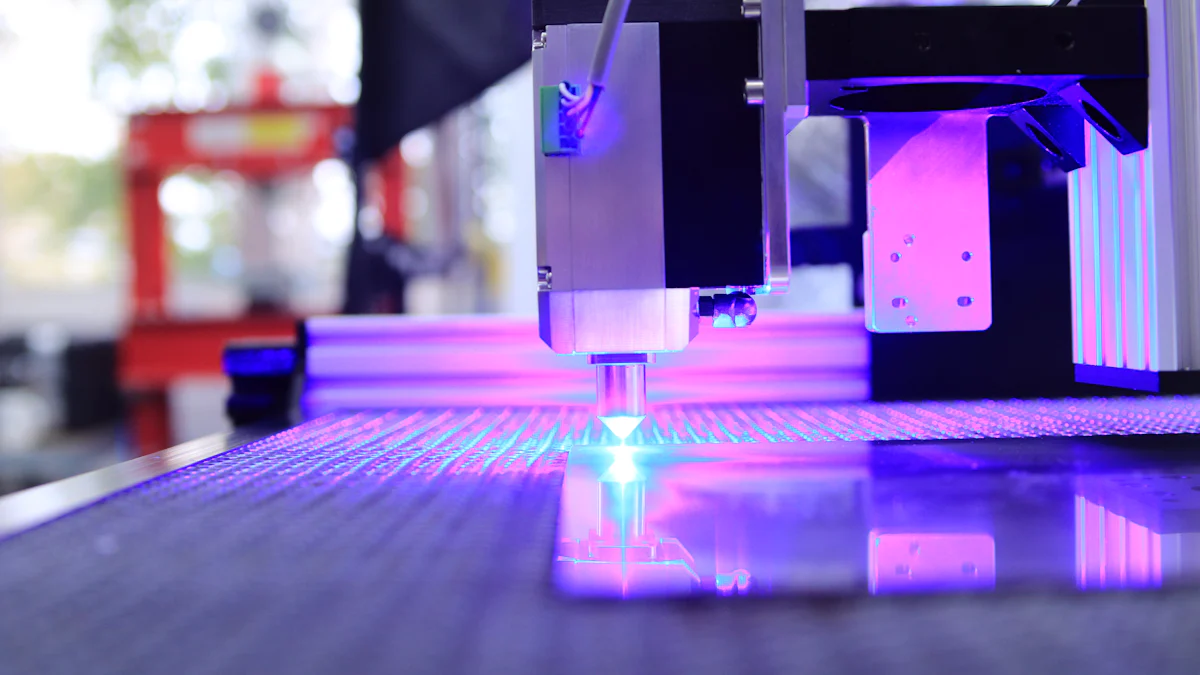

Pros and Cons of Fiber Laser Cutting Machines

Understanding what is fiber laser cutting machine is crucial for anyone considering this advanced technology. These machines have revolutionized industries with their high precision and speed. They offer significant advantages and disadvantages that you must weigh carefully. On the plus side, fiber laser cutting machines are highly efficient and versatile, making them suitable for various applications. However, they also come with challenges, such as high initial costs. By grasping these factors, you can make informed decisions that align with your operational needs and financial goals.

Advantages of Fiber Laser Cutting Machines

Fiber laser cutting machines have transformed the manufacturing landscape with their remarkable capabilities. Understanding the advantages of laser cutting can help you make informed decisions for your business.

High Speed in Fiber Laser Cutting

One of the most significant advantages of fiber laser cutting is its high speed. These machines operate at faster cutting speeds compared to traditional methods. You can complete projects more quickly, leading to greater productivity. This efficiency allows you to handle more orders, which can result in higher potential profit margins. The cutting speed of fiber laser cutting machines ensures that you stay competitive in a fast-paced market.

