What Are the Specifications of Laser Wood Cutting Machines

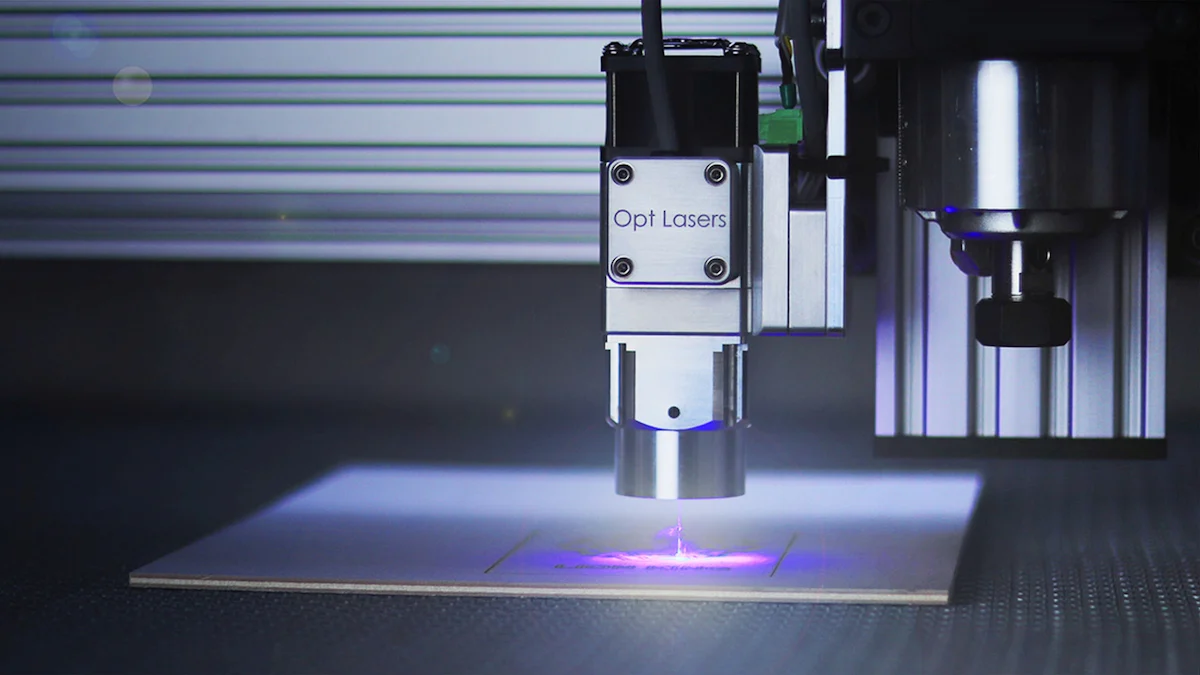

Laser wood cutting machines have revolutionized woodworking by offering unmatched accuracy and efficiency. These machines use advanced technology to cut and engrave various types of wood, including plywood, MDF, and hardwoods, with remarkable precision. Equipped with computer numerical control (CNC) systems, they allow you to create intricate designs and patterns effortlessly. The versatility of these machines makes them essential for crafting furniture, decorative items, and signage. Understanding what is the specification of wood cutting machine by laser helps you choose the right tool for your projects, ensuring optimal results and energy efficiency.

Overview of Laser Wood Cutting Machines

Laser wood cutting machines have transformed the way you work with wood. These machines combine precision and efficiency, making them essential for both hobbyists and professionals. By understanding their specifications and functionality, you can unlock their full potential for your projects.

What is the Specification of Wood Cutting Machine by Laser?

When exploring what is the specification of wood cutting machine by laser, you’ll find several key factors to consider. These machines typically feature power outputs ranging from 40W to over 300W. Higher power levels allow you to cut thicker wood and achieve faster results. The cutting area varies by model, with common sizes like 1300mm x 900mm, which accommodate a wide range of project dimensions.

Precision is another critical specification. Most laser cutting machines offer accuracy up to 0.01mm, enabling you to create intricate designs with ease. Material compatibility is equally important. These machines can handle various types of wood, including plywood, MDF, and hardwoods. Cooling systems, such as water chillers, ensure consistent performance during extended use. By evaluating these specifications, you can select a machine that aligns with your needs.

