Why Laser Cutting Machines Are Vital for Makerspaces

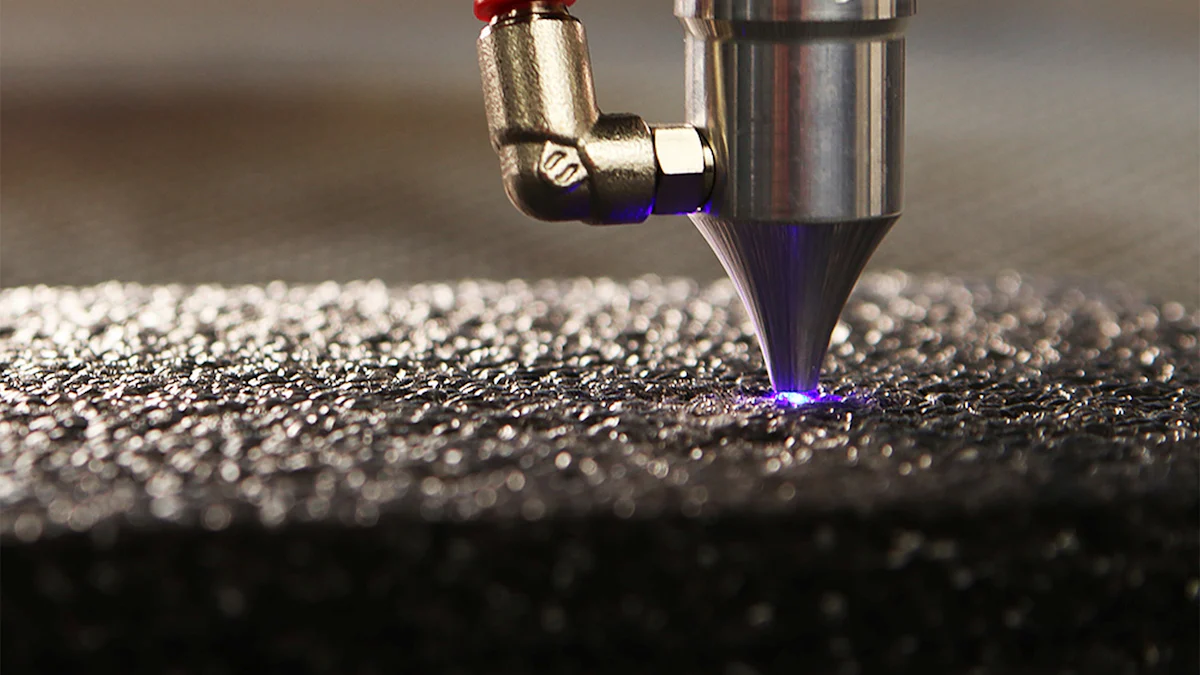

Step into any makerspace, and you’ll likely find laser cutting machines at the center of the action. These machines don’t just cut materials—they unlock possibilities. Whether you’re crafting intricate designs or building prototypes, their precision and versatility make them indispensable. You can work with wood, acrylic, fabric, or even metal, turning raw materials into something extraordinary. For makers, these tools fuel creativity and transform ideas into tangible results. Wondering what can I do with a laser cutting machine? The answer is simple: almost anything your imagination can dream up.

The Benefits of Laser Cutting Machines in Makerspaces

Laser cutting machines have become essential in any makerspace. They offer a combination of precision, speed, and versatility that traditional tools simply can’t match. Let’s explore how these machines elevate your projects and make your creative process smoother.

Precision and Accuracy

When it comes to precision cutting, laser cutting machines are unmatched. They allow you to create intricate designs with pinpoint accuracy, whether you’re working on a delicate artistic project or a detailed prototype. Unlike traditional cutting tools, which can leave rough edges or require manual adjustments, laser cutting machines deliver clean, precise results every time.

For example, if you’re designing a custom piece of jewelry or crafting a complex architectural model, the laser ensures every detail is flawless. This level of precision not only saves you time but also reduces material waste, making your projects more efficient and cost-effective.

“Laser cutting offers high precision and unlimited 2D complexity, making it ideal for makerspaces focused on innovation and creativity.”

Speed and Efficiency

Time is often a critical factor in any maker space, and laser cutting machines excel in this area. These machines work quickly, cutting through materials in a fraction of the time it would take with traditional tools. Whether you’re producing a single piece or multiple items, the speed of laser cutting machines helps you meet deadlines without compromising quality.

