What Is 2D Fiber Laser Cutting Machine and Its Benefits

What is a 2D fiber laser cutting machine? It is a high-precision tool engineered to cut flat materials with remarkable accuracy. Utilizing advanced fiber laser technology, it produces a focused beam of light capable of effortlessly slicing through metals, plastics, and various other materials. This cutting-edge machine is essential in modern industries, offering faster processing speeds and significantly reducing material waste. Compared to traditional cutting methods, it delivers cleaner cuts while minimizing the risk of material deformation, making it a crucial asset in manufacturing, automotive, and aerospace sectors.

What Is a 2D Fiber Laser Cutting Machine?

Definition and Overview

A 2D fiber laser cutting machine is a state-of-the-art tool designed to cut flat materials with unmatched precision. It uses advanced fiber laser technology to generate a highly focused laser beam, enabling you to achieve clean and accurate cuts on various materials. Unlike traditional cutting methods, this machine operates without physical contact, reducing wear and tear while maintaining the integrity of the material. Its compact design and energy-efficient operation make it a preferred choice for industries like automotive, aerospace, and electronics.

The machine's ability to handle intricate designs and complex patterns sets it apart from other cutting technologies. With its automated features, you can process materials faster and more efficiently, making it an essential tool for high-volume manufacturing. Whether you're working with metals, plastics, or composites, this machine ensures consistent results, helping you meet the demands of modern industrial applications.

Key Features of 2D Laser Technology

High-precision cutting capabilities

One of the standout features of 2D laser technology is its exceptional precision. The fiber laser's short wavelength, typically around 1.064 micrometers, allows the beam to focus into an extremely small spot size. This enables you to create intricate designs and detailed cuts with minimal material waste. For example, manufacturers in the electronics industry rely on this precision to produce components like circuit boards and enclosures.

The non-contact nature of the cutting process further enhances accuracy. The laser beam melts or vaporizes the material without applying physical force, ensuring that the final product remains free from deformation. This level of precision is particularly valuable when working on safety-critical parts in industries such as aerospace.

Energy-efficient and compact design

2D fiber laser cutting machines are known for their energy efficiency. They consume significantly less power compared to older technologies like CO2 lasers. This not only reduces operational costs but also aligns with the growing emphasis on eco-friendly manufacturing practices. The compact design of these machines makes them easy to integrate into your production line, even in facilities with limited space.

Additionally, the automated features of these machines, such as dynamic motorized lens functions, further enhance efficiency. For instance, the Prime laser cutting machine can automatically adjust the focus based on the material's thickness, reducing setup time and improving productivity. This adaptability ensures that you can handle a wide range of materials and applications with ease.

Use of advanced fiber laser technology

Fiber laser technology is at the core of 2D laser cutting machines. This technology offers several advantages over traditional methods. The laser beam's high intensity enables faster cutting speeds, allowing you to complete projects in less time. For example, a fiber laser cutter can process thin materials at speeds of up to 20 meters per minute, making it ideal for high-volume production.

Modern 2D laser systems also come equipped with intelligent hardware and software. Features like automatic nozzle changers, height sensors, and real-time monitoring ensure consistent performance and reliability. These advancements make it easier for you to achieve high-quality results while minimizing downtime and maintenance requirements.

How Does a 2D Fiber Laser Cutting Machine Work?

Understanding how a 2D fiber laser cutting machine operates can help you appreciate its efficiency and precision. This advanced technology relies on a combination of core components and a well-orchestrated cutting process to deliver exceptional results.

Core Components of 2D Laser Cutting Machines

Fiber laser source

The fiber laser source serves as the heart of the machine. It generates a concentrated beam of light with high intensity, which is essential for cutting through various materials. Unlike older CO2 lasers, fiber lasers use solid-state technology, making them more energy-efficient and reliable. This design ensures consistent performance, even during extended periods of operation. The compact nature of the fiber laser source also contributes to the machine's overall space-saving design.

