What's the Newest Laser Cutting Key Machine Today?

The Supracode stands out as the newest innovation in laser cutting machines. This advanced device combines precision and speed, offering unmatched accuracy for cutting high-security and vehicle keys. Its groundbreaking feature, the first automatic engraving system for key grips, eliminates manual effort entirely. With seamless integration into the JMA Key Code Pro 2.0 app, you gain full control over the cutting process. This machine redefines efficiency and precision, making it a game-changer for professional key cutters. If you're wondering what's the newest laser cutting key machine, the Supracode sets a new benchmark in the industry.

What Are Laser Key Cutting Machines?

Overview of Laser Key Cutting Machines

Definition and purpose of laser key cutting machines.

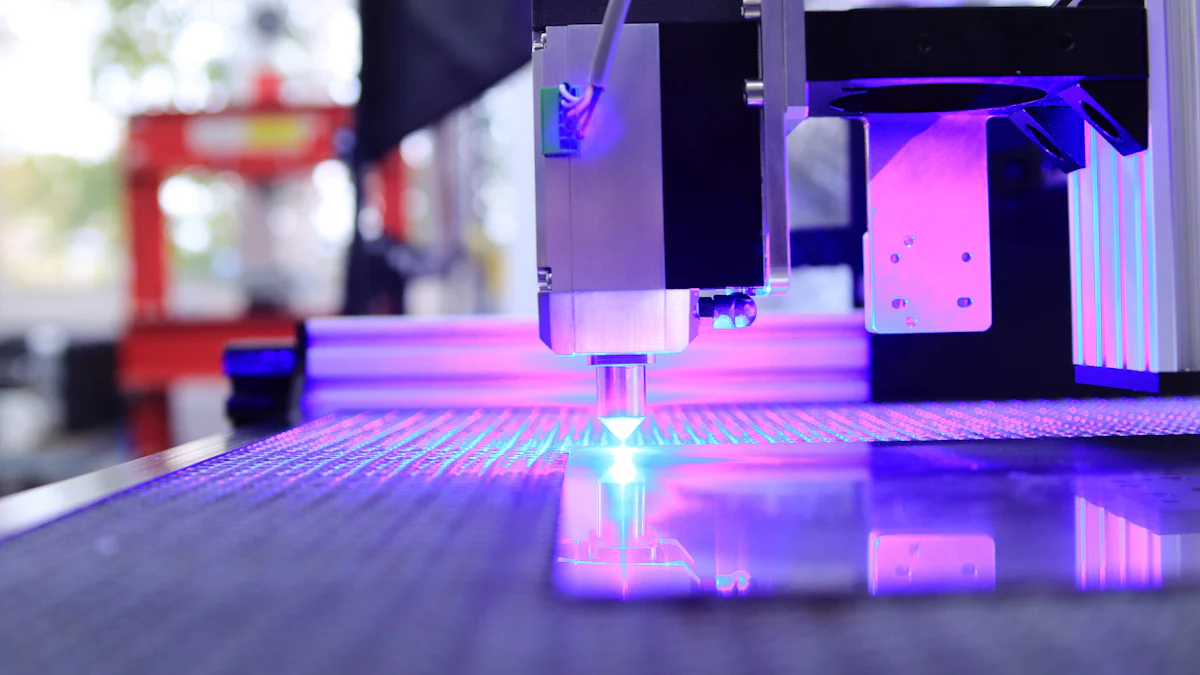

Laser key cutting machines are advanced tools designed to create precise and accurate key replicas. Unlike traditional key cutting methods, these machines use laser technology to carve intricate patterns into metal keys. This process ensures that every cut matches the original key's specifications with exceptional precision. Whether you need to duplicate a standard house key or craft a high-security automotive key, these machines provide unmatched reliability.

The primary purpose of laser key cutting machines is to enhance the efficiency and accuracy of key duplication and creation. They cater to locksmiths, automotive professionals, and businesses requiring high-quality key cutting solutions. By using laser technology, these machines eliminate human errors and deliver consistent results, even for complex key designs.

How laser technology improves key cutting precision.

Laser technology revolutionizes key cutting by offering sub-millimeter precision. Traditional methods often rely on manual adjustments, which can lead to slight inaccuracies. In contrast, laser key cutting machines use advanced optics and software to ensure every cut aligns perfectly with the original design. This level of precision is especially crucial for high-security keys, where even minor deviations can render a key unusable.

