Steps to Cut Metal with a Desktop CNC Machine

Cutting metal with a desktop CNC machine opens up a world of precision and creativity. These machines, designed for intricate tasks, allow you to shape metals like aluminum, brass, or steel with unmatched accuracy. Unlike traditional methods, CNC machines eliminate human error, ensuring every cut is flawless. This precision not only reduces material waste but also saves time by minimizing rework. Whether you're crafting prototypes or manufacturing components, the ability to achieve clean cuts makes CNC machining an essential tool. So, can CNC machine cut metal? Absolutely, and it does so with efficiency and reliability.

Key Takeaways

Choose a desktop CNC machine specifically designed for metal cutting to ensure durability and precision. Gather essential tools, including high-quality cutting tools, clamping devices, and safety gear, to prepare for a successful cutting process.

- Prioritize safety by wearing protective gear, ensuring proper ventilation, and inspecting the machine for any damage before use.

- Set up your CNC machine correctly by homing it and securing the workpiece to achieve accurate cuts.

- Understand and set work and tool offsets to ensure the CNC machine knows where to cut and compensates for tool dimensions.

- Generate and load G-code accurately to instruct the CNC machine on how to execute your design.

- Monitor the cutting process closely to catch any issues early and ensure a smooth operation.

Preparation and Required Tools

Before you start cutting metal with a desktop CNC machine, preparation is key. Having the right tools and understanding safety measures will set you up for success. Let’s dive into what you’ll need and how to stay safe during the process.

Tools and Materials Checklist

To achieve precise and clean cuts, gather the following essentials:

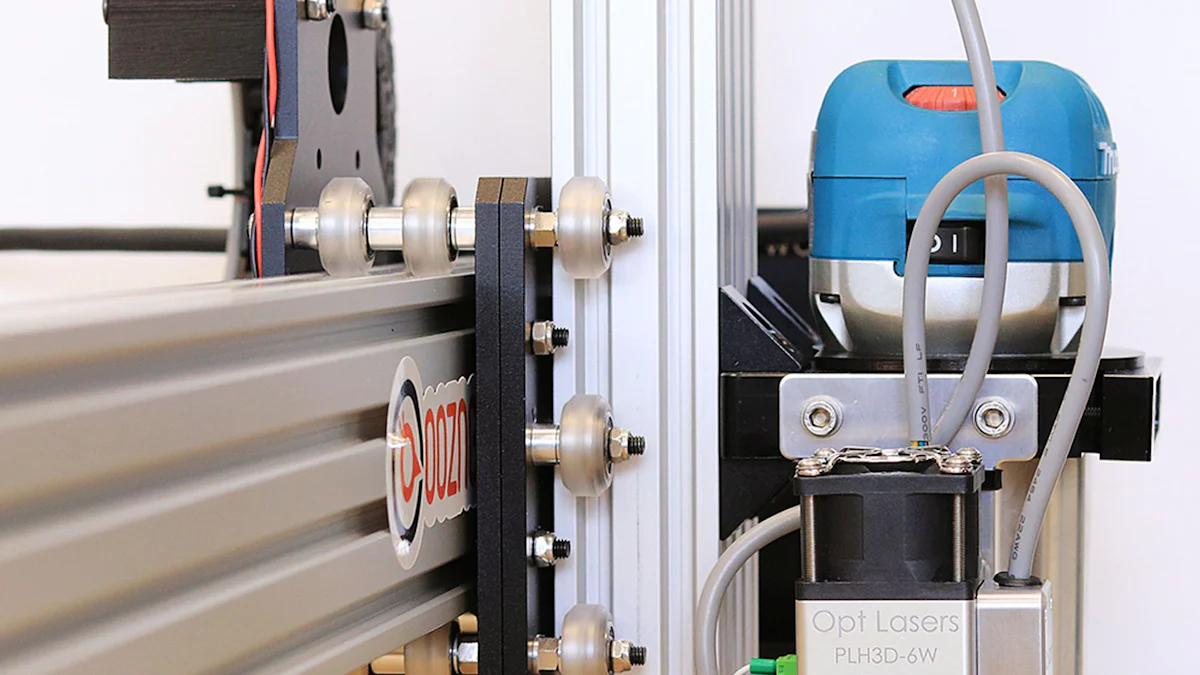

- Desktop CNC machine designed for metal cutting: Not all CNC machines can handle metal. Choose one specifically built for this purpose to ensure durability and accuracy.