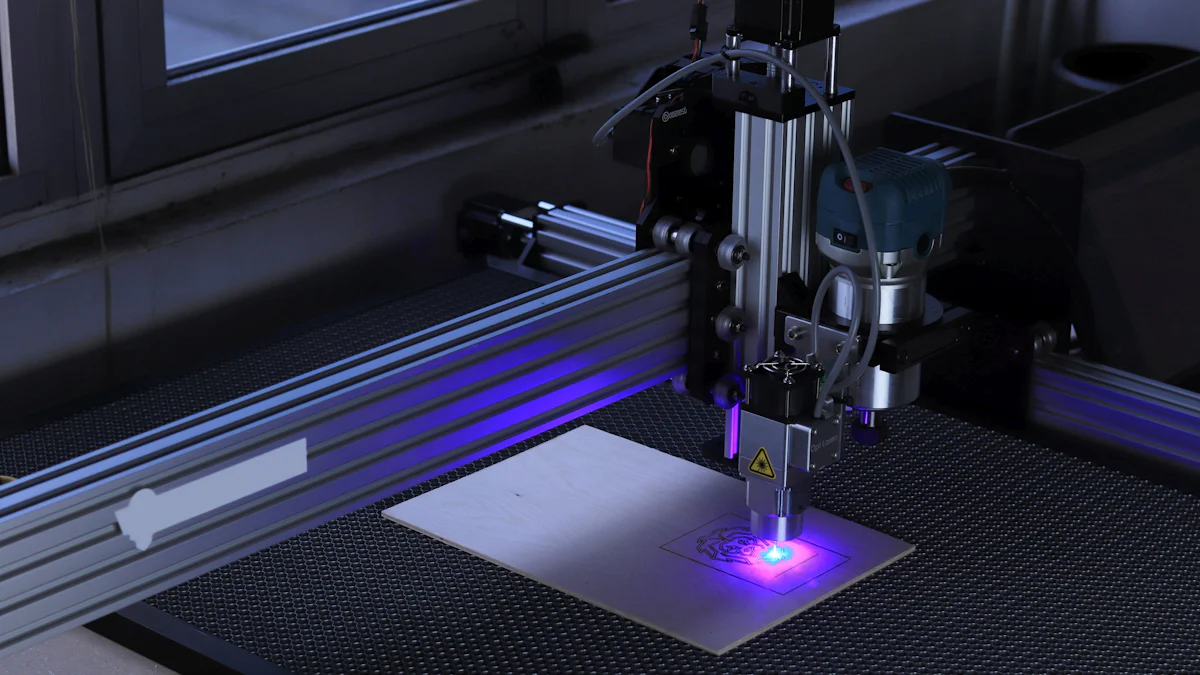

Precision in Laser Cutting

Fiber laser cutting machines are renowned for their high precision and accuracy. They deliver high precision cutting, which is crucial for intricate designs and detailed work. The precision in laser cutting minimizes material waste, saving you money and resources. With high precision, you achieve superior cut edge quality, reducing the need for additional finishing processes. This precision makes fiber laser cutting ideal for industries where detail and accuracy are paramount.

Low Operating Costs of Fiber Laser Cutting Machines

Another advantage of fiber laser cutting is its low operating costs. These machines consume less energy compared to other laser cutting machines, making them cost-effective in the long run. The maintenance requirements are minimal, reducing downtime and operational expenses. Fiber laser cutting machines offer versatility, allowing you to work with various materials without incurring additional costs. This versatility enhances your ability to meet diverse customer needs efficiently.

Material Compatibility in Fiber Laser Cutting

Fiber laser cutting machines excel in their ability to handle a wide range of materials. This material versatility makes them a valuable asset in various industries. You can use these machines to cut metals such as steel, aluminum, and copper with ease. Their precision ensures clean cuts, even on reflective materials like brass and silver.

"Fiber lasers are highly versatile and can be used for a variety of applications, including cutting, welding, and marking of different materials."

The adaptability of fiber lasers extends beyond metals. You can also process non-metal materials, including plastics and composites. This capability allows you to diversify your production line and meet different customer demands. The superior edge quality achieved with fiber lasers reduces the need for additional finishing, saving you time and resources.

Moreover, fiber laser cutting machines require minimal maintenance. This feature ensures consistent performance across various materials. The non-contact nature of the cutting process minimizes heat distortion, preserving the integrity of the material. This aspect is crucial when working with delicate or thin materials.

Disadvantages of Fiber Laser Cutting Machines

While fiber laser cutting machines offer numerous benefits, you should also consider their drawbacks. Understanding these disadvantages of laser cutting will help you make a well-rounded decision.

High Initial Costs of Fiber Laser Cutting Machines

One of the most significant challenges you may face is the high initial cost of acquiring a fiber laser cutting machine. These machines represent a substantial investment, which can be daunting for small businesses or startups. The advanced technology and precision engineering involved in manufacturing these machines contribute to their high price. However, it's essential to weigh this cost against the potential benefits, such as increased productivity and efficiency. Over time, the return on investment time can justify the initial expenditure, especially if you plan to use the machine extensively.

Complexity in Operating Fiber Laser Cutting Machines

Operating a fiber laser cutting machine requires a certain level of expertise. You need to understand the machine's settings and capabilities to achieve optimal results. This complexity can pose a challenge, especially if you lack experience with laser cutting technology. Training and skill development become crucial to ensure that you can operate the machine effectively. While fiber lasers are easier to maintain than some other technologies, the learning curve can still be steep. Investing in proper training can mitigate this issue and enhance your ability to utilize the machine's full potential.

Limitations in Material Thickness for Laser Cutting

Fiber laser cutting machines excel in cutting thin materials with high precision. However, they have limitations when it comes to cutting thicker materials. You may find that fiber lasers lose their efficiency and precision as material thickness increases. For materials over 20 mm thick, other cutting technologies, such as CO2 lasers, might offer better performance. This limitation can restrict the range of projects you can undertake with a fiber laser cutting machine. It's important to assess your specific needs and determine if the machine's capabilities align with your production requirements.

Comparison with Other Cutting Technologies

When considering laser cutting machines, it's essential to compare fiber laser cutting with other technologies. Each method has unique strengths and weaknesses, impacting your decision based on specific needs.