Additionally, laser technology allows for smoother and cleaner cuts. The laser beam melts and vaporizes the material, leaving no rough edges or imperfections. This not only improves the functionality of the key but also extends its lifespan. For professionals like locksmiths, this precision translates into higher customer satisfaction and fewer errors during the cutting process.

Key Features of Laser Key Cutting Machines

Precision and accuracy.

One of the standout features of laser key cutting machines is their ability to achieve unparalleled precision. These machines can replicate even the most intricate key designs with exact measurements. This accuracy ensures that the keys function seamlessly in their respective locks, reducing the risk of malfunctions. For locksmiths and businesses, this feature guarantees consistent quality and reliability.

Speed and efficiency.

Laser key cutting machines excel in speed and efficiency. They can produce multiple keys in a fraction of the time it takes with traditional methods. This rapid production capability makes them ideal for high-demand environments, such as automotive workshops or locksmith shops. By automating the cutting process, these machines save you time and effort, allowing you to focus on other tasks.

Automation and ease of use.

Modern laser key cutting machines come equipped with user-friendly interfaces and automated features. Many models integrate with software that guides the cutting process, making it easy for users to operate the machine without extensive training. Automation reduces the need for manual intervention, minimizing errors and ensuring consistent results. For professionals, this ease of use translates into increased productivity and reduced operational costs.

Types of Key Cutting Machines

Manual Laser Key Cutting Machines

Description and how they work.

Manual key cutting machines rely on operator skill to create precise key replicas. These machines require you to manually position the key blank and guide the cutting process. Unlike automated systems, manual machines depend on your expertise to ensure accuracy. They often feature a hand-operated lever or wheel to control the cutting blade. While they lack advanced software or automation, they provide a straightforward and reliable method for key duplication.

Common uses and applications.

Manual key cutting machines are ideal for low-volume tasks and specialized key designs. Locksmiths often use them for custom key cutting or when working with unique key types. These machines are also suitable for small businesses that handle occasional key duplication. Their simplicity makes them a practical choice for environments where precision is more critical than speed.

Pros and cons.

Pros:

- High accuracy when operated by skilled users.

- Cost-effective for small-scale operations.

- Durable and easy to maintain.

Cons:

- Slower than automated machines.

- Requires significant operator expertise.

- Limited efficiency for high-volume tasks.

Semi-Automatic Laser Key Cutting Machines

Description and how they work.

Semi-automatic laser key cutting machines combine manual operation with some level of automation. You still need to position the key blank and initiate the process, but the machine assists with cutting. These machines often include features like pre-programmed cutting patterns and motorized components. This blend of manual and automated functions allows you to achieve faster results without sacrificing precision.

Common uses and applications.

Semi-automatic machines are well-suited for locksmiths and businesses that handle moderate volumes of key duplication. They are particularly useful for duplicating standard keys quickly while maintaining a high level of accuracy. Automotive professionals also use these machines for cutting and engraving vehicle keys, as they balance speed and precision effectively.

Pros and cons.

Pros:

- Faster than manual machines.

- Easier to use with minimal training.

- Suitable for a variety of key types.

Cons:

- More expensive than manual machines.

- Still requires some manual effort.

- Limited automation compared to fully automatic models.

Fully Automatic Laser Key Cutting Machines

Description and how they work.

