What Can You Do With a Laser Engraving Machine

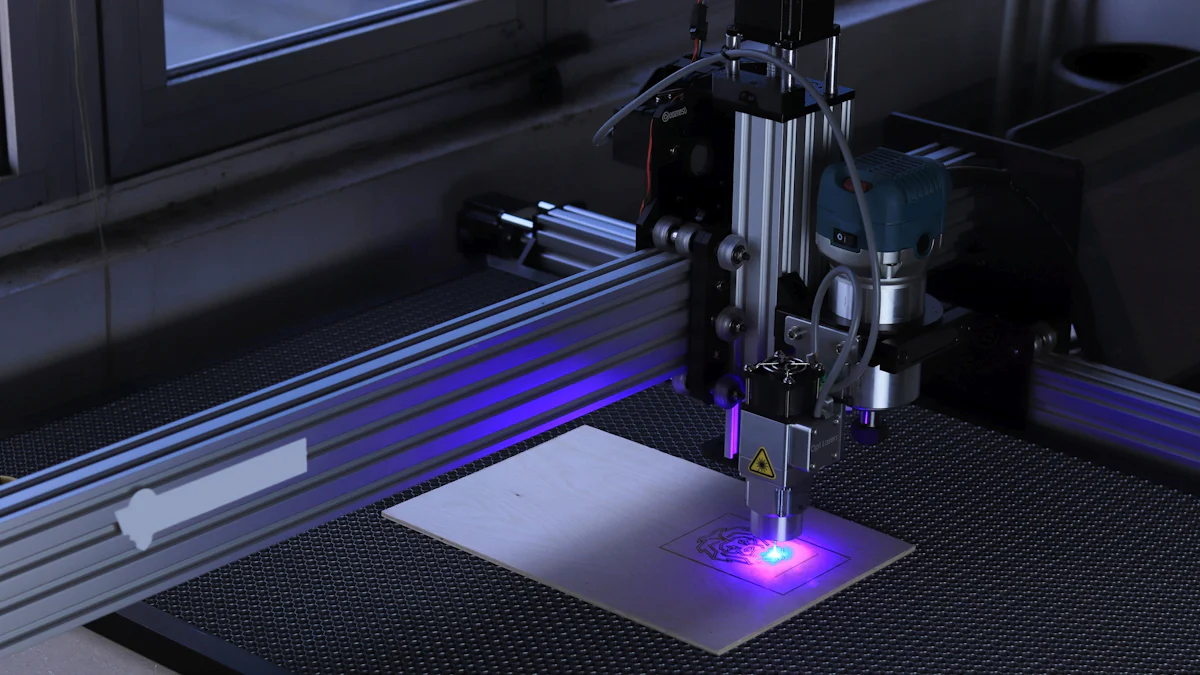

A laser engraving cutting machine is more than just a tool; it’s a gateway to precision and creativity. You can transform ordinary materials like wood, metal, glass, and acrylic into personalized masterpieces or functional items. So, what can you do with a laser engraving cutting machine? Whether you’re crafting custom gifts, designing intricate art, or managing inventory with traceable markings, laser engraving opens up endless possibilities. The versatility of laser engraving and cutting machines allows you to work with diverse materials while maintaining exceptional detail and quality. With laser engraving technology, you can bring your ideas to life and explore new ways to innovate and create.

Personal and Creative Projects with a Laser Engraving Machine

Laser engraving machines are perfect for bringing your creative ideas to life. Whether you’re crafting unique gifts or designing intricate art, these machines offer endless possibilities. Let’s explore some exciting ways you can use a laser engraving machine for personal and creative projects.

Custom Jewelry and Accessories

Imagine creating one-of-a-kind jewelry pieces that reflect your style or make the perfect gift. With a laser engraving machine, you can design custom necklaces, bracelets, earrings, and more. Materials like wood, acrylic, metal, and leather work beautifully for these projects. You can engrave names, meaningful dates, or intricate patterns to make each piece truly special.