- Metal workpiece: Common options include aluminum, brass, or steel. Each material has unique properties, so pick one that suits your project.

- Cutting tools: Use high-quality tools like end mills or drill bits. These are crucial for achieving smooth cuts and extending tool life.

- Clamping tools: Secure your workpiece with a vise or clamps. Stability is critical to prevent movement during cutting.

- Safety gear: Protect yourself with safety glasses and gloves. These will shield you from flying debris and sharp edges.

- Coolant or lubricant: Some metals require cooling to reduce heat buildup. Check if your material needs this step.

- Computer with CNC software: A reliable computer and software are essential for designing and executing your cuts.

Having these tools ready ensures a smooth workflow and minimizes interruptions.

Safety Considerations

Safety should always come first when working with a CNC machine. Follow these guidelines to protect yourself and your equipment:

Importance of wearing safety gear

Always wear safety glasses to protect your eyes from metal shavings. Gloves can shield your hands, but avoid loose-fitting ones that might get caught in the machine.

Ensuring proper ventilation

Metal cutting can produce fumes, especially when using coolants or lubricants. Work in a well-ventilated area to avoid inhaling harmful substances.

Checking the machine for any damage or loose parts

Inspect your CNC machine before every use. Look for loose screws, worn-out parts, or any signs of damage. Addressing these issues early prevents accidents and ensures consistent performance.

"CNC machines represent modern high-tech production methods, combining advanced computer numerical control technology with cutting machinery." This precision makes them invaluable for metal fabrication.

By preparing thoroughly and prioritizing safety, you’ll create a solid foundation for your metal-cutting projects. With the right tools and precautions, you can confidently answer the question, "Can CNC machine cut metal?" Yes, it can—and it does so with precision and efficiency.

Setting Up the CNC Machine

Setting up your CNC machine properly is essential for achieving precise and clean cuts. This step ensures that your machine operates smoothly and delivers the results you expect. Let’s break it down into manageable tasks.

Powering On and Referencing the Machine

Turning on the CNC machine and software

Start by powering on your CNC machine. Once it’s on, launch the CNC software on your computer. This software acts as the brain of your machine, translating your design into actionable commands. Make sure the software connects to the machine without any errors. If you notice any issues, double-check the connections and restart the system.

Homing the machine to establish a reference point

After powering up, home the machine. Homing tells the CNC machine where its starting point is. This step ensures that the machine knows its exact position in the workspace. Use the software to guide the machine to its home position, which is usually at the farthest corner of the cutting area. Homing prevents misalignment and ensures accurate cuts.

