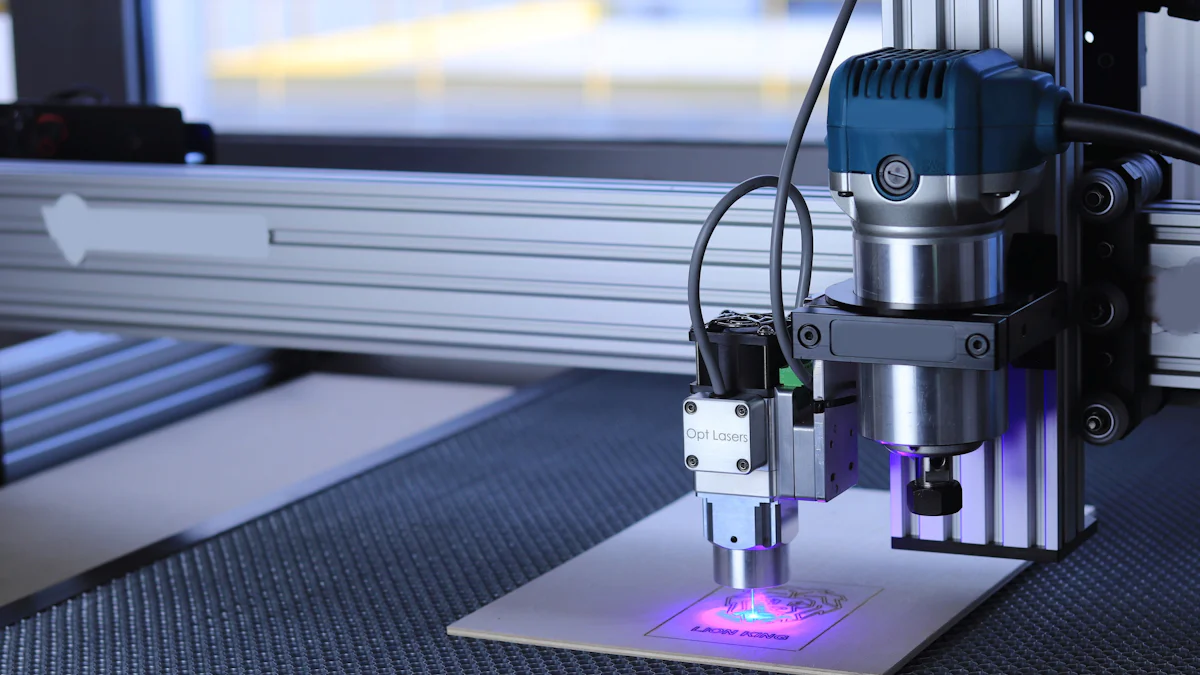

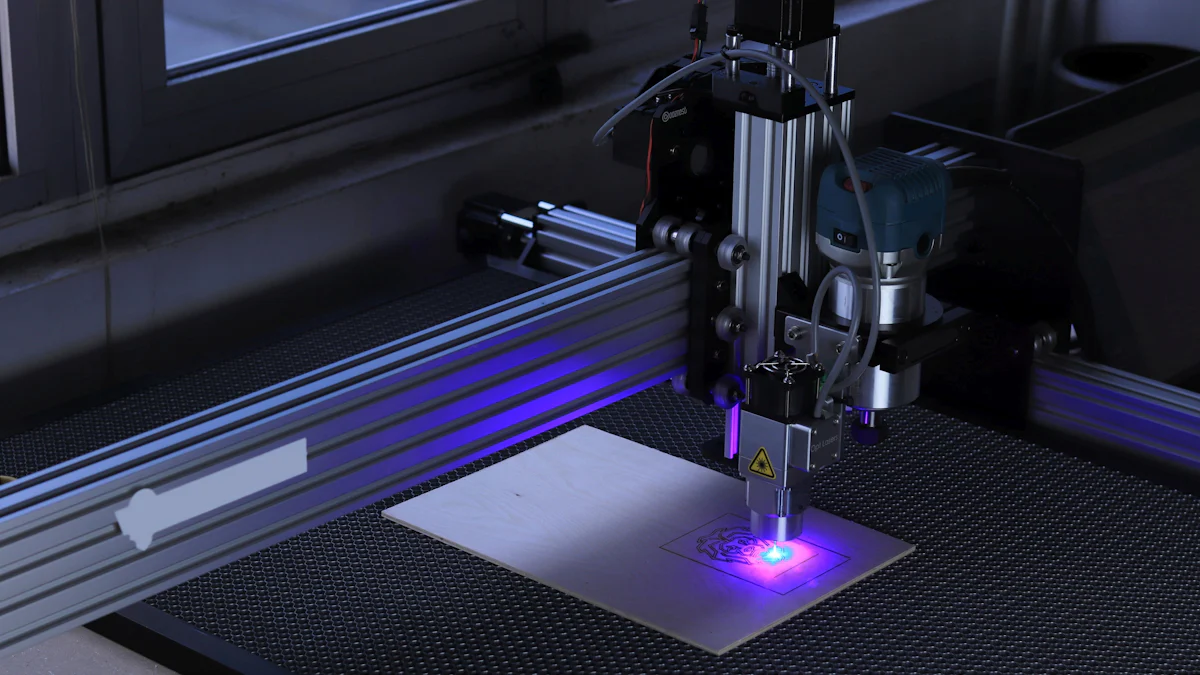

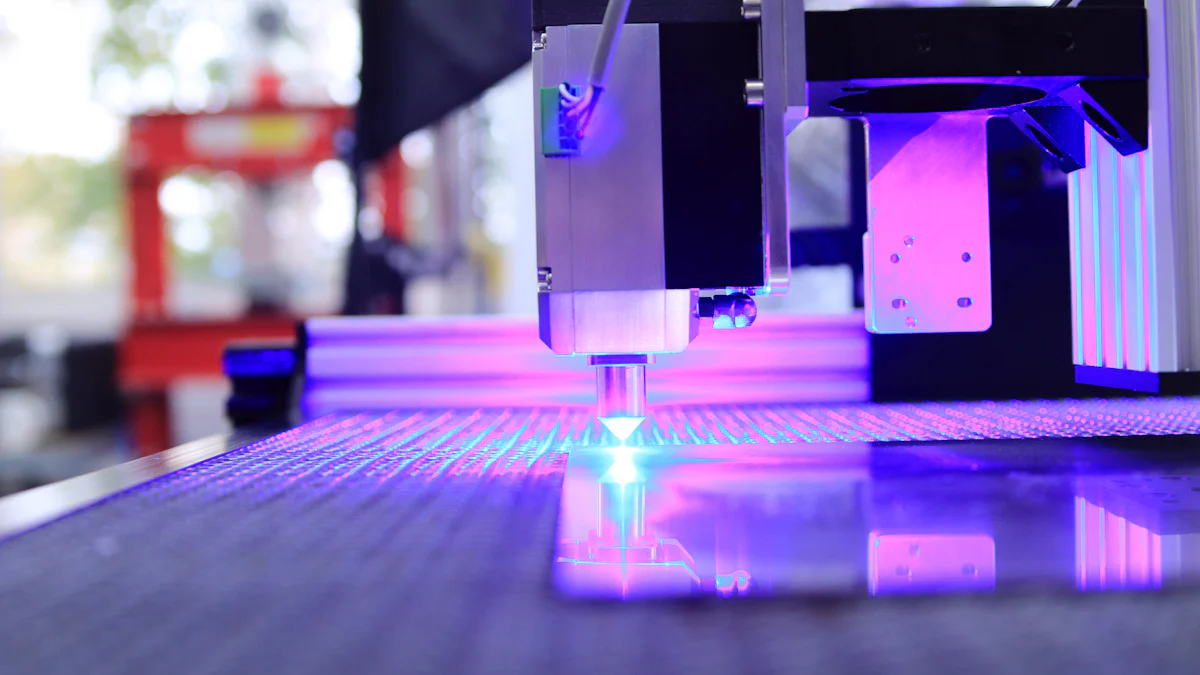

How to Make Your Own Laser Cutting Machine Safely

Laser cutting offers incredible precision and versatility, but it comes with serious risks if you don’t take proper safety precautions. Direct exposure to the laser beam can cause severe burns or permanent eye damage. Toxic fumes released during cutting can irritate your respiratory system or lead to long-term health issues. Without proper ventilation, these fumes and particles can accumulate, creating hazardous conditions. Fires are another danger, especially when flammable materials are present. Understanding laser cutter safety is essential if you want to learn how to make your own laser cutting machine without compromising your well-being.

