyl chloride) is another material you should avoid. When cut with a CO2 laser, PVC releases toxic fumes that can harm both you and the machine. Always prioritize safety by steering clear of hazardous materials and choosing safer alternatives like cardboard or acrylic.

By selecting the right materials, you can unlock the full potential of your CO2 laser cutter. Whether you’re working with wood, textiles, or plastics, understanding their properties ensures clean, precise, and professional results.

Limitations and Safety Considerations for CO2 Laser Cutting Machines

Understanding the limitations and safety considerations of CO2 laser cutting machines is essential for maximizing their potential while ensuring safe operation. While these machines offer remarkable precision and versatility, they do have certain constraints and risks that you should be aware of.

Limitations of CO2 Laser Cutters

Challenges with cutting metals and reflective materials

CO2 laser cutting machines excel at working with non-metallic materials, but they struggle with metals. The longer wavelength of the CO2 laser beam makes it less effective for cutting metals like aluminum or steel. Reflective materials, such as polished metals, pose an additional challenge. These surfaces can reflect the laser beam back into the machine, potentially causing damage to its components. If your project involves metals, you may need to explore alternative laser types, such as fiber lasers, which are better suited for these tasks.

Size constraints for larger projects

The size of the cutting bed limits the scale of projects you can undertake. Most CO2 laser cutters are designed for small to medium-sized materials, making them unsuitable for large-scale applications. For instance, creating oversized furniture pieces or large industrial components may require specialized equipment. Understanding these size constraints helps you plan your projects effectively and avoid unnecessary complications.

Safety Tips for Using CO2 Laser Cutting Machines

Ensuring proper ventilation to avoid harmful fumes

When using a CO2 laser cutter, you must prioritize ventilation. Cutting certain materials, such as plastics or synthetic compounds, can release harmful fumes. These fumes not only pose health risks but can also damage the machine over time. Installing an efficient exhaust system or operating the machine in a well-ventilated area ensures a safer working environment. Always check the material's properties before cutting to avoid exposure to toxic emissions.

Wearing protective gear and following safety protocols

Safety gear is essential when operating a CO2 laser cutter. Protective eyewear shields your eyes from the intense laser beam, reducing the risk of injury. Gloves and masks provide additional protection, especially when handling materials that produce dust or fumes. Adhering to safety protocols, such as keeping flammable objects away from the machine and never leaving it unattended during operation, minimizes the risk of accidents. Regular maintenance of the machine also ensures it operates safely and efficiently.

By recognizing the limitations and adhering to safety measures, you can make the most of your CO2 laser cutting machine. These precautions not only protect you but also extend the lifespan of your equipment, allowing you to achieve consistent and high-quality results.

Benefits of Using CO2 Laser Cutting Machines

CO2 laser cutting machines provide numerous advantages that make them indispensable tools for various industries. Their ability to deliver precise results, handle diverse materials, and reduce costs ensures they remain a top choice for professionals and hobbyists alike.

Precision and Accuracy

Ability to create intricate designs

CO2 laser cutters excel in precision cutting, allowing you to craft intricate designs with ease. Whether you are working on detailed patterns in wood or engraving delicate shapes on acrylic, these machines ensure every detail is sharp and accurate. The focused laser beam interacts with the material at a microscopic level, enabling you to achieve results that would be nearly impossible with traditional tools.

Consistency in repeated cuts

When you need to produce multiple identical pieces, CO2 laser cutters guarantee consistency. The machine follows the programmed design with exactness, ensuring each cut or engraving matches the original. This reliability makes it ideal for projects requiring uniformity, such as creating components for manufacturing or producing custom designs in bulk.

Versatility Across Applications

Suitable for a wide range of materials

One of the standout features of CO2 laser cutters is their ability to work with a broad range of materials. From organic options like wood and leather to synthetic choices like acrylic and plastics, these machines adapt to your needs. You can switch between materials without compromising on quality, making them perfect for diverse projects. For instance, you can cut intricate patterns in wood one moment and engrave logos on acrylic the next.

Adaptable for both industrial and creative uses

CO2 laser cutters bridge the gap between industrial efficiency and creative freedom. In industrial settings, they streamline production by delivering precise cuts for components. For creative projects, they offer a high level of customization, enabling you to experiment with unique designs and materials. Whether you are crafting decorative items or developing prototypes, these machines provide the flexibility to bring your ideas to life.

Cost-Effectiveness

Reduced material waste

CO2 laser cutters minimize material waste by focusing the laser beam precisely where it is needed. This precision ensures clean cuts without unnecessary damage to the surrounding material. For example, when cutting wood or acrylic, the machine optimizes the use of the material, reducing scraps and saving costs. This efficiency not only benefits your budget but also supports sustainable practices.