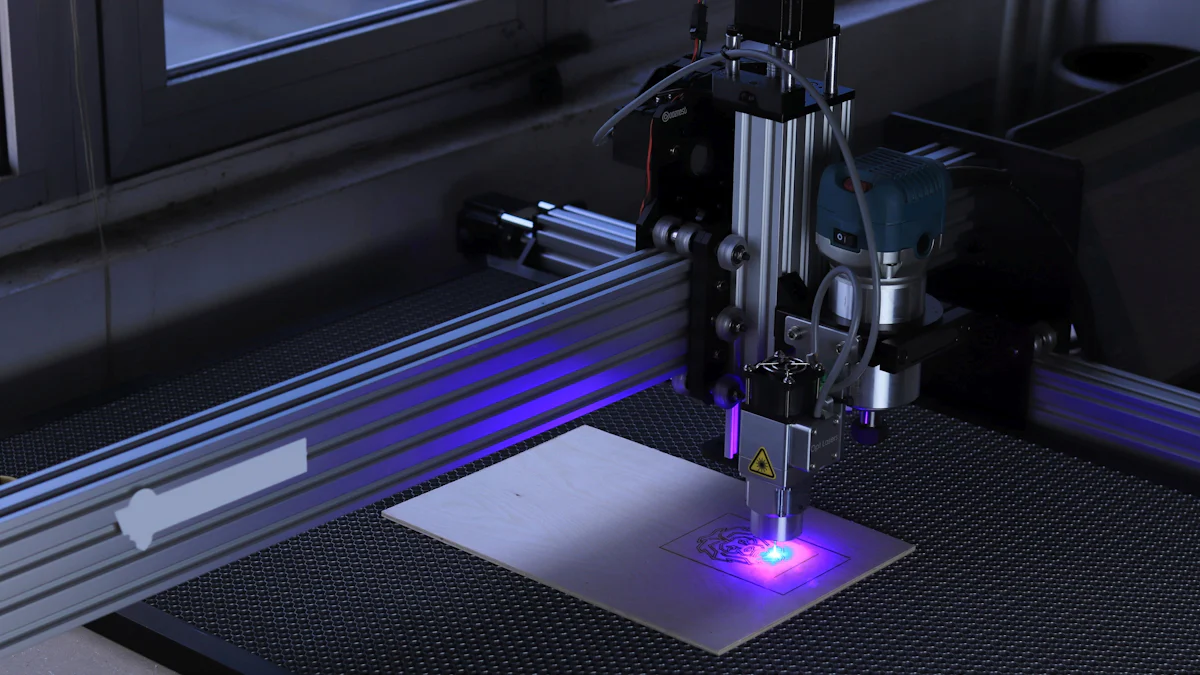

Fully automatic laser key cutting machines operate with minimal manual intervention. These machines use advanced software and computer-driven systems to handle the entire cutting process. You simply input the key specifications, and the machine takes care of the rest. They are designed to deliver high-speed, precise results with little room for error. Many models also support cutting and engraving, making them versatile tools for professional use.

Common uses and applications.

Fully automatic machines are perfect for high-volume environments like locksmith shops and automotive workshops. They excel in producing large quantities of keys quickly and accurately. These machines are also ideal for cutting complex or high-security keys, where precision is crucial. Their ability to automate repetitive tasks makes them a valuable asset for businesses aiming to maximize productivity.

Pros and cons.

Pros:

- Extremely fast and efficient.

- Highly accurate with minimal errors.

- User-friendly with advanced automation.

Cons:

- High initial cost.

- Requires regular maintenance.

- May be overkill for low-volume operations.

Types of Laser Cutters for Key Cutting

Laser cutters play a crucial role in modern key cutting, offering precision and efficiency across various applications. Understanding the different types of laser cutters can help you choose the right one for your needs. Below, we explore three popular types of laser cutters used in key cutting.

Fiber Laser Key Cutting Machines

Features and applications.

