Top Tips for Maintaining Your Laser Cutting Machine

Regular maintenance for your laser cutting machine is crucial. It ensures that your equipment runs smoothly and efficiently. By keeping up with maintenance, you not only extend the lifespan of your machine but also save money in the long run. Imagine avoiding costly repairs and unexpected breakdowns. That's the power of regular upkeep. Plus, a well-maintained machine delivers precise cuts every time, enhancing your productivity. So, if you're wondering where to buy a laser cutting machine, remember that maintenance is key to getting the most out of your investment.

Cleaning Your Laser Cutting Machine

Keeping your laser cutting machine in top shape starts with regular cleaning. This not only ensures optimal performance but also extends the life of your equipment. Let's dive into some essential cleaning practices.

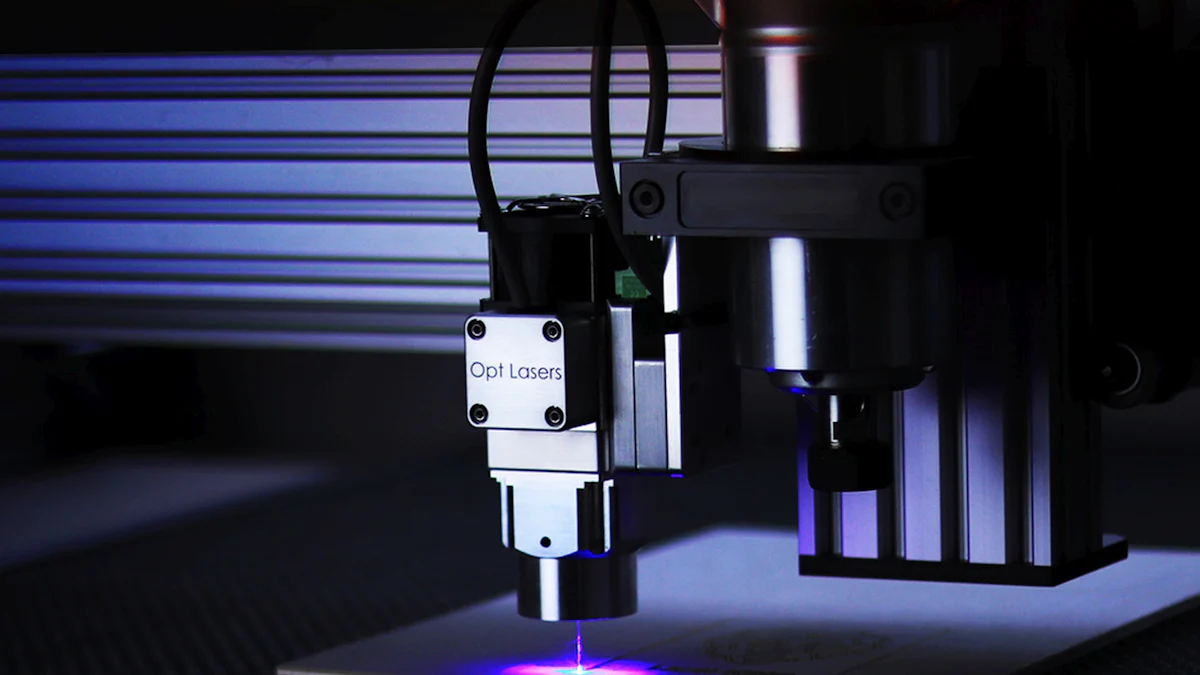

Cleaning Lenses and Mirrors

Importance of Keeping Optical Components Clean

Your laser cutting machine relies heavily on its optical components, like lenses and mirrors, to function correctly. Dust and debris can accumulate on these parts, leading to reduced cutting precision and efficiency. By keeping them clean, you ensure that the laser beam remains focused and powerful, which is crucial for achieving high-quality cuts.

Recommended Cleaning Materials and Techniques

When it comes to cleaning, using the right materials is key. Opt for a soft, lint-free cloth or specialized lens wipes to gently remove any dust or smudges. Avoid using harsh chemicals that could damage the delicate surfaces. Instead, a small amount of isopropyl alcohol or a dedicated lens cleaner works wonders. Always handle these components with care to prevent scratches or other damage.

Cleaning the Machine Interior

Removing Dust and Debris from the Machine

Dust and debris can accumulate inside your laser cutting machine, affecting its performance. To tackle this, start by turning off the machine and disconnecting it from the power source. Use a vacuum or compressed air to remove any loose particles from the interior. Pay special attention to areas around the cutting head and the machine bed, as these spots tend to collect the most debris.

