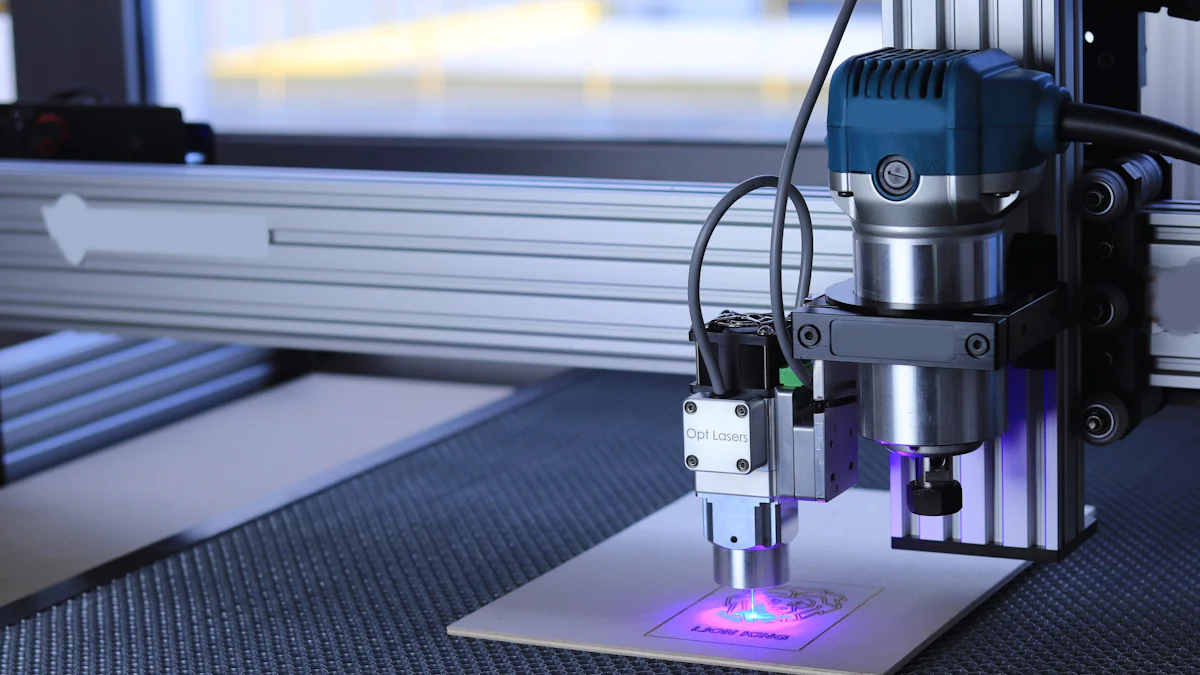

How Motor Reducers Enhance Laser Cutting Machine Efficiency

Motor reducers transform the way laser cutting machines operate by enhancing their torque and precision, which raises the question: what is a motor reducer laser cutting machine? These devices ensure smooth acceleration and deceleration, preventing jerky movements during the cutting process. By optimizing the performance of the machinery, motor reducers allow you to achieve consistent cutting quality across various materials. They also improve processing efficiency by reducing production time and energy consumption. This leads to higher productivity and better product quality. With motor reducers, laser cutting becomes more stable, accurate, and cost-effective, making them an essential component in modern manufacturing.

What Is a Motor Reducer in a Laser Cutting Machine?

Definition of Motor Reducers

Motor reducers are mechanical devices that adjust the speed and torque of a motor to meet the specific requirements of machinery. In laser cutting machines, they play a vital role in ensuring smooth and precise operations.

Explanation of Speed Reduction and Torque Increase

Motor reducers work by using gears to reduce the rotational speed of a motor while simultaneously increasing its torque. This process allows the motor to handle heavier loads and maintain stability during operation. For example, when cutting through different materials, such as metals or plastics, the increased torque ensures that the laser head moves with precision and consistency. By moderating the motor's speed, motor reducers also prevent sudden jerks or irregular movements, which could compromise the quality of the cut.