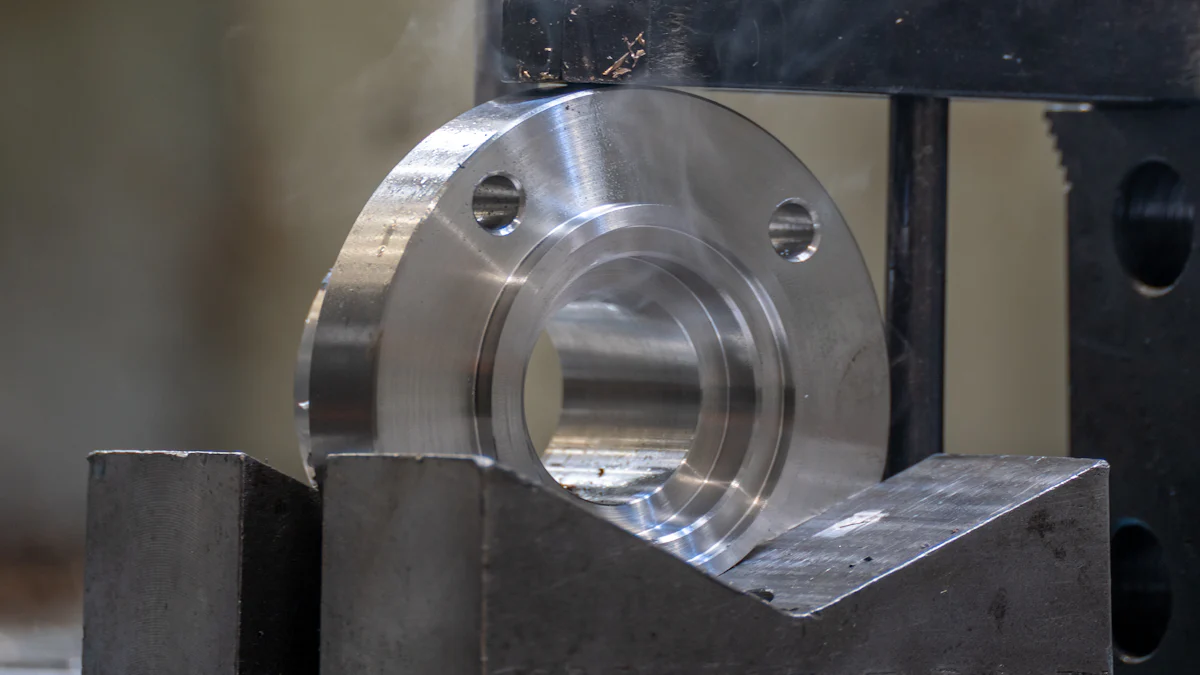

Securing the Metal Workpiece

Choosing the right clamping method

Securing your metal workpiece is crucial. Choose a clamping method that suits the size and shape of your material. For flat pieces, a vise works well. For irregular shapes, clamps or specialized fixtures provide better stability. Avoid over-tightening, as this can damage the material.

Ensuring the workpiece is level and stable

Once clamped, check that the workpiece is level. Use a leveling tool or visually inspect it from different angles. A stable and level workpiece ensures consistent cuts. If the material wobbles or shifts, adjust the clamps until it stays firmly in place.

Selecting and Installing the Cutting Tool

Choosing the appropriate tool for the material

Select a cutting tool designed for the type of metal you’re working with. For softer metals like aluminum, use high-speed steel or carbide end mills. For harder metals like steel, opt for tougher carbide tools. The right tool minimizes wear and produces cleaner cuts.

Properly securing the tool in the spindle

Insert the cutting tool into the spindle of your CNC machine. Tighten it securely using the appropriate wrench or tool provided with your machine. A loose tool can lead to inaccurate cuts or even damage the machine. Double-check that the tool is firmly in place before proceeding.

By following these steps, you’ll set up your CNC machine for success. Proper setup not only ensures precision but also answers the question, "Can CNC machine cut metal?" Yes, it can, and with the right preparation, it does so with remarkable accuracy.

Work and Tool Offsets

When working with a desktop CNC machine, understanding and setting offsets is essential for precision. Offsets ensure that your machine knows exactly where to cut, drill, or mill on the workpiece. Let’s break this process into two key parts: work offsets and tool offsets.

Understanding Work Offsets

Work offsets define the starting point of your machining process. They help the CNC machine understand the position of the workpiece in its workspace. Without proper work offsets, your cuts may end up in the wrong place.

Defining the work coordinate system

The work coordinate system (WCS) acts as a map for your CNC machine. It tells the machine where the workpiece is located relative to its home position. To define the WCS, you’ll need to align the machine’s axes with the edges or specific points on your material. This step ensures that the machine operates within the correct boundaries of your project.

Setting the X, Y, and Z zero points

Once you’ve defined the WCS, it’s time to set the zero points for the X, Y, and Z axes. These zero points act as the origin for your machining process. Use the CNC software to move the cutting tool to the desired starting position on the workpiece. For example, place the tool at the bottom-left corner of the material for X and Y, and just above the surface for Z. Confirm these positions in the software to lock them in as your zero points. Accurate zeroing ensures that every cut aligns perfectly with your design.

