Review of Top Laser Wood Cutting Machines

Are you searching for the best laser cutters for wood? Understanding the features, usability, performance, and value for money is crucial. The market for wood laser cutting machines is booming, with a projected growth from $1.2 billion in 2022 to $2.3 billion by 2030. This growth highlights the increasing demand for efficient and precise laser cutting solutions. Knowing how much is a laser wood cutting machine and what it offers can help you make an informed decision. Dive into the world of laser cutting and discover the perfect machine for your needs.

Buying Process and Initial Setup

When you decide to invest in a laser cutter for home business or personal projects, understanding the buying process and initial setup is crucial. This section will guide you through key considerations before purchase and the steps to set up your machine effectively.

Key Considerations Before Purchase

Budget and Pricing

Before purchasing a laser cutter, you need to determine your budget. The market offers a range of options, from the best budget laser cutter to high-end models. Consider what you can afford without compromising on essential features. Remember, a higher price often reflects better quality and durability. However, there are excellent budget-friendly options available that provide great value for money.

Intended Use and Material Compatibility

Understanding your intended use is vital. Are you looking for the best home crafting laser cutter, or do you need a more robust machine for a home business? Different machines offer varying power levels and capabilities. Ensure the laser cutter you choose can handle the type and thickness of wood you plan to use. Check the specifications to confirm compatibility with your materials.

Setting Up Your Machine

Installation Requirements

Once you've selected your laser cutter, proper installation is the next step. Ensure the machine is placed in a well-ventilated area to prevent the accumulation of harmful fumes. Follow the manufacturer's guidelines for setting up the exhaust system and grounding the machine. Safety should always be a priority, so never leave the laser running unattended.

Initial Calibration and Testing

After installation, calibrate your machine to ensure optimal performance. This involves aligning the laser and conducting test cuts on scrap wood. Adjust the laser power, speed, and frequency based on the material's thickness and type. Proper calibration ensures clean and precise cuts, reducing the risk of errors during your projects. Regular maintenance and adherence to safety protocols will help maintain the machine's longevity and performance.

By following these steps, you can confidently set up your laser cutter and start creating impressive wood projects. Whether you're using it for home crafting or as a laser cutter for home business, understanding the buying process and initial setup will enhance your experience and results.

Detailed Reviews of Top Machines

xTool P2 Review

Features and Specifications

The xTool P2 stands out with its impressive features. It offers a working area of 600×305mm, providing ample space for your projects. This machine supports engraving on uneven or curved surfaces, thanks to its CurveAce™ Technology. Such versatility makes it a top choice for those seeking the best premium laser cutter.

User Experience and Usability

You will find the xTool P2 user-friendly, with intuitive controls that simplify the engraving process. Its design caters to both beginners and experienced users, ensuring a smooth operation. The machine's compatibility with various materials enhances its usability, making it a reliable option for diverse projects.

Performance and Cutting Quality

Expect high-quality cuts with the xTool P2. Its precision and speed ensure clean edges and detailed designs. Whether you're working on intricate patterns or simple cuts, this machine delivers consistent results. The xTool P2's performance makes it one of the best laser cutters available today.

Price and Value for Money

When considering how much is a laser wood cutting machine, the xTool P2 offers excellent value. While it may not be the best budget laser cutter, its features justify the investment. You receive a robust machine that promises durability and efficiency, making it a worthwhile purchase for serious crafters.

Glowforge Review

Features and Specifications

The Glowforge Basic model is popular for its compact design and ease of use. It features a working area of 495×279mm, suitable for most home projects. The Glowforge Basic supports a wide range of materials, including wood, leather, and acrylic, making it versatile for various applications.

User Experience and Usability

Glowforge Basic is designed with the user in mind. Its straightforward setup and operation make it accessible to beginners. The Glowforge community provides additional support, offering tips and sharing experiences to enhance your engraving journey. This community aspect adds value to the overall user experience.