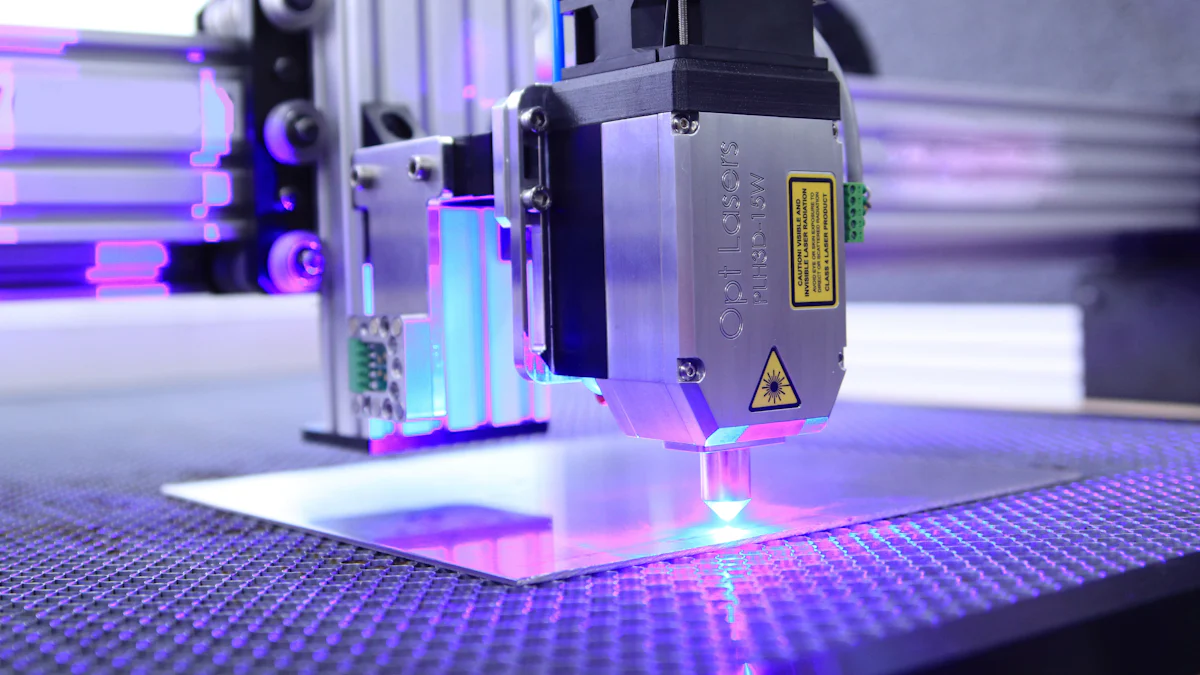

Fiber lasers are among the most versatile tools for key cutting. These machines use a fiber-optic cable to amplify light, creating a highly focused laser beam. This technology ensures exceptional precision, making it ideal for cutting intricate patterns on metal keys. Fiber lasers excel in high-security key production, where accuracy is paramount.

You’ll find fiber laser machines particularly useful in automotive key cutting. Their ability to handle various metals, including steel and brass, makes them indispensable for locksmiths and automotive professionals. Additionally, their speed allows you to produce multiple keys in a short time, boosting productivity in high-demand environments.

Advantages and limitations.

Advantages:

- High precision ensures flawless key duplication.

- Fast cutting speeds improve efficiency.

- Durable and low-maintenance design reduces operational costs.

- Compatible with a wide range of metals.

Limitations:

- Higher initial cost compared to other laser types.

- Limited effectiveness on non-metal materials.

CO2 Laser Key Cutting Machines

Features and applications.

CO2 lasers use a gas mixture to generate a laser beam, making them highly effective for cutting non-metal materials. While they are less common in traditional key cutting, they shine in specialized applications. For example, you can use CO2 lasers to engrave key grips or create decorative designs on key blanks.

These machines are also versatile outside of key cutting. They can handle materials like wood, acrylic, and plastic, making them a valuable addition to businesses that require multi-material processing. If you’re looking to expand your services beyond standard key duplication, CO2 lasers offer unique opportunities.

Advantages and limitations.

Advantages:

- Excellent for engraving and decorative work.

- Versatile across various non-metal materials.

- Affordable compared to fiber lasers.

Limitations:

- Limited capability for cutting metal keys.

- Slower cutting speeds for intricate designs.

Nd:YAG Laser Key Cutting Machines

Features and applications.

Nd:YAG lasers (neodymium-doped yttrium aluminum garnet) are known for their high power and precision. These machines are perfect for cutting and engraving hard materials, including high-security keys. Their robust design ensures consistent performance, even in demanding environments.

You’ll often see Nd:YAG lasers in automotive workshops and locksmith shops specializing in high-security key systems. Their ability to produce clean, precise cuts makes them a reliable choice for professionals who prioritize quality over speed.

Advantages and limitations.

Advantages:

- Exceptional precision for high-security keys.

- Reliable performance in heavy-duty applications.

- Capable of cutting and engraving hard materials.

Limitations:

- Higher maintenance requirements.

- Slower than fiber lasers for large-scale tasks.

What's the Newest Laser Cutting Key Machine?

The Supracode has redefined the standards of laser key cutting technology. If you're wondering what's the newest laser cutting key machine, this model stands out with its groundbreaking features and unmatched performance. It combines advanced engineering with user-centric design, making it a top choice for professionals in the locksmith and automotive industries.