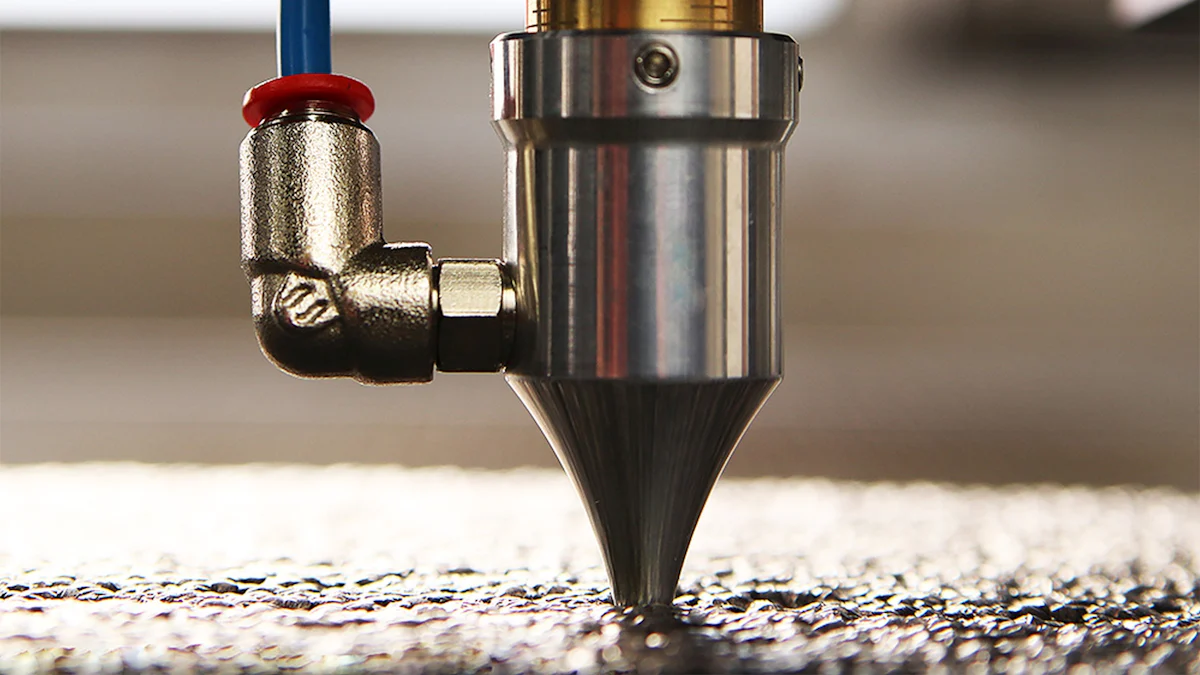

Cutting head and optics

The cutting head and optics play a crucial role in directing the laser beam onto the material. The cutting head houses lenses and mirrors that focus the beam into a precise spot. This focused beam allows you to achieve clean cuts with minimal heat-affected zones. Advanced cutting heads often include height sensors, which automatically adjust the distance between the head and the material. This feature ensures consistent cutting quality, even when working with uneven surfaces.

CNC control system

The CNC (Computer Numerical Control) system acts as the brain of the machine. It processes your design files and translates them into precise movements for the cutting head. This system ensures that every cut aligns perfectly with your specifications. Modern CNC systems come equipped with user-friendly interfaces, making it easier for you to program and monitor the machine. Real-time feedback from the CNC system helps maintain accuracy and reduces the likelihood of errors.

The Cutting Process in 2D Laser Cutting

Laser beam generation and focusing

The cutting process begins with the generation of the laser beam. The fiber laser source produces a high-intensity beam, which is then channeled through optical fibers to the cutting head. Inside the cutting head, lenses focus the beam into a small, precise spot. This focused beam delivers the energy needed to melt or vaporize the material, enabling you to create intricate designs with ease.

Material interaction and cutting mechanism

When the laser beam interacts with the material, it generates intense heat that melts or vaporizes the targeted area. The machine's non-contact nature ensures that the material remains free from physical stress or deformation. This precise interaction allows you to achieve smooth edges and detailed cuts. The cutting mechanism works seamlessly across various materials, including metals, plastics, and composites, making it highly versatile for industrial applications.

Role of assist gases in cutting

Assist gases, such as nitrogen, oxygen, or compressed air, play a vital role in the cutting process. These gases are directed onto the cutting area to remove molten material and prevent oxidation. For instance, nitrogen is often used for stainless steel to produce clean, oxide-free edges. Oxygen, on the other hand, enhances cutting speeds for thicker materials by promoting combustion. The choice of assist gas depends on the material and the desired finish, ensuring optimal results for your projects.