Performance and Cutting Quality

The Glowforge Basic excels in delivering precise cuts and detailed engraving. Its laser technology ensures accuracy, making it ideal for crafting intricate designs. Although it may not match the speed of some high-end models, it compensates with quality and reliability.

Price and Value for Money

For those wondering how much is a laser wood cutting machine, the Glowforge Basic offers a competitive price point. It is considered one of the best budget laser cutters, providing excellent features without breaking the bank. This model is perfect for hobbyists and small business owners looking for a cost-effective solution.

OMTech Engraving Machines

Features and Specifications

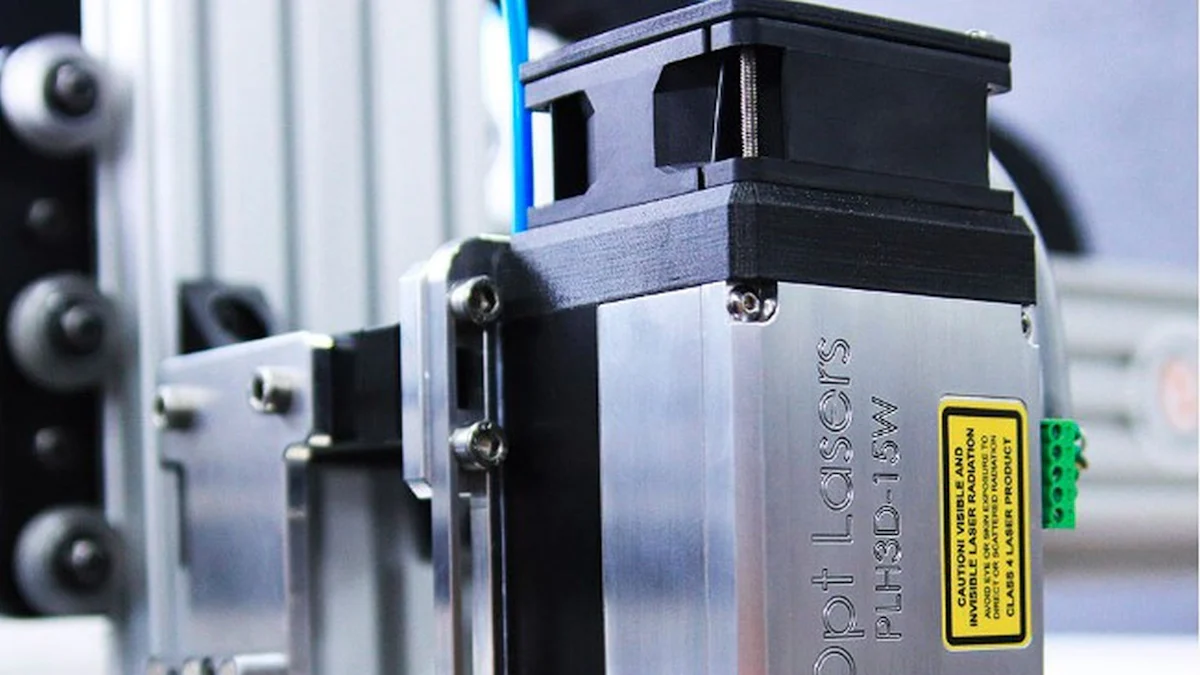

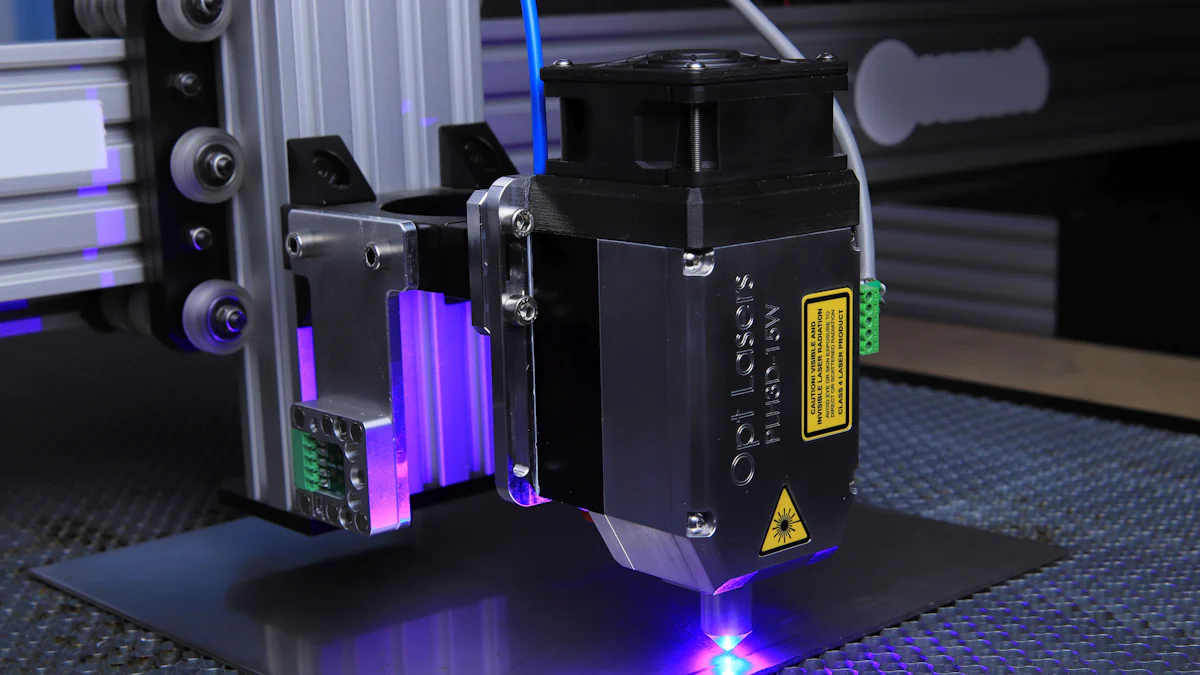

OMTech machines are known for their robust build and extensive features. They offer a generous warranty period of two years, providing peace of mind. These machines are equipped with powerful lasers, capable of cutting thicker materials, making them suitable for more demanding projects.

User Experience and Usability

You will appreciate the straightforward operation of OMTech machines. Their design focuses on efficiency, allowing you to achieve professional results with ease. The machines' compatibility with various software enhances their usability, catering to both beginners and seasoned users.

Performance and Cutting Quality

OMTech machines deliver exceptional performance, with precise cuts and detailed engraving. Their powerful lasers ensure quick and efficient processing, making them ideal for high-volume tasks. These machines are a great choice for those seeking a laser cutter for business purposes.

Price and Value for Money

While OMTech machines may not be the best budget laser cutter, they offer excellent value for their price. The combination of durability, performance, and extended warranty makes them a smart investment for serious users. If you're looking for a reliable laser cutter for home business, OMTech machines are worth considering.

Additional Software and Accessories

When using a laser engraver, selecting the right software and accessories enhances your experience and ensures optimal results. This section explores software compatibility and essential accessories that complement your laser cutting machine.

Software Compatibility and Features

Design Software Options

To achieve precise and intricate designs, you need reliable design software. Popular options include Adobe Illustrator and CorelDRAW. These programs allow you to create vector-based files, which are crucial for successful engraving. Vector lines guide the laser engraver, ensuring accuracy and detail in your projects. Choose software that suits your skill level and project requirements.

Integration with Machine

Seamless integration between your design software and laser engraver is vital. Most modern machines support various file formats, making it easier to transfer designs. Ensure your software is compatible with your machine's operating system. This compatibility streamlines the engraving process, reducing errors and enhancing efficiency. Regular updates to both software and machine firmware can further improve performance.