How Laser Cutting Machines Work

Laser cutting machines operate by directing a high-powered laser beam onto the wood surface. The laser generates intense heat, which vaporizes or melts the material along the cutting path. A computer numerical control (CNC) system guides the laser, ensuring precise cuts and engravings. This process eliminates the need for physical contact, reducing wear and tear on tools.

The technology behind laser cutting and engraving allows you to achieve detailed patterns and smooth edges. You can also adjust the laser’s intensity to switch between cutting and engraving modes. This versatility makes laser cutting machines ideal for creating custom designs, whether you’re crafting furniture or personalizing decorative items.

Applications of Laser Cutting Wood

Laser cutting wood opens up endless possibilities for creative and practical applications. You can use these machines to craft furniture pieces with intricate details or produce unique home décor items. Laser engraving wood adds a personal touch to gifts, such as customized plaques or ornaments.

In addition to artistic projects, laser cutting and engraving are widely used in industries like signage and architecture. You can create precise lettering, logos, and patterns that stand out. The ability to work with different types of wood ensures that your projects meet diverse requirements. Whether you’re a professional or a hobbyist, laser cutting wood offers unmatched flexibility and precision.

Key Specifications of Laser Cutting Machines

Understanding the key specifications of a laser cutting machine is essential for selecting the right tool for your woodworking projects. These specifications determine the machine's performance, efficiency, and suitability for various tasks. Below, we explore three critical aspects: power output, cutting area, and cutting speed.

Power Output

The power output of a laser cutting machine directly impacts its cutting capabilities. Machines typically range from 40W to over 15,000W, with higher wattage enabling deeper cuts and faster processing. For woodworking, most machines operate within the 40W to 300W range, which is sufficient for cutting and engraving materials like plywood, MDF, and hardwoods.

High-power machines, such as the YMM-12,000 Laser System, can handle industrial-scale tasks with precision. This system, equipped with a 12,000-watt laser, includes advanced features like capacitive focus positioning and water chillers for optimal performance. If you need a machine for intricate designs or thicker wood, consider one with higher power output.

Cutting Area

The cutting area defines the maximum size of material the machine can accommodate. Common dimensions include 1300mm x 900mm, which suits most woodworking projects. Larger cutting areas allow you to work on bigger pieces without repositioning the material, saving time and ensuring accuracy.

For high-volume production, machines like Bystronic’s New Fiber Laser Cutter offer expansive cutting areas combined with exceptional precision. When choosing a machine, assess your project requirements to ensure the cutting area aligns with your needs.

Cutting Speed

Cutting speed is a crucial factor that affects productivity. It refers to how quickly the laser moves across the material while cutting. Speeds can vary significantly based on the machine's power and the type of wood being processed. For instance, high-power fiber lasers can achieve speeds of up to 80 meters per minute when cutting thin materials like 1mm stainless steel. In contrast, CO2 lasers typically operate at slower speeds, around 20 to 30 meters per minute.

For woodworking, machines with adjustable speeds provide flexibility. You can slow down the process for intricate designs or increase the speed for straightforward cuts. The 15KW Ultra-High-Speed Fiber Laser Cutting Machine exemplifies cutting-edge technology, achieving unprecedented speeds and thickness capabilities. This innovation highlights the importance of selecting a machine with the right balance of speed and precision for your projects.

Material Compatibility

Material compatibility plays a crucial role when selecting a laser cutting machine for woodworking projects. These machines are designed to handle a variety of wood types, including plywood, MDF, and hardwoods. Each type of wood reacts differently to the laser beam, so understanding how your chosen material interacts with the machine ensures optimal results.

For instance, plywood and MDF are popular choices due to their uniform composition, which allows for smooth and consistent cuts. Hardwoods, on the other hand, require higher power output because of their density. Machines like the YMM-12,000 Laser System excel in cutting thicker and denser materials, thanks to their high-power capabilities and advanced cooling systems.

Laser cutting machines also adapt to non-wood materials, such as acrylic and leather, making them versatile tools for various projects. However, always verify the machine's specifications to ensure compatibility with your intended materials. This step prevents damage to both the machine and the material, saving you time and resources.

Precision and Beam Quality

Precision and beam quality define the performance of a laser cutting machine. High precision allows you to create intricate designs and detailed engravings, which are essential for artistic and professional woodworking. Most machines achieve precision levels of up to 0.01mm, ensuring clean and accurate cuts.