Understanding the Risks of Laser Cutting

Laser cutting is a powerful tool, but it comes with several potential hazards that you must address to ensure safety. Understanding these risks will help you take the necessary steps to protect yourself, your workspace, and your equipment.

Physical Risks to Users

Eye injuries from laser exposure

The laser beam used in laser cutting is highly concentrated and can cause severe eye damage if viewed directly or through reflections. Even brief exposure can lead to permanent vision loss. Always wear laser safety goggles designed for the specific wavelength of your laser. These goggles block harmful light while allowing you to see your work clearly.

Burns from direct contact with the laser beam

The laser beam generates intense heat capable of cutting through materials. Accidental contact with the beam can result in serious burns. Keep your hands and other body parts away from the laser path at all times. Use tools like clamps or tweezers to adjust materials instead of your hands.

Fire Hazards

Combustible materials catching fire during operation

Laser cutting involves high temperatures, which can ignite flammable materials such as wood, paper, or certain plastics. Always check the material's compatibility with laser cutting before starting. Keep a fire extinguisher nearby and ensure it is rated for electrical and material fires. This is one of the most critical fire safety precautions you can take.

Improper ventilation leading to overheating

Poor ventilation can cause heat to build up in your workspace, increasing the risk of fire. It can also lead to the accumulation of flammable gases released during cutting. Install proper ventilation systems to remove heat and fumes efficiently. A well-ventilated workspace not only reduces fire risks but also improves air quality.

Health Risks from Fumes

Toxic fumes from cutting certain materials

Some materials, like PVC or acrylic, release toxic fumes when cut with a laser. These fumes can irritate your respiratory system and, in some cases, cause long-term health issues. Avoid cutting materials known to emit harmful gases. If you must cut such materials, use a fume extractor to capture and filter the emissions.

Long-term exposure to harmful particles

Prolonged exposure to fine particles generated during laser cutting can harm your lungs. These particles may include carcinogenic substances, depending on the material being cut. Regularly clean your workspace to minimize dust accumulation. Wearing a mask or respirator adds an extra layer of protection against airborne particles.

By understanding these risks and implementing appropriate safety measures, you can significantly reduce the dangers associated with laser cutting. Prioritizing safety not only protects you but also ensures the longevity of your equipment and the quality of your work.

Equipment Damage

Misaligned components causing malfunctions

Misaligned components can disrupt the functionality of your laser cutting machine. When the laser beam is not properly aligned with the cutting path, it may result in uneven cuts or complete failure to cut through materials. This not only wastes time but also damages the material you are working on. To prevent this, you should regularly inspect the alignment of the laser module and mirrors. Use alignment tools or guides to ensure the laser beam follows the intended path accurately.

Improper alignment can also strain the machine’s internal mechanisms, leading to premature wear and tear. For example, a misaligned laser can cause the motorized parts to work harder than necessary, reducing their lifespan. By addressing alignment issues early, you can avoid costly repairs and maintain the precision of your machine.

Overloading the machine with improper materials

Using materials that exceed the machine’s capacity or are unsuitable for laser cutting can cause significant damage. For instance, reflective materials like certain metals can bounce the laser beam back into the machine, potentially harming the laser module or other sensitive components. Always check the manufacturer’s guidelines to determine which materials are safe to use with your specific laser cutter.

Overloading the machine with thick or dense materials can also overheat the laser module, leading to malfunctions. This overheating may warp the internal components or even cause the machine to shut down unexpectedly. To avoid this, select materials that match the power and capabilities of your laser cutter. Running test cuts on scrap pieces can help you fine-tune the settings and ensure compatibility.

Tip: Regular maintenance, such as cleaning the lens and mirrors, can further protect your machine from damage caused by improper material use. Dust and residue from unsuitable materials can accumulate and reduce the efficiency of the laser beam.