Advantages of Using 2D Fiber Laser Cutting Machines in Industrial Applications

Precision and Accuracy

Ability to achieve intricate designs

2D laser cutting stands out for its ability to deliver unmatched precision, making it ideal for creating intricate designs. The focused laser beam allows you to cut even the most complex patterns with ease. This capability is especially valuable in industries like electronics, where detailed components such as circuit boards require high precision. Unlike traditional methods, which often struggle with fine details, 2D laser cutting ensures every cut aligns perfectly with your design specifications. You can achieve results that maintain both structural integrity and aesthetic appeal.

The non-contact nature of laser cutting technology further enhances precision. The laser beam interacts directly with the material without applying physical force, eliminating the risk of deformation. This ensures that even delicate materials retain their original quality after cutting. Whether you're working on decorative designs or functional components, 2D laser cutting consistently delivers superior results.

Minimal material waste

Material waste can significantly impact production costs. With 2D laser cutting, you can minimize waste thanks to its precise cutting capabilities. The narrow kerf width ensures that only the necessary material is removed during the cutting process. This efficiency not only reduces scrap but also optimizes material usage, helping you save on costs. For example, manufacturers in the aerospace sector rely on this precision to maximize the use of expensive materials like titanium and aluminum.

Additionally, the clean cuts produced by 2D laser cutting eliminate the need for secondary finishing processes. This reduces the amount of material lost to grinding or polishing, further enhancing overall efficiency. By minimizing waste, you can contribute to more sustainable manufacturing practices while maintaining high-quality output.

Speed and Efficiency

Faster cutting times compared to traditional methods

Speed is a critical factor in modern industrial applications, and 2D laser cutting excels in this area. The advanced fiber laser technology enables you to cut materials at significantly faster rates compared to traditional methods like mechanical sawing or plasma cutting. For instance, thin sheets of metal can be processed at speeds of up to 20 meters per minute. This rapid processing allows you to meet tight production deadlines without compromising on quality.

The automation features of 2D laser cutting machines further enhance speed. Functions like automatic nozzle changers and real-time monitoring reduce setup time and ensure uninterrupted operation. These features streamline your workflow, enabling you to handle high-volume production with ease.

Reduced production downtime

Downtime can disrupt your operations and lead to financial losses. 2D laser cutting machines are designed to minimize downtime through their reliable performance and low maintenance requirements. The solid-state fiber laser source ensures consistent operation, even during extended use. This reliability allows you to maintain a steady production schedule without unexpected interruptions.

Moreover, the user-friendly CNC control system simplifies machine operation. You can quickly program new designs and make adjustments without lengthy delays. By reducing downtime, 2D laser cutting helps you improve overall productivity and maintain a competitive edge in your industry.

Cost-effectiveness

Lower operational costs due to energy efficiency

Energy efficiency is a key advantage of 2D laser cutting machines. These machines consume significantly less power compared to older technologies like CO2 lasers. This reduced energy consumption translates into lower operational costs, allowing you to allocate resources more effectively. For example, manufacturers who switch to fiber laser cutting often report substantial savings on electricity bills.

The compact design of 2D laser cutting machines also contributes to cost-effectiveness. Their smaller footprint reduces the need for extensive facility modifications, saving you money on installation. Additionally, the energy-efficient operation aligns with eco-friendly manufacturing practices, helping you meet sustainability goals while keeping costs under control.

Reduced maintenance requirements

Maintenance can be a major expense for industrial equipment. 2D laser cutting machines require minimal upkeep due to their robust design and advanced technology. The solid-state fiber laser source has fewer moving parts, reducing the likelihood of mechanical failures. This durability ensures that your machine remains operational for longer periods, lowering maintenance costs over time.

Modern 2D laser systems also include features like real-time monitoring and automatic calibration. These capabilities help you identify and address potential issues before they escalate, further reducing maintenance needs. By investing in a 2D laser cutting machine, you can enjoy long-term savings while maintaining high-quality production standards.

Material Versatility

Compatibility with metals, plastics, and composites

2D laser cutting machines excel in their ability to handle a wide range of materials, making them indispensable in industrial settings. You can use these machines to cut metals like steel, aluminum, and titanium with remarkable precision. Their advanced technology also allows you to work with non-metallic materials such as plastics and composites, expanding their applications beyond traditional metal fabrication. For instance, in the electronics industry, you can rely on 2D laser cutting to create intricate designs on circuit boards or plastic enclosures.