Another advantage is the elimination of post-processing. The clean cuts produced by lasers mean you won’t need to spend extra time sanding or finishing your pieces. This efficiency allows you to focus more on the creative aspects of your projects rather than the tedious manual labor.

Imagine you’re working on a batch of custom coasters for an event. With a laser cutting machine, you can cut and engrave multiple pieces simultaneously, ensuring consistency and saving hours of work.

Material Compatibility

One of the most exciting aspects of laser cutting machines is their ability to handle a wide range of materials. From wood and acrylic to fabric and metal, these versatile tools open up endless possibilities for makers. You can experiment with different materials to bring your ideas to life, whether you’re creating functional prototypes or decorative art pieces.

For instance, if you’re designing a product that combines wood and acrylic elements, a laser cutting machine can seamlessly cut both materials with precision. This flexibility makes it easier for you to innovate and push the boundaries of your creativity.

Additionally, laser cutting and engraving capabilities allow you to add intricate details to your projects, such as logos, patterns, or text. This feature is especially valuable for makers looking to personalize their work or create professional-grade products.

Ease of Use

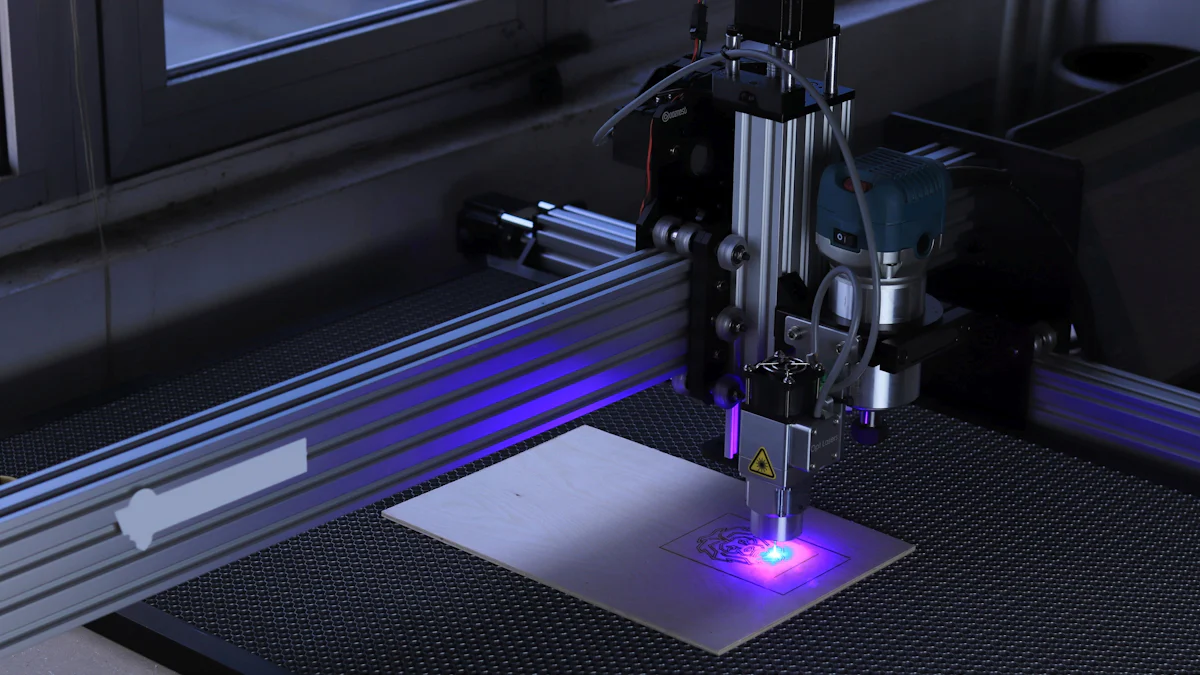

Laser cutting machines are surprisingly easy to use, even if you’re new to them. Their intuitive design and user-friendly software make the learning curve manageable for beginners while still offering advanced features for experienced makers. You don’t need to be a tech expert to get started—most machines come with straightforward instructions and pre-installed settings that guide you through the process.

Many laser cutting machines include software that allows you to upload your designs directly. You can create your artwork in programs like Adobe Illustrator or CorelDRAW, then send it to the machine with just a few clicks. The interface is often simple, letting you adjust settings like speed, power, and material type without hassle. This streamlined workflow saves time and reduces frustration, so you can focus on bringing your ideas to life.