By taking these precautions, you can extend the life of your laser cutting machine and ensure it operates safely and effectively.

Essential Safety Equipment for Laser Cutter Safety

When working with a laser cutter, having the right safety equipment is essential to protect yourself and your workspace. This equipment minimizes risks like injuries, fires, and exposure to harmful fumes. By equipping yourself properly, you can ensure a safer and more efficient laser cutting experience.

Personal Protective Equipment (PPE)

Laser safety goggles

Your eyes are highly vulnerable to the intense light emitted by a laser cutter. Even a brief exposure to the laser beam or its reflections can cause irreversible damage. Laser safety goggles are specifically designed to block harmful wavelengths while allowing you to see your work clearly. Always choose goggles that match the wavelength of your laser module. Wearing these goggles is not optional—it’s a critical step in laser cutter safety.

Heat-resistant gloves

The laser cutter generates extreme heat, which can cause burns if you accidentally touch heated materials or components. Heat-resistant gloves provide a protective barrier, allowing you to handle materials safely. These gloves also reduce the risk of accidental contact with sharp edges on cut materials. Make it a habit to wear gloves whenever you’re near the machine.

Workspace Safety Equipment

Fire extinguisher

Fires are one of the most significant risks when using a laser cutter. Materials like wood, paper, and certain plastics can ignite during cutting operations. A fire extinguisher rated for electrical and material fires should always be within arm’s reach. Regularly check that the extinguisher is fully charged and functional. Quick access to this tool can prevent a small flare-up from turning into a major incident.

Smoke and fire alarms

Smoke and fire alarms are vital for early detection of potential hazards. These devices alert you to smoke buildup or flames, giving you time to act before the situation escalates. Install alarms in your workspace and test them frequently to ensure they work properly. Early warnings can make all the difference in preventing damage or injury.

Proper ventilation systems

Laser cutting produces fumes and particles that can harm your health. Cutting materials like PVC or acrylic releases toxic gases, while other materials generate fine dust that can irritate your lungs. A proper ventilation system removes these harmful substances from the air, keeping your workspace safe. Consider adding a fume extractor to capture and filter emissions directly at the source. Good ventilation also reduces the risk of overheating, which can lead to fires.

Tip: Always review the Safety Data Sheet (SDS) for any material you plan to cut. This document provides crucial information about potential hazards and recommended safety measures.

By investing in the right safety gear and maintaining a well-equipped workspace, you can significantly reduce the risks associated with laser cutting. Prioritizing safety equipment not only protects you but also ensures the longevity of your machine and the quality of your projects.

Safety Precautions When Building Your Own Laser Cutting Machine

Building your own laser cutting machine can be an exciting and rewarding project. However, it requires careful attention to safety precautions to ensure the process is both safe and successful. By selecting the right components, following proper assembly practices, and thoroughly testing your machine, you can create a functional and secure laser cutter.

Selecting the Right Components

Choosing a laser module with appropriate power levels

The laser module is the heart of your machine, and selecting one with the correct power level is crucial. A laser that is too powerful can pose unnecessary risks, while an underpowered laser may fail to cut materials effectively. Consider the types of materials you plan to cut and their thickness when choosing your laser module. For beginners, starting with a lower-power laser (e.g., 5-10 watts) is often safer and easier to manage. Always check the manufacturer’s specifications to ensure the module meets your needs.

Using certified and tested parts

Using certified and tested components ensures your machine operates safely and reliably. Look for parts that meet industry standards and come with safety certifications. For example, opt for high-quality wiring and connectors to reduce the risk of electrical malfunctions. Avoid using second-hand or uncertified parts, as they may compromise the safety features of your machine. Investing in reliable components not only enhances safety but also improves the machine’s performance and longevity.

Tip: Keep a checklist of all required parts and verify their certifications before starting the assembly process.

Assembly Best Practices

Ensuring secure electrical connections

Proper electrical connections are essential to prevent short circuits, overheating, or even fires. Use insulated wires and connectors to minimize the risk of accidental contact. Double-check all connections to ensure they are tight and secure. Avoid overloading circuits by using a power supply that matches the requirements of your laser module and other components. If you’re unsure about wiring, consult a professional or refer to detailed guides.

