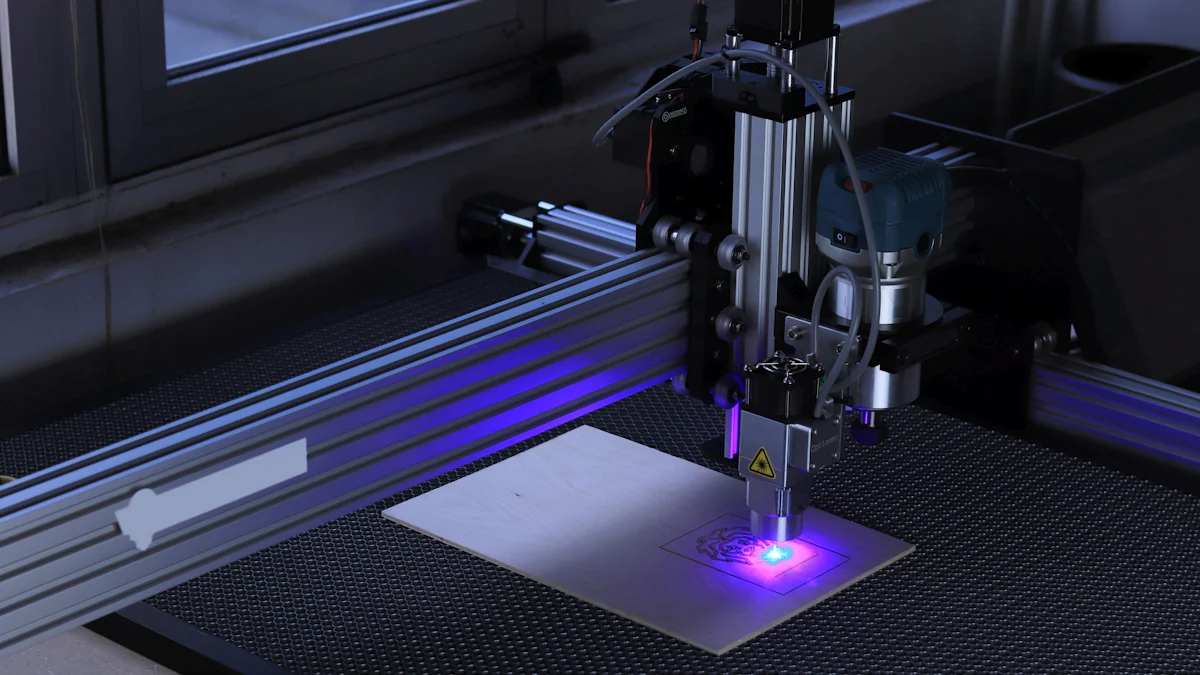

What Does a Laser Cutting Machine Do

A laser cutting machine uses a high-energy laser beam to deliver precise results on various materials, which raises the question: what does a laser cutting machine do? You can rely on it to create intricate designs, clean edges, and detailed engravings. The process involves heating the material until it melts or vaporizes, ensuring smooth and accurate cuts. Industries like automotive, electronics, and manufacturing depend on this technology for its efficiency and precision. With the global market projected to grow significantly, laser technology continues to revolutionize how materials are processed, offering unmatched accuracy and versatility.

How Laser Cutting Machines Work

Understanding how laser cutting machines operate can help you appreciate their precision and versatility. These machines rely on advanced technology to deliver high-energy beams that reshape or remove material with incredible accuracy. Let’s break down the process into three key stages.

The Laser Generation Process

The journey begins with the creation of the laser beam. A laser forms when energy excites atoms in a medium, such as gas, liquid, or solid. This energy pump, often an electrical current or another laser, causes the atoms to emit light. Mirrors at both ends of the medium amplify this light by reflecting it back and forth, creating a concentrated beam of coherent photons. This focused energy becomes the cutting tool that powers laser cutting machines.

Fun Fact: The term "laser" stands for "Light Amplification by Stimulated Emission of Radiation," highlighting its scientific roots.