Lower operational costs compared to traditional methods

Operating a CO2 laser cutter is more cost-effective than many traditional cutting methods. The machine requires minimal maintenance and uses energy efficiently. Additionally, its ability to handle multiple materials eliminates the need for separate tools, further reducing expenses. Over time, these savings make CO2 laser cutters a smart investment for both small-scale projects and large-scale operations.

By combining precision, versatility, and cost-effectiveness, CO2 laser cutting machines empower you to achieve exceptional results. Whether you are working with wood, acrylic, or other materials, these machines provide the tools you need to succeed in your projects.

CO2 laser cutting machines offer unmatched versatility and efficiency, making them indispensable for various industries and creative projects. You can use these machines to cut, engrave, and mark a wide range of materials with precision, from wood and acrylic to textiles and plastics. Their adaptability opens doors to endless applications, whether in manufacturing, design, or retail. By investing in this technology, you unlock new possibilities for innovation and customization. Explore how a CO2 laser cutter can transform your ideas into reality and elevate your projects to the next level.

FAQ

What projects can a CO2 laser cutting machine create?

A CO2 laser cutting machine can handle a variety of projects with precision and efficiency. You can use it to cut or engrave materials like acrylic, wood, textiles, and rubber. These machines are widely used in industries such as manufacturing, design, and prototyping. By understanding the properties of each material and applying the right cutting techniques, you can achieve optimal results and expand the range of applications for your projects.

Can a CO2 laser cutter work with metals?

CO2 laser cutters are not ideal for cutting metals. The longer wavelength of the CO2 laser beam makes it less effective for materials like aluminum or steel. Reflective surfaces, such as polished metals, can also pose risks by reflecting the laser beam back into the machine. If you need to cut metals, consider using a fiber laser cutter, which is better suited for such tasks.

What materials are best suited for CO2 laser cutting?

CO2 laser cutters work best with non-metallic materials. Popular choices include wood, acrylic, leather, textiles, and certain plastics. These materials respond well to the laser beam, allowing for clean cuts and detailed engravings. Avoid using hazardous materials like PVC, as they release toxic fumes when cut.

How do I ensure safety while using a CO2 laser cutter?

To operate a CO2 laser cutter safely, follow these steps:

- Ensure proper ventilation to remove harmful fumes.

- Wear protective eyewear to shield your eyes from the laser beam.

- Keep flammable objects away from the machine.

- Never leave the machine unattended during operation.

Regular maintenance of the machine also helps prevent accidents and ensures smooth performance.

Can I use a CO2 laser cutter for large-scale projects?

Most CO2 laser cutters are designed for small to medium-sized projects. The size of the cutting bed limits the scale of materials you can work with. For larger projects, you may need specialized equipment or machines with extended cutting beds.

What software is compatible with CO2 laser cutters?

CO2 laser cutters typically use computer-aided design (CAD) software. Programs like AutoCAD, CorelDRAW, and Adobe Illustrator are commonly used to create designs. Once you upload your design to the machine, it follows the programmed path to execute precise cuts or engravings.

How do I maintain a CO2 laser cutting machine?

Regular maintenance ensures your CO2 laser cutter operates efficiently. Clean the mirrors and lenses to maintain beam accuracy. Check the alignment of the laser components frequently. Replace the laser tube when its power output decreases. Keeping the cutting bed clean also prevents material buildup and improves performance.

What are the advantages of using a CO2 laser cutter?

CO2 laser cutters offer several benefits:

- Precision: They create intricate designs with sharp details.

- Versatility: They work with a wide range of materials.

- Cost-effectiveness: They reduce material waste and operational costs.

These features make them valuable tools for both industrial and creative applications.

Can I engrave custom designs with a CO2 laser cutter?

Yes, CO2 laser cutters excel at engraving custom designs. You can personalize items like gifts, décor, and jewelry by engraving names, messages, or intricate patterns. The machine’s precision allows you to bring your creative ideas to life with professional-quality results.

What should I avoid when using a CO2 laser cutter?

Avoid cutting materials that release toxic fumes, such as PVC. Do not attempt to cut metals unless the machine is specifically designed for it. Always ensure the machine is properly ventilated and never operate it without wearing protective gear. Following these precautions keeps you safe and protects the machine from damage.

See Also

Understanding Laser Cutting Machines And Their Various Types

The Functionality Of CNC Laser Cutting Machines Explained

Exploring Different Types Of Laser Cutting Technologies