“Laser cutting machines simplify complex tasks, making them accessible to creators of all skill levels.”

Another reason these machines are easy to use is their automation. Once you set up your design and material, the machine takes care of the rest. It follows your instructions with precision, eliminating the need for constant supervision. This hands-off approach lets you multitask or plan your next project while the machine works its magic.

For makerspaces, this ease of use is a game-changer. It encourages collaboration and learning because users can quickly grasp the basics and start experimenting. Whether you’re engraving a custom logo or cutting intricate shapes, the process feels seamless and rewarding. Plus, the ability to cut multiple pieces at once adds efficiency, making it easier to tackle larger projects.

If you’ve ever felt intimidated by high-tech tools, laser cutting machines will change your perspective. They’re designed to empower you, not overwhelm you. With a little practice, you’ll find yourself creating professional-quality results with minimal effort.

What Can I Do with a Laser Cutting Machine in a Makerspace?

Laser cutting machines are more than just tools—they’re gateways to endless possibilities. Whether you’re a hobbyist, an entrepreneur, or an educator, these machines can transform your ideas into reality. Let’s dive into some of the most exciting ways you can use them in a makerspace.

Prototyping and Product Development

If you’ve ever had an idea for a product, a laser cutting machine can help you bring it to life. These machines excel at creating prototypes with precision and speed. You can cut intricate shapes, engrave details, and experiment with different materials—all in one place. This makes them perfect for testing designs and refining concepts.

For example, imagine you’re designing a new gadget. You can use the laser cutter to create components from wood, acrylic, or even metal. The accuracy ensures that each piece fits perfectly, saving you time and reducing frustration. Plus, the ability to quickly iterate on your designs means you can move from concept to finished product faster than ever.

“Laser cutting machines streamline the prototyping process, allowing makers to focus on innovation and problem-solving.”

In a makerspace, this capability fosters collaboration. You can share your prototypes with others, gather feedback, and refine your ideas. Whether you’re working on a personal project or developing a product for market, laser cutting machines make the process efficient and enjoyable.

Artistic and Creative Projects

For those who love creative pursuits, laser cutting machines open up a world of artistic possibilities. These machines let you craft intricate designs that would be nearly impossible to achieve by hand. From decorative wall art to custom jewelry, the only limit is your imagination.

One popular use is creating personalized gifts. You can engrave names, quotes, or patterns onto materials like wood, glass, or leather. Whether it’s a custom keychain or a beautifully engraved photo frame, these projects add a personal touch that makes them truly special.

Another exciting option is experimenting with mixed media. You can combine materials like wood and acrylic to create unique pieces that stand out. For instance, you might design a layered artwork where each layer is cut from a different material. The precision of laser cutter designs ensures that every piece aligns perfectly, giving your project a professional finish.

“Laser cutting machines empower makers to explore their creativity and produce stunning, one-of-a-kind creations.”

In a makerspace, these artistic projects often inspire others. Seeing what someone else has created can spark new ideas and encourage collaboration. It’s a space where creativity thrives, and laser cutting machines play a big role in making that happen.

Educational and Collaborative Projects

Makerspaces are all about learning and sharing knowledge, and laser cutting machines are fantastic educational tools. They’re easy to use, making them accessible to beginners, yet powerful enough to challenge experienced users. This versatility makes them ideal for teaching design, engineering, and problem-solving skills.

For educators, laser cutting machines offer hands-on learning opportunities. Students can design their own projects, from simple shapes to complex models, and see their ideas come to life. This process not only teaches technical skills but also encourages critical thinking and creativity.

In a collaborative setting, these machines bring people together. Teams can work on group projects, combining their skills to create something amazing. For example, a group might design and build a scale model of a city, with each member contributing different elements. The laser cutter ensures that every piece fits seamlessly, making the project a success.

“Laser cutting machines in makerspaces promote teamwork, learning, and innovation, creating a vibrant community of makers.”

Whether you’re an educator, a student, or just someone who loves to learn, laser cutting machines make the process engaging and rewarding. They turn abstract concepts into tangible results, helping you understand and appreciate the power of design and technology.

Industry-Specific Applications

Laser cutting machines have revolutionized industries by offering unmatched precision, speed, and versatility. In a makerspace, these machines empower you to explore industry-specific applications that go beyond hobbyist projects. Whether you're crafting intricate designs or fabricating functional components, laser cutters open doors to professional-grade results.