Overview of Motor Reducer Components and Mechanisms

A motor reducer typically consists of several key components, including gears, shafts, and housings. The gears, often a combination of large and small ones, work together to achieve the desired speed reduction and torque boost. The housing protects these components and ensures durability during high-speed operations. In laser cutting machines, these mechanisms allow the motor reducer to deliver power efficiently, enabling the machine to cut materials of different thicknesses with accuracy.

Role of Motor Reducers in Laser Cutting Machines

Motor reducers are indispensable in laser cutting machines due to their ability to enhance performance and precision.

Importance of Torque Control for Cutting Through Various Materials

When working with different materials, such as wood, steel, or acrylic, maintaining proper torque is essential. Motor reducers provide the necessary torque control to ensure the laser head can cut through these materials effectively. This control becomes even more critical when dealing with materials of varying densities or thicknesses. Without adequate torque, the cutting process may result in uneven edges or incomplete cuts.

How Motor Reducers Enable Precise and Stable Cutting Operations

Precision is a cornerstone of laser cutting. Motor reducers contribute to this by ensuring the laser head follows the programmed path without deviation. They minimize vibrations and stabilize the cutting process, even at high speeds. This stability is crucial for achieving consistent results, especially when creating intricate designs or working on projects that demand high accuracy. By integrating motor reducers, you can rely on your laser cutting machine to deliver superior performance across a wide range of applications.

Key Benefits of Motor Reducers in Laser Cutting Machines

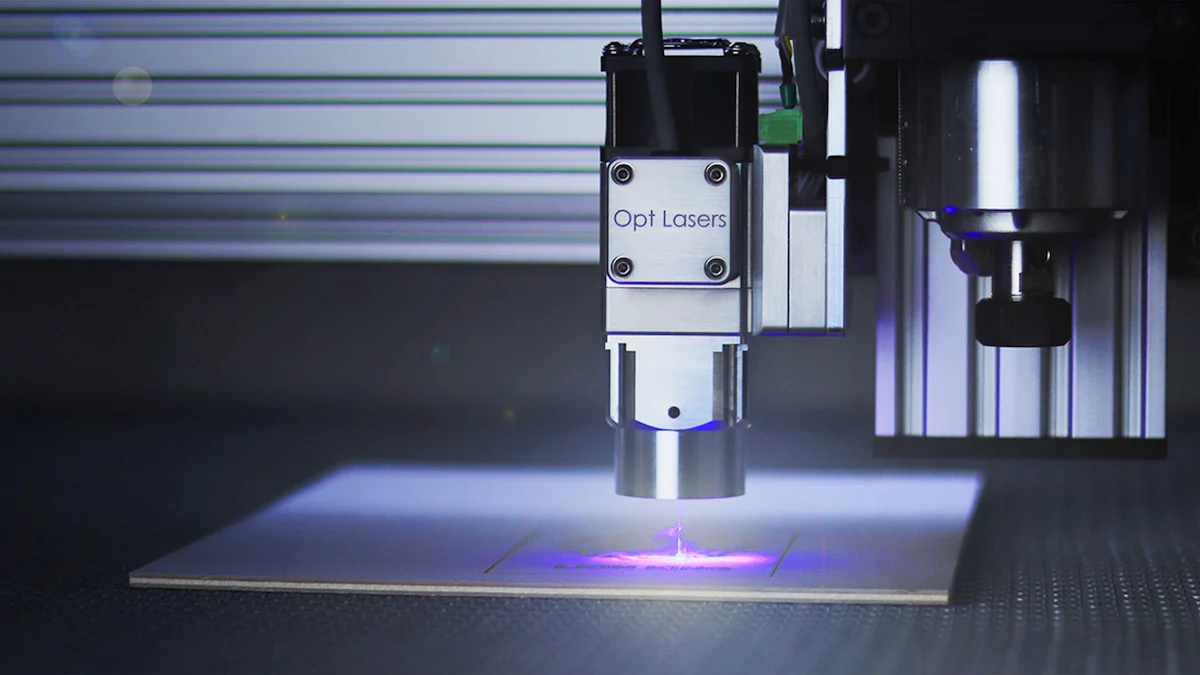

Enhanced Precision

How motor reducers minimize errors in cutting

Motor reducers play a pivotal role in ensuring precision during laser cutting. By controlling the torque and speed of the motor, they eliminate irregular movements that could lead to errors. This precise control allows the laser head to follow the programmed path accurately, even when working on intricate designs. The result is a clean and flawless cut, regardless of the material's complexity or thickness. With motor reducers, you can achieve superior cutting performance while maintaining the highest level of quality.

