Top 3 Pros and Cons of 8x4 Laser Cutters

When you explore how much laser cutting machines for 8x4 metal are, you'll find three standout advantages. First, these machines offer high precision, allowing you to achieve intricate designs with ease. Second, their efficiency and speed significantly reduce production time compared to traditional methods. Third, their versatility enables you to cut various materials, from metals to non-metals. However, consider the drawbacks. The high initial cost can be a barrier for many. Additionally, maintenance and operating costs add up over time. Lastly, their size and space requirements demand ample room in your workshop.

Pros of 8x4 Laser Cutters

High Precision

Explanation of precision capabilities

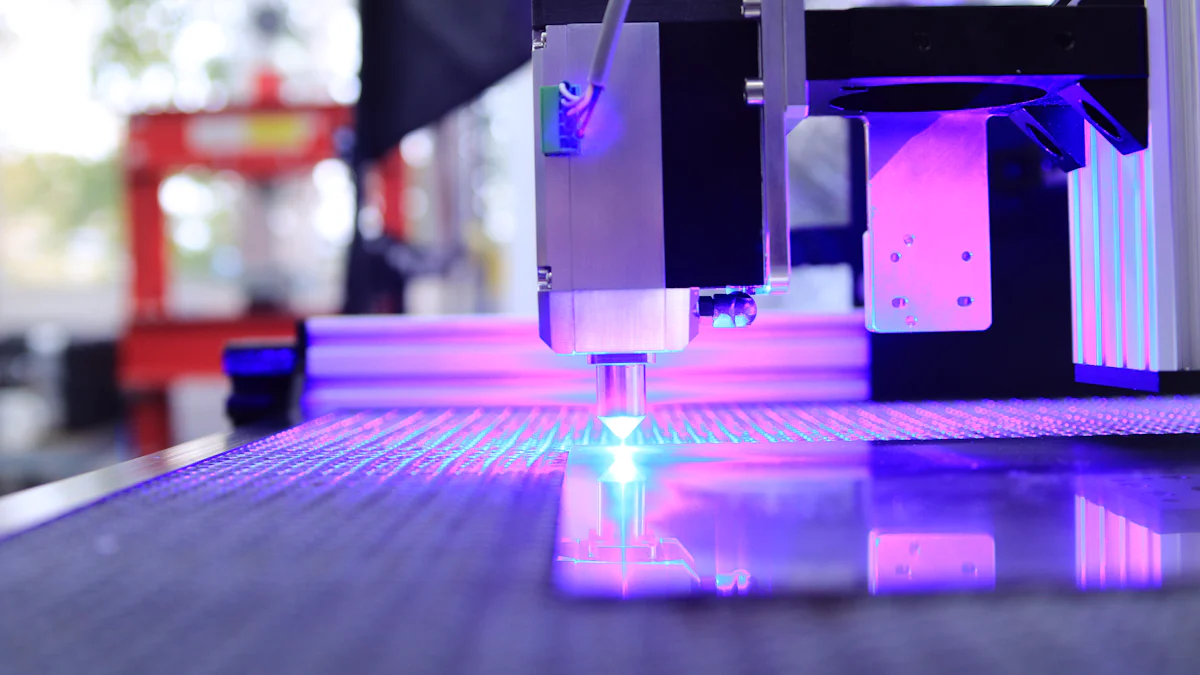

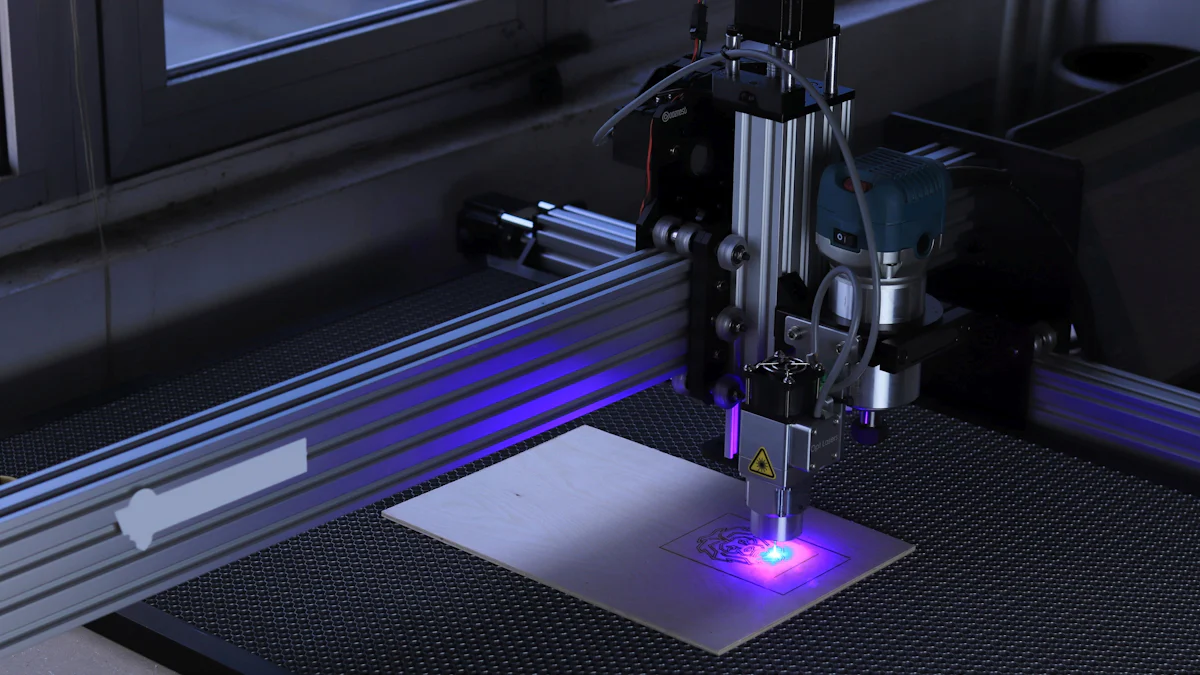

You will find that 8x4 laser cutters excel in precision. The laser beam focuses to a very small point, allowing for extremely accurate cuts. This precision ensures that you can achieve intricate designs without any material contamination. Unlike traditional methods, laser cutting maintains the integrity of the material, providing clean and smooth edges.

Examples of applications requiring precision

In industries where precision is paramount, such as aerospace and automotive, 8x4 laser cutters play a crucial role. You can use them to create complex components like engine parts and intricate metal designs. Additionally, in the electronics industry, these machines help in crafting precise circuit boards and delicate components.

Efficiency and Speed

Discussion on time-saving benefits

When it comes to efficiency, 8x4 laser cutters stand out. You can complete tasks much faster than with traditional cutting methods. The high-speed operation reduces production time significantly, allowing you to meet tight deadlines and increase your output.

Impact on production rates

The speed of laser cutting directly impacts production rates. By using an 8x4 laser cutter, you can enhance your production capacity. This efficiency translates into higher profitability, as you can produce more units in less time. The ability to quickly switch between different cutting tasks further boosts productivity.

Versatility

Ability to cut various metal types

Versatility is another strong suit of 8x4 laser cutters. You can cut a wide range of materials, from metals like stainless steel and aluminum to non-metals such as wood and acrylic. This adaptability makes these machines suitable for diverse projects and industries.

Adaptability to different projects

Whether you are working on a small-scale project or a large industrial task, 8x4 laser cutters adapt to your needs. You can easily adjust the settings to accommodate different materials and thicknesses. This flexibility allows you to tackle various projects without needing multiple machines, saving both space and resources.