Beam quality, often measured by the M² value, determines how well the laser focuses on the material. A lower M² value indicates better beam quality, resulting in finer cuts and reduced material wastage. Machines like the 15KW Ultra-High-Speed Fiber Laser Cutting Machine demonstrate exceptional beam quality, enabling you to achieve high precision even at faster cutting speeds.

When working with wood, maintaining consistent beam quality is vital. Variations in the laser beam can lead to uneven cuts or burns on the material. Regular maintenance, such as cleaning the lenses and mirrors, helps preserve the machine's beam quality and ensures reliable performance over time.

Cooling Systems and Maintenance Requirements

Cooling systems are essential for maintaining the efficiency and longevity of a laser cutting machine. The intense heat generated during laser cutting can affect the machine's components and overall performance. Advanced cooling systems, such as water chillers, regulate the temperature and prevent overheating during extended use.

For example, the Axial Fast Flow Laser Cutting Machine incorporates adaptable cooling mechanisms, ensuring consistent operation even under demanding conditions. Proper cooling not only enhances the machine's lifespan but also improves the quality of cuts by stabilizing the laser beam.

Maintenance requirements for laser cutting machines include routine cleaning and inspection of critical components. Regularly clean the lenses, mirrors, and cutting bed to remove debris and residue that may interfere with the laser's performance. Additionally, check for wear and tear on parts like the laser tube and cooling system to address potential issues before they escalate.

By adhering to these maintenance practices, you can maximize the efficiency and durability of your laser cutting machine. This proactive approach ensures that your machine delivers high precision and consistent results for all your woodworking projects.

Types of Laser Cutting Machines

Understanding the different types of laser cutting machines helps you choose the right tool for your woodworking projects. Each type offers unique features, making them suitable for specific tasks and materials. Below, we explore three popular types of laser cutting machines: CO2, diode, and fiber.

CO2 Laser Cutting Machines

CO2 laser cutting machines are among the most common tools for woodworking. These machines use a gas mixture, primarily carbon dioxide, to generate the laser beam. They excel in cutting and engraving various types of wood, including plywood, MDF, and hardwoods. Their precision and efficiency make them ideal for creating intricate designs and smooth edges.

Key Features of CO2 Laser Cutting Machines:

- High compatibility with wood and other non-metal materials like acrylic and leather.

- Cutting accuracy up to 0.01mm, ensuring detailed and clean results.

- Moderate maintenance requirements, including regular cleaning of lenses and mirrors.

CO2 lasers are cost-effective and versatile, making them a popular choice for hobbyists and small businesses. However, they may require more frequent maintenance compared to other types due to their reliance on optical components.

