How Many Types of Laser Cutting Machines Exist?

When exploring the world of laser cutting, you encounter several types of machines. These include CO2 lasers, fiber lasers, diode lasers, and crystal lasers. Each type offers unique capabilities and applications. Understanding how many types of laser cutting machines exist helps you make informed decisions. For instance, CO2 lasers excel in cutting various materials like metals and plastics, while fiber lasers provide precision and efficiency, especially in metal cutting. By knowing these differences, you can select the right machine that aligns with your specific needs and budget.

Types of Laser Cutting Machines

Understanding how many types of laser cutting machines exist is crucial for selecting the right tool for your needs. Each type offers distinct features and benefits, making them suitable for various applications. Let's explore these types in detail.

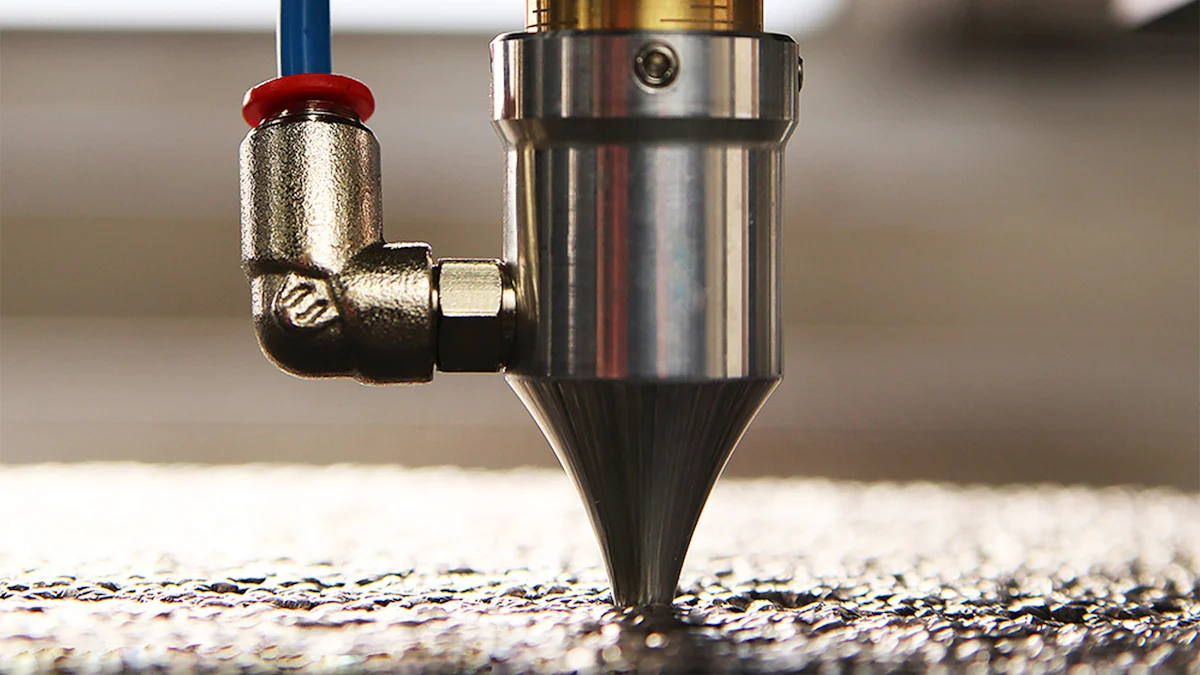

CO2 Lasers

CO2 lasers are among the most popular laser cutting machines. They operate at a wavelength of 10.6 micrometers, which makes them highly effective for non-metallic materials.

Applications of CO2 Lasers

CO2 lasers excel in cutting and engraving a wide range of materials. You can use them for:

- Wood

- Acrylic

- Rubber

- Glass

- Plastics

These lasers are particularly effective in manufacturing settings where precision and versatility are required.

Advantages and Disadvantages of CO2 Lasers

Advantages:

- High precision and ability to cut various materials.

- Reliable solution with a long history in manufacturing.

Disadvantages:

- Large and expensive.

- Require frequent maintenance and adjustments.