"Geometry offsets help with program zero assignment," according to MMS Online. This step is vital for achieving precise results in CNC machining.

Setting Tool Offsets

Tool offsets account for the physical dimensions of your cutting tools. Each tool has a unique length and diameter, which can affect the depth and accuracy of your cuts. By setting tool offsets, you ensure that the machine compensates for these differences.

Measuring tool length

Start by measuring the length of your cutting tool. Many CNC machines come with a tool length probe, which automatically measures the tool’s length when you lower it onto the probe’s surface. If your machine doesn’t have this feature, you can manually measure the tool length using a ruler or caliper. Record this measurement carefully, as it directly impacts the depth of your cuts.

Inputting tool offset values into the CNC software

After measuring the tool length, input the value into your CNC software. Most software programs have a dedicated section for tool offsets. Enter the length measurement under the appropriate tool number. If you’re using multiple tools, repeat this process for each one. Proper tool offsets ensure that the programmed depth matches the actual depth of the cut, as highlighted by Zero Divide’s insights on tool length offset.

By mastering work and tool offsets, you’ll unlock the full potential of your CNC machine. These steps not only improve accuracy but also answer the question, "Can CNC machine cut metal?" Yes, it can, and with precise offsets, it does so with unmatched reliability.

Can CNC Machine Cut Metal? Executing the Cutting Process

Once your desktop CNC machine is set up and ready, it’s time to bring your design to life. This stage involves creating the instructions for your machine, running the program, and finishing up with post-cutting tasks. Let’s break it down step by step.

Generating and Loading G-Code

G-code is the language your CNC machine understands. It tells the machine how to move, where to cut, and at what speed. Creating and loading G-code is a crucial step in the cutting process.

Designing the part in CAD software

Start by designing your part using CAD (Computer-Aided Design) software. Programs like Fusion 360 or SolidWorks are popular choices. These tools let you create precise digital models of your project. Focus on accuracy here because the design directly impacts the final result. Keep the material and cutting tool in mind while finalizing the design.

Converting the design to G-code using CAM software

Once your design is complete, use CAM (Computer-Aided Manufacturing) software to convert it into G-code. This step translates your digital model into a series of commands the CNC machine can follow. Many CAD programs have built-in CAM features, making this process seamless. Double-check the generated G-code to ensure it matches your design specifications.

Loading the G-code into the CNC machine

After generating the G-code, transfer it to your CNC machine. Most machines allow you to upload the file via USB, Wi-Fi, or a direct computer connection. Open the file in your CNC software and preview the toolpath. This preview shows how the machine will move and cut, giving you a chance to spot any errors before starting.

"Desktop CNC milling machines are user-friendly and versatile, making them ideal for tasks like generating and executing G-code efficiently."

Running the CNC Program

With the G-code loaded, you’re ready to start the cutting process. This is where your preparation and setup come together.

Starting the cutting process

Begin by starting the CNC program. The machine will follow the G-code instructions to cut, drill, or mill your metal workpiece. Pay attention to the initial movements to ensure everything aligns as expected. If something seems off, pause the program and make adjustments.

Monitoring the operation for any issues

Stay close to the machine while it’s running. Watch for signs of trouble, like unusual noises, excessive vibration, or overheating. These could indicate problems with the tool, material, or machine settings. Monitoring the process helps you catch issues early and avoid damaging the workpiece or machine.

CNC cutting operates faster than manual methods, saving time and delivering precise results. However, careful monitoring ensures the process runs smoothly.

Post-Cutting Steps

Once the cutting process is complete, there are a few final steps to wrap up your project.

Turning off the machine and cleaning the workspace

Turn off the CNC machine and disconnect it from the power source. Clean the workspace by removing metal shavings, dust, and debris. A clean environment keeps your machine in good condition and prepares it for the next project.

Inspecting the finished part for accuracy and quality

Examine the finished part closely. Check the dimensions, edges, and surface finish to ensure they match your design. Use calipers or other measuring tools for precise checks. If you notice any imperfections, consider what adjustments you can make for future cuts.

