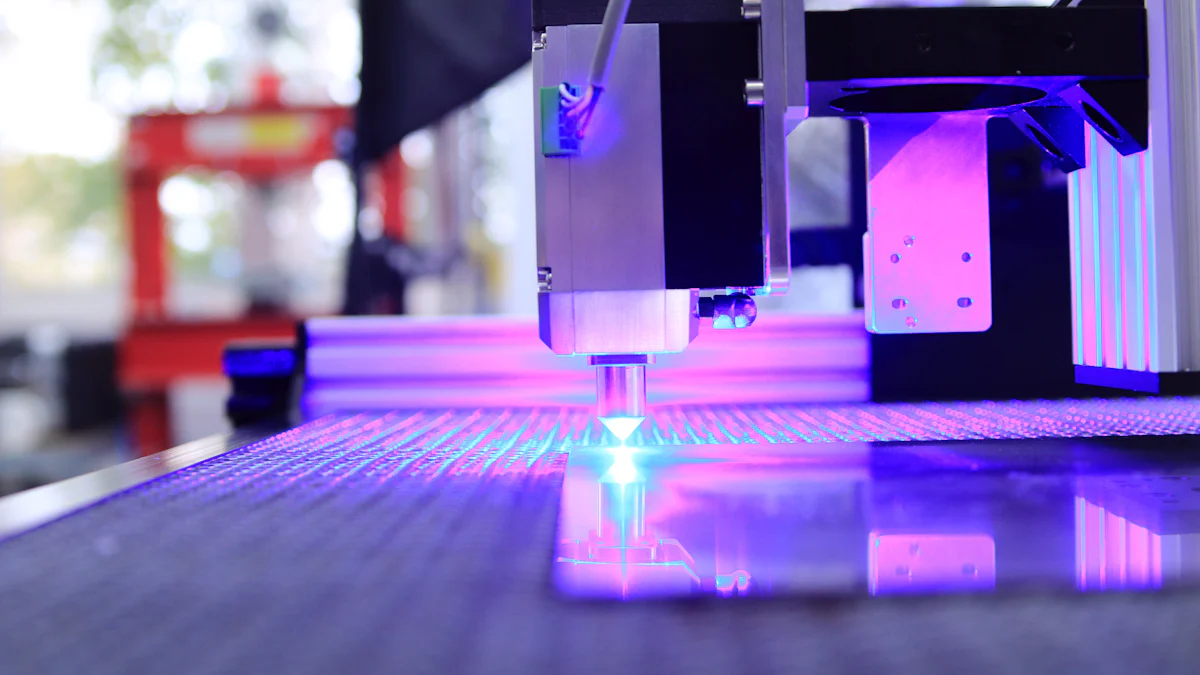

Safety Tips for Laser PCB Cutting Machines

Operating a laser cutter for PCB production, especially when learning how to make a laser PCB cutting machine, demands your full attention to safety. The intense laser beam can cause severe injuries, including permanent eye damage or skin burns, if mishandled. Toxic fumes released during cutting pose serious respiratory risks, while improper use increases the likelihood of fires. You must follow laser cutting safety protocols to protect yourself and others. Proper training, protective gear, and a well-maintained workspace are essential. Neglecting these measures not only endangers health but also compromises the efficiency of your work environment.

Understanding Common Hazards in Laser PCB Cutting

Fire Risks in Laser Cutting

Fire remains one of the most serious hazards when using a laser cutter. The intense heat generated by the laser can ignite flammable materials, leading to dangerous situations. For example, cutting plastics or other combustible materials may result in small flames that can quickly escalate if not monitored. You must eliminate any flammable objects near the machine to reduce this risk. Always keep a fire extinguisher within reach and inspect it regularly to ensure it is functional. Never leave the laser cutter unattended during operation, as even a minor spark can lead to significant damage. Prioritizing fire safety in your workspace protects both you and your equipment.

Harmful Fumes and Vapors

Laser cutting often produces harmful fumes and vapors, especially when working with materials like plastics or coated metals. These fumes can irritate your respiratory system and, in some cases, release toxic chemicals into the air. Without proper ventilation, these airborne hazards can accumulate and pose serious health risks. Install an effective exhaust system to remove fumes from the workspace. Additionally, ensure the room has adequate airflow to prevent the buildup of harmful substances. Wearing a mask designed for industrial use can provide extra protection against inhaling dangerous particles. Taking these precautions ensures a safer environment for you and others nearby.