For example, during the holiday season, personalized jewelry becomes a highly sought-after gift. A laser engraving machine allows you to craft these items with precision and detail, making them stand out. Whether you’re making jewelry for yourself, loved ones, or even starting a small business, this is one of the most popular and rewarding uses of laser engraving.

Home Decor and Art

Transform your living space with custom home decor and artistic creations. Laser engraving machines let you add a personal touch to everyday items like coasters, picture frames, and wall art. You can engrave quotes, designs, or even detailed images onto materials like wood, glass, or acrylic.

For art enthusiasts, laser engraving opens up new possibilities. You can create intricate patterns or replicate your digital designs with incredible accuracy. Whether it’s a decorative sign for your home or a unique piece of art to display, laser engraving helps you turn your vision into reality.

DIY Hobbies and Crafts

If you love DIY projects, a laser engraving machine is your ultimate tool. It’s perfect for crafting personalized gifts, custom keychains, or even intricate puzzles. You can experiment with different materials and techniques to bring your ideas to life.

Looking for inspiration? Try exploring laser engraving ideas online or in crafting communities. Many hobbyists use laser engraving machines to create memorable keepsakes or practical items like engraved cutting boards and bookmarks. The versatility of these machines makes them ideal for any creative project you can imagine.

From jewelry to home decor and DIY crafts, laser engraving machines empower you to express your creativity in countless ways. They’re not just tools—they’re gateways to turning your ideas into tangible, beautiful creations.

Business and Industrial Applications of Laser Engraving

A laser engraving machine isn’t just for creative projects—it’s a game-changer for businesses and industries. Whether you’re looking to enhance your brand, streamline production, or expand your product offerings, laser engraving can help you achieve your goals with precision and efficiency. Let’s dive into how this technology can transform your business.

Branding and Marketing

Your brand’s identity is everything, and laser engraving offers a unique way to make it unforgettable. You can create custom-branded items like promotional products, corporate gifts, or even packaging that leaves a lasting impression. Engraving your logo or tagline onto materials like metal, wood, or acrylic adds a touch of sophistication and professionalism.

For example, imagine handing out engraved pens, keychains, or notebooks at a trade show. These items not only promote your business but also showcase your attention to detail and commitment to quality. Laser engraving machines allow you to produce these items quickly and consistently, making them ideal for bulk orders. Compared to traditional methods, laser engraving provides faster turnaround times and ensures every piece looks flawless.

“Laser engraving enhances production efficiency, precision, and customization ability compared to traditional methods.”

By incorporating laser engraving into your marketing strategy, you can elevate your brand and stand out in a crowded marketplace.

Manufacturing and Prototyping

In manufacturing, precision and speed are critical. A laser engraving machine excels in both areas, making it an invaluable tool for creating prototypes, marking parts, or even cutting components. Whether you’re working with metal, plastic, or other materials, laser engraving ensures consistent results with minimal waste.

For prototyping, laser engraving allows you to test designs and make adjustments quickly. This flexibility can save you time and money during the development process. In industrial settings, you can use laser engraving to mark serial numbers, barcodes, or QR codes on products. These markings improve traceability and help protect intellectual property.

Compared to traditional methods, laser engraving reduces setup time and works with a wider variety of materials. It’s also more reliable and efficient, especially for mass production. If you’re looking to optimize your manufacturing process, a laser engraving machine is a smart investment.

Retail and E-commerce

If you run a retail or e-commerce business, laser engraving opens up endless possibilities for product customization. Personalized items are in high demand, and a laser engraving machine lets you meet this demand with ease. From engraved jewelry to custom phone cases, you can offer unique products that attract customers and boost sales.

Customization doesn’t just add value—it creates an emotional connection with your customers. For instance, an engraved cutting board with a family name or a personalized tumbler makes a thoughtful gift. These kinds of products often command higher prices, increasing your profit margins.

In e-commerce, speed and efficiency are crucial. Laser engraving machines allow you to fulfill orders quickly without compromising on quality. You can also experiment with new product ideas and expand your inventory without significant upfront costs. This versatility makes laser engraving an excellent choice for entrepreneurs looking to grow their businesses.