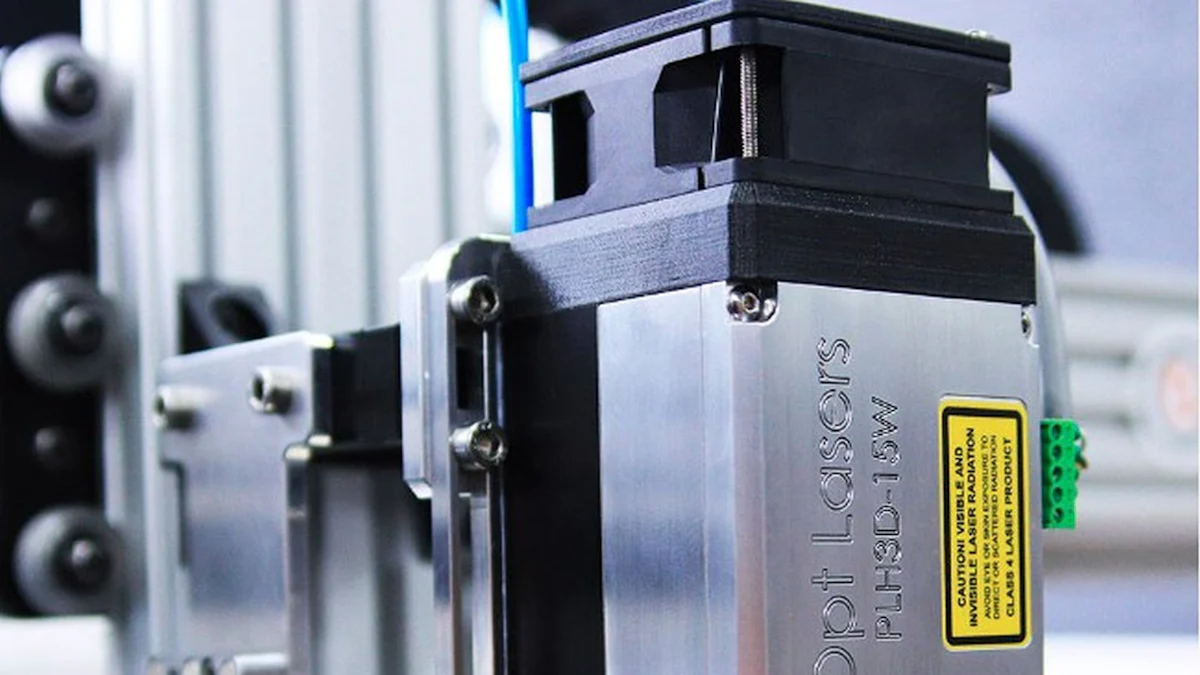

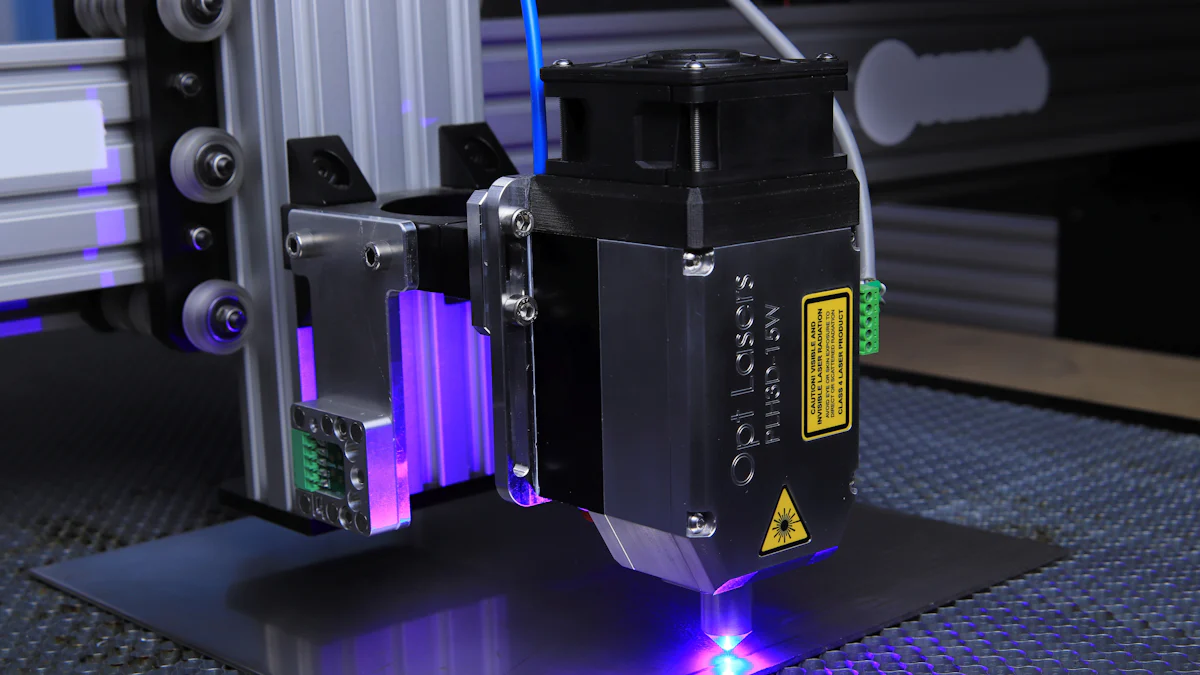

Diode Laser Cutting Machines

Diode laser cutting machines are compact and user-friendly, making them perfect for beginners or small-scale projects. These machines use semiconductor diodes to produce the laser beam. While they typically have lower power output than CO2 lasers, they still perform well for engraving and cutting thin wood materials.

Advantages of Diode Laser Cutting Machines:

- Portable and lightweight design, suitable for home workshops.

- Lower initial cost compared to other types of laser cutting machines.

- Easy to operate, with minimal setup requirements.

Diode lasers are best suited for light-duty tasks, such as engraving decorative patterns or cutting thin plywood. Their lower power output limits their ability to handle thicker or denser wood, but they remain an excellent option for simple projects.