Physical Injuries from Laser Exposure

Direct exposure to the laser beam can cause severe injuries, including permanent eye damage and skin burns. The high-intensity light emitted by the laser cutter is powerful enough to harm unprotected eyes, even from indirect reflections. Always wear laser safety glasses specifically rated for the wavelength of your machine. Cover exposed skin to minimize the risk of burns, especially when working with high-power lasers. Avoid bypassing safety interlocks or tampering with protective covers, as these features are designed to shield you from accidental exposure. Staying vigilant and using the right protective gear significantly reduces the likelihood of physical injuries.

Electrical Hazards in Laser Cutter Operation

Electrical hazards pose a significant risk when operating a laser cutter. The high-voltage components inside the machine can cause severe injuries or even fatalities if mishandled. Faulty wiring, damaged power cords, or improper grounding increase the likelihood of electrical shocks. You must inspect the machine’s electrical connections regularly to ensure they remain intact and free from wear. Replace damaged cables immediately to prevent accidents.

Moisture in the workspace can also amplify electrical risks. Keep the area around the laser cutter dry and clean at all times. Avoid placing liquids near the machine to reduce the chance of spills that could lead to short circuits. Additionally, ensure the machine is connected to a properly grounded outlet to minimize the risk of electrical surges.

Safety interlocks play a crucial role in preventing electrical accidents. These mechanisms shut down the machine if a protective cover is opened or tampered with. Never disable or bypass these features, as doing so compromises your safety. Always follow the manufacturer’s guidelines for electrical maintenance and operation.

In case of an emergency, knowing how to disconnect the power supply quickly is essential. Familiarize yourself with the location of the main power switch or circuit breaker. This knowledge allows you to act swiftly if an electrical issue arises, reducing the potential for harm.

By staying vigilant and maintaining the machine’s electrical systems, you can significantly lower the risks associated with laser cutter operation. Prioritizing electrical safety ensures a safer and more efficient workspace.

Essential Safety Precautions for Laser PCB Cutting

Importance of Proper Training and Certification

Operating a laser cutter without proper training can lead to serious accidents. You must understand the machine’s functionality, safety features, and potential hazards before using it. Training programs teach you how to handle the equipment safely and respond to emergencies. Certification ensures that you meet the required standards for operating the machine. Many manufacturers and workplaces mandate this step to minimize risks.

Proper training also helps you recognize unsafe practices. For example, you learn to avoid bypassing safety features like interlocks or tampering with protective covers. These mechanisms are designed to protect you from laser exposure and electrical hazards. By completing training and obtaining certification, you gain the knowledge and confidence to operate the machine safely and efficiently.

Using Approved Materials for Laser Cutting

Not all materials are safe for laser cutting. Some release toxic fumes or catch fire easily when exposed to the laser beam. You should always verify that the materials you use are approved for laser cutting. For instance, cutting PVC or other chlorine-based plastics can produce harmful gases that damage both your health and the machine.

Using approved materials reduces the risk of fire and ensures cleaner cuts. Manufacturers often provide a list of compatible materials for their machines. Refer to this list to avoid accidents and maintain the machine’s performance. Additionally, inspect materials for coatings or adhesives that may react unpredictably during cutting. Prioritizing material safety protects you and extends the lifespan of your equipment.

Regular Equipment Maintenance for Safety

Routine maintenance is essential for keeping your laser cutter in safe working condition. Dust, debris, and worn-out components can compromise the machine’s performance and increase safety risks. You should clean the machine regularly to prevent the buildup of flammable particles. Check the laser lens and mirrors for dirt or damage, as these can affect the beam’s accuracy and intensity.

Inspect electrical connections and cables for wear or damage. Faulty wiring can lead to electrical hazards, including shocks or fires. Replace damaged parts immediately to avoid accidents. Test the machine’s safety features, such as interlocks and emergency stop buttons, to ensure they function correctly. Following the manufacturer’s maintenance guidelines helps you identify potential issues before they escalate.

A well-maintained machine operates more efficiently and reduces the likelihood of accidents. Schedule regular inspections and keep a maintenance log to track repairs and replacements. By prioritizing maintenance, you create a safer and more reliable workspace.