Jewelry Design and Manufacturing

If you’re passionate about creating custom jewelry, laser cutting machines are your ultimate tool. They allow you to cut and engrave delicate materials like metal, acrylic, and wood with incredible accuracy. You can design intricate patterns for earrings, pendants, or bracelets that would be nearly impossible to achieve by hand. The precision ensures every piece looks polished and professional, making it perfect for small-scale production or personalized gifts.

For example, imagine designing a pair of earrings with layered geometric shapes. A laser cutter can handle the fine details, ensuring each layer aligns perfectly. This capability not only saves time but also elevates the quality of your creations, helping you stand out in the competitive jewelry market.

“Laser cutting machines bring your jewelry designs to life with precision and efficiency, making them ideal for both beginners and professionals.”

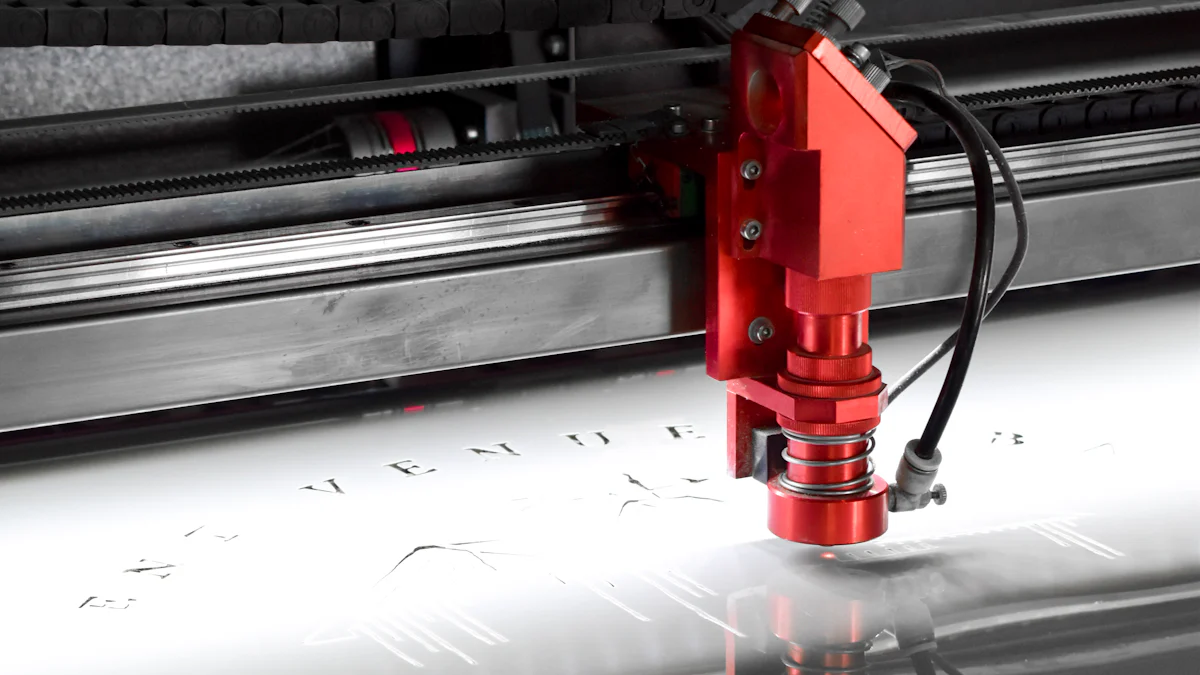

Signage and Displays

In industries like retail and events, signage plays a crucial role in grabbing attention. Laser cutting machines excel at producing high-quality signs and displays. You can cut letters, logos, or intricate patterns from materials like acrylic, wood, or metal. The clean edges and sharp details make your designs look professional and visually appealing.

For instance, if you’re working on a project for a local business, you can create a custom sign with their logo engraved on wood or acrylic. The laser cutter ensures every detail is crisp, giving the final product a polished look. This application is especially valuable in a makerspace, where collaboration and creativity thrive.

Industrial Machinery Components

Laser cutting machines aren’t just for creative projects—they’re also essential in manufacturing. Industries rely on these machines to fabricate components like gears, brackets, and frames. The precision and speed of laser technology streamline production, reducing material waste and improving efficiency.

In a makerspace, you can experiment with creating functional parts for machinery or robotics. For example, you might design and cut a metal bracket for a mechanical project. The laser cutter ensures the dimensions are exact, so the part fits seamlessly into your design. This hands-on experience helps you understand industrial applications while honing your technical skills.