Aligning the laser beam correctly to avoid misfires

Misaligned laser beams can lead to accidents or damage to your machine. During assembly, carefully align the laser module with the cutting path. Use alignment tools or guides to ensure precision. A misaligned beam can cause the laser to hit unintended areas, increasing the risk of burns or equipment damage. Regularly inspect the alignment during and after assembly to maintain accuracy.

Pro Tip: Perform alignment in a well-lit workspace and wear laser safety goggles to protect your eyes during the process.

Testing and Calibration

Running low-power tests to check functionality

Before using your laser cutter at full power, conduct low-power tests to verify its functionality. These tests allow you to identify any issues without risking damage to the machine or materials. Start by testing the movement of the laser head and the responsiveness of the controls. Gradually increase the power to ensure the laser cuts as expected. Document the settings that work best for different materials to streamline future operations.

Inspecting for loose or faulty components

After assembly, thoroughly inspect your machine for any loose or faulty components. Check screws, bolts, and electrical connections to ensure everything is secure. Pay special attention to the laser module and mirrors, as these are critical for accurate cutting. Address any issues immediately to prevent malfunctions or accidents during operation.

Reminder: Regular maintenance and inspections are key to keeping your laser cutter in top condition.

By following these safety precautions, you can confidently learn how to make your own laser cutting machine. Prioritizing safety features during the building process not only protects you but also ensures your machine operates efficiently and delivers high-quality results.

Safe Operation Practices for Laser Cutting

Operating a laser cutter safely requires careful preparation, attention during use, and proper post-operation practices. By following these steps, you can minimize risks and ensure a smooth and secure laser cutting experience.

Preparing the Workspace

Keeping flammable materials away from the machine

Before starting, inspect your workspace for any flammable materials. Items like paper, fabric, or wood scraps should be stored far from the laser cutter. Even small sparks can ignite these materials, leading to dangerous fires. Keep your workspace organized and clutter-free to reduce fire hazards. A clean environment not only enhances safety but also improves your focus while working.

Ensuring proper ventilation to avoid toxic fumes

Laser cutting generates fumes and particles that can harm your health. Materials like acrylic or PVC release toxic gases when cut, which can irritate your lungs or cause long-term health issues. Install a ventilation system to remove these harmful substances from the air. A fume extractor positioned near the cutting area works best for capturing emissions at the source. Proper ventilation also prevents heat buildup, reducing the risk of overheating.

Tip: Always check the material's Safety Data Sheet (SDS) to understand its potential hazards and ventilation requirements.

Operating the Machine Safely

Never leaving the machine unattended during use

Never walk away while the laser cutter is running. Fires can start quickly, especially when cutting flammable materials. Staying nearby allows you to respond immediately if something goes wrong. Keep a fire extinguisher within reach and know how to use it effectively. Your presence ensures that minor issues don’t escalate into major problems.

Using appropriate settings for different materials

Each material requires specific laser settings for safe and effective cutting. Incorrect power or speed settings can damage the material or the machine. For example, using too much power on thin materials may cause them to burn, while insufficient power might fail to cut through thicker materials. Refer to the manufacturer’s guidelines or conduct test cuts on scrap pieces to determine the best settings. Adjusting the settings properly ensures precise cuts and protects your equipment.

Pro Tip: Create a log of successful settings for different materials to save time and improve consistency in future projects.

Post-Operation Safety

Allowing the machine to cool down before handling

After completing your work, give the machine time to cool down. The laser module and other components can remain hot for several minutes after use. Handling them too soon may result in burns or damage to the equipment. Turn off the machine and wait until all parts have cooled before performing any maintenance or adjustments.

Cleaning and maintaining the machine regularly

Regular cleaning keeps your laser cutter in optimal condition. Dust, debris, and residue from previous cuts can accumulate on the lens, mirrors, and cutting bed, reducing the machine’s efficiency. Use a soft cloth or specialized cleaning tools to remove buildup. Inspect the machine for loose screws, worn-out parts, or misaligned components. Routine maintenance not only extends the life of your laser cutter but also ensures consistent performance.

Reminder: Schedule periodic deep cleanings and inspections to address any hidden issues that may affect safety or functionality.