Required Safety Gear and Protective Measures

When operating a laser cutter, using the right safety gear and protective measures is essential. These tools and systems shield you from potential hazards, ensuring a safer and more efficient workspace.

Personal Protective Equipment (PPE) for Laser Cutter Safety

Personal protective equipment (PPE) plays a critical role in protecting you from injuries during laser cutting. The intense laser beam can cause severe eye damage and skin burns if you don’t take precautions. Always wear laser safety glasses that match the wavelength of your machine. These glasses block harmful light and prevent eye injuries caused by direct or reflected beams.

Covering your skin is equally important. Use lab coats or long-sleeved clothing made from non-flammable materials to reduce the risk of burns. Gloves designed for industrial use can protect your hands from accidental contact with hot surfaces or sharp edges. Avoid loose clothing or accessories that could get caught in the machine.

Proper PPE ensures you stay safe while working with high-powered equipment. By equipping yourself with the right gear, you minimize the risks associated with laser exposure.

Ventilation Systems for Laser Cutting Safety

Laser cutting generates fumes and vapors that can harm your respiratory system. Without proper ventilation, these airborne particles accumulate and create a hazardous environment. Installing an effective exhaust system removes harmful substances from the air, keeping the workspace safe.

Position the ventilation system to capture fumes directly at the source. This setup prevents the spread of toxic particles. Ensure the system is regularly maintained to avoid blockages or reduced efficiency. In addition to exhaust systems, maintain good airflow in the room by using fans or opening windows when possible.

For added protection, consider wearing a respirator mask designed for industrial environments. This mask filters out fine particles and reduces the risk of inhaling harmful substances. A well-ventilated workspace protects your health and enhances overall safety.

Fire Safety Equipment for Laser PCB Cutting Machines

Fire hazards are a significant concern when using a laser cutter. The intense heat from the laser can ignite flammable materials, leading to dangerous situations. Having the right fire safety equipment on hand is crucial for preventing accidents.

Keep a fire extinguisher within easy reach of the machine. Choose an extinguisher rated for electrical and flammable material fires. Inspect it regularly to ensure it remains functional. Place a fire blanket nearby as an additional safety measure for smothering small flames.

Eliminate combustible materials from the workspace to reduce fire risks. Store flammable items, such as solvents or cleaning agents, in a separate area away from the machine. Never leave the laser cutter unattended during operation. Constant monitoring allows you to respond quickly to any signs of fire.

By prioritizing fire safety equipment, you create a safer environment for yourself and others. These precautions help you manage risks effectively and maintain a secure workspace.

Best Practices for Safe Operation of Laser PCB Cutting Machines

Never Leave the Laser Cutter Unattended

Leaving a laser cutter running without supervision is one of the most dangerous mistakes you can make. The intense heat generated by the laser can ignite materials unexpectedly, even those considered safe for cutting. Fires can escalate quickly, especially if flammable objects are nearby. By staying present during operation, you can immediately address any sparks, flames, or malfunctions.

Always monitor the cutting process closely. Watch for unusual signs, such as excessive smoke, irregular noises, or unexpected pauses in the machine’s movement. If you notice anything abnormal, stop the machine immediately and inspect it for issues. Keeping a fire extinguisher within reach ensures you can respond promptly to emergencies. This simple habit can prevent accidents and protect your workspace.

Follow Manufacturer Guidelines for Laser Cutting Safety

Manufacturers design their machines with specific safety features and operating procedures in mind. Ignoring these guidelines increases the risk of accidents and reduces the lifespan of your equipment. Always read the user manual thoroughly before using the laser cutter. Familiarize yourself with the recommended settings, compatible materials, and maintenance schedules.

Adhering to these guidelines ensures the machine operates efficiently and safely. For example, manufacturers often specify the correct pulse rate and power settings for different materials. Using incorrect settings can lead to poor cuts, excessive wear on the machine, or even fires. Additionally, never disable safety features like interlocks or emergency stop buttons. These mechanisms exist to protect you from harm.

If you encounter issues not covered in the manual, contact the manufacturer or a certified technician for assistance. Avoid attempting repairs or modifications without proper knowledge, as this can void warranties and compromise safety. Following the manufacturer’s instructions keeps you and your equipment safe while maintaining optimal performance.