Fiber Laser Cutting Machines

Fiber laser cutting machines represent the pinnacle of laser cutting technology. These machines use optical fibers to amplify the laser beam, resulting in exceptional power and precision. While they are primarily designed for cutting metals, some models can also handle wood with remarkable efficiency.

Why Choose Fiber Laser Cutting Machines?

- Superior cutting speed and precision, ideal for high-volume production.

- Minimal maintenance requirements due to their solid-state design.

- High energy efficiency, reducing operational costs over time.

Fiber lasers are the most advanced option among the types of laser cutting machines. They are well-suited for industrial applications and large-scale woodworking projects. However, their higher cost and complexity may not make them the best choice for casual users or small businesses.

By understanding the strengths and limitations of each type, you can select the laser cutting machine that aligns with your needs. Whether you prioritize affordability, portability, or cutting-edge performance, there is a machine tailored to your woodworking goals.

How to Choose the Right Laser Wood Cutting Machine

Choosing the right laser wood cutting machine requires careful consideration of your specific needs and goals. By evaluating key factors like project requirements, budget, and machine features, you can make an informed decision that ensures efficiency and precision in your woodworking projects.

Assessing Project Needs

Start by identifying the types of projects you plan to undertake. Consider the materials you will work with, such as plywood, MDF, or hardwoods, and the thickness of the wood you need to cut or engrave. For intricate designs or detailed engravings, prioritize machines with high precision and beam quality. Machines like CO2 laser cutting machines are ideal for woodworking due to their ability to handle a wide range of wood thicknesses and densities.

Think about the scale of your projects. If you work on larger pieces, choose a machine with a spacious cutting area, such as 1300mm x 900mm, to accommodate your materials without repositioning. For smaller or decorative projects, compact machines like diode laser cutting machines may suffice. Matching the machine’s capabilities to your project needs ensures optimal performance and results.

Budget and Long-Term Costs

Your budget plays a significant role in selecting a laser wood cutting machine. While initial costs vary, consider the long-term expenses associated with maintenance, energy consumption, and replacement parts. For example, diode laser cutting machines are cost-effective and energy-efficient, making them suitable for small-scale projects or hobbyists. On the other hand, fiber laser cutting machines offer high-speed performance and minimal maintenance but come with a higher upfront cost.

Evaluate the machine’s energy efficiency to reduce operational costs over time. Machines like CO2 lasers achieve energy conversion efficiency of up to 25%, making them a practical choice for frequent use. Additionally, factor in the cost of consumables, such as lenses and mirrors, and the availability of technical support or spare parts. Balancing your budget with the machine’s features ensures a worthwhile investment.

Evaluating Features and Software Compatibility

Examine the features of each laser cutting machine to determine which one aligns with your requirements. Look for adjustable power output, cutting speed, and cooling systems to enhance versatility and performance. Machines like the CO2 laser cutting machines excel in cutting thick wood materials over 10mm, while fiber lasers are better suited for reflective materials and high-speed tasks.

Software compatibility is another critical factor. Many laser cutting machines support popular design software like AutoCAD and CorelDRAW, enabling you to create and execute complex designs seamlessly. Ensure the machine’s software is user-friendly and compatible with your existing tools. This compatibility simplifies the design process and enhances productivity.

By thoroughly assessing your project needs, budget, and desired features, you can select a laser wood cutting machine that meets your expectations. Whether you prioritize affordability, precision, or advanced technology, the right machine will elevate your woodworking projects to new heights.

Benefits of Using a Laser Cutting Machine

Precision and Efficiency

A laser cutting machine offers unmatched precision, allowing you to create intricate designs and detailed patterns with ease. The laser beam focuses on a specific point, ensuring clean and accurate cuts. This level of precision is essential for woodworking projects that demand fine details, such as decorative carvings or custom engravings. You can achieve results with an accuracy of up to 0.01mm, which minimizes errors and reduces material waste.

Efficiency is another significant advantage. Laser cutting eliminates the need for manual tools, speeding up the production process. The machine operates with consistent performance, enabling you to complete projects faster without compromising quality. Whether you are cutting thin plywood or dense hardwood, the laser ensures smooth edges and uniform results. This combination of precision and efficiency makes laser cutting machines indispensable for both hobbyists and professionals.

Versatility for Different Projects

Laser cutting machines excel in versatility, making them suitable for a wide range of woodworking projects. You can use these machines to cut or engrave various types of wood, including plywood, MDF, and hardwoods. Each type of wood reacts differently to the laser, but the machine’s adjustable settings allow you to customize the process for optimal results.