Essential Accessories

Safety Gear

Safety should always be your top priority when operating a laser engraver. Invest in quality safety gear to protect yourself from potential hazards. Essential items include safety goggles to shield your eyes from laser beams and gloves to handle materials safely. A well-ventilated workspace also minimizes exposure to fumes generated during the engraving process.

Maintenance Tools

Regular maintenance keeps your laser engraver in top condition. Basic tools like cleaning brushes and lens wipes help maintain the machine's components. Periodic checks and cleaning prevent dust buildup, ensuring consistent performance. Proper maintenance not only extends the lifespan of your engraver but also guarantees safe operation. The glowforge community often shares valuable maintenance tips, providing additional support for users.

By choosing the right software and accessories, you enhance the functionality and safety of your laser engraver. Whether you're a hobbyist or a professional, these tools and practices ensure you achieve the best results in your wood engraving projects.

Comparison of Technical Specifications and Pricing

When choosing the best laser cutters, understanding their technical specifications and pricing is essential. This section provides a detailed comparison to help you make an informed decision.

Technical Specifications Overview

Power and Speed

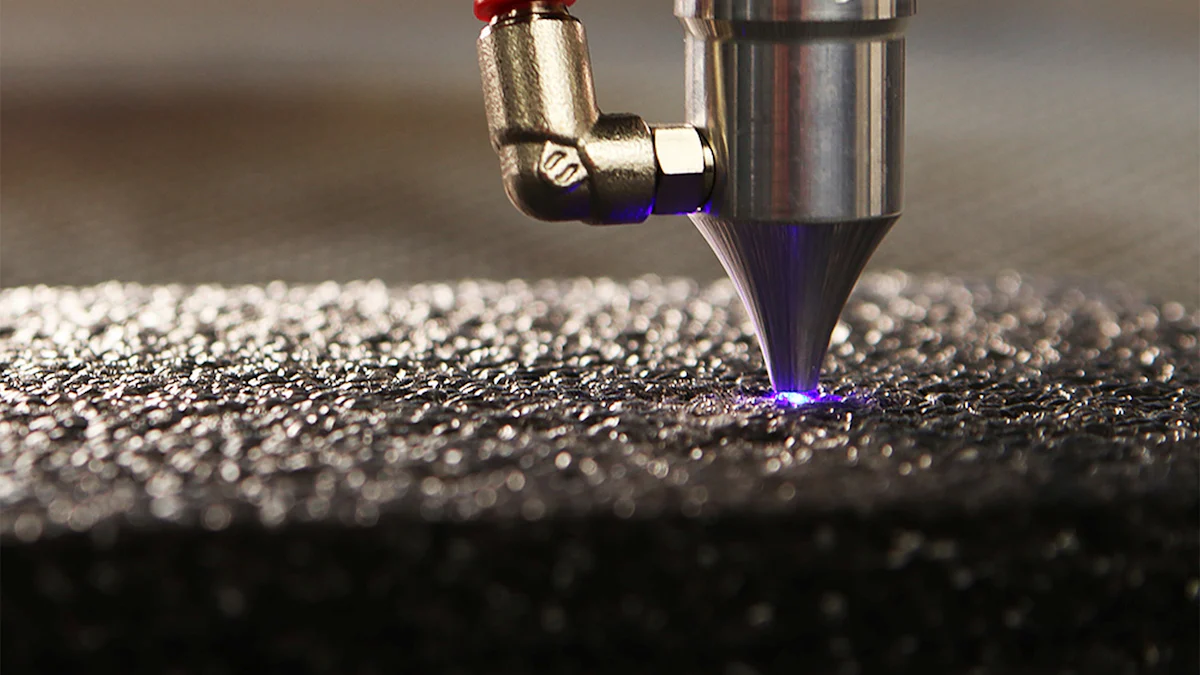

Power and speed are crucial factors in determining the efficiency of a laser engraver. High power allows the machine to cut through thicker materials, while speed affects how quickly you can complete projects. For instance, a 100W CO2 laser tube offers high cutting speed and accuracy, making it ideal for both intricate engraving and large-scale projects. This combination ensures smooth edges and precise cuts, enhancing the quality of your wood projects.

