What Does a Laser Fiber Cutting Machine Do Better

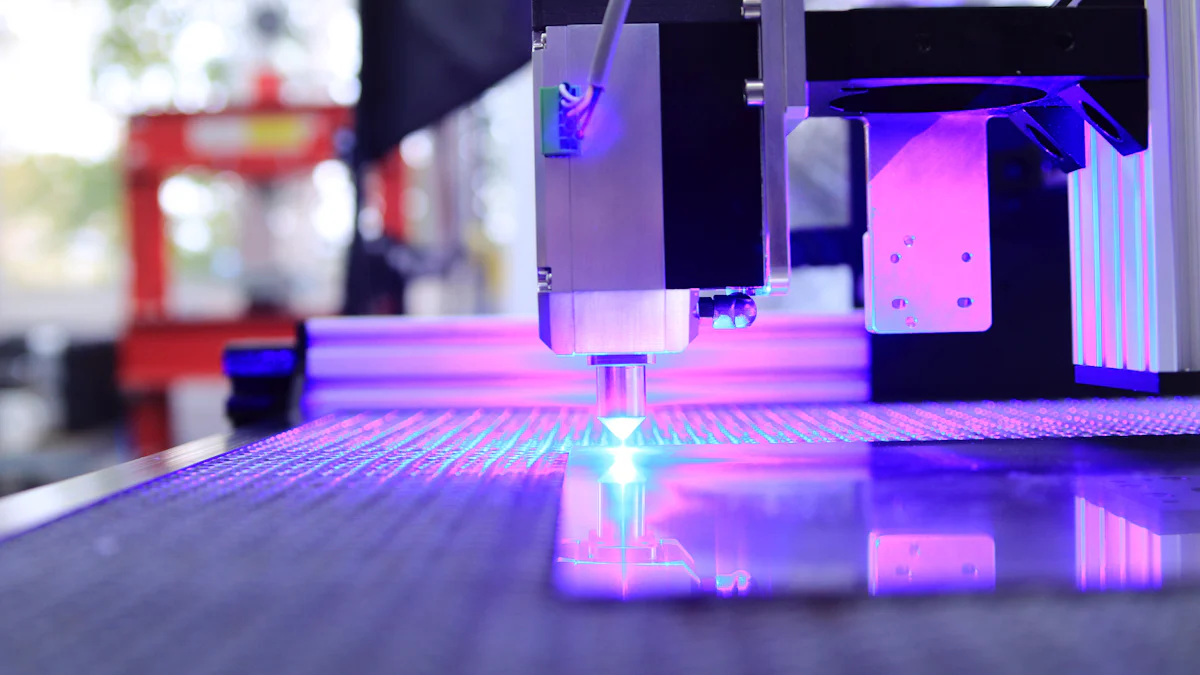

Fiber laser cutting machines redefine what does a laser fiber cutting machine achieve in modern manufacturing. These machines deliver unmatched precision, remarkable speed, and exceptional efficiency. Unlike traditional laser cutting machines, fiber laser cutting machines utilize advanced technology to convert energy into laser light with minimal loss, ensuring superior performance. Their ability to handle diverse materials, especially metals, makes them a game-changer. Businesses benefit from reduced operational costs, enhanced quality, and faster production cycles. With their solid-state design and innovative approach, fiber laser cutting machines set a new standard for laser cutting machines.

How Fiber Laser Cutting Machines Work

Fiber laser cutting machines operate using advanced technology that transforms energy into a highly focused laser beam. This beam delivers exceptional precision and efficiency, making it ideal for modern manufacturing needs. Understanding how these machines function can help you appreciate their capabilities and why they outperform traditional methods.

The Basics of Fiber Laser Technology

Fiber laser cutting machines rely on solid-state technology to generate their laser beams. Unlike CO2 lasers, which use gas as the medium, fiber lasers use a bank of diodes to produce light. This light travels through flexible fiber-optic cables, which amplify and focus it into a powerful beam. The shorter wavelength of the beam allows it to cut metals, including reflective materials like aluminum and copper, with remarkable accuracy.

The laser beam's high absorption rate in metals ensures efficient energy transfer, reducing waste and improving cutting performance. This makes fiber laser cutting machines particularly effective for intricate designs and fine details. Their ability to maintain consistent quality across various applications highlights the superiority of this technology.