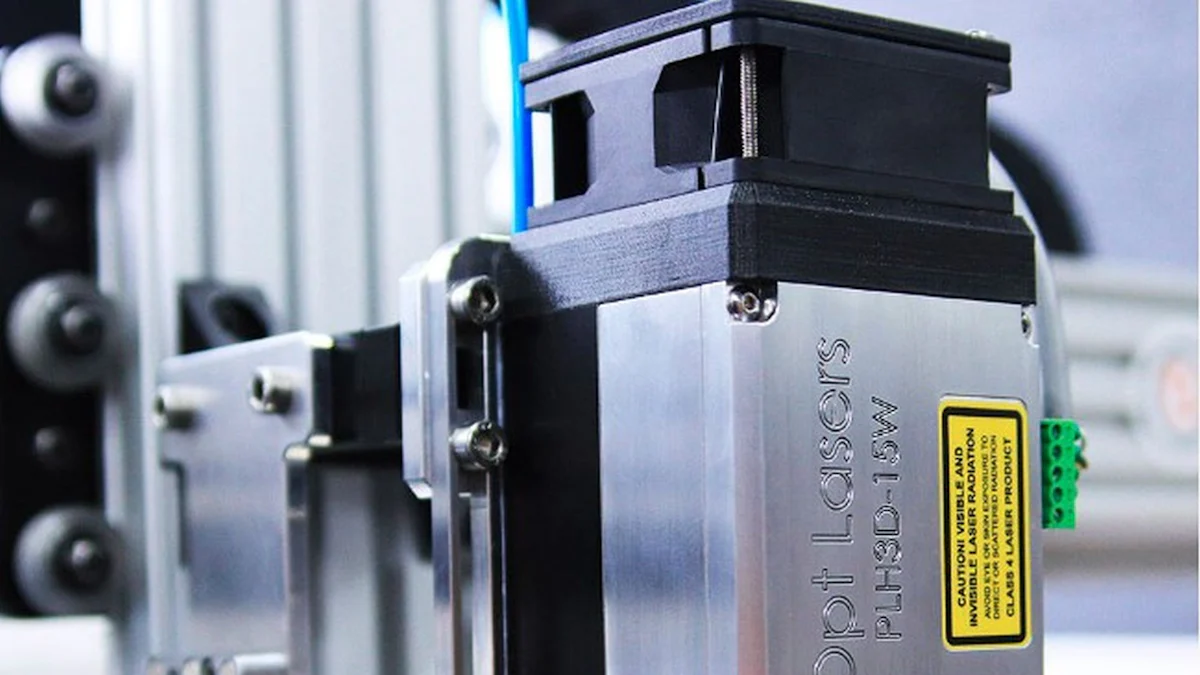

Fiber Lasers

Fiber lasers are known for their speed and efficiency, especially when cutting metals. They use a solid-state technology that provides high precision.

Applications of Fiber Lasers

Fiber lasers are optimized for cutting metals. You can find them useful in industries that require:

- Metal cutting

- Precision engraving

- High-speed operations

Their efficiency makes them a preferred choice for metalworking tasks.

Advantages and Disadvantages of Fiber Lasers

Advantages:

- Faster and more efficient than traditional CO2 lasers.

- Excellent for metal cutting.

Disadvantages:

- Higher initial cost compared to other types.

- Limited effectiveness on non-metallic materials.