Focusing the Laser Beam

Once generated, the laser beam must be precisely focused to achieve the desired cutting effect. This is done using lenses, mirrors, and compressed gases like carbon dioxide. These components direct the beam through a nozzle, narrowing it to a fine point. The focused beam creates a small, high-temperature spot capable of melting, vaporizing, or burning through materials. Computer Numerical Control (CNC) systems guide the laser head or material, ensuring the beam follows the exact design or pattern programmed into the machine.

Interaction with Materials

When the focused laser beam meets the material, the real magic happens. The intense heat rapidly melts or vaporizes the material at the contact point. Depending on the application, the laser cutting process may involve:

- Melting and blowing: The laser melts the material, and a jet of gas removes the molten residue.

- Vaporization: The beam heats the material to its boiling point, turning it into vapor.

- Burning: The laser burns away the material, leaving clean edges.

This non-contact process ensures minimal damage to surrounding areas, making laser cutting ideal for intricate designs and delicate materials. Whether you're cutting thick steel sheets or engraving fine details on wood, the laser cutting process delivers consistent and high-quality results.

Types of Laser Cutting Machines

Laser cutting machines come in different types, each designed to meet specific needs. Understanding these variations helps you choose the right tool for your projects. Below, we explore three common types of laser cutters and their unique features.

CO2 Laser Cutting Machines

CO2 laser cutting machines are among the most widely used options. These machines rely on a gas mixture, primarily carbon dioxide, to generate the laser beam. They excel at cutting non-metal materials like wood, acrylic, leather, and plastics. Their ability to produce smooth edges makes them ideal for applications requiring high-quality finishes.

You’ll find CO2 lasers particularly effective for engraving and etching. They can create intricate designs on surfaces without causing damage to the surrounding material. However, they struggle with cutting metals unless equipped with specialized enhancements. For general-purpose use, CO2 laser cutters remain a popular choice due to their versatility and affordability.

Quick Tip: If you work with non-metals or need a machine for creative projects, a CO2 laser cutter might be your best option.

Fiber Laser Cutting Machines

Fiber laser cutting machines are optimized for cutting metals and other challenging materials. These machines use optical fibers to amplify the laser beam, resulting in higher cutting speeds and greater precision. They handle metals like stainless steel, aluminum, copper, and brass with ease, making them indispensable in industrial manufacturing.

Fiber lasers consume less power compared to other types, which reduces operational costs. They also have a long lifespan, often exceeding 25,000 hours of use without requiring maintenance. While they excel at cutting thin materials, higher-powered models can handle thicker metals effectively. If your projects involve metalwork, a fiber laser cutter offers unmatched efficiency and durability.

Did You Know? Fiber lasers are not only fast but also environmentally friendly due to their lower energy consumption.

Nd:YAG Laser Cutting Machines

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) laser cutting machines are specialized tools designed for high-energy applications. These machines are perfect for tasks requiring extreme precision, such as drilling, welding, and engraving. They work well with metals and ceramics, making them a go-to choice for industries like aerospace and electronics.

Nd:YAG lasers deliver short, intense bursts of energy, allowing you to cut through tough materials with minimal heat damage. However, they are less common for general-purpose cutting due to their higher cost and complexity. If your work demands precision on hard materials, this type of laser cutter provides exceptional results.

Pro Tip: Consider an Nd:YAG laser cutter if your projects involve intricate designs on metals or ceramics.

Each type of laser cutting machine serves a unique purpose. Whether you need a versatile CO2 laser, a high-speed fiber laser, or a precision-focused Nd:YAG laser, understanding their strengths ensures you make the right investment for your needs.

Applications of Laser Cutting Machines

Laser cutting machines have transformed how industries and creators approach precision work. Their versatility allows them to excel in diverse fields, from large-scale production to intricate artistic endeavors. Below, you’ll discover how laser cutting is applied across various domains.