Key Features That Set Fiber Lasers Apart

Solid-state design and fiber optics

The solid-state design of fiber lasers eliminates the need for mirrors or moving parts, which are common in CO2 lasers. This design enhances durability and reduces maintenance requirements. Fiber-optic cables play a crucial role in transmitting the laser beam with minimal energy loss. These cables also allow for greater flexibility in machine design, enabling customization for specific industrial needs.

The compact nature of fiber laser systems makes them space-efficient. You can integrate them into smaller workspaces without compromising performance. This feature, combined with their robust construction, ensures long-term reliability and cost savings.

High energy density and beam quality

Fiber laser cutting machines produce a laser beam with high energy density, which translates to faster cutting speeds and cleaner edges. The beam's superior quality ensures precise cuts, even on thin materials. This level of precision minimizes the need for post-processing, saving you time and resources.

The high energy density also enables the machine to handle challenging materials. Reflective metals, which often pose problems for other cutting methods, are easily managed by fiber lasers. This versatility makes them a valuable tool for industries requiring both speed and accuracy.

Key Advantages of Fiber Laser Cutting Machines

Speed and Efficiency

Faster cutting speeds for thin materials

Fiber laser cutting machines excel in delivering unmatched speed when working with thin materials. Their advanced technology allows you to achieve cutting speeds up to six times faster than traditional CO2 lasers, especially for materials like stainless steel with a thickness of 1 mm. This rapid performance not only boosts productivity but also reduces the time required to complete intricate projects. By choosing a fiber laser cutting machine, you can meet tight deadlines without compromising on quality or precision.

The shorter wavelength of the laser beam enhances its interaction with metals, enabling faster energy absorption. This feature ensures that the cutting process remains efficient and effective, even for reflective materials such as aluminum and brass. With this capability, you can handle a variety of projects with ease and confidence.

Higher energy efficiency and reduced power consumption

Fiber laser cutting machines stand out for their remarkable efficiency. They convert up to 35% of electrical power into laser light, significantly reducing energy waste. This high conversion rate translates to lower electricity consumption, making these machines an environmentally friendly choice. For instance, the operating cost of a fiber laser cutter can be as low as 56 cents per hour, compared to $3.19 per hour for a typical CO2 laser. This substantial difference allows you to save on operational expenses while maintaining top-tier performance.

Additionally, fiber laser cutting machines eliminate the need for gas-based mediums, further reducing resource usage. Their energy-efficient design ensures that you can achieve optimal results without incurring excessive costs, making them a cost-effective solution for businesses focused on sustainability and profitability.

Precision and Quality

Superior edge quality with minimal post-processing

Fiber laser cutting machines deliver smoother cut edges that require little to no post-processing. The high energy density of the laser beam ensures clean and precise cuts, even on delicate or intricate designs. This level of high precision minimizes imperfections, allowing you to produce components that meet exact specifications. Whether you're working on thin sheets or reflective metals, the results consistently exhibit superior quality.

The ability to achieve smoother cut edges not only saves time but also reduces labor costs associated with additional finishing work. By investing in a fiber laser cutting machine, you can streamline your workflow and focus on delivering flawless products to your clients.

Consistent performance across intricate designs

Fiber laser cutting machines maintain consistent precision across complex patterns and detailed designs. Their advanced beam control ensures uniform results, regardless of the material's thickness or reflectivity. This reliability makes them ideal for industries requiring intricate components, such as electronics, jewelry, and aerospace.

The solid-state design of these machines eliminates mechanical wear and tear, ensuring stable performance over time. You can rely on their cutting accuracy to meet the demands of high-volume production without sacrificing quality. This consistency enhances your ability to deliver exceptional results, even for the most challenging projects.

Cost-Effectiveness

Lower operating costs due to energy savings

Fiber laser cutting machines offer significant cost advantages through their energy-efficient operation. Their ability to convert electrical power into laser light with minimal loss reduces electricity bills, making them a financially sound investment. Over time, these savings can add up, allowing you to allocate resources to other areas of your business.

The absence of consumable gases further lowers operating expenses. Unlike CO2 lasers, which rely on gas-based mediums, fiber laser cutting machines operate without additional material costs. This feature ensures that you can maintain profitability while delivering high-quality results.