Prototyping for Electronics

Electronics require precise components, and laser cutting machines deliver just that. You can use them to create circuit boards, enclosures, or intricate parts for gadgets. The ability to work with various materials, including plastics and metals, makes laser cutters invaluable for prototyping.

Imagine you’re developing a new gadget in a makerspace. You can design and cut a custom enclosure that fits your circuit board perfectly. The laser cutter’s accuracy ensures all ports and buttons align correctly, giving your prototype a professional finish. This capability accelerates the development process, allowing you to focus on refining your ideas.

Fashion and Textiles

The fashion industry has embraced laser cutting for its ability to create intricate patterns on fabrics. In a makerspace, you can experiment with cutting or engraving textiles to design unique clothing, accessories, or home décor items. For example, you might use a laser cutter to create a detailed lace pattern on fabric for a dress or scarf.

This application isn’t limited to professionals. Even if you’re a beginner, laser cutting machines make it easy to explore fashion design. The user-friendly software lets you upload your designs and adjust settings for different materials, so you can bring your vision to life with minimal effort.

“From custom jewelry to industrial components, laser cutting machines adapt to a wide range of industries, making them indispensable tools in any makerspace.”

How Laser Cutting Machines Empower Makers

Supporting Small Business Opportunities

Laser cutting machines open doors for small business ventures, giving you the tools to turn creative ideas into profitable products. Whether you're crafting custom jewelry, personalized gifts, or intricate home décor, these machines let you produce high-quality items with precision and speed. For example, you could design leather keychains engraved with names or create laser-cut wedding invitations that stand out with their intricate details. These unique offerings can help you carve out a niche in competitive markets.

The versatility of laser cutters also allows you to experiment with different materials like wood, acrylic, and fabric. This flexibility means you can diversify your product line without needing additional equipment. Imagine starting with custom coasters and expanding into signage or decorative wall art. Each project becomes an opportunity to grow your skills and your business.

For makerspaces, this capability fosters entrepreneurship. You can test product ideas, refine designs, and even produce small batches for sale. The low cost of materials and the efficiency of laser cutting make it easier to take the leap into small business ownership. With the right training and a bit of creativity, you can transform your passion into a thriving venture.

“Laser cutting machines empower makers to explore business opportunities, turning hobbies into income-generating ventures.”

Encouraging Design Thinking

Laser cutting machines are more than just tools—they’re catalysts for innovation. They encourage you to think critically and creatively, solving problems through design thinking. This process involves brainstorming, prototyping, and refining ideas, all of which are made easier with the precision and versatility of laser cutters.

For instance, imagine you’re designing a 3D object like a storage box. You can use the machine to cut precise interlocking pieces, test the assembly, and adjust the design as needed. This hands-on approach helps you understand how different elements work together, improving your problem-solving skills.

Laser cutters also inspire you to push boundaries. You might start with simple projects like engraved greeting cards and progress to more complex creations like layered artwork or functional prototypes. Each project challenges you to think outside the box, fostering a mindset of continuous learning and improvement.

In a makerspace, this culture of design thinking thrives. Collaborating with others exposes you to new ideas and techniques, sparking innovation. Whether you’re working on personal projects or group endeavors, laser cutting machines make the creative process more accessible and rewarding.

“Design thinking transforms challenges into opportunities, and laser cutting machines provide the perfect platform for this creative journey.”

Skill Development and Learning

Using a laser cutting machine is a hands-on learning experience that builds valuable skills. From operating the machine to mastering design software, you gain technical expertise that can be applied to various fields. These skills are not only useful for personal projects but also highly sought after in industries like manufacturing, fashion, and product design.

For beginners, laser cutters offer an approachable way to learn. The user-friendly software and intuitive controls make it easy to get started, even if you’ve never used similar tools before. As you gain confidence, you can tackle more advanced projects, exploring new techniques and materials.

In a makerspace, the learning doesn’t stop with the machine. You’ll have the opportunity to collaborate with others, share knowledge, and participate in workshops or training sessions. This community-driven environment accelerates your growth, helping you develop both technical and creative skills.

Imagine working on a group project to create a scale model of a city. You might focus on designing intricate buildings while others handle landscaping or assembly. This collaborative effort not only enhances your skills but also teaches you the value of teamwork and communication.