This versatility stems from the machine's ability to adjust its laser intensity and focus based on the material type. Whether you're working with delicate plastics or robust metals, the machine ensures clean cuts without compromising the material's integrity. Unlike traditional methods, which often require separate tools for different materials, 2D laser cutting offers a unified solution. This adaptability not only saves time but also reduces the need for additional equipment, streamlining your fabrication process.

Ability to handle thin and thick materials

2D laser cutting machines are equally adept at processing both thin and thick materials. You can achieve precise cuts on thin sheets of metal or plastic without causing warping or deformation. The focused laser beam ensures minimal heat-affected zones, preserving the quality of the material. For thicker materials, the machine's high-powered laser can penetrate with ease, delivering clean and accurate results.

This capability is particularly valuable in metal fabrication, where material thickness can vary significantly. For example, in construction projects, you might need to cut thin steel panels for decorative purposes or thick structural components for support. With 2D laser cutting, you can handle both tasks efficiently, ensuring consistency across all your projects. This flexibility makes the technology a preferred choice for industries requiring diverse material handling.

Environmental Benefits

Reduced energy consumption

2D laser cutting machines stand out for their energy efficiency, offering a more sustainable alternative to traditional cutting methods. These machines consume significantly less power compared to older technologies like CO2 lasers or plasma cutters. By using advanced fiber laser technology, you can reduce your energy usage while maintaining high cutting speeds and precision. This efficiency not only lowers operational costs but also aligns with eco-friendly manufacturing practices.

For example, in metal fabrication, where energy-intensive processes are common, switching to 2D laser cutting can help you achieve substantial energy savings. The reduced power consumption contributes to a smaller carbon footprint, making your operations more environmentally responsible. This advantage is particularly important as industries increasingly prioritize sustainability in their production processes.

Minimal emissions and waste

2D laser cutting minimizes environmental impact by producing fewer emissions and less waste compared to traditional methods. The non-contact cutting process generates minimal byproducts, ensuring cleaner operations. You can also reduce material waste due to the machine's high precision, which allows for optimal material utilization. For instance, in metal fabrication, the narrow kerf width ensures that only the necessary material is removed, leaving little to no scrap.

Additionally, the use of assist gases like nitrogen or oxygen further enhances the cutting process without releasing harmful pollutants. This clean-cutting approach makes 2D laser cutting an environmentally friendly choice for industries aiming to reduce their ecological footprint. By adopting this technology, you not only improve your production efficiency but also contribute to a more sustainable future.

Common Industrial Applications of 2D Fiber Laser Cutting Machines

Automotive Industry

Cutting components for vehicles

In the automotive industry, precision and efficiency are critical. 2D laser cutting machines excel in producing high-quality components for vehicles. You can use these machines to cut intricate shapes and designs required for car frames, exhaust systems, and engine parts. The ability to handle both thin and thick materials ensures that every component meets the exact specifications needed for assembly. This precision reduces errors, saving time and resources during production.

The speed of 2D laser cutting also enhances productivity. For example, you can process large volumes of sheet metal quickly, ensuring that manufacturing timelines stay on track. This capability makes the technology indispensable for high-volume automotive production lines. By adopting 2D laser cutting, you can achieve consistent results while minimizing material waste, which is essential for cost-effective manufacturing.

Precision in manufacturing parts

Automotive parts demand a high level of accuracy to ensure safety and functionality. 2D laser cutting machines deliver this precision by creating clean edges and detailed cuts. You can rely on these machines to produce parts like brackets, gears, and panels with minimal deviation from design specifications. This accuracy is especially important for components that must fit seamlessly into larger assemblies.

The non-contact nature of the cutting process prevents material deformation, preserving the integrity of each part. Additionally, the use of assist gases like nitrogen ensures oxide-free edges, which is crucial for parts that require welding or further processing. With 2D laser cutting, you can maintain the quality and reliability of your automotive components, meeting the stringent standards of the industry.