Minimal maintenance requirements and downtime

The robust construction of fiber laser cutting machines minimizes maintenance needs. Their solid-state design eliminates moving parts, reducing the risk of mechanical failures. This durability translates to less downtime, allowing you to maximize productivity and meet project deadlines consistently.

With fewer components requiring regular upkeep, you can focus on your core operations without worrying about unexpected repairs. The long lifespan of fiber laser components ensures that your investment remains reliable and cost-effective for years to come. By choosing a fiber laser cutting machine, you can enjoy uninterrupted performance and long-term savings.

Material Versatility

Ability to cut reflective metals like aluminum and brass

Fiber laser cutting machines excel in handling reflective metals such as aluminum and brass, which often challenge traditional cutting methods. The shorter wavelength of the laser beam enhances its absorption by these materials, ensuring efficient and precise cuts. This capability allows you to work on projects involving metals that were previously difficult to process with older technologies.

Unlike CO2 lasers, which can struggle with reflective surfaces due to beam deflection, fiber laser cutting machines maintain consistent performance. This reliability ensures that you can achieve high-quality results without interruptions. Whether you're fabricating intricate designs or cutting large sheets, the machine's ability to handle reflective metals expands your range of possibilities.

Compatibility with a wide range of thicknesses

Fiber laser cutting machines offer remarkable flexibility when it comes to material thickness. You can cut thin sheets with exceptional speed and precision, making them ideal for industries like electronics and jewelry. At the same time, these machines can handle thicker materials, providing clean and accurate cuts across a variety of applications.

This versatility eliminates the need for multiple cutting tools, saving you time and resources. Whether you're working with delicate components or robust metal plates, a fiber laser cutting machine adapts to your needs. Its ability to maintain consistent quality across different thicknesses ensures that your projects meet the highest standards.

Durability and Lifespan

Longer lifespan of fiber laser components

Fiber laser cutting machines are built to last. Their solid-state design eliminates the need for moving parts, reducing wear and tear over time. The components, including the fiber-optic cables, are engineered for durability, ensuring that the machine operates reliably for years.

This longevity translates to significant cost savings. You won't need to frequently replace parts or deal with unexpected breakdowns. By investing in a fiber laser cutting machine, you secure a tool that delivers consistent performance and minimizes long-term expenses.

Reduced wear-and-tear compared to CO2 lasers

Fiber laser cutting machines experience less wear-and-tear compared to CO2 lasers. The absence of mirrors and gas-based mediums reduces the risk of mechanical failures. This robust construction ensures that the machine remains operational with minimal maintenance.

The reduced maintenance requirements mean less downtime for your operations. You can focus on meeting production goals without worrying about interruptions. Over time, the machine's durability enhances your productivity and provides a higher return on investment.

Comparison with CO2 Laser Cutting Machines

Cutting Speed and Efficiency

Fiber laser cutting machines excel in speed, particularly when working with thin materials. Their shorter wavelength allows for faster energy absorption, enabling you to cut materials like stainless steel up to six times faster than a CO2 laser cutter. This rapid performance makes fiber lasers ideal for industries that prioritize high productivity and quick turnaround times.

CO2 laser cutting machines, on the other hand, perform better when cutting thicker materials. Their ability to pierce through dense surfaces with smoother finishes gives them an edge in specific applications, such as heavy-duty metal fabrication. However, for most sheet metal fabrication tasks, fiber lasers deliver comparable or superior speeds, making them a more versatile choice for modern manufacturing.

Energy Consumption and Operating Costs

Fiber laser cutting machines are significantly more energy-efficient than CO2 laser cutters. They convert up to 35% of electrical power into laser light, reducing energy waste and lowering electricity costs. In contrast, CO2 systems typically have a lower conversion rate, which results in higher power consumption. Over time, this difference can lead to substantial savings for your business.

Operating costs also favor fiber lasers. These machines eliminate the need for consumable gases, which are essential for CO2 laser cutting. By avoiding gas-based mediums, you reduce ongoing expenses and simplify maintenance. For example, the cost of running a fiber laser cutter can be as low as 56 cents per hour, compared to $3.19 per hour for a CO2 laser cutter. This cost-effectiveness ensures a quicker return on investment and long-term profitability.