The versatility extends beyond woodworking. Many laser cutting machines can handle non-wood materials like acrylic, leather, and even fabric. This adaptability opens up endless possibilities for creative projects. For example, you can craft furniture, design intricate home décor, or personalize gifts with engraved messages. The ability to switch between cutting and engraving modes further enhances the machine’s flexibility, allowing you to tackle diverse tasks with a single tool.

Long-Term Cost Savings

Investing in a laser cutting machine can lead to significant long-term cost savings. Although the initial purchase may seem high, the machine’s efficiency and durability offset the expense over time. By reducing material waste through precise cuts, you save money on raw materials. The machine’s ability to handle various wood types also eliminates the need for multiple tools, streamlining your workflow and cutting down on additional equipment costs.

Maintenance requirements for laser cutting machines are minimal compared to traditional woodworking tools. Regular cleaning and occasional part replacements ensure consistent performance, extending the machine’s lifespan. Additionally, the energy efficiency of modern laser cutting machines lowers operational costs. For instance, CO2 lasers achieve high energy conversion rates, making them economical for frequent use. These factors contribute to long-term savings, making a laser cutting machine a valuable investment for your woodworking projects.

Maintenance and Care for Laser Cutting Machines

Proper maintenance ensures your laser cutting machine operates efficiently and lasts longer. By following routine care practices and addressing common issues promptly, you can maintain optimal performance and avoid costly repairs.

Routine Maintenance Tips

Regular maintenance keeps your laser cutting machine in top condition. Here are essential tips to follow:

-

Clean the Lenses and Mirrors

Dust and debris can accumulate on the lenses and mirrors, reducing the laser's precision. Use a soft, lint-free cloth and a cleaning solution designed for optics. Perform this task weekly or after heavy use to maintain beam quality. -

Inspect the Cutting Bed

Residue from wood or other materials can build up on the cutting bed. Remove debris after each session to ensure smooth material placement and prevent uneven cuts. A clean cutting bed also reduces the risk of fire hazards. -

Check the Cooling System

Cooling systems, such as water chillers, regulate the machine's temperature during operation. Inspect the coolant levels and replace the water periodically to prevent overheating. Ensure the cooling system functions properly to avoid damage to internal components. -

Lubricate Moving Parts

The machine's moving parts, like rails and belts, require lubrication to reduce friction and wear. Use a lubricant recommended by the manufacturer and apply it monthly. This step ensures smooth operation and extends the lifespan of mechanical components. -

Calibrate the Machine

Regular calibration ensures the laser maintains its precision. Check the alignment of the laser beam and adjust it if necessary. Calibration prevents errors in cutting and engraving, especially for intricate designs.

Pro Tip: Schedule a professional inspection annually to identify potential issues that may not be visible during routine maintenance.

Troubleshooting Common Issues

Even with proper care, you may encounter issues with your laser cutting machine. Knowing how to troubleshoot these problems can save time and prevent further damage.

-

Inconsistent Cutting Quality

If the machine produces uneven cuts or burns the material, check the lenses and mirrors for dirt or damage. Clean or replace them as needed. Verify the laser's power settings and adjust them based on the material's thickness and type. -

Overheating During Operation

Overheating often results from a malfunctioning cooling system. Inspect the water chiller or cooling fan for blockages or leaks. Replace the coolant if it appears dirty or low. Ensure the machine operates in a well-ventilated area to dissipate heat effectively. -

Laser Beam Misalignment

Misaligned beams can cause inaccurate cuts. Recalibrate the machine by aligning the laser beam with the cutting path. Follow the manufacturer's instructions for precise adjustments. -

Software or Connectivity Issues

If the machine fails to execute designs correctly, check the software for updates or compatibility issues. Ensure the design file is in the correct format and free of errors. Restart the machine and reconnect it to your computer to resolve connectivity problems. -

Unusual Noises or Vibrations

Strange sounds or excessive vibrations may indicate loose components. Inspect the machine's frame, belts, and screws for signs of wear or looseness. Tighten or replace parts as necessary to restore stability.

Quick Fix: Keep a troubleshooting guide handy to address minor issues without delay. Refer to the user manual for detailed solutions specific to your machine model.

By incorporating these maintenance practices and troubleshooting techniques, you can ensure your laser cutting machine remains reliable and efficient. Consistent care not only enhances performance but also protects your investment, allowing you to focus on creating high-quality woodworking projects.