Key Features and Innovations

Advanced technology and unique capabilities.

The Supracode introduces cutting-edge technology that sets it apart from other machines. Its automatic engraving system for key grips is the first of its kind, eliminating the need for manual engraving. This feature not only saves time but also ensures consistent results. The machine integrates seamlessly with the JMA Key Code Pro 2.0 app, giving you complete control over the cutting process through a user-friendly interface.

Another standout capability is its ability to handle a wide range of key types, including high-security and automotive keys. Unlike older models, the Supracode uses enhanced laser optics to deliver sub-millimeter precision. This ensures that every key cut matches the original design perfectly, even for the most intricate patterns.

Improvements over previous models.

The Supracode builds on the strengths of earlier machines while addressing their limitations. Compared to models like the XYZ Laser Key Cutter, it offers a broader range of key compatibility and higher cutting accuracy. While the ABC Laser Key Cutter is known for speed and durability, the Supracode combines these qualities with superior precision and automation. This balance makes it a versatile tool for various applications, from locksmithing to automotive key production.

Additionally, the Supracode features a more robust build and requires less maintenance. Its advanced cooling system prevents overheating during extended use, ensuring consistent performance over time. These improvements make it a reliable investment for professionals seeking efficiency and longevity in their equipment.

Comparison with Previous Models

Performance upgrades.

The Supracode delivers significant performance upgrades over its predecessors. It cuts keys faster than manual and semi-automatic machines, reducing production time without compromising accuracy. Its laser system produces cleaner cuts, eliminating the rough edges often seen with older models. This improvement enhances the functionality and lifespan of the keys you produce.

In comparison to the XYZ Laser Key Cutter, the Supracode offers better precision and a wider range of key compatibility. While the ABC Laser Key Cutter excels in speed, the Supracode matches this speed while providing superior cutting quality. These upgrades make it an ideal choice for professionals who demand both efficiency and excellence.

Enhanced user experience.

The Supracode prioritizes ease of use, making it accessible even for those new to laser key cutting. Its integration with the JMA Key Code Pro 2.0 app simplifies the cutting process. You can input key specifications directly into the app, and the machine handles the rest. This level of automation reduces the risk of errors and ensures consistent results.

The machine's intuitive interface and automated features minimize the learning curve. Unlike older models that required extensive training, the Supracode allows you to start cutting keys almost immediately. Its quiet operation and compact design further enhance the user experience, making it suitable for small workshops and busy environments alike.

Ideal Use Cases

Locksmiths and small businesses.

The Supracode is a game-changer for locksmiths and small businesses. Its ability to cut high-security and standard keys with precision makes it a valuable asset for any locksmith shop. Small businesses benefit from its compact size and low maintenance requirements, which reduce operational costs. The machine's automation features also save time, allowing you to serve more customers efficiently.

For small-scale operations, the Supracode offers a perfect balance of affordability and functionality. Its versatility ensures that you can handle a variety of key types, from residential to commercial applications. This adaptability makes it a smart choice for businesses looking to expand their services.

Automotive key cutting professionals.

Automotive professionals will find the Supracode indispensable for their work. Its advanced laser system can cut complex automotive keys with unmatched accuracy. Whether you're duplicating a transponder key or creating a new one from scratch, the Supracode delivers flawless results every time.

The machine's speed and precision are particularly beneficial in high-demand environments like automotive workshops. You can produce multiple keys in a short time, meeting customer needs without delays. Its ability to handle various metals, including steel and brass, further enhances its suitability for automotive applications. For professionals in this field, the Supracode represents a significant upgrade in both efficiency and quality.

How to Choose the Right Laser Key Cutting Machine

Selecting the right laser key cutting machine can transform your key-making process. The right choice ensures efficiency, precision, and long-term reliability. To make an informed decision, you need to evaluate several factors and match them with your specific needs.

Factors to Consider

Budget and cost considerations.

Your budget plays a crucial role in determining the type of machine you can afford. Manual machines are often the most affordable, making them suitable for small-scale operations. Semi-automatic models cost more but offer a balance between price and functionality. Fully automatic key cutting machines, while expensive, provide unmatched speed and precision. Investing in a high-quality machine may seem costly upfront, but it reduces maintenance expenses and enhances productivity over time.

Volume of work and business needs.