Desktop CNC mills excel in handling various materials and tasks, offering unmatched precision and versatility for projects like these.

By following these steps, you’ll execute the cutting process with confidence and efficiency. So, can CNC machine cut metal? Yes, it can, and it does so with remarkable precision and reliability when you follow the right process.

Cutting metal with a desktop CNC machine combines precision, creativity, and hands-on learning. By preparing thoroughly, setting up your machine correctly, and monitoring the process, you can achieve professional-quality results. These machines aren’t just tools—they’re gateways to innovation. Whether you’re a hobbyist, a small business owner, or an educator, they empower you to create high-quality components with ease.

"The future of metal cutting is in good hands," as SYIL highlights with their advanced CNC mills.

Experiment with different materials and designs. Each project helps you refine your skills and unlock new possibilities in modern manufacturing.

FAQ

What types of metals can a desktop CNC machine cut?

Desktop CNC machines can handle a variety of metals, including aluminum, brass, copper, and mild steel. These materials are softer and easier to work with compared to harder metals like stainless steel or titanium. If you're just starting out, aluminum is a great choice because it’s lightweight and forgiving.

Do I need a special CNC machine for cutting metal?

Yes, you need a CNC machine specifically designed for metal cutting. Machines built for wood or plastic lack the rigidity and power required to cut metal effectively. Look for a machine with a sturdy frame, high spindle speed, and compatibility with metal-cutting tools.

How do I choose the right cutting tool for my project?

The right cutting tool depends on the type of metal and the desired finish. For softer metals like aluminum, high-speed steel or carbide end mills work well. For harder metals like steel, use tougher carbide tools. Always match the tool size and shape to your design for the best results.

Is it necessary to use coolant or lubricant when cutting metal?

Coolant or lubricant is often necessary when cutting metal. It reduces heat buildup, prevents tool wear, and improves the surface finish. Some metals, like aluminum, may not require coolant for light cuts, but harder metals like steel benefit greatly from it.

How do I ensure my workpiece stays secure during cutting?

Use clamping tools like vises or clamps to secure your workpiece. Make sure the material is stable and level before starting the cutting process. For irregularly shaped pieces, consider using specialized fixtures to hold them in place.

Can I use any CAD software to design my project?

Most CAD software works for designing CNC projects. Popular options include Fusion 360, SolidWorks, and AutoCAD. Choose software that fits your skill level and offers features like 3D modeling and simulation. Many programs also integrate with CAM software for seamless G-code generation.

What should I do if the machine makes unusual noises during cutting?

Unusual noises often indicate a problem. Stop the machine immediately and inspect the cutting tool, workpiece, and machine settings. Common issues include dull tools, incorrect feed rates, or loose components. Addressing these problems early prevents damage to your machine or material.

How do I maintain my desktop CNC machine?

Regular maintenance keeps your CNC machine running smoothly. Clean the machine after each use to remove debris and metal shavings. Lubricate moving parts as recommended by the manufacturer. Periodically check for loose screws or worn-out components and replace them as needed.

Can I cut intricate designs with a desktop CNC machine?

Yes, desktop CNC machines excel at creating intricate designs. Their precision allows you to cut detailed patterns, engravings, and complex shapes. Use high-quality CAD software to design your project and ensure your machine is properly calibrated for the best results.

Is CNC metal cutting safe for beginners?

CNC metal cutting is safe for beginners if you follow proper safety guidelines. Always wear safety gear like glasses and gloves. Work in a well-ventilated area and inspect your machine before each use. Start with simple projects to build confidence and gradually take on more complex tasks.

"Plasma cutting, while generally easy and efficient, isn’t always as easy as pull and cut." Similarly, CNC metal cutting requires preparation and attention to detail, but with practice, it becomes a rewarding skill.

See Also

Techniques to Enhance CNC Machines for Metal Cutting

Understanding How Machines Slice Metal Like Paper

Is It Possible for CNC Machines to Cut Wood