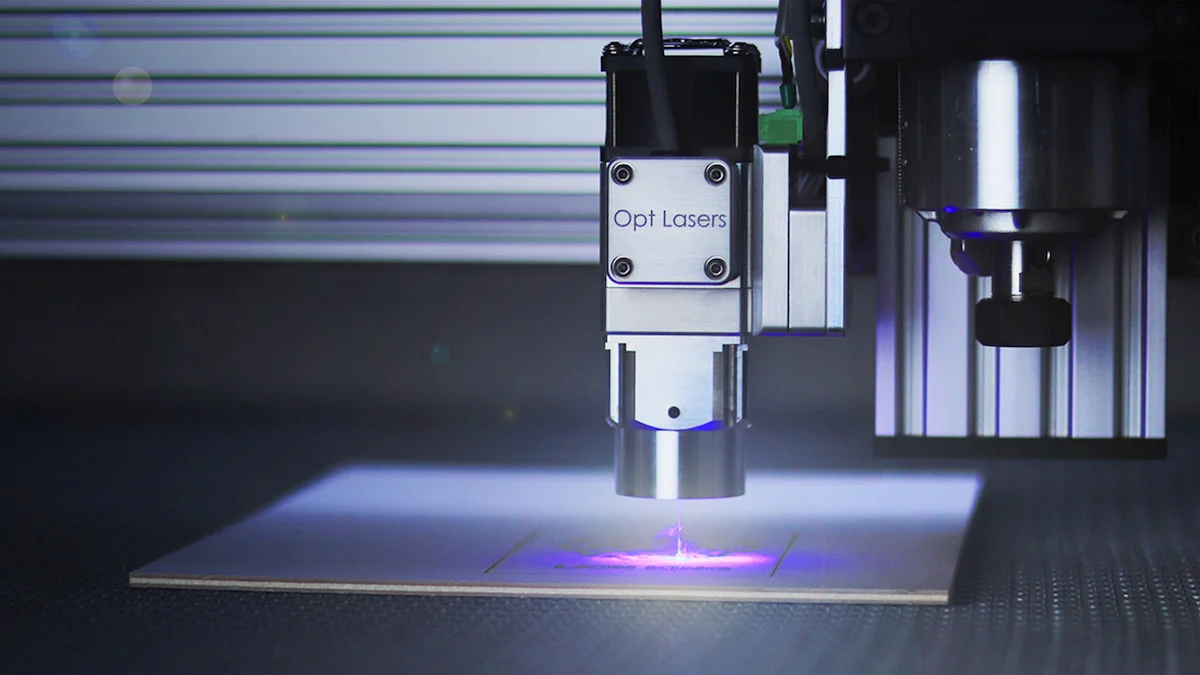

What Can You Make with a Laser Cutting Machine?

Imagine transforming raw materials into intricate designs with precision and ease. That's exactly what you can make with a laser cutting machine. This technology allows you to craft a wide array of items, from delicate jewelry to robust architectural models. Its unmatched accuracy and speed make it indispensable in industries like automotive and electronics. Whether you're working with metals, wood, or acrylic, the laser cutting machine offers flexibility and efficiency. Dive into the world of laser cutting and discover the endless possibilities of what you can make with a laser cutting machine for your creative projects.

Popular Projects Made with a Laser Cutting Machine

Laser cutting machines open up a world of creative possibilities. You can craft stunning pieces that captivate and inspire. Let's explore some popular projects you can undertake with this versatile tool.

Home Decor and Art

Wall Art

With a laser cutting machine, you can transform simple materials into intricate wall art. Imagine creating a piece that becomes the focal point of any room. You can use wood laser cutting to craft detailed designs that showcase your artistic flair. Whether it's a geometric pattern or a nature-inspired scene, the precision of laser cutting ensures every detail is perfect.

Custom Lampshades

Custom lampshades add a personal touch to your home lighting. By using laser cut acrylic, you can design lampshades that diffuse light beautifully, creating a warm and inviting atmosphere. The flexibility of laser cutting allows you to experiment with different shapes and patterns, making each lampshade a unique work of art.