“Laser engraving machines offer faster customization ability, precision, efficiency, and long-lasting results compared to traditional methods.”

By integrating laser engraving into your retail or e-commerce operations, you can stay ahead of trends and deliver products that customers love.

Laser engraving isn’t just a tool—it’s a competitive advantage. Whether you’re building your brand, improving manufacturing processes, or expanding your product line, a laser engraving machine can help you achieve your business goals with unmatched precision and efficiency.

Material-Specific Uses of a Laser Engraving Machine

A laser engraving machine is a versatile tool that works wonders on various materials. Each material offers unique possibilities, allowing you to create stunning designs, functional items, and personalized products. Let’s explore how you can use laser engraving to transform wood, metal, and glass into something extraordinary.

Wood

Wood is one of the most popular materials for laser engraving. Its natural texture and versatility make it perfect for creating both decorative and functional items. With a laser engraving machine, you can craft intricate patterns, detailed images, or even text with remarkable precision.

Here are some ideas for working with wood:

- Custom Wall Art: Design personalized signs, decorative panels, or unique artwork for homes and offices. Engraving quotes, family names, or intricate designs adds a personal touch.

- Personalized Gifts: Create engraved cutting boards, coasters, or photo frames. These make thoughtful gifts for weddings, anniversaries, or housewarming events.

- DIY Projects: Use laser engraving to enhance your woodworking projects. Add fine details to furniture, boxes, or ornaments to elevate their appeal.

For example, you could design wooden lantern centerpieces with intricate patterns and engrave names or dates for special occasions. The precision of laser engraving ensures every detail stands out beautifully.

Metal

Metal engraving takes customization to a whole new level. A laser engraving machine can etch text, logos, or designs onto metal surfaces with unmatched accuracy. This makes it ideal for both personal and industrial applications.

Here’s how you can use laser engraving on metal:

- Jewelry and Accessories: Personalize bracelets, necklaces, or keychains with names, dates, or meaningful symbols. Metal engraving adds a sleek and professional finish.

- Industrial Markings: Engrave serial numbers, barcodes, or QR codes on tools, machinery, or parts. These markings improve traceability and ensure compliance with industry standards.

- Corporate Gifts: Create branded items like engraved pens, business card holders, or trophies. These make excellent promotional products or employee recognition awards.

Laser engraving on metal is not just about aesthetics. It also provides durability, ensuring that the engraved details remain intact over time. Whether you’re crafting a keepsake or marking industrial components, metal engraving delivers exceptional results.

Glass

Glass engraving offers a sophisticated way to create elegant designs and personalized items. A laser engraving machine can etch delicate patterns or text onto glass surfaces without causing cracks or damage.

Here are some creative uses for glass engraving:

- Custom Drinkware: Personalize wine glasses, beer mugs, or tumblers with names, monograms, or special messages. These make great gifts for weddings, birthdays, or corporate events.

- Decorative Pieces: Design etched vases, candle holders, or ornaments. The frosted effect created by laser engraving adds a touch of elegance to any item.

- Awards and Plaques: Create stunning acrylic or glass awards with engraved text and logos. These are perfect for recognizing achievements in corporate or academic settings.

For instance, you could craft customized information engraving on glass awards, combining text and intricate designs to create a professional and polished look. The precision of laser engraving ensures every detail is sharp and clear.

By understanding the unique characteristics of each material, you can unlock the full potential of your laser engraving machine. Whether you’re working with wood, metal, or glass, the possibilities are endless. Experiment with different designs and techniques to create items that are not only functional but also visually stunning.

Acrylic and Plastics

Acrylic and plastics offer incredible versatility when used with a laser engraving machine. These materials are lightweight, durable, and available in various colors and finishes, making them ideal for both creative and practical projects. Whether you're crafting personalized items or producing professional-grade products, acrylic and plastics can help you achieve stunning results.

Why Choose Acrylic and Plastics?