By preparing your workspace, staying vigilant during operation, and maintaining your machine after use, you can create a safer environment for laser cutting. These practices protect you, your equipment, and the quality of your projects.

Common Mistakes to Avoid in Laser Cutter Safety

Mistakes in laser cutter safety can lead to accidents, equipment damage, or health risks. By recognizing and avoiding these common errors, you can create a safer environment and ensure your laser cutter operates effectively.

Skipping Safety Gear

Operating without goggles or gloves

Failing to wear proper safety gear exposes you to serious risks. Laser safety goggles protect your eyes from the intense light emitted by the laser. Without them, even brief exposure can cause permanent eye damage. Always choose goggles designed for the specific wavelength of your laser cutter. This ensures maximum protection while allowing you to see your work clearly.

Heat-resistant gloves are equally important. The laser generates extreme heat, and handling materials immediately after cutting can result in burns. Gloves provide a barrier between your skin and hot surfaces, keeping you safe during operation. Skipping this essential gear compromises your safety and increases the likelihood of injuries.

Tip: Make it a habit to check your safety gear before starting any laser cutting project. Proper preparation minimizes risks.

Ignoring Maintenance

Failing to clean the machine after use

Neglecting regular maintenance can lead to malfunctions and safety hazards. Dust, debris, and residue from previous cuts accumulate on the laser bed, lens, and mirrors. This buildup reduces the efficiency of the laser beam and increases the risk of overheating. Over time, it can also damage critical components, shortening the lifespan of your machine.

Cleaning your laser cutter after each use prevents these issues. Use a soft cloth to wipe down surfaces and remove debris. Inspect the lens and mirrors for smudges or residue, as these can distort the laser beam. Regular maintenance ensures your machine operates safely and delivers consistent results.

Reminder: Schedule periodic deep cleanings and inspections to address hidden issues that may not be visible during routine maintenance.

Overloading the Machine

Using materials that exceed the machine's capacity

Overloading your laser cutter with unsuitable materials can cause significant damage. Thick or dense materials may strain the laser module, leading to overheating or malfunctions. Reflective materials, such as certain metals, can bounce the laser beam back into the machine, potentially harming sensitive components.

Always check the manufacturer’s guidelines to determine which materials are compatible with your laser cutter. Running test cuts on scrap pieces helps you fine-tune the settings and ensures the material is safe to use. Avoid pushing the machine beyond its limits, as this not only risks damage but also compromises the quality of your work.

Pro Tip: Keep a log of materials and their optimal settings. This saves time and prevents errors in future projects.

By addressing these common mistakes, you can enhance laser cutter safety and improve the performance of your machine. Prioritizing safety gear, regular maintenance, and proper material selection protects you and ensures a smooth cutting experience.

Emergency Preparedness for Laser Cutting

Emergencies can happen even when you follow all safety precautions. Being prepared ensures you can respond quickly and effectively to minimize harm. Whether dealing with a fire or an injury, knowing the right steps can make all the difference.

Handling Fire Incidents

Using a fire extinguisher effectively

A fire extinguisher is your first line of defense against small fires. Always keep one nearby when operating your laser cutter. Ensure it is rated for both electrical and material fires, as these are the most common risks in laser cutting. Before using the extinguisher, remember the PASS method:

- Pull the pin to unlock the extinguisher.

- Aim the nozzle at the base of the fire, not the flames.

- Squeeze the handle to release the extinguishing agent.

- Sweep the nozzle side to side until the fire is out.

Proper fire extinguisher training is essential. Practice using an extinguisher in a controlled environment to build confidence. Regularly check that your extinguisher is fully charged and functional. Acting quickly and correctly can prevent a small fire from escalating into a major disaster.

Tip: Never attempt to extinguish a fire if it grows too large. Your safety comes first.

Evacuating the area if the fire spreads

If a fire becomes uncontrollable, evacuate immediately. Do not waste time trying to save equipment or materials. Alert others in the area and guide them to safety. Use the nearest exit and avoid inhaling smoke by staying low to the ground. Once outside, call emergency services and provide clear details about the situation.