Personalized Gifts

Engraved Jewelry

Jewelry becomes more meaningful when personalized. With laser engraving, you can add names, dates, or special messages to pieces of jewelry. This technique works well on various materials, including metals and wood. Laser engraving wood, for example, can produce elegant pendants or bracelets that carry sentimental value.

Custom Keychains

Keychains are practical yet personal gifts. You can use a laser cutting machine to create custom keychains that reflect individual styles or interests. Whether it's a favorite animal or a memorable quote, laser cut designs make each keychain special. These items are perfect for gifts or promotional items.

Educational Models

Architectural Models

Architectural models require precision and detail. A laser cutting machine excels in producing accurate scale models of buildings or structures. You can use materials like wood or acrylic to construct models that help visualize architectural concepts. These models are invaluable in educational settings, providing a tangible representation of theoretical designs.

Scientific Models

Scientific models benefit from the accuracy of laser cutting. You can create models that illustrate complex scientific concepts, such as molecular structures or anatomical features. Laser cut leather or other materials can be used to craft durable and detailed models that enhance learning experiences.

By exploring these projects, you can see how a laser cutting machine can transform your creative ideas into reality. Each project showcases the machine's ability to cut, engrave, and shape materials with precision and artistry.

Suitable Materials for Laser Cutting

When you use a laser cutting machine, selecting the right materials is crucial. Different materials offer unique properties that can enhance your projects. Let's explore some suitable materials for laser cutting.

Wood

Wood is a versatile material that works well with laser cutting. It offers a natural aesthetic and can be used for various applications.

Plywood

Plywood is a popular choice for laser cutting. It consists of thin layers of wood veneer glued together, providing strength and stability. You can use plywood to create intricate designs and models. Its layered structure allows for clean cuts and detailed engravings.

MDF (Medium-Density Fiberboard)

MDF is another excellent option for laser cutting. Made from wood fibers and resin, MDF provides a smooth surface ideal for engraving. It is denser than plywood, which makes it suitable for projects requiring precision. You can use MDF for furniture, decorative items, and more.

Plastics

Plastics are widely used in laser cutting due to their versatility and ease of use. They come in various types, each offering distinct advantages.

Acrylic

Acrylic is a popular plastic for laser cutting. It is lightweight, shatterproof, and available in different colors and finishes. You can use acrylic to create signs, displays, and decorative items. Its clarity and smooth edges make it ideal for projects that require a polished look.

Polycarbonate

Polycarbonate is another type of plastic suitable for laser cutting. It is known for its impact resistance and durability. You can use polycarbonate for protective covers, enclosures, and other applications where strength is essential. However, ensure your laser cutter is compatible with this material, as some types may not be suitable.

Metals

Laser cutting machines can also handle metals, allowing you to create robust and precise components.

Stainless Steel

Stainless steel is a durable metal that resists corrosion. It is ideal for projects that require strength and longevity. You can use stainless steel for industrial parts, kitchenware, and decorative items. Its reflective surface can add a modern touch to your designs.

Aluminum

Aluminum is a lightweight metal that is easy to work with. It offers excellent thermal conductivity and corrosion resistance. You can use aluminum for automotive parts, electronic enclosures, and architectural elements. Its versatility makes it a favorite among designers and engineers.

By understanding the properties of these materials, you can choose the most suitable materials for laser cutting projects. Each material offers unique benefits, allowing you to explore endless creative possibilities.

Fabrics and Leather

Laser cutting machines offer remarkable precision when working with fabrics and leather, allowing you to create intricate designs and patterns. These materials are popular choices for fashion, accessories, and home decor projects.

Felt

Felt is a versatile fabric that responds well to laser cutting. You can use it to create a variety of items, from decorative pieces to functional products. The soft texture of felt makes it ideal for crafting coasters, ornaments, and even educational toys. Laser cutting ensures clean edges and precise shapes, enhancing the overall quality of your creations. Additionally, felt comes in a wide range of colors, giving you the freedom to experiment with different designs and color combinations.