Industrial Manufacturing

In industrial manufacturing applications, laser cutting plays a pivotal role in producing high-quality components. You can find its use in industries like automotive, aerospace, and consumer electronics. For example, in the automotive sector, laser cutting enables the creation of complex body panels and chassis parts with exceptional accuracy. This precision ensures seamless integration of components, enhancing vehicle safety and performance.

Laser cutting machines also handle advanced materials like aluminum and high-strength steels. These materials are essential for manufacturing lightweight, fuel-efficient vehicles that meet strict emission standards. Additionally, the non-contact nature of laser cutting minimizes material waste and reduces operational costs, making it a cost-effective solution for mass production.

In consumer electronics, where sleek designs and miniaturization are critical, laser cutting machines shine. They allow manufacturers to create intricate patterns and perforations in devices like smartphones and laptops. This level of detail would be challenging to achieve with traditional cutting methods.

Quick Insight: Laser cutting’s ability to maintain material integrity while delivering precise results makes it indispensable in modern manufacturing.

Creative and Artistic Fields

Laser cutting isn’t just for industrial purposes—it’s a favorite tool for artists and designers. If you’re working on a creative project, a laser cutting machine can help you bring intricate designs to life. Artists often use these machines to engrave or cut materials like wood, acrylic, and leather, producing stunning decorative pieces.

One of the key advantages of laser cutting in artistic fields is its ability to handle delicate materials without causing damage. For example, you can create detailed patterns on thin sheets of metal or carve intricate designs into fragile surfaces like glass. The precision of laser cutting ensures that even the most complex designs are executed flawlessly.

Many creators combine laser cutting with other technologies, such as 3D printing, to achieve ultimate design freedom. This synergy allows for innovative projects that push the boundaries of traditional craftsmanship.

Pro Tip: If you’re exploring artistic applications, consider using CAD software to design intricate patterns that a laser cutting machine can execute with pinpoint accuracy.

Medical and Electronics Industries

In the medical field, laser cutting machines contribute to the production of life-saving devices and tools. You’ll find them used to create surgical instruments, implants, and intricate components for medical equipment. The precision of laser cutting ensures that these items meet the stringent quality standards required in healthcare.

The electronics industry also benefits significantly from laser cutting. Manufacturers rely on this technology to produce tiny, precise components for circuit boards and other electronic devices. The ability to cut and engrave with extreme accuracy makes laser cutting ideal for creating parts that fit seamlessly into compact designs.

Additionally, laser cutting supports innovation in both industries by enabling rapid prototyping. Engineers and designers can quickly test and refine their ideas, accelerating the development of new products.

Did You Know? Laser cutting machines can achieve tolerances as tight as +/- 0.1 mm, making them perfect for applications requiring extreme precision.

From industrial manufacturing to artistic creations and medical advancements, laser cutting applications continue to expand. Whether you’re producing large-scale components or crafting intricate designs, this technology offers unmatched precision and versatility.

Advantages of Laser Cutting Machines

Laser cutting machines have revolutionized the way materials are processed, offering benefits that surpass traditional methods. Their advanced technology ensures you achieve exceptional results, whether you're working on industrial projects or creative designs. Below, you'll explore the key advantages that make laser cutting a preferred choice.

High Precision and Accuracy

Laser cutting delivers unmatched precision cutting, allowing you to create intricate designs and complex shapes with ease. The laser beam focuses on a small area, producing clean and consistent edges. This high level of accuracy ensures minimal material waste and eliminates the need for additional finishing.

For example, in industrial applications, laser cutting achieves tolerances as tight as +/- 0.1 mm. This capability makes it ideal for producing components that require exact measurements, such as parts for electronics or medical devices. Unlike traditional cutting methods, laser cutting minimizes material warping and contamination, ensuring the integrity of your work.

Quick Insight: The non-contact nature of laser cutting reduces the risk of damage to delicate materials, making it perfect for projects requiring fine details.

Versatility

One of the standout features of laser cutting is its versatility. You can use it to cut, engrave, or etch a wide range of materials, including metals, wood, acrylic, leather, and even glass. This flexibility allows you to tackle diverse projects without needing multiple tools or machines.