Role in maintaining consistent cutting quality

Consistency is essential in laser cutting machines, especially when producing large quantities of products. Motor reducers stabilize the cutting process by reducing vibrations and maintaining steady movements. This stability ensures that every cut meets the same high-quality standards, whether you're working on a single piece or a batch of hundreds. By integrating motor reducers, you enhance the overall processing efficiency of your machine, leading to better productivity and reliable results.

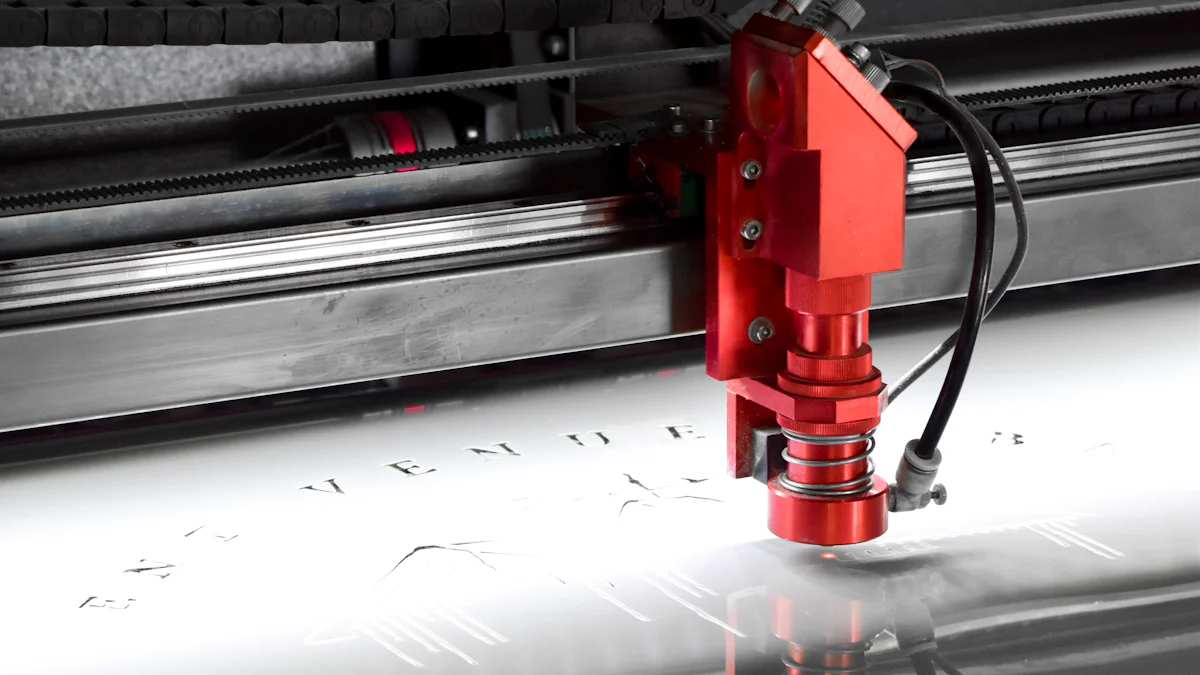

Improved Speed Control

How motor reducers enable variable speed adjustments

Motor reducers allow you to adjust the cutting speed of different materials with ease. This flexibility is crucial when working with materials that require specific speeds for optimal results. For instance, metals may need slower speeds for precision, while plastics might benefit from faster cutting. By enabling variable speed adjustments, motor reducers ensure that your laser cutting machine operates at the ideal speed for each material, improving the cutting speed and overall efficiency.