Genuine Leather

Genuine leather is a premium material that adds a touch of luxury to any project. With a laser cutting machine, you can craft detailed patterns and engravings on leather, making it perfect for creating custom wallets, belts, and bags. The precision of laser cutting allows you to achieve intricate designs that would be challenging with traditional cutting methods. Leather's durability and timeless appeal make it a favorite for both fashion and interior design projects. When working with leather, ensure proper ventilation and safety measures, as the cutting process can produce fumes.

By exploring the possibilities with fabrics and leather, you can expand your creative horizons and produce unique, high-quality items. Each material offers distinct advantages, allowing you to tailor your projects to specific needs and preferences.

Considerations for Choosing Materials

When working with a laser cutting machine, selecting the right materials is crucial for achieving the best results. You need to consider several factors to ensure your projects are successful and safe.

Thickness and Density

The thickness and density of the material significantly impact the laser cutting process. Thicker materials require more powerful lasers to cut through effectively. For instance, when working with leather, you might need multiple passes to achieve a clean cut if the material is particularly thick. On the other hand, thinner materials like certain fabrics can be cut with lower power settings. It's essential to adjust the laser settings according to the material's thickness and density to avoid incomplete cuts or damage.

Material Composition

Understanding the composition of your cutting materials is vital. Natural textiles such as cotton, silk, and wool are excellent candidates for laser cutting. They generally produce clean cuts with low to moderate power settings. However, synthetic fabrics can pose challenges due to their tendency to melt or catch fire. Achieving stable settings for synthetic materials is possible, but it requires careful experimentation. Leather, whether genuine or faux, is another popular choice. CO2 lasers are particularly effective for cutting leather, providing precise cuts without damaging the fibers.

Safety and Ventilation

Safety should always be a top priority when using a laser cutting machine. Some materials release harmful fumes when cut, necessitating proper ventilation. For example, cutting leather can produce fumes, so ensure your workspace is well-ventilated. Additionally, always follow safety guidelines and wear appropriate protective gear to prevent accidents. Using a blower at low pressure can help manage fumes and keep the material in place during cutting.

By considering these factors, you can choose the most suitable materials for your laser cutting projects, ensuring both quality and safety.

Materials to Avoid in Laser Cutting

When using a laser cutting machine, you must be cautious about the materials you choose. Some materials can pose safety risks or damage the machine. Here are some materials you should not try to cut with a laser cutter:

PVC (Polyvinyl Chloride)

PVC is a common plastic found in many household items. However, you should avoid cutting PVC with a laser cutter. When heated, PVC releases harmful chlorine gas, which can be dangerous to your health and corrode the machine's components. Always check the material composition before cutting to ensure safety.

Polycarbonate (Certain Types)

Polycarbonate is a strong and durable plastic, but not all types are suitable for laser cutting. Some polycarbonates can melt or catch fire during the cutting process. This can lead to incomplete cuts and potential hazards. If you need to work with polycarbonate, test a small sample first to see how it reacts to the laser.

Reflective Metals (Copper, Brass, Bronze, Silver, Gold)

Reflective metals like copper, brass, bronze, silver, and gold can be challenging to cut with a laser. Their reflective surfaces can bounce the laser beam back into the machine, causing damage. Additionally, these metals require high power settings, which most standard laser cutters cannot provide. Consider alternative methods for cutting these metals to avoid damaging your equipment.

By understanding which materials you should not try to cut, you can protect both yourself and your laser cutting machine. Always prioritize safety and material compatibility when planning your projects.

Tips for Successful Laser Cutting Projects

Preparing Your Design

To achieve the best results with your laser cutting projects, start by preparing your design meticulously. Use design software that supports vector graphics, such as Adobe Illustrator or CorelDRAW. These programs allow you to create precise and scalable designs. Ensure your design is in the correct format for your laser cutter, typically a vector file like SVG or DXF. Pay attention to the line thickness; thin lines work best for cutting, while thicker lines are suitable for engraving. Organize your design elements logically to minimize material waste and optimize cutting time.