Cons of 8x4 Laser Cutters

High Initial Cost

Overview of purchase costs

When you consider purchasing an 8x4 laser cutter, the initial cost can be significant. Prices typically range from $1,500 to over $55,000, depending on the machine's specifications and capabilities. In India, the cost can vary between INR 30 lakhs to 1 crore. More advanced models with higher wattage and additional features may exceed this range. This substantial investment can be a barrier for small businesses or hobbyists.

Comparison with other cutting technologies

Compared to other cutting technologies, such as plasma or waterjet cutters, laser cutters often come with a higher price tag. While plasma cutters are generally more affordable, they lack the precision and versatility of laser cutters. Waterjet cutters, on the other hand, can match the precision but often involve higher operational costs. Therefore, while the initial investment in a laser cutter is high, it offers unmatched precision and versatility.

Maintenance and Operating Costs

Regular maintenance requirements

Owning an 8x4 laser cutter involves regular maintenance to ensure optimal performance. You need to clean and align the laser optics frequently. Additionally, replacing consumables like lenses and nozzles is necessary. Regular maintenance prevents downtime and extends the machine's lifespan, but it also adds to the overall cost of ownership.

Cost implications of operation

Operating an 8x4 laser cutter incurs ongoing costs. Electricity consumption can be significant, especially for high-wattage machines. You also need to consider the cost of consumables and potential repairs. These operational expenses can accumulate over time, impacting your budget. Therefore, it's crucial to factor in these costs when evaluating the total cost of ownership.

Size and Space Requirements

Space needed for installation

An 8x4 laser cutter requires ample space for installation. You need a dedicated area in your workshop to accommodate the machine's size. The space should allow for easy access to all sides of the machine for maintenance and operation. Additionally, you must ensure proper ventilation to manage heat and fumes generated during cutting.

Considerations for workshop layout

When planning your workshop layout, consider the space needed for the laser cutter and its accessories. You may need to rearrange existing equipment or invest in additional storage solutions. Adequate space around the machine is essential for safety and efficiency. Planning your layout carefully ensures a smooth workflow and maximizes the benefits of your laser cutter.

How Much Are Laser Cutting Machines for 8x4 Metal

When you consider purchasing an 8x4 laser cutting machine, understanding the price range is crucial. These machines vary significantly in cost, depending on their features and capabilities.