Laser cutting machines also integrate seamlessly with CAD/CAM software, enabling you to execute complex designs with precision. Whether you're crafting artistic pieces or manufacturing industrial components, laser cutting adapts to your needs. Its ability to handle both thick and thin materials further enhances its versatility, making it a valuable tool across various industries.

Pro Tip: If you're working on creative projects, laser cutting lets you experiment with intricate patterns and unique materials, expanding your design possibilities.

Efficiency and Speed

Laser cutting machines excel in efficiency and speed, helping you complete projects faster without compromising quality. The high-energy laser beam cuts through materials quickly, reducing production time. This speed is especially beneficial in industrial settings, where meeting tight deadlines is crucial.

Automation plays a significant role in enhancing efficiency. Many laser cutting machines come equipped with CNC systems, which allow you to program designs and let the machine handle the rest. This reduces manual intervention and ensures consistent results. Additionally, laser cutting optimizes material usage, lowering costs and minimizing waste.

Did You Know? Fiber laser cutting machines consume less power while delivering faster cutting speeds, making them an eco-friendly and cost-effective option.

By combining precision, versatility, and efficiency, laser cutting machines provide a comprehensive solution for modern material processing. Whether you're aiming for intricate designs or large-scale production, these machines deliver results that meet the highest standards.

Limitations of Laser Cutting Machines

While laser cutting machines offer precision and versatility, they come with certain limitations. Understanding these drawbacks helps you make informed decisions when considering this technology for your projects.

Material Restrictions

Laser cutting machines excel at processing a wide range of materials, but they have limitations. The thickness of the material plays a crucial role in determining the effectiveness of the cut. For instance, while fiber lasers handle thin metals like stainless steel or aluminum efficiently, they may struggle with thicker sheets. Similarly, CO2 lasers work well on non-metals such as wood and acrylic but often require enhancements to cut metals effectively.

Some materials, like reflective metals, pose additional challenges. These surfaces can reflect the laser beam, reducing its cutting efficiency and potentially damaging the machine. Moreover, certain materials, such as PVC or polycarbonate, release toxic fumes when exposed to the laser. This makes them unsuitable for laser cutting unless proper ventilation and safety measures are in place.

Quick Insight: Always check the compatibility of your material with the laser cutter to avoid inefficiencies or safety hazards.

High Initial Cost

Investing in a laser cutting machine requires a significant upfront cost. The advanced technology, high-precision engineering, and durable components contribute to the price. For small businesses or hobbyists, this initial expense can be a barrier. Even though the long-term operational costs, such as reduced material waste and minimal maintenance, may offset the investment, the upfront cost remains a challenge for many.

Additionally, specialized laser types, like fiber or Nd:YAG lasers, tend to cost more due to their enhanced capabilities. If you need a machine for specific applications, such as cutting thick metals or intricate designs, the price increases further. Budget planning becomes essential when considering a laser cutter for your needs.

Pro Tip: Evaluate your project requirements and potential return on investment before purchasing a laser cutting machine.

Safety Concerns

Operating a laser cutting machine involves certain safety risks. The high-energy laser beam generates intense heat, which can cause burns or fires if mishandled. Proper training and adherence to safety protocols are essential to minimize these risks. Additionally, the process often produces harmful fumes and gases, especially when cutting plastics or other synthetic materials. Without adequate ventilation, these emissions can pose health hazards.

Eye protection is another critical consideration. Direct exposure to the laser beam or its reflections can damage your eyes. Most machines come with built-in safety features, such as enclosures and interlocks, but you must remain vigilant during operation.

Did You Know? Many laser cutting machines include safety certifications and guidelines to help you operate them responsibly.

By understanding these limitations, you can take steps to mitigate their impact. Whether it’s choosing the right materials, budgeting for the initial investment, or following safety protocols, addressing these challenges ensures you get the most out of your laser cutting machine.