Laser wood cutting machines provide unmatched precision, versatility, and efficiency, making them indispensable for woodworking projects. By understanding the specifications, such as power output, cutting area, and material compatibility, you can select a machine tailored to your needs. Evaluate your project requirements carefully, considering factors like wood type, budget, and desired features. This approach ensures you choose a laser cutting machine that enhances your productivity and delivers exceptional results. With the right machine, you can unlock endless possibilities for creating intricate designs and achieving professional-quality finishes.

FAQ

What makes laser cutting better than traditional woodworking tools?

Laser cutting offers unmatched precision and efficiency. Unlike traditional tools, it creates intricate designs with smooth edges and minimal material waste. The high precision of laser technology, often up to 0.01mm, ensures detailed cuts that are difficult to achieve with manual methods. Additionally, the process is faster and eliminates physical contact, reducing wear on tools.

Can a laser cutting machine handle all types of wood?

Yes, most laser cutting machines can work with various types of wood, including plywood, MDF, and hardwoods. Each type of wood reacts differently to the laser beam. For example, plywood and MDF cut smoothly due to their uniform composition, while hardwoods may require higher power settings because of their density. Always check the machine's specifications to ensure compatibility with your chosen material.

What is the best wood for laser cutting?

The best wood for laser cutting depends on your project. Plywood and MDF are popular choices due to their consistent structure, which allows for clean and precise cuts. Softwoods like pine are easier to cut but may char more easily. Hardwoods, such as oak or walnut, produce excellent results but require higher power output. Selecting the right wood ensures optimal performance and quality.

How do I maintain my laser cutting machine?

Routine maintenance keeps your laser cutting machine in top condition. Clean the lenses and mirrors regularly to maintain beam quality. Inspect the cutting bed for debris after each use. Check the cooling system to prevent overheating, and lubricate moving parts monthly. Calibration ensures precision, so align the laser beam periodically. Following these steps extends the machine's lifespan and ensures consistent performance.

Is laser cutting safe for beginners?

Yes, laser cutting is safe when you follow proper guidelines. Most machines come with safety features like enclosed designs and emergency stop buttons. Wear protective eyewear to shield your eyes from the laser beam. Ensure the workspace is well-ventilated to avoid inhaling fumes from materials like wood or acrylic. By adhering to safety protocols, beginners can use laser cutting machines confidently.

How does laser cutting achieve such high precision?

Laser cutting achieves high precision through its focused laser beam, which vaporizes or melts the material along the cutting path. The beam's accuracy, often measured at 0.01mm, allows for intricate designs and detailed engravings. A computer numerical control (CNC) system guides the laser, ensuring consistent and precise results. This technology makes laser cutting ideal for projects requiring fine details.

Can laser cutting machines engrave as well as cut?

Yes, laser cutting machines can both cut and engrave. By adjusting the laser's intensity, you can switch between cutting through the material and engraving its surface. This versatility allows you to create custom designs, such as engraved patterns or personalized messages, alongside precise cuts. It makes the machine suitable for a wide range of creative and professional applications.

What factors should I consider when choosing a laser cutting machine?

When selecting a laser cutting machine, consider your project needs, budget, and desired features. Assess the types of wood you plan to work with and the thickness you need to cut. Look for machines with adjustable power output, cutting speed, and a suitable cutting area. Software compatibility is also essential for executing complex designs. Evaluating these factors ensures you choose the right machine for your goals.

Are laser cutting machines cost-effective in the long run?

Yes, laser cutting machines are cost-effective over time. Although the initial investment may seem high, the machine's efficiency and durability offset the expense. Precise cuts reduce material waste, saving money on raw materials. Maintenance costs are minimal compared to traditional tools, and energy-efficient models lower operational expenses. These factors make laser cutting machines a valuable long-term investment.

Can laser cutting machines be used for non-wood materials?

Yes, many laser cutting machines can handle non-wood materials like acrylic, leather, and fabric. The machine's adjustable settings allow you to customize the process for different materials. However, always verify the machine's specifications to ensure compatibility. Using the correct settings prevents damage to both the material and the machine, expanding its versatility for various projects.

See Also

Is CNC Machinery Capable of Efficiently Cutting Wood?

Understanding the Functionality of CNC Laser Cutters

Comparative Guide to Laser Cutting Machine Prices