Testing Material Samples

Before committing to a full project, test material samples. This step helps you understand how different materials react to the laser. For instance, thin acrylic sheets cut swiftly and precisely, but thicker acrylic may require multiple passes, increasing the risk of charring or melting. Testing allows you to adjust the laser settings, such as power and speed, to achieve clean cuts without damaging the material. Keep a record of successful settings for future reference. Testing also helps you identify unsuitable materials, like thick polycarbonate sheets, which can catch fire and emit thick smoke.

Maintenance of the Laser Cutter

Regular maintenance of your laser cutter ensures optimal performance and longevity. Clean the machine's lenses and mirrors frequently to prevent dust and debris from affecting the laser's accuracy. Check the alignment of the laser beam regularly, as misalignment can lead to uneven cuts. Replace worn-out parts promptly to avoid disruptions during projects. Additionally, ensure the ventilation system is functioning correctly to remove fumes and maintain a safe working environment. By maintaining your laser cutter, you enhance its efficiency and extend its lifespan, allowing you to continue creating high-quality projects.

Exploring Creative Possibilities with a Laser Cutting Machine

Laser cutting machines offer endless opportunities for creativity. You can explore various techniques to enhance your projects and make them truly unique. Let's delve into some creative possibilities you can try.

Combining Materials

Mixing different materials can add depth and interest to your projects. You can combine wood and acrylic to create stunning contrasts in your designs. For example, use wood for the base of a decorative piece and add acrylic accents for a modern touch. Mixing metals with other materials can also yield impressive results. Try using stainless steel with leather to craft unique accessories. By experimenting with combinations, you can discover new textures and effects that elevate your work.

Experimenting with Textures

Textures can transform the look and feel of your creations. You can use a laser cutting machine to engrave intricate patterns on various materials. For instance, engrave a geometric design on wood to add a tactile element to your project. You can also experiment with different engraving depths to create a layered effect. Textured surfaces can enhance the visual appeal of items like jewelry, home decor, and more. By playing with textures, you can add a new dimension to your designs.

Customizing Designs

Personalization makes any project special. With a laser cutting machine, you can customize designs to suit individual preferences. Add names, dates, or messages to items like keychains, plaques, or gifts. You can also create custom shapes and patterns that reflect personal styles. Customization allows you to tailor your projects to specific occasions or themes. By offering personalized options, you can create meaningful and memorable pieces that resonate with others.

Exploring these creative possibilities can unlock new potential in your laser cutting projects. By combining materials, experimenting with textures, and customizing designs, you can push the boundaries of what you can achieve with a laser cutting machine.

Laser cutting machines offer you a world of creative possibilities. Their versatility allows you to craft everything from intricate jewelry to large-scale architectural models. With a laser cutting machine, you can experiment with various materials like wood, metal, and acrylic, pushing the boundaries of design. This technology empowers you to innovate and bring your ideas to life efficiently and cost-effectively. As you explore different projects, remember that the only limit is your imagination. Embrace the potential of laser cutting machines and let your creativity soar.

FAQ

What is a laser cutting machine?

A laser cutting machine uses a focused laser beam to cut or engrave materials. It offers high precision and speed, making it ideal for intricate designs. You can use it on various materials like wood, metal, and acrylic.