Tips for Maintaining a Clean Work Environment

A clean work environment contributes significantly to the overall maintenance of your laser cutting machine. Regularly inspect and clean the filter to ensure proper airflow and prevent overheating. Keep the surrounding area free from clutter and dust, which can easily find its way into the machine. By maintaining a tidy workspace, you reduce the risk of contamination and enhance the machine's longevity.

Incorporating these cleaning practices into your routine will help you get the most out of your laser cutting machine. Remember, frequent cleaning of machine components is a simple yet effective way to ensure your equipment runs smoothly and efficiently.

Calibration for Precision

Calibration is the secret sauce to achieving top-notch cutting quality with your laser cutting machine. Regular calibration ensures that your machine delivers precise and accurate cuts every time. Let's explore why this is so important and how you can do it yourself.

Importance of Regular Calibration

Ensuring Precision and Accuracy in Cutting

When you calibrate your laser cutting machine regularly, you maintain its cutting quality. This process ensures that the laser beam aligns perfectly with the cutting path, resulting in clean and precise cuts. Without proper calibration, you might notice jagged edges or misaligned cuts, which can compromise the quality of your work. Consistent calibration keeps your machine in check, ensuring every cut meets your high standards.

Signs That Calibration Is Needed

How do you know when it's time to calibrate? Look out for signs like inconsistent cutting quality or a noticeable drop in precision. If your machine starts producing cuts that don't match your usual quality, it's a clear indicator that calibration is overdue. Regular checks help you catch these issues early, preventing material waste and maintaining your machine's efficiency.

How to Perform Calibration

Step-by-Step Guide to Calibrating the Machine

Calibrating your laser cutting machine might sound daunting, but it's quite manageable with the right approach. Here's a simple guide to get you started:

- Power Down: Turn off your machine and disconnect it from the power source for safety.

- Clean the Optics: Ensure lenses and mirrors are free from dust and debris.

- Check Alignment: Use alignment tools to verify that the laser beam aligns with the cutting path.

- Adjust Settings: Make necessary adjustments to the machine's settings to correct any misalignments.

- Test Cut: Perform a test cut to ensure the adjustments have improved the cutting quality.

Tools and Equipment Required for Calibration

You'll need a few essential tools to calibrate effectively. A set of alignment tools, such as a laser alignment kit, is crucial. Additionally, keep a soft cloth and lens cleaner handy for cleaning optics. These tools help you achieve the precision needed for high-quality cuts.

Expert Testimony:

Certified Technician: "They have the expertise and tools to ensure your laser cuts with razor-sharp precision."

By following these steps and using the right tools, you can maintain the cutting quality of your laser cutting machines. Regular calibration not only enhances the quality of your cuts but also extends the lifespan of your equipment. Keep your machine in top shape, and you'll enjoy consistent, high-quality results.

Lubrication Maintenance Tips

Keeping your laser cutting machine in top condition involves regular lubrication. This simple step can significantly extend the life of your equipment and ensure smooth operation. Let's explore which parts need attention and how to apply lubricants effectively.