Establish clear emergency procedures for your workspace. Post evacuation routes and ensure everyone knows where to go in case of a fire. Practicing drills can help you and others respond calmly and efficiently during an actual emergency.

Reminder: Never re-enter the building until authorities declare it safe.

Responding to Injuries

First aid for burns or eye injuries

Accidents can happen even with proper precautions. If you or someone else suffers a burn, act quickly. Cool the affected area with running water for at least 10 minutes. Avoid using ice, as it can damage the skin further. Cover the burn with a clean, non-stick dressing to protect it from infection.

For eye injuries caused by laser exposure, immediate action is critical. Do not rub the eyes, as this can worsen the damage. Seek medical attention as soon as possible. While waiting for help, keep the injured person calm and avoid exposing their eyes to bright light.

Important: Always have a first aid kit in your workspace. Stock it with supplies specifically for burns and eye injuries.

Seeking medical attention when necessary

Some injuries require professional care. Severe burns, persistent eye pain, or vision changes should never be ignored. Contact a healthcare provider or visit an emergency room promptly. Delaying treatment can lead to complications or permanent damage.

Proper training in first aid can prepare you to handle injuries effectively. Consider taking a certified course to learn how to respond to common laser cutting accidents. Knowing what to do in those critical moments can protect your health and the well-being of others.

Pro Tip: Keep emergency contact numbers visible in your workspace for quick access during a crisis.

By preparing for emergencies, you can reduce the risks associated with laser cutting. Equip your workspace with the right tools, practice fire extinguisher training, and establish clear emergency procedures. These steps ensure you can act confidently and protect yourself and others when unexpected situations arise.

Benefits of Prioritizing Safety in Laser Cutting

Prioritizing safety in laser cutting is not just about avoiding accidents. It enhances your overall experience, protects your health, and ensures the longevity of your equipment. By taking safety seriously, you can achieve better results while minimizing risks.

Protecting Yourself and Others

Reducing the risk of accidents and injuries

When you follow safety protocols, you significantly lower the chances of accidents. Wearing proper protective gear, such as laser safety goggles and heat-resistant gloves, shields you from burns and eye injuries. Keeping your workspace organized and free of flammable materials reduces fire hazards. These precautions protect not only you but also anyone nearby.

Experts emphasize that proper training is essential before operating a laser cutter. Understanding the risks and learning how to handle the machine safely ensures you can respond effectively to potential issues. By prioritizing safety, you create a secure environment for everyone involved.

Tip: Always review the operating manual and safety guidelines for your laser cutter. Familiarity with the machine helps you avoid common mistakes.

Prolonging the Life of Your Machine

Preventing damage through proper use and maintenance

A well-maintained laser cutter lasts longer and performs better. Regular cleaning prevents dust and debris from accumulating on critical components like the lens and mirrors. Proper alignment of the laser beam ensures smooth operation and reduces wear on internal parts. These practices protect your machine from unnecessary strain and costly repairs.

Using the right materials and settings also plays a key role. Overloading the machine or cutting unsuitable materials can cause overheating or damage to sensitive components. Following manufacturer guidelines and conducting test cuts help you avoid these issues. When you treat your machine with care, it rewards you with consistent performance over time.

Pro Tip: Schedule routine inspections to identify and address minor issues before they escalate into major problems.

Ensuring Better Results

Achieving precise and consistent cuts with a well-maintained machine

Safety measures directly impact the quality of your work. A clean and properly calibrated laser cutter delivers precise and consistent cuts. When you use the correct settings for each material, you avoid burns, uneven edges, or incomplete cuts. This attention to detail enhances the final product and saves you time by reducing errors.

Proper ventilation also contributes to better results. Removing fumes and particles from the workspace ensures clear visibility and prevents residue from affecting the cutting process. A safe and efficient environment allows you to focus on your project without distractions or interruptions.

Reminder: Document successful settings for different materials to streamline future projects and maintain consistency.

By prioritizing safety, you protect yourself, extend the life of your equipment, and achieve superior results. These benefits make safety an investment in both your well-being and the success of your laser cutting projects.