Aerospace Industry

Cutting lightweight materials like aluminum

The aerospace industry often relies on lightweight materials such as aluminum to enhance fuel efficiency and performance. 2D laser cutting machines are ideal for processing these materials with precision. You can use them to cut aluminum sheets into complex shapes required for aircraft structures, such as fuselage panels and wing components. The focused laser beam ensures smooth edges, reducing the need for secondary finishing processes.

The energy-efficient operation of 2D laser cutting machines aligns with the aerospace sector's emphasis on sustainability. By consuming less power and minimizing material waste, these machines support eco-friendly manufacturing practices. This combination of precision and efficiency makes 2D laser cutting a valuable tool for aerospace applications.

Ensuring high accuracy for safety-critical parts

Safety is paramount in aerospace manufacturing, where even minor inaccuracies can have serious consequences. 2D laser cutting machines provide the high level of accuracy needed for safety-critical parts. You can use them to produce components like turbine blades, brackets, and fasteners with exact dimensions. This precision ensures that each part performs reliably under extreme conditions.

The advanced CNC control system of 2D laser cutting machines allows you to replicate designs with consistent quality. Real-time monitoring features help you maintain accuracy throughout the production process. By using 2D laser cutting, you can meet the rigorous safety and performance standards required in the aerospace industry.

Electronics and Electrical Industry

Cutting intricate designs for circuit boards

In the electronics industry, intricate designs are a common requirement. 2D laser cutting machines excel in creating detailed patterns for circuit boards and other electronic components. You can achieve precise cuts that accommodate the complex layouts of modern circuits. This precision ensures that each board functions as intended, supporting the performance of devices like smartphones, computers, and medical equipment.

The non-contact cutting process prevents damage to delicate materials, such as thin copper layers used in circuit boards. Additionally, the narrow kerf width minimizes material waste, making the process both efficient and cost-effective. By using 2D laser cutting, you can produce high-quality electronic components that meet the demands of today's technology-driven world.

Manufacturing enclosures and components

Beyond circuit boards, 2D laser cutting machines are also valuable for creating enclosures and other electrical components. You can use these machines to cut metals and plastics into precise shapes for device housings, switch panels, and connectors. The ability to handle a variety of materials ensures that you can meet diverse manufacturing needs.

The clean cuts produced by 2D laser cutting eliminate the need for additional finishing, saving time and resources. This efficiency is particularly beneficial for high-volume production in the electronics and electrical industry. By adopting 2D laser cutting, you can streamline your manufacturing process while maintaining the quality and functionality of your products.

Metal Fabrication and Construction

Creating Custom Metal Parts

In metal fabrication, precision and customization are essential. A 2D fiber laser cutting machine empowers you to create custom metal parts with unmatched accuracy. Whether you need intricate designs or simple shapes, the focused laser beam ensures clean cuts that align perfectly with your specifications. This precision eliminates the need for additional finishing processes, saving you time and resources.

You can also handle a wide variety of metals, including steel, aluminum, and titanium. The machine’s ability to adjust its laser intensity allows you to work with different material thicknesses effortlessly. For example, you can craft decorative metal panels for architectural projects or produce functional components for machinery. This versatility makes 2D laser cutting an indispensable tool for fabricators who value efficiency and quality.

Moreover, the process minimizes material waste. The narrow kerf width ensures that only the necessary material is removed, optimizing usage and reducing scrap. According to studies, fiber laser cutting aligns with sustainable practices by lowering energy consumption and enhancing recyclability. By adopting this technology, you not only improve production efficiency but also contribute to eco-friendly manufacturing.

Cutting Structural Components for Buildings

Construction projects demand durable and precisely cut structural components. A 2D fiber laser cutting machine enables you to meet these requirements with ease. You can produce beams, columns, and brackets that fit seamlessly into building frameworks. The machine’s high-powered laser ensures clean edges, which enhances the strength and reliability of the components.

Speed is another advantage. You can process large sheets of metal quickly, ensuring that construction timelines stay on track. For instance, cutting steel panels for roofing or cladding becomes a streamlined task. The automation features of the machine further reduce setup time, allowing you to focus on other critical aspects of your project.

Environmental benefits also play a significant role in construction applications. Fiber laser cutting consumes less energy compared to traditional methods, aligning with sustainable building practices. Additionally, the process generates minimal emissions and waste, making it a greener choice for fabricating structural components. By using this technology, you can achieve both operational efficiency and environmental responsibility in your construction projects.