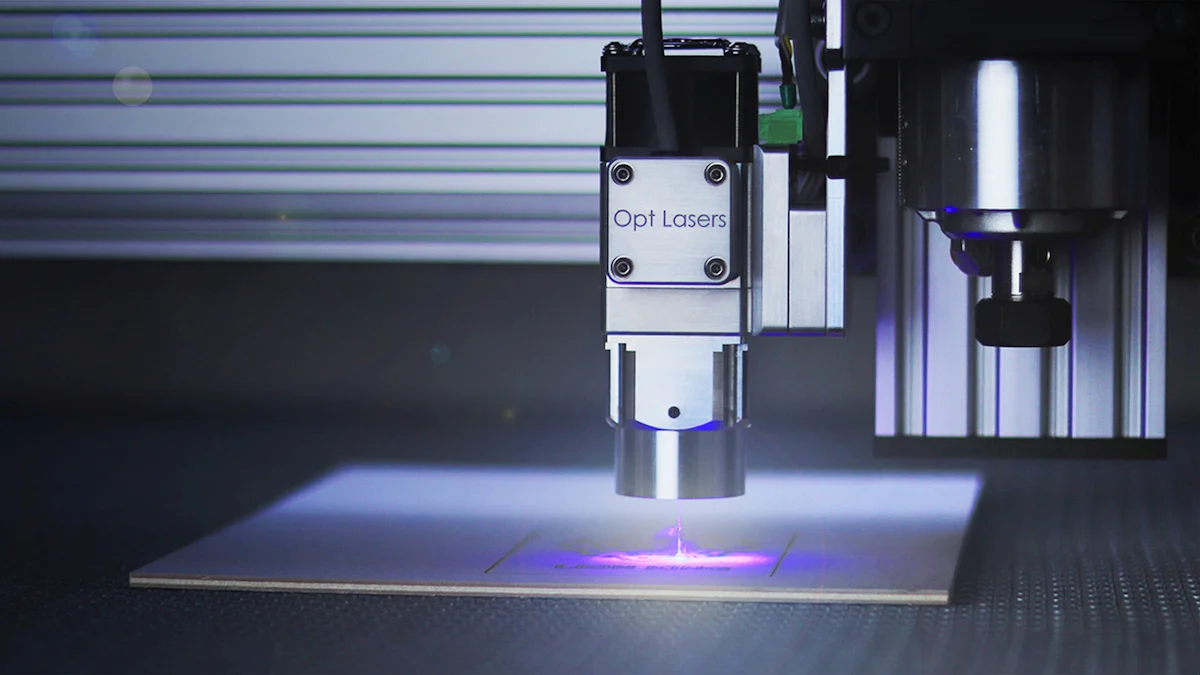

Diode Lasers

Diode lasers are compact and versatile, making them suitable for various applications.

Applications of Diode Lasers

Diode lasers are often used for:

- Engraving

- Marking

- Cutting thin materials

Their compact size allows for easy integration into different systems.

Advantages and Disadvantages of Diode Lasers

Advantages:

- Compact and versatile.

- Cost-effective for small-scale applications.

Disadvantages:

- Limited power compared to CO2 and fiber lasers.

- Less effective for cutting thick materials.

Crystal Lasers

Crystal lasers utilize solid-state technology, making them a versatile choice for various applications. These lasers, such as Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) and Nd:YVO (Neodymium-doped Yttrium Orthovanadate), operate at wavelengths that are effective for both cutting and engraving tasks.

Applications of Crystal Lasers

Crystal lasers find their niche in industries requiring precision and versatility. You can use them for:

- Metal Engraving: Ideal for detailed work on metals.

- Medical Devices: Used in the production of precise medical instruments.

- Aerospace Components: Suitable for cutting and shaping complex aerospace parts.

These applications highlight the adaptability of crystal lasers in high-precision environments.

Advantages and Disadvantages of Crystal Lasers

Advantages:

- High Precision: Crystal lasers offer exceptional accuracy, making them suitable for intricate designs.

- Versatility: They can handle a variety of materials, including metals and ceramics.

Disadvantages:

- Cost: Crystal lasers tend to be more expensive than other types.

- Maintenance: They require regular maintenance to ensure optimal performance.

Understanding how many types of laser cutting machines exist, including crystal lasers, helps you choose the right tool for your specific needs. Each type offers unique benefits, and knowing these can guide you in making an informed decision.

Comparing Laser Cutting Machines

When choosing a laser cutting machine, understanding the differences in performance, cost, and material compatibility is crucial. Each type of laser offers unique benefits, making them suitable for various applications. Let's delve into these aspects to help you make an informed decision.

Performance and Efficiency

Performance and efficiency are key factors when selecting a laser cutting machine. CO2 lasers operate at a wavelength of 10.6 micrometers, making them highly effective for non-metallic materials like wood, glass, and plastics. They provide high precision and versatility, which is essential in manufacturing settings. However, they require frequent maintenance.

Fiber lasers, on the other hand, excel in speed and efficiency, especially for metal cutting. Their solid-state technology ensures high precision, making them ideal for industries that demand quick and accurate operations. Crystal lasers, such as Nd:YAG, offer exceptional accuracy and versatility, suitable for intricate designs and high-precision environments.

Cost Considerations

Cost plays a significant role in your decision-making process. CO2 lasers tend to be large and expensive, with ongoing maintenance costs. Fiber lasers have a higher initial cost but offer long-term savings due to their efficiency and lower maintenance needs. Diode lasers are more cost-effective for small-scale applications, while crystal lasers can be costly due to their precision and versatility.

Material Compatibility

Material compatibility is another critical factor. CO2 lasers are perfect for non-metallic materials, making them suitable for industries working with wood, plastic, and glass. Fiber lasers are optimized for metal cutting, providing excellent results in metalworking tasks. Diode lasers work well for engraving and marking thin materials. Crystal lasers handle a variety of materials, including metals and ceramics, offering high precision and adaptability.