Cutting Area and Precision

The cutting area determines the size of the material you can work with. Larger cutting areas provide more flexibility, allowing you to tackle bigger projects. Precision, on the other hand, ensures that your designs are accurately replicated on the material. Machines with non-contact cutting technology offer high precision, which is vital for detailed engraving tasks. When selecting a laser cutter for home business, consider both the cutting area and precision to ensure it meets your project requirements.

Pricing Comparison

Cost Analysis

Cost is a significant consideration when investing in a laser engraver. Prices vary based on features, power, and brand reputation. While some machines are budget-friendly, others fall into the best premium laser category, offering advanced features and superior performance. It's important to analyze what each machine offers in relation to its price. A cost-effective option might provide the necessary features without unnecessary extras, making it a smart choice for those on a budget.

Long-term Investment Value

Investing in a laser cutter involves considering its long-term value. A machine with a robust build and reliable performance can serve you well for years, making it a worthwhile investment. The best home crafting laser cutter should offer durability and efficiency, ensuring you get the most out of your purchase. Consider the warranty period and customer support services, as these factors contribute to the overall value of the machine. By evaluating these aspects, you can choose a laser cutter that not only meets your current needs but also supports future projects.

By comparing technical specifications and pricing, you can identify the best laser cutters that align with your needs and budget. Whether you're looking for a laser cutter for home business or personal use, understanding these factors will guide you in making a sound investment.

Choosing the right laser wood cutting machine depends on your specific needs and budget. Here's a quick summary to guide you:

- xTool P2: Offers high precision and versatility, making it ideal for intricate engraving tasks. It's a solid investment if you're willing to spend more for quality and durability.

- Glowforge Basic: Known for its user-friendly design and community support. This machine suits hobbyists and small businesses looking for cost-effective solutions. The glowforge review conclusion highlights its excellent value for money.

- OMTech Machines: Provide robust performance and are perfect for demanding projects. They may not be the cheapest, but their power and reliability justify the cost.

Understanding how much is a laser wood cutting machine helps you weigh these options effectively. Consider the advantages and limitations of each to make an informed decision that aligns with your creative goals.

FAQ

How much does it cost to buy a laser wood cutter?

The cost of a laser wood cutter varies based on its type and features. An entry-level wood laser cutter typically ranges from $2,680 to $3,280. If you're interested in a hobby laser wood cutting machine, expect to pay around $3,680. Industrial-grade machines can range from $6,000 to $29,800. The final price depends on factors like the laser generator, power, and additional parts or accessories.

What are the advantages of laser wood cutting?

Laser wood cutting offers several benefits. It uses a non-contact cutting method, which means no wood chip pollution and no tool wear. You won't need to change tools, and there's no noise pollution. The patterns produced are more beautiful compared to traditional machine tools, and the process is cost-effective.

What are the design possibilities with laser cutting wood?

Laser cutting technology opens up a world of design possibilities. You can create diverse and complex designs, from small decorative items to large architectural elements. This versatility makes laser cutting an ideal choice for artists, designers, and hobbyists.

What frequency is usually required for laser cutting wood?

When laser cutting wood, you typically need a frequency between 10,000 and 50,000 Hz. However, specific settings can vary based on the type of wood, its thickness, and the capabilities of your machine.

What are the major applications of wood laser cutting machines?

Wood laser cutting machines have a wide range of applications. They are commonly used in furniture manufacturing, interior decoration, and the creation of crafts and DIY products. These machines offer precision and efficiency, making them valuable tools in various industries.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Essential Advice for Selecting the Best Wood Cutting Machine

Is a CNC Machine Effective for Wood Cutting?