The volume of keys you plan to cut daily should guide your choice. For low-volume tasks, manual or semi-automatic machines are sufficient. However, if your business handles high-demand environments, such as automotive workshops or locksmith shops, fully automatic machines are ideal. These machines excel in producing large quantities of keys quickly without compromising on quality. Matching the machine’s capacity to your workload ensures smooth operations and prevents bottlenecks.

Types of keys being cut.

Different machines cater to different key types. If you frequently cut high-security or automotive keys, you need a machine with advanced precision cutting capabilities. Fully automatic machines often support a wide range of key types, including intricate designs. For businesses focusing on standard residential or commercial keys, semi-automatic models may suffice. Understanding the material compatibility of the machine is also essential, especially if you work with various metals like steel or brass.

The Supracode represents a leap forward in key cutting machines, offering unmatched precision, speed, and automation. Its innovative features, such as the automatic engraving system and seamless app integration, set it apart as a top choice for professionals. Across the spectrum of manual, semi-automatic, and fully automatic machines, each type serves unique needs, from small-scale operations to high-volume production.

When choosing a machine, consider your workload, budget, and the types of keys you handle. By evaluating your specific requirements, you can invest in the right technology to enhance efficiency and stay competitive in the evolving market.

FAQ

Can laser-cut keys be copied?

Yes, laser-cut keys can be copied, but the process requires specialized equipment and expertise. These keys feature enhanced security designs, making duplication more challenging than traditional keys. Professional locksmiths use advanced laser key cutting machines to replicate them accurately.

How do key cutting machines work?

Key cutting machines operate by carving a blank key to match the unique pattern of an original key. Laser key cutting machines use precise laser technology to ensure accuracy. The machine reads the key's design, then replicates it with sub-millimeter precision, creating a flawless duplicate.

What are the critical specifications to consider when selecting a laser key cutter?

When choosing a laser key cutter, focus on these key factors:

- Cutting Accuracy: Ensure the machine delivers precise cuts for a perfect fit.

- Speed: Faster machines improve productivity, especially in high-demand settings.

- Ease of Use: Look for user-friendly interfaces that simplify operation and training.

- Software Compatibility: Verify the machine supports software for handling various key types.

- Maintenance and Support: Check for reliable manufacturer support and easy access to replacement parts.

What is required for making laser-cut keys?

Creating laser-cut keys demands advanced equipment and skilled labor. These keys often include a transponder chip inside the plastic cap, adding an extra layer of security. The process involves using high-precision laser cutting machines, which are expensive and require professional expertise to operate.

What type of machine is needed to cut laser keys?

To cut laser keys, you need a specialized key-cutting machine equipped with a bid guided by a tracer. These machines replicate the intricate patterns of laser-cut keys with exceptional precision, ensuring the keys function seamlessly in their respective locks.

Are laser key cutting machines suitable for all key types?

Laser key cutting machines excel at producing high-security and automotive keys. They handle intricate designs and complex patterns with ease. However, for simpler key types or non-metal materials, other machines like manual or CO2 laser cutters may be more appropriate.

Why are laser-cut keys more secure than traditional keys?

Laser-cut keys offer enhanced security due to their unique designs and precise cuts. Their thicker structure and internal grooves make them harder to duplicate without specialized equipment. Additionally, many laser-cut keys include transponder chips, adding another layer of protection.

How long does it take to cut a key with a laser key cutting machine?

The time required depends on the machine's speed and the complexity of the key design. Advanced laser key cutting machines can produce a key in just a few minutes. Fully automatic models are particularly efficient, making them ideal for high-volume environments.

Do laser key cutting machines require regular maintenance?

Yes, regular maintenance ensures optimal performance and longevity. Cleaning the machine, checking the laser optics, and updating the software are essential tasks. Many manufacturers provide detailed maintenance guidelines and support services to help you keep the machine in top condition.

Can I use a laser key cutting machine for engraving?

Many laser key cutting machines also support engraving. This feature allows you to add decorative designs or custom text to key grips. Machines like the Supracode even include automatic engraving systems, making the process seamless and efficient.

See Also

A Comprehensive Guide To Laser Cutting Machine Costs

Understanding The Optimal Functioning Of Key Cutting Machines

Exploring Laser Cutting Machines And Their Various Types