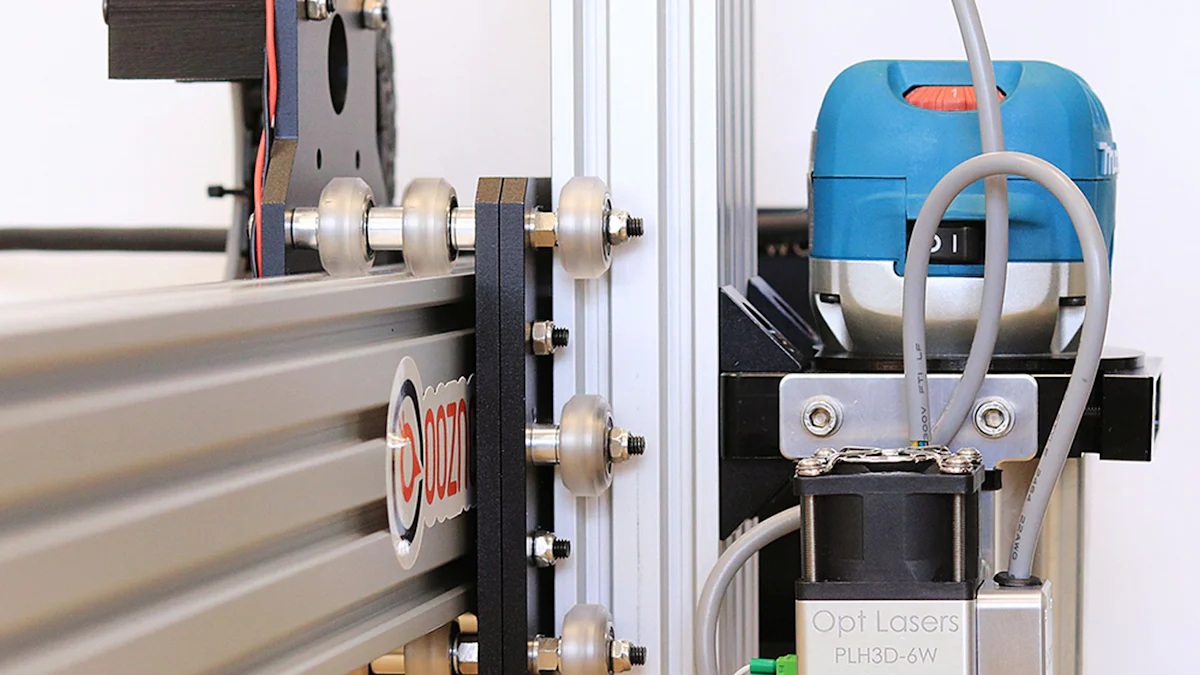

Parts That Need Lubrication

Identifying Moving Parts That Require Lubrication

Your laser cutting machine has several moving parts that need regular lubrication to function correctly. These include the rails, bearings, and guiderails. By keeping these components well-lubricated, you reduce friction and wear, which helps maintain the machine's efficiency. Always refer to your machine's manual to identify specific lubrication points.

Frequency of Lubrication

How often should you lubricate? It depends on how frequently you use your machine. For heavy use, consider lubricating every few weeks. For lighter use, monthly lubrication might suffice. Regular checks will help you determine the best schedule for your needs. Consistent lubrication keeps your machine running smoothly and prevents premature wear and tear.

Recommended Lubrication Practices

Types of Lubricants to Use

Choosing the right lubricant is crucial. Typically, a light machine oil or a specialized lubricant for linear rails works best. These products reduce wear and tear, ensuring your machine operates efficiently. Always consult your laser cutter's manual for the recommended lubricant type to avoid any potential damage.

Tips for Applying Lubricants Effectively

Applying lubricants correctly is just as important as choosing the right type. Here are some tips to help you:

- Clean First: Before applying lubricant, clean the parts to remove any dust or debris. This ensures the lubricant can work effectively.

- Use Sparingly: A few drops of lubricant are usually enough. Over-lubrication can attract dust and cause buildup.

- Apply Evenly: Ensure the lubricant covers the entire surface of the moving parts. This helps prevent uneven wear.

By following these maintenance tips, you can keep your laser cutting machines in excellent condition. Regular lubrication not only enhances performance but also extends the lifespan of your equipment. Remember, a well-maintained machine is a reliable machine.

Cooling System Maintenance for CO2 Laser Machines

Keeping your laser cutting machine in top shape requires regular attention to its cooling system. This component plays a vital role in preventing overheating and ensuring your machine operates efficiently. Let's explore why maintaining the cooling system is crucial and how you can do it effectively.

Importance of Maintaining the Cooling System

Preventing Overheating and Damage

Your laser cutting machine generates a lot of heat during operation. Without a well-functioning cooling system, this heat can cause significant damage. Overheating not only affects the machine's performance but can also lead to costly repairs. By maintaining the cooling system, you prevent these issues and keep your machine running smoothly.

Ensuring Efficient Operation

A properly maintained cooling system ensures that your laser cutting machine operates at peak efficiency. When the cooling system works well, it stabilizes the laser beam, which is essential for precise cuts. Regular maintenance helps you avoid disruptions and maintain the quality of your work.

Steps for Cooling System Maintenance

Checking and Replacing Coolant

Regularly checking the coolant levels is a simple yet effective way to maintain your cooling system. Low coolant levels can lead to overheating, so it's crucial to keep them in check. If you notice the coolant is dirty or has debris, replace it immediately. Clean coolant ensures optimal heat transfer and prolongs the life of your machine.

Inspecting and Cleaning Cooling Components

Inspecting the cooling components is another essential step in co2 laser machine maintenance. Look for any signs of wear or damage in the hoses, pumps, and filters. Clean these components regularly to prevent blockages that could hinder the cooling process. A clean cooling system not only enhances performance but also extends the lifespan of your laser cutting machines.

By following these maintenance steps, you ensure that your cooling system functions effectively. Regular attention to this vital component keeps your laser cutting machine in excellent condition, allowing you to enjoy consistent, high-quality results.

Preventive Maintenance Routines

Keeping your laser cutting machine in peak condition involves more than just occasional cleaning or lubrication. Regular maintenance routines are essential to ensure your equipment runs smoothly and efficiently. Let's dive into some essential maintenance tips that will help you prevent production breakdowns and extend the life of your machine.