Maintenance and Durability

Fiber laser cutting machines require less maintenance due to their solid-state design. The absence of mirrors and moving parts minimizes wear and tear, ensuring reliable performance over extended periods. This durability translates to fewer breakdowns and reduced downtime, allowing you to maintain consistent productivity. A standard fiber laser is designed to operate for over 30,000 hours, providing a dependable solution for years.

In comparison, CO2 laser cutters demand more frequent upkeep. Their reliance on mirrors and gas-based systems increases the likelihood of mechanical issues. This results in higher maintenance costs and potential interruptions to your workflow. While CO2 lasers remain effective for certain applications, their maintenance requirements make them less appealing for businesses seeking efficiency and reliability.

Material Compatibility and Limitations

Fiber laser cutting machines showcase remarkable versatility in material processing, making them a preferred choice for many industries. Their ability to cut metals, including reflective materials like aluminum and brass, sets them apart from traditional methods. The shorter wavelength of the fiber laser beam enhances energy absorption, ensuring precise and efficient cuts on these challenging surfaces. This capability allows you to work with a wide range of metals without compromising quality or speed.

However, fiber lasers do have limitations. While they excel in cutting thin and medium-thickness metals, they may not perform as effectively on thicker materials. For instance, a co2 laser cutter often provides smoother finishes and faster piercing times when working with dense surfaces. This makes co2 laser cutting machines a better option for specific applications, such as heavy-duty metal fabrication or projects requiring intricate cuts on thicker materials.

Another limitation lies in non-metal materials. Fiber lasers are optimized for metals, but they struggle with cutting non-metals like wood, acrylic, or certain plastics. In contrast, co2 laser cutters handle these materials with ease, offering greater flexibility for businesses that require diverse material processing. If your projects involve a mix of metals and non-metals, you might need to consider the strengths of both technologies to meet your needs effectively.

Despite these limitations, fiber lasers remain a powerful tool for industries focused on precision and efficiency. Their ability to handle reflective metals, combined with their energy efficiency and low maintenance requirements, makes them an excellent investment for most metal fabrication tasks. By understanding the strengths and weaknesses of fiber lasers, you can make informed decisions about their suitability for your specific applications.