“Laser cutting machines turn every project into a training ground, helping makers build skills that last a lifetime.”

Accessibility and Safety of Laser Cutting Machines

Laser cutting machines have become more accessible than ever, making them a staple in makerspaces worldwide. Their design prioritizes ease of use, safety, and affordability, ensuring that anyone can harness their potential. Let’s explore how these machines balance user-friendly features, safety, and maintenance to provide seamless access to technology.

User-Friendly Features

Modern laser cutting machines are designed with you in mind. They simplify complex tasks, allowing you to focus on creativity rather than technical hurdles. Most machines come with intuitive software that lets you upload designs directly from popular programs like Adobe Illustrator or CorelDRAW. You can adjust settings such as speed and power with just a few clicks, making the process straightforward even for beginners.

Many machines also include pre-set configurations for different materials. Whether you’re working with wood, acrylic, or fabric, you can select the appropriate setting and start cutting without guesswork. This feature ensures consistent results and reduces the learning curve.

Another standout feature is automation. Once you set up your design, the machine takes over, executing your instructions with precision. You don’t need to monitor every step, freeing you to plan your next project or collaborate with others in the makerspace. This hands-off approach makes laser cutting machines accessible to users of all skill levels.

“The simplicity of laser cutting machines ensures that everyone, from hobbyists to professionals, can access their full potential.”

Safety Considerations

Safety is a top priority when using laser cutting machines. Manufacturers incorporate multiple features to protect you while operating these powerful tools. For instance, many machines include enclosed designs that prevent accidental exposure to the laser beam. This enclosure also contains fumes and debris, keeping the workspace clean and safe.

Some models come with built-in ventilation systems to remove harmful fumes generated during cutting. These systems improve air quality, especially when working with materials like acrylic or leather. Additionally, safety sensors automatically shut down the machine if the enclosure is opened during operation, reducing the risk of accidents.

You should always wear protective eyewear when working with open-frame laser cutters. Even with built-in safety features, following best practices ensures a secure environment. Makerspaces often provide training sessions to teach proper handling and maintenance, empowering you to use the machines confidently.

“Laser cutting machines combine advanced safety features with proper training, creating a secure and user-friendly experience.”

Cost and Maintenance

Laser cutting machines offer a balance between performance and affordability, making them an excellent investment for makerspaces. Entry-level models provide reliable functionality at a reasonable price, giving you access to technology without breaking the bank. For those seeking advanced features, mid-range and high-end models deliver enhanced capabilities while remaining cost-effective for group use.

Maintenance is straightforward, ensuring long-term usability. Regular cleaning of the laser lens and mirrors keeps the machine running efficiently. Many machines include self-diagnostic tools that alert you to potential issues, simplifying troubleshooting. Replacing consumables like laser tubes or filters is infrequent and manageable, especially when shared among makerspace members.

The durability of these machines further reduces costs. With proper care, a laser cutter can last for years, providing consistent performance for countless projects. This longevity makes them a valuable addition to any makerspace, offering both creative freedom and financial practicality.

“Affordable pricing and low maintenance make laser cutting machines a smart choice for makerspaces looking to maximize value.”

The Role of Laser Cutting Machines in Fostering Innovation

Bridging the Gap Between Ideas and Reality

Laser cutting machines act as a bridge between your imagination and the physical world. They take your ideas—whether sketched on paper or designed digitally—and transform them into tangible creations with unmatched precision. This ability to turn concepts into reality fuels innovation, allowing you to experiment, iterate, and refine your designs quickly.

For example, imagine you’ve come up with a new product idea. With a laser cutter, you can prototype it in hours instead of days. You can test different materials like wood, acrylic, or metal to see what works best. The accuracy of the machine ensures that every detail of your design is replicated perfectly, giving you confidence in your final product. As JQ Laser, a leader in technology, explains, “Laser cutters use a focused beam of light to cut through materials, meaning that any shape or design can be accurately replicated on different types of material.” This precision eliminates guesswork and reduces waste, making the process efficient and cost-effective.

The speed of laser cutting also plays a crucial role. Traditional methods often require extensive manual labor, but laser cutters streamline the process. You can focus on refining your ideas instead of spending time on tedious tasks. This efficiency not only saves time but also encourages you to push boundaries and explore more complex designs. Whether you’re crafting a prototype for a new gadget or creating intricate artwork, laser cutting machines make the journey from concept to creation seamless.

“Laser cutting machines streamline the prototyping process, allowing makers to focus on innovation and problem-solving.”