Key Considerations for Using 2D Fiber Laser Cutting Machines

When investing in a 2D fiber laser cutting machine, understanding its operational needs and limitations ensures you maximize its potential. Below are key factors to consider for maintaining efficiency and achieving cost savings.

Maintenance Requirements

Regular cleaning and calibration

To maintain peak performance, you must clean and calibrate your 2D fiber laser cutting machine regularly. Dust, debris, and residue from materials can accumulate on the optics and cutting head, reducing the machine's precision. Cleaning these components prevents performance degradation and ensures consistent cutting quality. Calibration is equally important. It aligns the laser beam and cutting head, guaranteeing accuracy in every cut. Neglecting these tasks can lead to errors, increased downtime, and higher maintenance costs.

For example, in industries like aerospace, where precision is critical, regular maintenance ensures that safety-critical parts meet stringent quality standards. By adhering to a maintenance schedule, you can extend the machine's lifespan and avoid costly repairs.

Importance of proper cooling systems

A reliable cooling system is essential for the efficient operation of a 2D fiber laser cutting machine. The laser source generates significant heat during operation, which can damage internal components if not managed properly. Cooling systems, such as water chillers, regulate the machine's temperature and prevent overheating. Without adequate cooling, you risk frequent breakdowns and reduced efficiency.

In high-demand sectors like automotive manufacturing, where machines often run continuously, proper cooling systems ensure uninterrupted production. Investing in a robust cooling solution minimizes downtime and contributes to long-term cost savings by reducing wear and tear on the machine.

Material Compatibility

Types of materials that can be cut

One of the strengths of 2D fiber laser cutting machines is their versatility. You can cut a wide range of materials, including metals like steel, aluminum, and titanium, as well as non-metals such as plastics and composites. This adaptability makes the machine suitable for diverse industries, from electronics to construction. For instance, in cleanroom facilities, these machines produce high-precision components for specialized equipment, ensuring quality and reliability.

The ability to handle various materials allows you to take on different projects without needing additional tools. This versatility enhances your operational efficiency and reduces the need for multiple cutting systems, leading to significant cost savings.

Limitations with certain materials

Despite their versatility, 2D fiber laser cutting machines have limitations. Reflective materials like copper and brass can pose challenges, as they reflect the laser beam, reducing cutting efficiency. Additionally, some non-metallic materials, such as certain types of glass or ceramics, may not be compatible with the machine. Understanding these limitations helps you avoid material wastage and ensures optimal performance.

If your projects involve materials that are difficult to cut with a fiber laser, consider alternative methods or consult with the machine manufacturer for guidance. Being aware of these constraints allows you to plan effectively and avoid unnecessary costs.

Cost Considerations

Initial investment vs. long-term savings

The upfront cost of a 2D fiber laser cutting machine can be significant. However, this investment often translates into substantial long-term savings. These machines consume less energy compared to older technologies, reducing your operational costs over time. Additionally, their precision minimizes material waste, further contributing to cost savings.

For example, manufacturers in the automotive industry benefit from the machine's ability to produce high-quality components quickly and efficiently. While the initial cost may seem high, the machine's durability and low maintenance requirements make it a cost-effective choice in the long run.

Factors affecting operational costs

Several factors influence the operational costs of a 2D fiber laser cutting machine. Energy consumption is a primary consideration. Fiber lasers are energy-efficient, but running the machine continuously can still impact your electricity bills. Material type and thickness also affect costs, as cutting thicker or harder materials requires more power and time.

Maintenance expenses, including cleaning, calibration, and replacement parts, should also be factored in. Properly maintaining the machine reduces these costs and ensures consistent performance. Lastly, the choice of assist gases, such as nitrogen or oxygen, can influence operational expenses. Selecting the right gas for your material and application helps you optimize costs without compromising quality.

By understanding these factors, you can manage your expenses effectively and maximize the machine's efficiency, ensuring a strong return on investment.

2D laser cutting machines offer unmatched precision, speed, and versatility, making them indispensable in modern manufacturing. These machines empower you to create intricate designs, reduce material waste, and streamline production processes. By integrating this technology, businesses have achieved remarkable results, such as cutting production times by half and improving efficiency by 30%. Whether you aim to enhance product quality or lower operational costs, 2D laser cutting provides a reliable solution. Explore this cutting-edge technology to elevate your manufacturing capabilities and stay competitive in today’s fast-paced industrial landscape.