Applications of Fiber Laser Cutting Machines

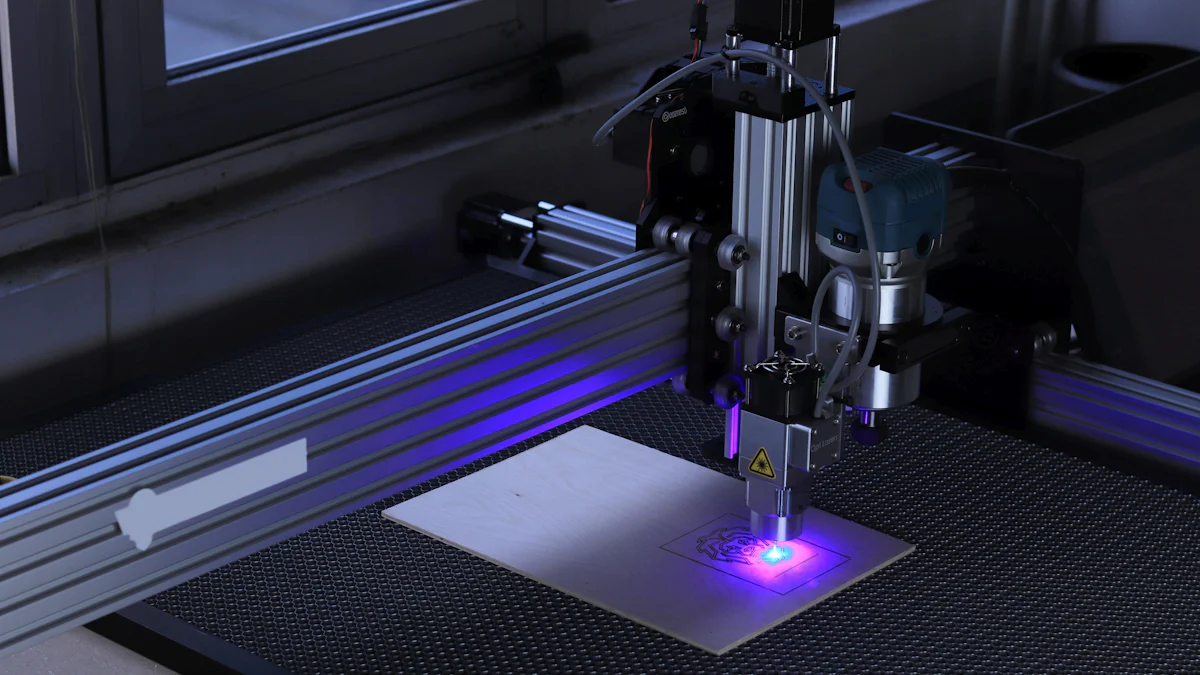

Metal Fabrication

Fiber laser cutting machines have revolutionized the metal fabrication industry. Their ability to deliver precise cuts with minimal waste makes them indispensable for creating high-quality metal components. You can use these machines to cut a variety of metals, including stainless steel, aluminum, and brass. The shorter wavelength of the fiber laser beam ensures efficient energy absorption, allowing you to achieve clean edges and intricate designs.

In addition to precision, these machines offer unmatched speed. For thin metal sheets, fiber lasers can cut up to six times faster than traditional CO2 lasers. This speed boosts productivity, enabling you to complete projects in less time. Whether you're crafting custom parts or mass-producing components, fiber laser cutting machines help you meet tight deadlines without sacrificing quality.

Their energy efficiency also benefits your bottom line. By converting a higher percentage of electrical power into laser light, these machines reduce electricity consumption. This efficiency, combined with minimal maintenance requirements, ensures that your operations remain cost-effective over the long term.

Automotive and Aerospace Industries

The automotive and aerospace industries demand precision and reliability, and fiber laser cutting machines excel in meeting these requirements. You can rely on these machines to produce lightweight yet durable components, which are essential for improving fuel efficiency and performance in vehicles and aircraft.

Fiber lasers handle reflective metals like aluminum and titanium with ease, making them ideal for crafting parts such as engine components, structural panels, and exhaust systems. Their ability to cut intricate designs ensures that even the most complex geometries meet exact specifications. This precision is critical for maintaining safety and performance standards in these industries.

Another advantage lies in the machines' durability. With a lifespan often exceeding 25,000 working hours, fiber lasers provide consistent performance over time. This reliability minimizes downtime, allowing you to maintain steady production schedules. By investing in fiber laser technology, you can enhance your manufacturing capabilities and stay competitive in these high-demand sectors.