Benefits of speed control for complex cutting patterns

Complex cutting patterns demand precise speed control to avoid errors and maintain quality. Motor reducers provide this control by moderating the motor's speed and torque. This capability allows the laser head to navigate intricate designs smoothly, without compromising accuracy. Whether you're creating detailed patterns for jewelry or cutting components for industrial use, motor reducers help you achieve exceptional results while maximizing productivity.

Energy Efficiency

Reduction in energy consumption during operation

Motor reducers optimize the use of laser energy by ensuring that the motor operates efficiently. By reducing unnecessary speed and torque, they minimize energy wastage during the cutting process. This efficiency not only lowers your energy bills but also contributes to a more sustainable manufacturing process. With motor reducers, you can cut costs while maintaining high-quality output.

Long-term cost savings for manufacturers

Investing in motor reducers offers significant long-term benefits for manufacturers. Their ability to enhance processing efficiency reduces wear and tear on the machine, leading to fewer maintenance requirements. Additionally, the energy savings they provide translate into lower operational costs over time. By improving the cutting speed of different materials and ensuring consistent quality, motor reducers boost productivity and deliver a strong return on investment.

Real-World Applications of Motor Reducers in Laser Cutting

Case Study: Automotive Industry Application

Overview of the problem: Inconsistent cutting quality in automotive parts

In the automotive industry, precision plays a critical role in manufacturing components. However, inconsistent cutting quality often disrupts production. For instance, when cutting metal sheets for car body panels, uneven edges or incomplete cuts can lead to defective parts. These issues not only waste materials but also increase production costs and delay timelines. The root cause often lies in the inability of machinery to maintain stable torque and speed while cutting through different materials with varying thicknesses.

Solution and results: Integration of motor reducers improved precision and reduced production time

Motor reducers provided an effective solution to this challenge. By enhancing torque control and stabilizing cutting operations, they allowed laser cutting machines to handle different materials with greater accuracy. The integration of motor reducers ensured that the laser head moved smoothly, following precise paths without deviations. This improvement eliminated errors, resulting in cleaner cuts and consistent quality. Additionally, the optimized speed control reduced production time significantly. Manufacturers reported higher productivity and fewer rejected parts, demonstrating the transformative impact of motor reducers in automotive applications.

Industry Examples

Use in aerospace for cutting lightweight, high-strength materials

The aerospace industry relies on laser cutting for crafting lightweight yet durable components. Materials like titanium and carbon fiber require precise cutting due to their high strength and unique properties. Motor reducers play a vital role in this process by ensuring the laser cutting machine operates at the optimal speed and torque. This capability allows you to achieve clean cuts without damaging the material's structural integrity. For example, when producing aircraft parts, motor reducers help maintain the precision needed to meet strict safety and performance standards.

Benefits observed in small-scale manufacturing, such as jewelry and custom designs

Motor reducers also benefit small-scale manufacturers, including jewelers and custom design creators. These industries often work with intricate patterns and delicate materials like gold, silver, and acrylic. Motor reducers enable precise control over the laser cutting process, ensuring flawless results even for the most complex designs. By stabilizing the cutting operation, they minimize errors and reduce material waste. This efficiency not only enhances the quality of the final product but also saves time and resources, making motor reducers an invaluable asset for artisans and small businesses.

How to Choose the Right Motor Reducer for Your Laser Cutting Machine

Selecting the right motor reducer for your laser cutting machine is essential for achieving optimal performance and efficiency. By understanding your machine's needs and following proper maintenance practices, you can ensure long-term reliability and precision.

Factors to Consider

Machine Specifications and Requirements

Start by evaluating the specific requirements of your laser cutting machine. Consider the type of materials you cut most frequently and the level of precision your projects demand. For instance, cutting metals like steel or titanium may require a motor reducer with higher torque capabilities, while working with plastics or wood might prioritize speed adjustments. Assess the machine's power output and operational limits to ensure the motor reducer can handle the workload without compromising performance.