Price Range Overview

The price of 8x4 laser cutting machines can range widely. Entry-level models start at around $2,600, making them accessible for small businesses or hobbyists. However, more advanced machines with higher wattage and additional features can cost up to $300,000. In India, prices typically range from INR 30 lakhs to 1 crore. This broad spectrum allows you to choose a machine that fits your budget and needs.

Factors Influencing Cost

Several factors influence how much laser cutting machines for 8x4 metal cost:

- Wattage: Higher wattage machines cut thicker materials more efficiently, but they also come with a higher price tag.

- Technology Type: Fiber laser machines generally cost more than CO2 lasers due to their efficiency and precision.

- Features: Advanced features like automated loading systems or enhanced software capabilities increase the cost.

- Brand and Build Quality: Reputable brands with durable builds often charge more, reflecting their reliability and longevity.

Understanding these factors helps you make an informed decision when selecting a machine.

Cost-Effectiveness for Different Users

The cost-effectiveness of an 8x4 laser cutting machine depends on your specific needs and usage:

- Small Businesses: For small businesses, investing in a mid-range machine can balance cost and functionality. These machines offer sufficient power and versatility without breaking the bank.

- Large Enterprises: Large enterprises may benefit from high-end models. These machines provide superior speed and precision, essential for high-volume production.

- Hobbyists: Hobbyists might opt for entry-level machines. These models offer basic cutting capabilities at a lower cost, suitable for personal projects.

By evaluating your requirements, you can determine how much are laser cutting machines for 8x4 metal worth to you, ensuring you choose the most cost-effective option.

In summary, 8x4 laser cutters offer significant advantages and some drawbacks. You benefit from high precision, efficiency, and versatility, making these machines ideal for various applications. However, you must consider the high initial cost, ongoing maintenance, and space requirements. When choosing a laser cutter, focus on key technical features like power and cutting area to make an informed decision. Whether you're a small business, large enterprise, or hobbyist, understanding these factors helps you determine the suitability of 8x4 laser cutters for your needs.

FAQ

What is an 8x4 laser cutting machine designed for?

An 8x4 laser cutting machine is designed to cut materials like stainless steel, aluminum, brass, and copper with high precision and speed. The bed size of 8 feet by 4 feet accommodates standard sheet materials without needing extra cuts. This design ensures efficiency and reduces material waste.

How does the precision of an 8x4 laser cutter benefit my projects?

The precision of an 8x4 laser cutter allows you to achieve intricate designs with clean and smooth edges. This capability is crucial for industries like aerospace and automotive, where accuracy is paramount. You can create complex components and detailed designs without compromising material integrity.

Are there any specific maintenance requirements for these machines?

Yes, regular maintenance is essential for optimal performance. You need to clean and align the laser optics frequently. Replacing consumables like lenses and nozzles is also necessary. Regular upkeep prevents downtime and extends the machine's lifespan, ensuring consistent cutting quality.

What factors influence the cost of an 8x4 laser cutting machine?

Several factors influence the cost, including wattage, technology type, features, and brand. Higher wattage machines cut thicker materials more efficiently but come with a higher price tag. Fiber laser machines generally cost more than CO2 lasers due to their efficiency and precision. Advanced features and reputable brands also increase the cost.

Can I use an 8x4 laser cutter for non-metal materials?

Yes, you can use an 8x4 laser cutter for non-metal materials. These machines are versatile and can cut materials like wood and acrylic. This adaptability makes them suitable for diverse projects across various industries.

How much space do I need for installing an 8x4 laser cutter?

You need ample space for installation. The machine requires a dedicated area in your workshop to accommodate its size. Ensure easy access to all sides for maintenance and operation. Proper ventilation is also necessary to manage heat and fumes generated during cutting.

Is an 8x4 laser cutter cost-effective for small businesses?

For small businesses, investing in a mid-range machine can balance cost and functionality. These machines offer sufficient power and versatility without breaking the bank. Evaluating your specific needs helps determine the most cost-effective option for your business.

What are the ongoing costs associated with operating an 8x4 laser cutter?

Operating an 8x4 laser cutter incurs ongoing costs like electricity consumption, especially for high-wattage machines. You also need to consider the cost of consumables and potential repairs. These operational expenses can accumulate over time, impacting your budget.

How does the speed of an 8x4 laser cutter impact production rates?

The speed of an 8x4 laser cutter significantly impacts production rates. You can complete tasks much faster than with traditional cutting methods. This efficiency translates into higher profitability, as you can produce more units in less time and meet tight deadlines.

What should I consider when choosing an 8x4 laser cutter?

When choosing an 8x4 laser cutter, focus on key technical features like power and cutting area. Consider your specific needs and usage to determine the most suitable machine. Understanding factors like cost, maintenance, and space requirements helps you make an informed decision.

See Also

Understanding Laser Cutting Machines: Benefits and Drawbacks

Advantages and Disadvantages of DE TECH Fabric Cutters

Benefits and Limitations of Cricut Plastic Cutting Machines