Acrylic, often referred to as plexiglass, is a popular choice for laser engraving due to its smooth surface and ability to produce crisp, clean designs. Plastics, on the other hand, come in many forms, such as ABS, polycarbonate, and PETG, each offering unique properties for different applications. Both materials are easy to work with and respond well to the precision of laser engraving.

Here are some reasons to consider these materials:

- Durability: Acrylic and plastics resist wear and tear, ensuring your engraved designs last for years.

- Versatility: They can be used for decorative, functional, or industrial purposes.

- Customization: Laser engraving allows you to create intricate patterns, detailed text, or logos with ease.

Creative Uses for Acrylic and Plastics

A laser engraving machine can transform acrylic and plastics into eye-catching creations. Here are some ideas to inspire you:

- Awards and Trophies: Engrave text, logos, or intricate designs onto acrylic plaques or blocks. These make elegant awards for corporate events, sports competitions, or academic achievements. The clear and polished finish of acrylic adds a professional touch.

- Custom Signage: Design unique signs for businesses, weddings, or home decor. Laser engraving ensures sharp details and precise cuts, making your signage stand out.

- Decorative Items: Create personalized ornaments, coasters, or decorative panels. You can experiment with different shapes and designs to match any theme or occasion.

For example, you could craft acrylic awards with engraved names and logos, combining functionality with a sleek, modern aesthetic. The precision of laser engraving ensures every detail is flawless.

Practical Applications in Business and Industry

Acrylic and plastics aren't just for creative projects—they're also valuable in business and industrial settings. Laser engraving machines excel at producing high-quality, customized products quickly and efficiently.

Here are some practical applications:

- Product Labels: Engrave logos, serial numbers, or barcodes onto plastic components. This improves traceability and ensures compliance with industry standards.

- Prototyping: Use laser engraving to test designs on acrylic or plastic sheets. This allows you to refine your ideas before moving to mass production.

- Retail Displays: Design custom acrylic stands, holders, or display cases. These add a polished look to your products and enhance their presentation.

"Laser engraving machines enable industries to customize information on manufactured products, providing unmatched precision and efficiency."

Tips for Working with Acrylic and Plastics

To get the best results, keep these tips in mind:

- Choose the Right Settings: Adjust the laser power and speed based on the thickness and type of material.

- Use Masking Tape: Apply masking tape to the surface to prevent scorch marks during engraving.

- Experiment with Designs: Test different patterns and techniques to see how the material reacts.

Acrylic and plastics open up endless possibilities for creativity and functionality. With a laser engraving machine, you can bring your ideas to life and create products that are both beautiful and durable.

Buying Guide: How to Choose a Laser Engraving Machine

Choosing the right laser engraving machine can feel overwhelming, especially with so many options available. Whether you're a hobbyist looking for the best laser engraver for beginners or a professional seeking an ideal laser engraving machine for your business, this buying guide will help you make an informed decision. Let’s break it down step by step.

Define Your Niche and Needs

The first step in selecting a laser engraving machine is understanding your specific needs. Are you planning to create custom jewelry, personalized gifts, or industrial prototypes? Defining your niche will help you narrow down your options. For example:

- If you're a hobbyist, a beginner laser engraver with basic features might be sufficient.

- For business use, you may need a machine with higher precision and production capacity.

Think about the materials you’ll work with most often. Wood, acrylic, metal, and glass each require different capabilities. For instance, a CO2 laser engraving machine works well for wood and acrylic, while fiber laser engravers are better suited for metals. Knowing your niche ensures you choose the right laser engraving machine for your projects.

“Understanding your niche is one of the most important things to know before buying a laser engraving machine.”

Consider Material Size and Machine Dimensions

The size of the materials you plan to engrave plays a big role in your decision. Laser engraving machines come in various sizes, from compact desktop models to larger industrial units. Ask yourself:

- Will you work on small items like keychains or larger pieces like signage?

- Do you have enough workspace to accommodate a bigger machine?