By comparing these aspects, you can determine which laser cutting machine aligns best with your specific needs. Understanding the performance, cost, and material compatibility of each type will guide you in making an informed choice.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine involves careful consideration of your specific needs and long-term goals. With various types available, such as CO2, fiber, diode, and crystal lasers, understanding how many types of laser cutting machines exist is crucial for making an informed decision.

Assessing Your Needs

Begin by evaluating your specific requirements. Consider the materials you plan to work with and the precision needed for your projects. For instance, CO2 lasers excel in cutting non-metallic materials like wood and plastic, while fiber lasers are ideal for metal cutting due to their speed and efficiency. If you require compact and versatile solutions, diode lasers might be suitable for engraving and marking thin materials. Crystal lasers offer high precision and versatility, making them a good choice for intricate designs and diverse applications.

Evaluating Long-term Benefits

Think about the long-term benefits of each type of laser cutting machine. Fiber lasers may have a higher initial cost, but they offer efficiency and lower maintenance needs, which can lead to cost savings over time. CO2 lasers require more frequent maintenance, which could increase operational costs. Consider the lifespan and power of each machine type. Diode lasers are cost-effective for small-scale applications, while crystal lasers provide exceptional accuracy and adaptability, though they may require regular maintenance.

Consulting with Experts

Consulting with industry experts can provide valuable insights into the best laser cutting machine for your needs. Experts can help you understand the nuances of each machine type, including performance, material compatibility, and cost-effectiveness. They can also guide you in assessing your specific requirements and evaluating the long-term benefits of different machines. By leveraging expert advice, you can make a well-informed decision that aligns with your goals and budget.

Choosing the right laser cutting machine requires a thorough understanding of your needs, an evaluation of long-term benefits, and expert consultation. By considering these factors, you can select a machine that meets your specific requirements and supports your business objectives.

Understanding how many types of laser cutting machines exist empowers you to make informed decisions. Each type—CO2, fiber, diode, and crystal—offers unique advantages. To select the right machine, consider your specific applications and budget. CO2 lasers excel in versatility, fiber lasers in metal precision, diode lasers in compactness, and crystal lasers in high precision. Research thoroughly before purchasing. Consulting with experts can provide valuable insights into the best choice for your needs. By aligning your requirements with the machine's capabilities, you ensure optimal performance and investment.

FAQ

What are the main types of laser cutting machines?

You will find four primary types of laser cutting machines: CO2 lasers, fiber lasers, diode lasers, and crystal lasers. Each type offers unique capabilities and applications, making them suitable for different tasks.

How do I choose the right laser cutting machine for my needs?

To select the right machine, consider factors like material compatibility, precision requirements, and budget. Evaluate your specific needs and long-term goals. Consulting with experts can also provide valuable insights.

What materials can CO2 lasers cut?

CO2 lasers excel in cutting non-metallic materials. You can use them for materials like wood, acrylic, rubber, glass, and plastics. They offer high precision and versatility in manufacturing settings.

Are fiber lasers better for metal cutting?

Yes, fiber lasers are optimized for metal cutting. They provide high precision and efficiency, making them ideal for industries that require quick and accurate operations on metals.

What should I consider before purchasing a laser cutting machine?

Before purchasing, consider factors such as maintenance needs, floor space availability, maximum material size, and power requirements. These factors will help you choose a machine that fits your workspace and operational needs.

How do diode lasers differ from other types?

Diode lasers are compact and versatile. They are suitable for engraving, marking, and cutting thin materials. Their compact size allows for easy integration into different systems, making them cost-effective for small-scale applications.

What are the advantages of crystal lasers?

Crystal lasers offer high precision and versatility. They can handle a variety of materials, including metals and ceramics. These lasers are suitable for intricate designs and high-precision environments.

How important is it to conduct trials or demos before purchasing?

Conducting trials or demos is crucial. It allows you to evaluate the machine's performance, ease of use, and suitability for your specific applications. This step ensures you make an informed decision.

What are the cost considerations when choosing a laser cutting machine?

Consider both the initial investment and ongoing operating expenses. CO2 lasers may have higher maintenance costs, while fiber lasers offer long-term savings due to their efficiency. Diode lasers are more cost-effective for smaller applications.

Can I use a laser cutting machine for multiple materials?

Yes, but it depends on the type of laser. CO2 lasers work well with non-metallic materials, while fiber lasers are best for metals. Crystal lasers offer versatility for various materials, including metals and ceramics. Always check the machine's compatibility with your intended materials.

See Also

Exploring Various Types of Laser Cutting Technologies

Understanding Laser Cutting Machines and Their Varieties

Cost Overview of Cutting Machines and Their Types