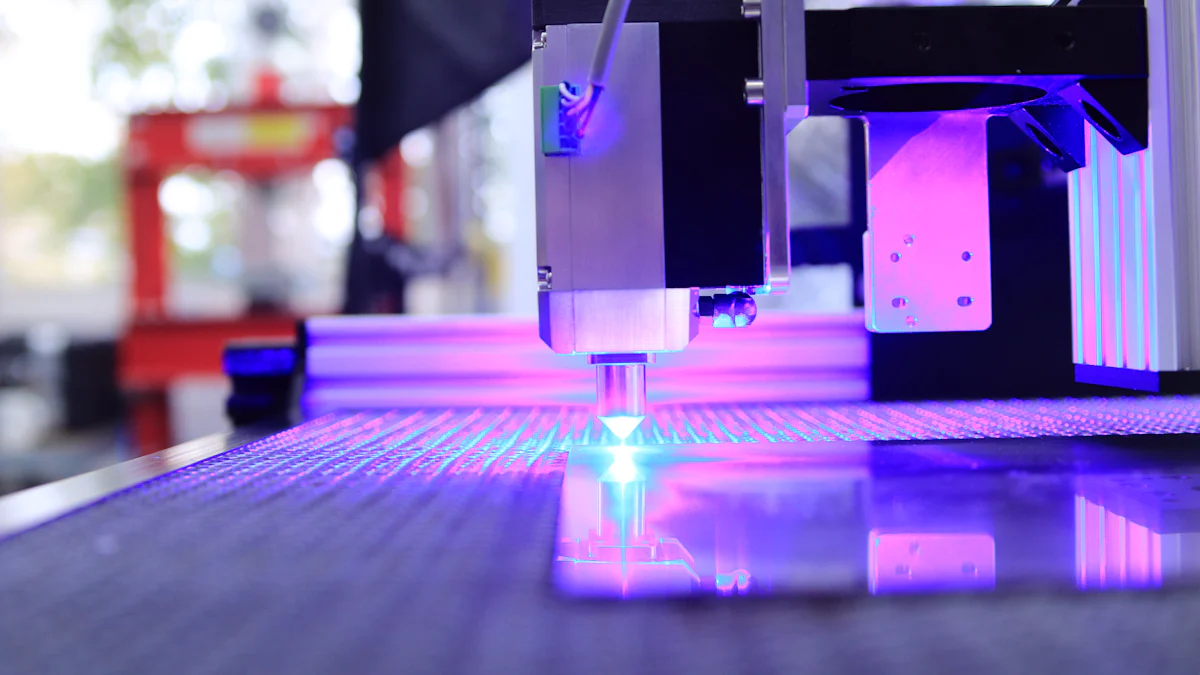

How does laser cutting work?

Laser cutting works by directing a high-powered laser beam onto the material. The laser melts, burns, or vaporizes the material, creating clean cuts. You control the laser's path using computer software, ensuring accuracy.

What materials can I cut with a laser cutting machine?

You can cut a wide range of materials, including wood, acrylic, leather, and certain metals. Each material requires specific settings for optimal results. Always check compatibility before starting a project.

Are there materials I should avoid cutting?

Yes, avoid cutting materials like PVC and certain polycarbonates. These can release harmful fumes or damage the machine. Reflective metals like copper and brass can also pose challenges due to their reflective surfaces.

Why is laser cutting popular in industries?

Laser cutting is popular because it offers unparalleled precision and speed. It reduces material waste and allows for complex designs. Industries like automotive and electronics rely on it for efficient production.

Can I use a laser cutting machine for personal projects?

Absolutely! Laser cutting machines are great for personal projects. You can create custom gifts, home decor, and educational models. The possibilities are endless, limited only by your creativity.

How do I maintain a laser cutting machine?

Regular maintenance is crucial. Clean the lenses and mirrors to ensure accuracy. Check the alignment of the laser beam and replace worn parts. Proper ventilation is also important to manage fumes.

What safety precautions should I take?

Always wear protective gear when operating a laser cutter. Ensure your workspace is well-ventilated to avoid inhaling fumes. Follow the manufacturer's safety guidelines to prevent accidents.

How can I improve my laser cutting projects?

Start by preparing your design carefully. Test material samples to find the best settings. Experiment with different materials and techniques to enhance your projects. Regular practice will improve your skills.

What are the creative possibilities with laser cutting?

Laser cutting offers endless creative possibilities. You can combine materials, experiment with textures, and customize designs. This technology empowers you to bring your ideas to life with precision and artistry.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding Laser Cutting Machines and Their Varieties

Comparative Guide to Laser Cutting Machine Prices