Laser cutting machines have revolutionized how you approach material processing. Their precision and efficiency make them indispensable in industries like manufacturing, art, and medicine. Since the development of gas-based laser cutting in the 1980s, this technology has driven innovation and transformed production methods. The introduction of carbon dioxide lasers expanded its versatility, allowing you to work with a broader range of materials. While these machines come with limitations, their ability to deliver consistent, high-quality results ensures their value. Whether for practical tasks or creative projects, laser cutting empowers you to achieve exceptional outcomes.

FAQ

What Materials Can a Laser Cutting Machine Process?

Laser cutting machines work with a wide range of materials. You can cut metals like stainless steel, aluminum, and brass using fiber lasers. CO2 lasers handle non-metals such as wood, acrylic, leather, and plastics. However, certain materials, like PVC or polycarbonate, release harmful fumes when cut, so you should avoid using them unless proper ventilation is in place.

How Accurate Are Laser Cutting Machines?

Laser cutting machines deliver exceptional accuracy, often achieving tolerances as tight as +/- 0.1 mm. This precision ensures clean edges and intricate designs without additional finishing. Whether you're working on industrial components or artistic projects, you can rely on laser cutting for consistent, high-quality results.

Are Laser Cutting Machines Safe to Use?

Laser cutting machines include safety features like enclosures and interlocks to protect you during operation. However, you must follow safety protocols. Wear protective eyewear to shield your eyes from the laser beam. Ensure proper ventilation to manage fumes, especially when cutting synthetic materials. Training and adherence to guidelines minimize risks.

Can I Use a Laser Cutting Machine for Engraving?

Yes, laser cutting machines excel at engraving. You can create detailed patterns, logos, or text on materials like wood, acrylic, glass, and metal. The precision of the laser ensures that even intricate designs are executed flawlessly. Engraving adds a professional touch to both personal and commercial projects.

What Is the Difference Between CO2 and Fiber Lasers?

CO2 lasers are ideal for cutting non-metals like wood, acrylic, and leather. They produce smooth edges and are commonly used for engraving. Fiber lasers, on the other hand, specialize in cutting metals such as stainless steel and aluminum. They offer faster cutting speeds and greater energy efficiency, making them suitable for industrial applications.

How Do I Maintain a Laser Cutting Machine?

Regular maintenance keeps your laser cutting machine in top condition. Clean the lenses and mirrors to ensure optimal beam quality. Check and replace filters in the ventilation system to manage fumes effectively. Inspect the machine's components for wear and tear. Following the manufacturer's maintenance schedule extends the machine's lifespan.

What Factors Affect the Cutting Quality?

Several factors influence cutting quality. The material type and thickness play a significant role. The laser's power settings and focus also impact the results. Using the correct gas, such as nitrogen or oxygen, enhances edge quality. Proper calibration of the machine ensures precise cuts and minimizes errors.

Can Beginners Operate a Laser Cutting Machine?

Yes, beginners can operate a laser cutting machine with proper training. Many machines come with user-friendly interfaces and pre-programmed settings. Learning to use CAD software helps you design patterns and upload them to the machine. Start with simple projects to build confidence before tackling complex designs.

How Much Does a Laser Cutting Machine Cost?

The cost of a laser cutting machine varies based on its type and capabilities. CO2 lasers are generally more affordable, starting at a few thousand dollars. Fiber lasers and Nd:YAG lasers, designed for industrial use, can cost significantly more. Consider your project needs and budget before investing in a machine.

What Are the Common Applications of Laser Cutting?

Laser cutting machines are versatile tools used across industries. In manufacturing, they produce components for automotive and aerospace sectors. Artists use them to create intricate designs on wood, acrylic, and leather. In medicine, they help fabricate surgical instruments and implants. Their adaptability makes them valuable for both practical and creative purposes.

See Also

Understanding The Functionality Of Fiber Laser Cutters

Exploring Different Types Of Laser Cutting Machines

A Simple Explanation Of Laser Cutting Machine Operation