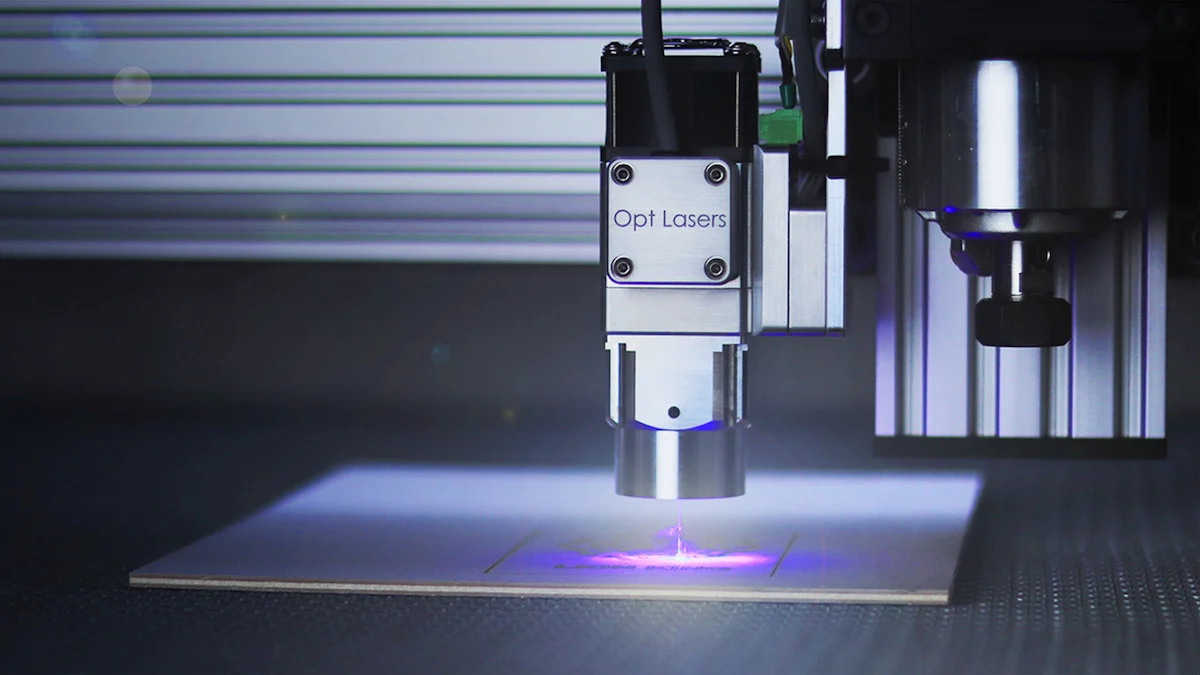

Electronics and Precision Engineering

Fiber laser cutting machines play a vital role in electronics and precision engineering. Their ability to produce fine, detailed cuts makes them perfect for creating small components like circuit boards, connectors, and microchips. You can achieve exceptional accuracy, ensuring that each part fits seamlessly into larger assemblies.

The machines' high energy density allows for clean cuts on thin materials, which is essential for delicate electronic components. Unlike traditional methods, fiber lasers minimize heat-affected zones, reducing the risk of warping or damage. This precision ensures that your products maintain their functionality and reliability.

In addition to electronics, fiber lasers are widely used in precision engineering applications. From medical devices to intricate tools, these machines enable you to create components with exacting tolerances. Their versatility and efficiency make them a valuable asset for industries that prioritize accuracy and innovation.

Jewelry and Artistic Applications

Fiber laser cutting machines have transformed the way you can approach jewelry design and artistic creations. Their precision and versatility allow you to craft intricate patterns and delicate details with ease, making them an essential tool for artisans and designers.

Unmatched Precision for Intricate Designs

When working on jewelry, precision is everything. Fiber lasers excel in creating fine, detailed cuts that meet the exacting standards of the jewelry industry. You can use these machines to carve complex patterns, engrave personalized messages, or cut delicate shapes from metals like gold, silver, and platinum. The high energy density of the laser beam ensures clean edges, reducing the need for additional polishing or finishing.

This level of accuracy also benefits artistic applications. Whether you're designing sculptures, decorative panels, or custom ornaments, fiber lasers allow you to bring your creative visions to life. Their ability to handle intricate designs ensures that every detail is captured with stunning clarity.

Versatility Across Materials

Fiber laser cutting machines are not limited to precious metals. You can use them to work with a variety of materials, including stainless steel, brass, and titanium. This versatility opens up endless possibilities for creating unique pieces that combine different textures and finishes. For example, you can craft mixed-metal jewelry or incorporate reflective metals into your designs without worrying about performance issues.

Additionally, fiber lasers handle thin materials exceptionally well. This makes them ideal for producing lightweight jewelry pieces or intricate artistic elements. Their compatibility with various thicknesses ensures that you can experiment with different styles and techniques, giving you the freedom to innovate.

Efficiency and Cost-Effectiveness

Fiber lasers not only enhance your creative capabilities but also improve your efficiency. Their fast cutting speeds allow you to complete projects quickly, enabling you to meet tight deadlines or produce items in bulk. This is particularly valuable for jewelry makers who need to fulfill custom orders or maintain inventory for retail.

The machines' energy efficiency further reduces operational costs. By converting a higher percentage of electrical power into laser light, fiber lasers consume less electricity compared to traditional methods. This cost-effectiveness ensures that you can focus on your craft without worrying about excessive expenses.

Durability for Long-Term Use

Fiber laser cutting machines are built to last, making them a reliable investment for your artistic endeavors. Their solid-state design minimizes wear and tear, ensuring consistent performance over time. You can rely on these machines to handle high-volume production or intricate one-of-a-kind pieces without frequent maintenance.

With their long lifespan and minimal upkeep requirements, fiber lasers provide a dependable solution for artists and jewelers. They allow you to focus on creating exceptional work while enjoying the benefits of advanced technology.

"Fiber laser cutting machines empower you to push the boundaries of creativity, combining precision, versatility, and efficiency to produce stunning jewelry and artistic masterpieces."

By incorporating fiber laser technology into your workflow, you can elevate your craftsmanship and deliver pieces that captivate and inspire. Whether you're a jeweler or an artist, these machines offer the tools you need to achieve excellence.