Additionally, think about the cutting applications you perform. If your projects involve intricate designs or complex patterns, choose a motor reducer that offers precise control over speed and torque. This ensures smooth and accurate movements during the cutting process, reducing errors and material waste.

Compatibility with Existing Systems

Compatibility plays a crucial role when integrating a motor reducer into your laser cutting machine. Ensure the motor reducer aligns with the machine's working mechanism and functionality. Check the dimensions, mounting options, and connection points to avoid installation issues. A mismatch could lead to inefficiencies or even damage to the machine.

You should also consider the software and control systems your machine uses. Some motor reducers work better with specific control systems, enhancing synchronization and responsiveness. By selecting a compatible motor reducer, you can maximize the efficiency and stability of your laser cutting operations.

Tips for Maintenance and Longevity

Regular Inspection and Servicing

Routine maintenance is vital for keeping your motor reducer in top condition. Inspect the gears, shafts, and other components regularly for signs of wear or damage. Look for unusual noises, vibrations, or performance drops, as these may indicate underlying issues. Addressing problems early prevents costly repairs and downtime.

Schedule periodic servicing by professionals to ensure all parts function correctly. Lubricate the gears and bearings as recommended by the manufacturer to reduce friction and extend the lifespan of the motor reducer. Consistent maintenance not only improves performance but also enhances the safety of your laser cutting machine.

Importance of Using High-Quality Components

Investing in high-quality components for your motor reducer ensures durability and reliability. Cheap or substandard parts may save money initially but often lead to frequent breakdowns and higher long-term costs. Opt for components made from robust materials that can withstand the demands of laser cutting.

When replacing parts, always use those recommended by the manufacturer. This guarantees compatibility and maintains the integrity of the motor reducer. High-quality components also contribute to smoother operations, allowing your laser cutting machine to deliver consistent results over time.

The Future of Motor Reducers in Laser Cutting Technology

Innovations in Motor Reducer Design

Advancements in materials and engineering

The design of motor reducers continues to evolve, driven by advancements in materials and engineering techniques. Manufacturers now use lightweight yet durable materials like polyacetal and advanced alloys to enhance performance and reduce wear. These materials improve the lifespan of motor reducers while maintaining their efficiency under high operational demands. For example, the integration of metal worms and polyacetal worm wheels has proven effective in reducing reverse rotation, ensuring stability during operation. This innovation minimizes wear and tear, making motor reducers more reliable for laser cutting applications.

Engineering breakthroughs also focus on optimizing gear mechanisms. Precision-engineered gears reduce friction and energy loss, enabling smoother and more efficient torque transmission. These improvements allow you to achieve consistent cutting quality, even when working with challenging materials. By adopting these advanced designs, motor reducers can handle higher workloads without compromising accuracy or durability.

Integration with smart technologies

The rise of automation has brought smart technologies into the realm of motor reducers. Modern motor reducers now feature sensors and IoT-enabled components that monitor performance in real time. These sensors track parameters like torque, speed, and temperature, providing valuable data to optimize operations. For instance, if a motor reducer detects excessive heat, it can adjust its performance to prevent damage, ensuring uninterrupted laser cutting processes.

Smart technologies also enable predictive maintenance. By analyzing data from the motor reducer, you can identify potential issues before they lead to failures. This proactive approach reduces downtime and extends the lifespan of your equipment. Additionally, integrating motor reducers with centralized control systems enhances synchronization across the entire laser cutting machine, improving overall efficiency and precision.

Trends in Laser Cutting Efficiency

Growing demand for precision and automation

The demand for precision and automation in manufacturing continues to grow. Industries like aerospace, automotive, and electronics require components with exact specifications, leaving no room for errors. Motor reducers play a crucial role in meeting these demands by ensuring precise control over speed and torque. This precision allows laser cutting machines to produce intricate designs and maintain consistent quality across large production runs.

Automation has become a cornerstone of modern manufacturing. Automated systems reduce human intervention, increasing productivity and minimizing errors. Motor reducers, equipped with smart technologies, seamlessly integrate into automated workflows. They enhance the responsiveness and stability of laser cutting machines, enabling you to achieve higher efficiency and accuracy in your operations.