CO2 Laser Cutting vs. Fiber Laser Cutting

CO2 laser cutting machines have been a staple in the industry for years. They excel in cutting non-metal materials like wood, acrylic, and glass. However, fiber laser cutting machines offer advantages in speed and precision, especially for metal cutting. You will find that fiber lasers consume less energy, reducing operating costs over time. While CO2 lasers can handle thicker materials, fiber lasers provide superior edge quality and require less maintenance. If your focus is on metal cutting with high efficiency, fiber laser technology might be the better choice.

Plasma Cutting vs. Fiber Laser Cutting

Plasma cutting is another popular method, particularly for thick metal sheets. It uses an electrically conductive gas to cut through materials. Plasma cutters are generally more affordable than fiber lasers, making them attractive for budget-conscious buyers. However, fiber laser cutting machines offer higher precision and cleaner cuts. You will notice that fiber lasers produce less heat distortion, preserving material integrity. If you prioritize precision and minimal post-processing, fiber laser cutting stands out as the superior option.

Waterjet Cutting vs. Fiber Laser Cutting

Waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through various substances. This method excels in cutting thick and non-metal materials without generating heat. However, fiber laser cutting machines provide faster processing speeds and are more efficient for metal applications. You will appreciate the versatility of fiber lasers in handling different metals with ease. While waterjet cutting avoids heat-related issues, fiber lasers offer unmatched precision and speed for intricate designs.

"Fiber lasers are currently limited in terms of the materials they can cut. While most metals can be cut using this method, certain materials such as copper, brass, and aluminum may not be compatible with the process."

Fiber laser cutting machines offer numerous advantages, such as high speed, precision, and low operating costs. However, they also present challenges like high initial costs and limitations in cutting thicker materials. To determine if fiber laser technology suits your needs, consider your specific applications and production requirements. Evaluate the benefits against the drawbacks. For potential buyers, conducting further research and consulting with industry experts can provide valuable insights. This approach ensures you make informed decisions that align with your operational goals and financial capabilities.

FAQ

What is a fiber laser cutting machine?

A fiber laser cutting machine uses a high-powered laser beam to cut through materials. It is known for its speed and precision, making it ideal for various industrial applications. You can use it to cut metals, plastics, and other materials with high accuracy.

How does fiber laser cutting differ from CO2 laser cutting?

Fiber laser cutting machines use a solid-state laser, while CO2 lasers use a gas-filled tube. Fiber lasers are more efficient and require less maintenance. They excel in cutting metals, whereas CO2 lasers are better for non-metal materials like wood and acrylic.

What are the main advantages of using fiber laser cutting machines?

Fiber laser cutting machines offer several benefits:

- High speed: They cut faster than traditional methods.

- Precision: They provide accurate cuts with minimal waste.

- Low operating costs: They consume less energy and require minimal maintenance.

- Material versatility: They can cut a wide range of materials.

Are there any disadvantages to fiber laser cutting machines?

Yes, there are some drawbacks:

- High initial cost: The machines are expensive to purchase.

- Complexity: Operating them requires expertise and training.

- Material thickness limitations: They may not perform well on very thick materials.

How do I choose the right laser cutting machine for my needs?

To choose the right machine, consider:

- Material type and thickness: Determine what materials you will cut.

- Budget: Evaluate both initial investment and ongoing costs.

- Production needs: Assess your required speed and precision.

- Operational capabilities: Ensure you have the necessary skills and resources.

Can fiber laser cutting machines handle all types of materials?

Fiber laser cutting machines are versatile but have limitations. They excel in cutting metals like steel and aluminum. However, they may struggle with certain reflective materials and very thick substances. Always check material compatibility before purchasing.

What maintenance is required for fiber laser cutting machines?

Fiber lasers require minimal maintenance compared to other types. Regular cleaning and occasional part replacements are necessary. This low maintenance reduces downtime and operational costs, making them a cost-effective choice over time.

How does fiber laser cutting impact production efficiency?

Fiber laser cutting significantly boosts production efficiency. Its high speed allows you to complete projects faster, increasing throughput. The precision reduces material waste, saving costs and resources. This efficiency helps you stay competitive in a fast-paced market.

Is training necessary to operate a fiber laser cutting machine?

Yes, training is essential. Operating these machines requires understanding their settings and capabilities. Proper training ensures you achieve optimal results and utilize the machine's full potential. Investing in training can enhance your operational efficiency.

What should I consider before investing in a fiber laser cutting machine?

Before investing, consider:

- Your long-term vision: Align the machine's capabilities with your future goals.

- Current applications: Evaluate your existing needs and limitations.

- Expert consultation: Seek advice from industry experts to make an informed decision.

See Also

Understanding Laser Cutting Machines: Benefits and Drawbacks

Advantages and Disadvantages of DE TECH Fabric Cutters

The Functionality of Fiber Laser Cutting Machines Explained

Evaluating Cricut Machines: Benefits and Limitations for Plastic