Regular Checks and Inspections

Creating a Maintenance Schedule

Creating a maintenance schedule is your first step toward effective preventive maintenance. By scheduling periodic preventive maintenance, you can address small issues before they become costly breakdowns. Think of it as a roadmap for your machine's health. A well-planned schedule helps you keep track of what needs attention and when. You might want to set reminders for tasks like cleaning, lubrication, and calibration. This proactive approach minimizes the risk of unexpected breakdowns and keeps your machine running at its best.

Key Areas to Inspect Regularly

Regular inspections are crucial for identifying potential problems early. Focus on key areas such as the optics, cooling system, and moving parts. Check for signs of wear or damage, and ensure everything is functioning correctly. Pay attention to any unusual noises or vibrations, as these could indicate underlying issues. By inspecting these areas regularly, you can catch problems before they escalate, saving you time and money in the long run.

Professional Servicing

Benefits of Professional Maintenance Services

While regular maintenance is something you can handle, professional servicing offers additional benefits. Experts have the knowledge and tools to perform thorough inspections and repairs. They can spot issues you might miss and provide solutions to keep your machine in top shape. Professional maintenance services not only enhance your machine's performance but also extend its lifespan. As Benjamin Franklin wisely noted, addressing small issues early prevents costly breakdowns.

How to Choose a Reliable Service Provider

Choosing the right service provider is crucial for effective equipment maintenance. Look for providers with a solid reputation and experience in servicing laser cutting machines. Ask for recommendations from other users or read reviews online. Ensure the provider offers comprehensive services, including inspections, repairs, and calibration. A reliable service provider becomes a valuable partner in maintaining your machine's efficiency and longevity.

By incorporating these preventive maintenance routines into your workflow, you ensure your laser cutting machine remains reliable and efficient. Regular maintenance not only prevents production breakdowns but also maximizes your investment in the long run. Remember, a little effort now can save you a lot of trouble later.

You've now got a solid understanding of how to keep your laser cutting machine in top shape. Regular maintenance isn't just a chore; it's your ticket to enhanced performance and a longer machine lifespan. By adopting a consistent maintenance routine, you minimize downtime and maximize productivity. Remember, a well-maintained machine not only saves you money but also ensures high-quality cuts every time. So, make maintenance a priority and enjoy the long-term benefits it brings to your laser cutting operations.

FAQ

How should you maintain the laser cutting machine every day?

Daily maintenance plays a crucial role in keeping your laser cutting machine in top-notch condition. By performing regular checks and cleaning, you ensure that the machine operates at its best. This routine care helps the machine deliver superior cutting performance and reduces the likelihood of unexpected failures. Make it a habit to inspect the lenses, mirrors, and working area for any dust or debris. A little effort each day goes a long way in maintaining your machine's efficiency.

What are the signs that my laser cutting machine needs calibration?

You might notice a drop in cutting precision or inconsistent quality in your cuts. These are clear indicators that your machine requires calibration. Regular calibration ensures that the laser beam aligns perfectly with the cutting path, maintaining the high performance you expect. If you observe jagged edges or misaligned cuts, it's time to recalibrate.

How often should I clean the lenses and mirrors?

Cleaning the lenses and mirrors should be part of your regular maintenance routine. For machines cutting mainly plastics, clean these components every 4 to 6 weeks. If you're cutting woods like MDF or plywood, aim for every 2 to 3 weeks. Keeping these optical components clean ensures optimal performance and prevents any loss in cutting quality.

What type of lubricant should I use for my laser cutting machine?

For lubrication, choose a light machine oil or a specialized lubricant designed for linear rails. These lubricants reduce wear and tear, ensuring smooth operation. Always refer to your machine's manual for specific recommendations to avoid any potential damage. Proper lubrication keeps the moving parts functioning efficiently, enhancing overall performance.

How can I prevent my laser cutting machine from overheating?

Maintaining the cooling system is key to preventing overheating. Regularly check the coolant levels and replace them if necessary. Inspect hoses, pumps, and filters for any signs of wear or blockages. A well-maintained cooling system ensures efficient operation and protects your machine from heat-related damage.

Why is professional servicing important for my laser cutting machine?

Professional servicing offers expertise that goes beyond regular maintenance. Technicians have the tools and knowledge to perform thorough inspections and repairs. They can identify issues you might overlook and provide solutions to keep your machine in peak condition. Investing in professional services enhances performance improvements and extends the lifespan of your equipment.

How do I create an effective maintenance schedule?

Start by listing all the maintenance tasks your machine requires, such as cleaning, lubrication, and calibration. Set reminders for each task based on your machine's usage and manufacturer's recommendations. A well-planned schedule helps you stay on top of maintenance, ensuring your machine remains in top-notch condition and performs optimally.

See Also

Mastering Effective Techniques for Laser Cutting Machines

Essential Strategies for Enhancing CNC Metal Cutting

Understanding the Functionality of CNC Laser Cutters