Fiber laser cutting machines redefine what does a laser fiber cutting machine achieve in modern manufacturing. They surpass the capabilities of a CO2 laser cutter by delivering unmatched speed, precision, and material versatility. Their advanced technology ensures smoother cut edges, high precision, and consistent performance across intricate designs. You benefit from reduced operating costs, minimal maintenance, and long-term reliability. By investing in this cutting-edge technology, you secure superior quality, enhanced productivity, and a higher return on investment. Fiber laser cutting machines set a new standard for efficiency and performance in diverse industries.

FAQ

What is a fiber laser cutting machine?

A fiber laser cutting machine uses advanced solid-state technology to generate a highly focused laser beam. This beam cuts through materials with exceptional precision and speed. Unlike CO2 lasers, fiber lasers rely on diodes and fiber-optic cables to produce and transmit the laser light. This design ensures higher energy efficiency and better performance, especially for cutting metals like aluminum, brass, and stainless steel.

How does a fiber laser cutting machine differ from a CO2 laser cutter?

Fiber laser cutting machines excel in cutting metals, particularly reflective ones, due to their shorter wavelength and higher absorption rate. They operate faster on thin materials and consume less energy compared to CO2 lasers. CO2 lasers, however, perform better on thicker materials and non-metals like wood or acrylic. Fiber lasers also require less maintenance because they lack moving parts like mirrors.

What materials can a fiber laser cutting machine process?

Fiber laser cutting machines handle a wide range of metals, including stainless steel, aluminum, brass, and copper. They are particularly effective with reflective metals, which can be challenging for other cutting methods. However, they are not ideal for cutting non-metal materials like wood, acrylic, or certain plastics. For non-metal applications, CO2 lasers are a better choice.

Why are fiber laser cutting machines more energy-efficient?

Fiber laser cutting machines convert up to 35% of electrical power into laser light, minimizing energy waste. This efficiency reduces electricity consumption and lowers operating costs. In comparison, CO2 lasers have a lower conversion rate, which leads to higher energy usage. The absence of gas-based mediums in fiber lasers further enhances their energy efficiency.

Are fiber laser cutting machines suitable for intricate designs?

Yes, fiber laser cutting machines excel at intricate designs. Their high energy density and superior beam quality allow for precise cuts, even on complex patterns. This makes them ideal for industries like jewelry, electronics, and aerospace, where accuracy is critical. The clean edges they produce often eliminate the need for additional finishing work.

How durable are fiber laser cutting machines?

Fiber laser cutting machines are built for long-term use. Their solid-state design eliminates moving parts, reducing wear and tear. Components like fiber-optic cables are engineered for durability, ensuring consistent performance over thousands of hours. Many machines operate reliably for over 30,000 hours, making them a cost-effective investment.

What industries benefit the most from fiber laser cutting machines?

Fiber laser cutting machines are widely used in industries like automotive, aerospace, electronics, and metal fabrication. In automotive and aerospace, they produce lightweight yet durable components. In electronics, they create precise parts like circuit boards. Their versatility also makes them valuable in jewelry design and artistic applications.

How fast can a fiber laser cutting machine cut materials?

Fiber laser cutting machines are significantly faster than CO2 lasers, especially for thin materials. For example, they can cut 1 mm stainless steel up to six times faster than a CO2 laser. This speed boosts productivity and allows you to complete projects quickly without compromising quality.

What are the maintenance requirements for fiber laser cutting machines?

Fiber laser cutting machines require minimal maintenance. Their solid-state design eliminates the need for mirrors or gas-based systems, reducing the risk of mechanical failures. Regular cleaning and occasional checks of the fiber-optic cables are usually sufficient to keep the machine running efficiently. This low-maintenance design minimizes downtime and operational costs.

Is investing in a fiber laser cutting machine worth it?

Investing in a fiber laser cutting machine offers significant benefits. You gain faster cutting speeds, higher precision, and lower operating costs. The machine's energy efficiency and durability ensure long-term savings. For industries focused on metal fabrication, precision engineering, or high-volume production, fiber laser technology provides a strong return on investment.

See Also

Understanding The Functionality Of Fiber Laser Cutters

A Simple Explanation Of Laser Cutting Machine Operation

Tips For Effective Use Of Laser Cutting Machines