Building Community and Collaboration

Makerspaces thrive on collaboration, and laser cutting machines play a central role in fostering a sense of community. These tools bring people together, encouraging them to share ideas, learn from one another, and work on projects collectively. Whether you’re a seasoned maker or a beginner, the shared experience of using a laser cutter creates opportunities for connection and growth.

In a makerspace, you’ll often find groups of creative individuals gathered around a laser cutter, brainstorming and experimenting. This collaborative environment sparks innovation as members combine their unique skills and perspectives. For instance, one person might excel at designing intricate patterns, while another has expertise in material selection. Together, they can create something truly extraordinary. As HF Laser, an expert in manufacturing, highlights, “Laser cutting machines have become essential tools for creating high-quality products efficiently and accurately.” This efficiency allows teams to focus on creativity and problem-solving rather than technical challenges.

Laser cutters also make it easier to involve the broader community in makerspace activities. Workshops and demonstrations centered around these machines attract people of all ages and skill levels. Participants can see their designs come to life, inspiring them to explore their own ideas. This inclusivity strengthens the makerspace community, turning it into a hub for innovation and learning.

“Laser cutting machines in makerspaces promote teamwork, learning, and innovation, creating a vibrant community of makers.”

By fostering collaboration, laser cutting machines help build a supportive environment where everyone feels empowered to contribute. They transform makerspaces into places where ideas flourish, skills grow, and connections deepen. Whether you’re working on a solo project or teaming up with others, the sense of community amplifies the joy of creating.

Future Trends in Laser Cutting for Makerspaces

The world of laser cutting is evolving rapidly, and makerspaces are at the forefront of this transformation. As technology advances and accessibility improves, these machines are becoming even more indispensable for creators like you. Let’s explore the exciting trends shaping the future of laser cutting in makerspaces.

Advancements in Technology

Laser cutting technology is advancing at an incredible pace, bringing new possibilities to modern manufacturing and makerspaces alike. One of the most significant developments is the integration of AI-powered systems. These systems can analyze your designs, optimize cutting paths, and even suggest improvements, making the process faster and more efficient. Imagine uploading a design and having the machine fine-tune it for the best results—saving you time and reducing material waste.

Another exciting innovation is the rise of multi-functional laser machines. These machines combine cutting, engraving, and even 3D printing capabilities into a single device. With one tool, you can cut intricate shapes, engrave detailed patterns, and add three-dimensional elements to your projects. This versatility allows you to experiment with new techniques and push the boundaries of your creativity.

The materials you can work with are also expanding. Modern laser cutters are now capable of handling advanced materials like carbon fiber, composites, and even certain types of ceramics. This opens up opportunities for creating more durable and innovative products. Whether you’re prototyping a gadget or crafting a piece of art, these advancements ensure you have the tools to bring your vision to life.

“The integration of AI and multi-functional capabilities is revolutionizing modern manufacturing, making laser cutting machines smarter and more versatile than ever.”

Finally, the precision of laser cutting continues to improve. Enhanced beam control and higher-resolution optics allow for even finer details, enabling you to create designs that were once impossible. Whether you’re working on a delicate jewelry piece or a complex industrial component, these advancements ensure flawless results every time.

Expanding Accessibility

As technology improves, laser cutting machines are becoming more accessible to makerspaces and individual creators. Manufacturers are focusing on creating compact, affordable models that fit smaller budgets without compromising on quality. This means you no longer need a massive investment to access professional-grade tools. Entry-level machines now offer impressive features, making them perfect for hobbyists and small-scale projects.

Cloud-based software is another game-changer. Many modern laser cutters now connect to cloud platforms, allowing you to store designs, access templates, and even collaborate with others remotely. This feature makes it easier than ever to share ideas and work on group projects, even if you’re not physically in the same space. For makerspaces, this connectivity fosters a sense of community and encourages collaboration among members.

Safety features are also improving, making these machines more user-friendly for beginners. Innovations like enclosed designs, automatic shut-offs, and built-in ventilation systems ensure a safer working environment. You can focus on your creativity without worrying about complex safety protocols.

“The growing affordability and enhanced safety of laser cutting machines are making modern manufacturing tools accessible to everyone, from hobbyists to professionals.”

Lastly, educational resources are expanding. Online tutorials, virtual workshops, and user-friendly manuals make it easier to learn how to use laser cutters effectively. Whether you’re a student, an educator, or a curious maker, these resources empower you to master the technology and unlock its full potential.