FAQ

What materials can a 2D fiber laser cutting machine handle?

You can use 2D fiber laser cutting machines to cut a wide range of materials. These include metals like steel, aluminum, and titanium, as well as non-metals such as plastics and composites. The machine’s adaptability allows you to work on diverse projects across industries like automotive, aerospace, and electronics. However, reflective materials like copper and brass may require additional considerations due to their tendency to reflect the laser beam.

How does a 2D fiber laser cutting machine minimize material wastage?

The precision of laser cutting systems ensures that only the necessary material is removed during the cutting process. The narrow kerf width reduces material wastage significantly, allowing you to optimize material usage. This feature is especially beneficial in industries like aerospace, where expensive materials like titanium are commonly used. By minimizing wastage, you can save costs and contribute to sustainable manufacturing practices.

What are the maintenance requirements for a 2D fiber laser cutting machine?

Regular maintenance is essential to keep your laser cutting systems running efficiently. You should clean the optics, mirrors, and lenses periodically to prevent debris buildup. Calibration ensures the laser beam aligns correctly with the cutting head, maintaining accuracy. Additionally, proper cooling systems, such as water chillers, help regulate the machine’s temperature and prevent overheating. Routine maintenance not only extends the machine’s lifespan but also enhances productivity by reducing downtime.

How fast can a 2D fiber laser cutting machine operate?

2D fiber laser cutting machines offer impressive cutting speeds, making them ideal for high-volume production. Thin materials can be processed at speeds of up to 20 meters per minute, depending on the material type and thickness. This speed allows you to meet tight deadlines without compromising on quality. Faster cutting speeds also improve overall productivity, enabling you to handle more projects in less time.

Can a 2D fiber laser cutting machine be used for prototyping?

Yes, these machines are excellent for prototyping. Their precision and versatility allow you to create intricate designs and test concepts quickly. You can experiment with different materials and shapes without the need for additional tools or equipment. This capability makes 2D fiber laser cutting systems a valuable asset for industries focused on innovation and product development.

What industries benefit the most from 2D fiber laser cutting machines?

Many industries rely on 2D fiber laser cutting machines for their precision and efficiency. The automotive industry uses them for cutting vehicle components, while the aerospace sector benefits from their ability to handle lightweight materials like aluminum. Electronics manufacturers rely on these machines for intricate designs on circuit boards and enclosures. Additionally, the construction and metal fabrication industries use them to create custom parts and structural components.

How do assist gases improve the cutting process?

Assist gases like nitrogen, oxygen, and compressed air play a crucial role in laser cutting systems. They remove molten material from the cutting area, ensuring clean edges. Nitrogen prevents oxidation, making it ideal for stainless steel. Oxygen enhances cutting speeds for thicker materials by promoting combustion. Choosing the right assist gas improves cutting quality and efficiency, depending on the material and application.

Are 2D fiber laser cutting machines environmentally friendly?

Yes, these machines are more eco-friendly compared to traditional cutting methods. They consume less energy, reducing your carbon footprint. The precision of laser cutting systems minimizes material wastage, contributing to sustainable manufacturing. Additionally, the process generates minimal emissions and byproducts, making it a cleaner option for industrial applications.

What factors affect the operational costs of a 2D fiber laser cutting machine?

Several factors influence the operational costs of these machines. Energy consumption is a primary consideration, as continuous operation can impact electricity bills. Material type and thickness also affect costs, with thicker or harder materials requiring more power. Maintenance expenses, including cleaning and calibration, should be factored in. The choice of assist gases, such as nitrogen or oxygen, can also influence costs. Proper planning helps you manage these expenses effectively.

How does a 2D fiber laser cutting machine improve productivity?

These machines enhance productivity by combining speed, precision, and automation. Faster cutting speeds allow you to complete projects quickly, while the precision minimizes errors and reduces the need for secondary finishing. Automation features, such as real-time monitoring and automatic nozzle changers, streamline operations and reduce downtime. By integrating a 2D fiber laser cutting machine into your workflow, you can handle high-volume production efficiently.

See Also

Understanding the Functionality of Fiber Laser Cutters

Exploring Different Types of Laser Cutting Machines

The Advantages and Disadvantages of Laser Cutting