Building and using a laser cutting machine safely starts with understanding the risks and taking proactive steps to address them. Equip yourself with the right tools, like safety goggles and proper ventilation systems, to create a secure workspace. Follow best practices during assembly and operation to prevent accidents and ensure consistent performance. Regular maintenance keeps your machine efficient and extends its lifespan. By prioritizing safety, you protect yourself and others while enjoying the precision and versatility of laser cutting. A safe approach transforms your experience into a rewarding and hazard-free journey.

FAQ

What safety gear do I need when using a laser cutter?

You must wear laser safety goggles to protect your eyes from harmful laser light. Choose goggles designed for the specific wavelength of your laser. Heat-resistant gloves are also essential to prevent burns when handling materials or components near the laser. These items form the foundation of personal protective equipment (PPE) and are non-negotiable for safe operation.

Tip: Always inspect your safety gear for damage before use. Damaged equipment may not provide adequate protection.

Why is proper ventilation important during laser cutting?

Laser cutting produces fumes and fine particles, especially when working with materials like acrylic or PVC. Without proper ventilation, these substances can harm your respiratory system and create a hazardous workspace. A ventilation system or fume extractor removes toxic gases and improves air quality.

Reminder: Poor ventilation can also lead to overheating, increasing the risk of fire. Always prioritize airflow in your workspace.

Can I use any material in my laser cutter?

No, not all materials are safe for laser cutting. Some, like PVC, release toxic fumes, while others, like reflective metals, can damage the machine. Always check the manufacturer’s guidelines to ensure compatibility. Running test cuts on scrap pieces helps you confirm the material is safe and suitable for your project.

Pro Tip: Keep a log of materials and their optimal settings to avoid mistakes in future projects.

How do I prevent fires when using a laser cutter?

Keep flammable materials away from the machine and always have a fire extinguisher nearby. Use materials compatible with laser cutting and monitor the machine during operation. Proper ventilation also reduces the risk of heat buildup, which can ignite flammable substances.

Important: Never leave the laser cutter unattended while it’s running. Fires can start quickly and escalate without warning.

What should I do if a fire starts?

Use a fire extinguisher rated for electrical and material fires. Follow the PASS method: Pull the pin, Aim at the base of the fire, Squeeze the handle, and Sweep side to side. If the fire grows uncontrollable, evacuate immediately and call emergency services.

Reminder: Your safety comes first. Do not attempt to fight a large fire on your own.

How often should I clean and maintain my laser cutter?

Clean your laser cutter after every use. Remove dust, debris, and residue from the lens, mirrors, and cutting bed. Regular maintenance, such as inspecting for loose components and aligning the laser beam, ensures the machine operates efficiently and safely.

Pro Tip: Schedule periodic deep cleanings to address hidden issues that may not be visible during routine maintenance.

Why is alignment important for a laser cutter?

Proper alignment ensures the laser beam follows the intended cutting path. Misalignment can cause uneven cuts, damage to materials, or strain on the machine’s components. Regularly check and adjust the alignment to maintain precision and prevent malfunctions.

Tip: Use alignment tools for accuracy and always wear safety goggles during the process.

Can I leave the laser cutter running while I step away?

No, you should never leave the machine unattended. Fires, malfunctions, or other hazards can occur unexpectedly. Staying nearby allows you to respond immediately if something goes wrong.

Important: Always monitor the machine during operation, even for short jobs.

What should I do if I get injured while using a laser cutter?

For burns, cool the area with running water for at least 10 minutes and cover it with a clean dressing. For eye injuries, avoid rubbing your eyes and seek medical attention immediately. Keep a first aid kit in your workspace and familiarize yourself with basic first aid procedures.

Reminder: Severe injuries require professional medical care. Don’t delay seeking help if needed.

How does prioritizing safety benefit me?

Prioritizing safety protects you from accidents and injuries, extends the life of your machine, and ensures better results. A well-maintained and safely operated laser cutter delivers precise cuts and consistent performance. Safety is an investment in both your health and the success of your projects.

Pro Tip: Treat safety as a habit, not an afterthought. Consistent precautions lead to a smoother and more rewarding laser cutting experience.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Functionality of CNC Laser Cutters

Comparative Analysis of Laser Cutting Machine Prices

Essential Techniques for Effective Plasma Cutting Machine Use