The future of laser cutting in makerspaces is bright. With cutting-edge technology and increasing accessibility, these machines are set to revolutionize modern manufacturing and creative spaces alike. Whether you’re a seasoned maker or just starting out, the opportunities are endless.

Laser cutting machines have become essential tools in every makerspace. They offer unmatched precision and versatility, allowing you to make designs come to life with ease. Whether you're working on personal projects, educational activities, or small business ventures, these machines empower you to innovate and grow. Their ability to handle diverse materials and deliver clean, accurate results makes them a cornerstone of modern maker spaces. As technology evolves, laser cutting machines will continue to drive creativity and shape the future of the maker movement. Dive into the possibilities and unlock your potential today.

FAQ

What is a laser cutting machine, and how does it work?

A laser cutting machine uses a focused beam of light to cut or engrave materials with precision. The laser heats the material to its melting or vaporization point, creating clean and accurate cuts. You can control the machine through design software, where you upload your patterns or shapes. Once the design is set, the laser follows the programmed path to bring your ideas to life.

Laser cutting machines are perfect for makerspaces because they simplify complex tasks, making them accessible to everyone.

What materials can I use with a laser cutting machine?

Laser cutting machines work with a wide range of materials, including wood, acrylic, fabric, leather, and even certain metals. Some advanced models can handle materials like carbon fiber or composites. Always check your machine’s specifications to ensure compatibility with the material you want to use. This versatility makes laser cutters ideal for diverse projects in a makerspace.

Are laser cutting machines safe to use?

Yes, modern laser cutting machines come with built-in safety features. Many models have enclosed designs to prevent exposure to the laser beam and contain fumes or debris. Machines often include ventilation systems to improve air quality and sensors that shut down the laser if the enclosure is opened. By following safety guidelines and wearing protective eyewear when necessary, you can use these machines confidently in any makerspace.

How much does a laser cutting machine cost?

The cost of a laser cutting machine varies based on its features and capabilities. Entry-level models start at a few hundred dollars, making them affordable for hobbyists or small makerspaces. Mid-range machines with advanced features can cost several thousand dollars, while industrial-grade models may go higher. Makerspaces often invest in mid-range machines to balance performance and affordability.

Do I need special skills to use a laser cutting machine?

No, you don’t need special skills to get started. Laser cutting machines are designed to be user-friendly, with intuitive software and pre-set configurations for different materials. Beginners can quickly learn the basics, while experienced users can explore advanced features. Makerspaces often provide training sessions or workshops to help you master the machine.

How do laser cutting machines support innovation in makerspaces?

Laser cutting machines bridge the gap between ideas and reality. They allow you to prototype, experiment, and refine your designs with speed and precision. Whether you’re crafting a product, creating art, or solving a problem, these machines make the process efficient and enjoyable. In a makerspace, they also foster collaboration, as members share ideas and work together on projects.

What are the maintenance requirements for a laser cutting machine?

Maintaining a laser cutting machine is straightforward. Regularly clean the laser lens and mirrors to ensure optimal performance. Check and replace consumables like filters or laser tubes as needed. Many machines include diagnostic tools to alert you to potential issues. With proper care, a laser cutter can last for years, making it a valuable addition to any makerspace.

Can I use a laser cutting machine for business purposes?

Absolutely! Laser cutting machines are excellent for small business ventures. You can create custom products like engraved gifts, jewelry, or signage. Their precision and speed allow you to produce high-quality items efficiently. Makerspaces often serve as incubators for entrepreneurs, providing access to laser cutters and other tools to test and develop business ideas.

What are the future trends in laser cutting technology?

The future of laser cutting includes advancements in automation, energy efficiency, and material compatibility. AI-powered systems will optimize cutting paths and suggest design improvements. Multi-functional machines that combine cutting, engraving, and 3D printing are becoming more common. These innovations will make laser cutting even more versatile and accessible, especially in makerspaces.

Why are laser cutting machines essential for makerspaces?

Laser cutting machines empower makerspaces by offering unmatched precision, versatility, and efficiency. They handle diverse materials, simplify complex tasks, and encourage creativity. Whether you’re a beginner or an expert, these machines help you turn ideas into reality. Their ability to foster collaboration and innovation makes them a cornerstone of any makerspace.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Understanding Laser Cutting Machines and Their Varieties

The Role of Laser Cutting Machines in Manufacturing