Role of motor reducers in meeting future industry needs

As industries continue to embrace automation, motor reducers will remain essential for addressing future challenges. The push for sustainability has led manufacturers to prioritize energy-efficient solutions. Motor reducers contribute to this goal by optimizing energy consumption during laser cutting processes. Their ability to reduce energy waste aligns with the growing emphasis on eco-friendly manufacturing practices.

The need for versatility in laser cutting machines will also drive innovation in motor reducers. Future designs will likely focus on adaptability, allowing you to switch between different materials and cutting patterns with ease. By enhancing the flexibility and efficiency of laser cutting systems, motor reducers will help you stay competitive in an ever-evolving market.

Motor reducers play a pivotal role in enhancing the efficiency of laser cutting machines. By improving torque control, speed adjustments, and energy usage, they ensure precise and consistent results. These devices not only enhance the quality of your cuts but also reduce production costs and time. Choosing the right motor reducer tailored to your machine's needs is essential for achieving optimal performance. Incorporating motor reducers into your operations can elevate the stability and accuracy of laser cutting, making them an indispensable component for improving overall productivity and quality.

FAQ

What is the primary function of a motor reducer in a laser cutting machine?

A motor reducer adjusts the motor's speed and torque to match the specific needs of your laser cutting machine. It reduces the motor's rotational speed while increasing torque, ensuring smooth and precise cutting operations. This adjustment allows the machine to handle various materials effectively, from metals to plastics.

How does a motor reducer improve cutting precision?

Motor reducers enhance precision by stabilizing the laser head's movements. They minimize vibrations and ensure the laser follows the programmed path accurately. This stability prevents errors, even when working on intricate designs or cutting materials with varying thicknesses.

Can a motor reducer help reduce energy consumption?

Yes, motor reducers optimize energy usage by ensuring the motor operates efficiently. By moderating speed and torque, they reduce unnecessary energy waste during cutting. This efficiency lowers energy costs and supports sustainable manufacturing practices.

What are the key components of a motor reducer?

A motor reducer typically includes gears, shafts, and a protective housing. The gears, often a mix of large and small ones, work together to reduce speed and increase torque. The housing ensures durability and protects the internal components during operation.

How do I choose the right motor reducer for my laser cutting machine?

To select the right motor reducer, consider your machine's specifications, such as power output and material requirements. Evaluate the type of materials you cut most often and the level of precision needed. Ensure the motor reducer is compatible with your machine's existing systems to avoid installation issues.

What is the difference between a gearbox and a motor reducer?

A gearbox is a component within a motor reducer. While both adjust speed and torque, a motor reducer includes additional mechanisms to integrate seamlessly with motors and machinery. Gearboxes focus primarily on gear arrangements, while motor reducers provide a complete solution for speed and torque control.

How often should I maintain my motor reducer?

Regular maintenance is essential for optimal performance. Inspect the gears and shafts periodically for wear or damage. Lubricate moving parts as recommended by the manufacturer. Scheduling professional servicing ensures all components function correctly and extends the motor reducer's lifespan.

Are motor reducers suitable for all types of laser cutting machines?

Yes, motor reducers can be adapted to various laser cutting machines. However, the specific type and configuration depend on your machine's requirements. For example, coaxial, parallel-shaft, or orthogonal assemblies may suit different applications. Consult your machine's specifications to determine the best fit.

What role do motor reducers play in automated laser cutting systems?

Motor reducers enhance automation by providing precise control over speed and torque. They integrate seamlessly with smart technologies, enabling real-time monitoring and adjustments. This capability improves synchronization and efficiency in automated workflows, ensuring consistent cutting quality.

How do motor reducers contribute to long-term cost savings?

Motor reducers reduce wear and tear on your laser cutting machine by stabilizing operations and optimizing energy use. This efficiency lowers maintenance costs and extends the machine's lifespan. Additionally, their ability to improve cutting precision and speed boosts productivity, delivering a strong return on investment.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Functionality of CNC Laser Cutters

Essential Tips for Enhancing CNC Metal Cutting Performance