For smaller projects, a compact machine is the best budget option. However, if you need to engrave larger materials, invest in a machine with a spacious work area. Keep in mind that larger machines often come with a higher price, so balance your needs with your budget.

Understand Laser Types (CO2 vs. Fiber Lasers)

When it comes to laser engraving, understanding the types of laser is crucial. The two most common options are CO2 and fiber lasers, each suited for different applications:

- CO2 Laser Engraving Machine: Ideal for non-metal materials like wood, acrylic, and plastics. These machines are versatile and widely used for creative projects and small businesses.

- Fiber Laser Engravers: Designed for metal engraving, these machines offer unmatched precision and durability. They’re perfect for industrial applications and marking tools or machinery.

If you’re unsure which type to choose, think about the materials you’ll use most frequently. A CO2 laser engraving machine is a great all-around choice, while fiber laser engravers are better for specialized tasks. Understanding these differences will help you avoid overspending on features you don’t need.

By following this buying guide, you can confidently navigate the process of how to choose a laser engraving machine. Define your niche, consider the size of your materials, and understand the types of laser available. Whether you’re looking for the best laser engraver for beginners or a professional-grade machine, these steps will ensure you make the right investment. Remember, the right machine isn’t just about price—it’s about finding the perfect fit for your needs and ideas.

Evaluate Laser Wattage and Production Volume

Choosing the right laser wattage is essential for achieving the results you want with your laser engraving machine. Wattage determines the power of the laser, which directly affects its ability to cut or engrave different materials. Higher wattage provides more cutting power and faster engraving speeds, while lower wattage offers precision for delicate designs.

If you plan to work with materials like wood or acrylic, a machine with 40–60 watts is often sufficient. For tougher materials like metal, you’ll need a higher-wattage machine, typically 100 watts or more. Consider the types of projects you’ll handle most frequently. For example, engraving intricate patterns on acrylic awards requires precision, while cutting thicker materials like wood demands more power.

Production volume is another critical factor. If you’re running a business, you’ll need a laser engraving machine that can handle high workloads without compromising quality. Machines designed for industrial use often feature higher wattage and larger work areas, making them ideal for mass production. On the other hand, hobbyists or small-scale creators may find a lower-wattage machine more cost-effective and easier to manage.

“Higher wattage ensures faster engraving and cutting, while lower wattage offers greater control for detailed designs.”

Evaluate your typical project size and frequency to find the perfect balance between power and efficiency. This step ensures your machine meets your production needs without unnecessary costs.

Check Software Compatibility and Support Options

The software you use with your laser engraving machine plays a huge role in your overall experience. Reliable software simplifies the design process and ensures smooth communication between your computer and the machine. Before purchasing, check if the machine is compatible with popular software like LightBurn or CorelDRAW. These programs offer user-friendly interfaces and advanced features for creating detailed designs.

Some machines come with proprietary software, which may limit your flexibility. Ensure the software supports the file formats you commonly use, such as SVG, DXF, or AI. Compatibility with your operating system—Windows, macOS, or Linux—is equally important.

Customer support and training resources are also vital. Look for manufacturers that provide comprehensive guides, tutorials, or even live support. A responsive support team can save you time and frustration when troubleshooting issues. Many companies also offer warranties, which add an extra layer of security for your investment.

“Good software compatibility and reliable customer support can significantly enhance your laser engraving experience.”

By choosing a machine with robust software and strong support options, you’ll set yourself up for success, whether you’re a beginner or a seasoned professional.

Budgeting for Your Laser Engraving Machine

Your budget will ultimately determine the type of laser engraving machine you can afford. Prices vary widely, from a few hundred dollars for entry-level models to tens of thousands for industrial-grade machines. Start by identifying your priorities. Are you looking for a basic machine for personal projects, or do you need a high-performance model for business use?

For hobbyists, compact desktop machines are often the best budget option. These machines are affordable and capable of handling small-scale projects like engraving custom keychains or ornaments. If you’re running a business, consider investing in a machine with higher wattage and advanced features. While the upfront cost may be higher, the increased efficiency and production capacity can quickly pay off.