Emergency Preparedness for Laser Cutter Safety

Being prepared for emergencies is a critical aspect of laser cutter safety. Accidents can happen despite your best efforts, so knowing how to respond quickly can minimize damage and prevent injuries. Start by identifying the location of emergency equipment, such as fire extinguishers, fire blankets, and the main power switch. Ensure these items are easily accessible and in good working condition.

Practice emergency drills to familiarize yourself with the steps to take during a crisis. For instance, learn how to shut down the machine immediately if a fire starts or if the laser malfunctions. Keep a clear path to exits in case you need to evacuate the area quickly. Inform others in the workspace about emergency protocols to ensure everyone knows how to respond.

Regularly inspect your safety equipment to confirm it is functional. Replace expired fire extinguishers and test emergency stop buttons to verify they work as intended. Staying prepared for emergencies not only protects you but also ensures a safer environment for everyone in the workspace.

Understanding and addressing the hazards of laser PCB cutting is essential for maintaining a safe workspace. By prioritizing proper training, you equip yourself with the knowledge to handle the laser cutter effectively and avoid accidents. Using safety gear and following best practices ensures protection against injuries and equipment damage. Adhering to these measures not only safeguards your health but also enhances the efficiency of your operations. Always make laser cutter safety your top priority to create a secure and productive environment for PCB production.

FAQ

What are the most common hazards when using a laser PCB cutting machine?

The most common hazards include fire risks, harmful fumes, physical injuries from laser exposure, and electrical hazards. The intense heat from the laser can ignite flammable materials, while cutting certain materials like plastics can release toxic fumes. Direct exposure to the laser beam can cause severe eye damage or skin burns. Faulty wiring or improper grounding can lead to electrical shocks. Understanding these risks helps you take the necessary precautions to stay safe.

How can I prevent fires during laser cutting?

To prevent fires, remove all flammable materials from the workspace. Always monitor the machine while it operates and never leave it unattended. Keep a fire extinguisher nearby and ensure it is functional. Regularly clean the machine to remove dust and debris that could ignite. Following these steps minimizes the chances of a fire starting.

Why is proper ventilation important for laser cutting?

Laser cutting produces fumes and vapors that can harm your respiratory system. Without proper ventilation, these hazardous particles can accumulate in the air. Installing an exhaust system removes these substances from the workspace. Good airflow, combined with a respirator mask, ensures you breathe clean air while working.

What personal protective equipment (PPE) should I use?

You should wear laser safety glasses rated for your machine’s wavelength to protect your eyes. Use lab coats or long-sleeved clothing made from non-flammable materials to shield your skin. Industrial gloves protect your hands from burns or sharp edges. Avoid loose clothing or accessories that could get caught in the machine.

Can I use any material for laser cutting?

No, not all materials are safe for laser cutting. Some, like PVC or chlorine-based plastics, release toxic gases when cut. Always check the manufacturer’s list of approved materials for your machine. Using the wrong materials can harm your health and damage the equipment.

How often should I maintain my laser cutter?

You should perform maintenance regularly to keep the machine in safe working condition. Clean the machine to remove dust and debris. Inspect the laser lens, mirrors, and electrical connections for damage. Test safety features like interlocks and emergency stop buttons. Following the manufacturer’s maintenance schedule ensures optimal performance and safety.

What should I do in case of an emergency?

In an emergency, shut down the machine immediately using the main power switch. Use a fire extinguisher or fire blanket if a fire occurs. Ensure you know the location of all emergency equipment and keep a clear path to exits. Practicing emergency drills prepares you to respond quickly and effectively.

Why is training important before operating a laser cutter?

Training teaches you how to use the machine safely and recognize potential hazards. It also helps you understand the safety features and emergency protocols. Certification ensures you meet the required standards for operating the equipment. Proper training reduces the risk of accidents and improves your confidence in handling the machine.

Can I bypass safety features like interlocks?

No, you should never bypass safety features. Interlocks and protective covers are designed to shield you from laser exposure and electrical hazards. Disabling these features compromises your safety and increases the risk of accidents. Always follow the manufacturer’s guidelines to ensure safe operation.

What are the best practices for safe laser cutter operation?

Always monitor the machine while it operates. Follow the manufacturer’s guidelines for settings, materials, and maintenance. Keep the workspace clean and free of flammable objects. Use proper PPE and ensure the ventilation system works effectively. Staying vigilant and prepared ensures a safe and efficient working environment.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Effective Techniques for Operating a Plasma Cutter

Understanding the Functionality of CNC Laser Cutters