Don’t forget to account for additional expenses, such as materials, software, and maintenance. Some machines require specific accessories, like air assist systems or rotary attachments, which can add to the overall cost. Research these extras beforehand to avoid surprises.

“Investing in the right machine ensures you get the best value for your money while meeting your creative or business goals.”

Set a realistic budget that aligns with your needs and long-term plans. Remember, a laser engraving machine is an investment in your creativity or business, so choose wisely.

A laser engraving machine is your gateway to endless possibilities. It empowers you to create personalized gifts, elevate your business, or streamline manufacturing processes with precision and efficiency. By understanding its applications and choosing the right machine for your needs, you can unlock its full potential. Whether you’re crafting intricate designs or exploring laser cutting for industrial use, this tool helps you bring your ideas to life. Take the first step today and transform your creativity into tangible results.

FAQ

What materials can you engrave with a laser engraving machine?

You can engrave a wide variety of materials, including wood, metal, glass, acrylic, leather, and certain plastics. Each material offers unique possibilities. For example, wood is great for creating intricate designs, while metal is ideal for durable markings like serial numbers or logos. Always check your machine’s specifications to ensure compatibility with the material you plan to use.

Is laser engraving safe to use at home?

Yes, laser engraving machines are safe for home use when you follow proper safety guidelines. Ensure your workspace is well-ventilated to avoid inhaling fumes from certain materials. Many machines come with safety features like protective covers and emergency stop buttons. Always wear safety glasses and avoid leaving the machine unattended during operation.

Do I need special software to operate a laser engraving machine?

Most laser engraving machines require design software to create and transfer your projects. Some models are compatible with popular programs like Adobe Illustrator or CAD, while others come with pre-installed software. Check the machine’s compatibility with your preferred software before purchasing. Reliable software simplifies the process and enhances your creative options.

How much does a laser engraving machine cost?

The cost of a laser engraving machine varies widely based on its features and capabilities. Entry-level models for hobbyists can start at a few hundred dollars, while professional-grade machines for businesses may cost several thousand. Financing options, like those offered by OMTech, can help reduce the financial burden if you’re investing in a high-end machine.

Can I start a business with a laser engraving machine?

Absolutely! Laser engraving machines are perfect for starting a business. You can create custom products like jewelry, home decor, or promotional items. Personalized gifts and branded merchandise are always in demand. With the machine’s precision and efficiency, you can fulfill orders quickly and maintain high-quality results.

How do I maintain my laser engraving machine?

Regular maintenance keeps your machine running smoothly. Clean the lens and mirrors frequently to ensure optimal laser performance. Check the cooling system and ventilation to prevent overheating. Replace worn-out parts like belts or filters as needed. Many manufacturers provide maintenance guides, so follow their recommendations for best results.

What’s the difference between CO2 and fiber laser engraving machines?

CO2 lasers work best for non-metal materials like wood, acrylic, and leather. They’re versatile and popular for creative projects. Fiber lasers, on the other hand, are designed for metal engraving and industrial applications. They offer unmatched precision and durability. Choose the type that aligns with the materials you’ll use most often.

Can I engrave curved or cylindrical objects?

Yes, many laser engraving machines support engraving on curved or cylindrical objects using a rotary attachment. This accessory rotates the object during engraving, ensuring consistent results. It’s perfect for customizing items like tumblers, bottles, or rings. Check if your machine is compatible with rotary attachments before purchasing.

How long does it take to engrave an item?

The engraving time depends on the material, design complexity, and machine settings. Simple designs on soft materials like wood may take just a few minutes. Intricate patterns on harder materials like metal could take longer. Adjusting the laser speed and power can also impact the time required.

Are there any hidden costs with laser engraving machines?

In addition to the machine itself, consider costs for materials, software, and maintenance. Some projects may require accessories like rotary attachments or air assist systems. Factor in these expenses when budgeting for your machine. Planning ahead ensures you’re prepared for any additional costs.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Industrial Applications of Laser Cutting

The Functionality of CNC Laser Cutting Machines