How to Make Money with a Laser Cutting Machine

Imagine turning your creativity into cash with a laser cutting machine. This tool opens doors to a world where you can make money by crafting unique, in-demand products. The market for laser-cut items is booming, with the global laser cutting machines market projected to grow from $5.95 billion in 2023 to $11.32 billion by 2030. People love personalized and intricate designs, making money with a laser cutter not just possible but exciting. Whether you're crafting custom jewelry or home decor, the opportunities are endless. Dive into this lucrative business and discover how to make money with a laser cutting machine today.

Understanding Your Laser Cutting Machine

To make the most out of your laser cutting business, you need to understand your machine. Let's dive into the different types of laser cutting machines and their key features.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each with unique capabilities. Knowing these can help you choose the right one for your needs.

CO2 Laser Cutters

CO2 laser cutters are popular for their versatility. They work well with non-metal materials like wood, acrylic, and leather. If you're planning to create intricate designs on these materials, a CO2 laser cutter might be your best bet.

Fiber Laser Cutters

Fiber laser cutting machines are the go-to choice for cutting metals. They offer high precision and speed, making them ideal for industrial applications. If you're looking to cut metals like stainless steel or aluminum, a fiber laser cutting machine will serve you well. These machines are also known for their efficiency and low maintenance needs.

Diode Laser Cutters

Diode laser cutters are compact and affordable. They are perfect for small-scale projects and hobbyists. While they may not have the power of CO2 or fiber lasers, they are great for engraving and cutting thin materials.

Key Features and Capabilities

Understanding the features of your laser cutting machine can help you maximize its potential.

Precision and Speed

Laser cutting machines are renowned for their precision and speed. They can create complex designs with minimal waste. This precision is crucial when working on detailed projects like custom jewelry or corporate branding products.

Material Compatibility

Different laser cutting machines work with different materials. CO2 lasers excel with non-metals, while fiber lasers are perfect for metals. Knowing your machine's material compatibility ensures you choose the right projects and avoid damaging your equipment.

By understanding these aspects of your laser cutting machine, you can make informed decisions and optimize your business operations. Whether you're crafting personalized gifts or exploring niche markets, the right machine and knowledge can set you on the path to success.

Identifying Profitable Products

When it comes to making money with a laser cutting machine, choosing the right products is key. You want to focus on items that are not only popular but also allow for personalization and creativity. Let's explore some profitable options.

Popular Laser-Cut Products

Laser cutting art offers a world of possibilities. Here are some popular products to consider:

Custom Jewelry

Creating laser-cut jewelry can be a lucrative venture. People love wearing unique pieces that reflect their personality. With a laser cutter, you can craft intricate designs that stand out. Whether it's earrings, necklaces, or bracelets, the demand for custom-made items is high. You can offer a wide product portfolio by experimenting with different materials like wood, acrylic, or metal.

Home Decor Items

Home decor is another area where laser cutting shines. From wall art to coasters, the possibilities are endless. You can create laser-engraved items that add a personal touch to any space. Consider making laser-cut bookmarks or a laser-cut sign for a personalized home accent. These products not only enhance living spaces but also make great gifts.

Personalized Gifts

Customized gifts are always in demand. People love giving and receiving individualized products that feel special. With a laser cutter, you can create creative individual items like custom products for weddings, birthdays, or anniversaries. Think about laser cutting wedding decorations or personalized ornaments. These items can become cherished keepsakes.

Niche Markets and Custom Orders

Exploring niche markets can boost your profitability. Here are some ideas:

Corporate Branding Products

Businesses often seek custom products for branding purposes. You can offer laser-cut items like nameplates, awards, or promotional products. These items help companies stand out and leave a lasting impression. By providing high-quality, customized gifts, you can tap into a steady stream of corporate clients.

Educational Tools

Educational tools present another exciting opportunity. Teachers and parents appreciate unique, engaging learning aids. You can create laser-cut puzzles, flashcards, or models that make learning fun. These products not only serve an educational purpose but also showcase your design ideas.

By focusing on a profitable product mix and offering personalized products, you can build a successful laser cutting business. Remember, the key is to combine creativity with market demand. Keep exploring new design ideas and stay open to custom orders. This approach will help you carve out a niche and attract loyal customers.

Steps to Start Your Laser Cutting Business

Starting a laser cutting business can be an exciting venture. With the right setup and planning, you can turn your passion into a profitable enterprise. Let's walk through the essential steps to get your business off the ground.

Setting Up Your Workspace

Creating an efficient workspace is crucial for your laser cutting business. You need a space that accommodates your equipment and ensures safety.

Equipment and Tools Needed

First, gather the necessary equipment. A fiber laser cutting machine is a great choice if you plan to work with metals. It offers precision and speed, making it ideal for detailed projects. Besides the laser cutter, you'll need a computer with design software to create your patterns. Don't forget about ventilation systems to manage fumes and dust. Proper lighting and sturdy worktables will also enhance your workspace.

Safety and Maintenance

Safety should be a top priority. Ensure your workspace complies with safety regulations. Install fire extinguishers and first-aid kits. Regularly inspect your fiber laser cutting machine for wear and tear. Routine maintenance keeps your equipment running smoothly and prevents accidents. Train yourself and any employees on safe operating procedures. This knowledge protects everyone and prolongs the life of your tools.

Legal and Financial Considerations

Before you start offering services, address the legal and financial aspects of your business.

Business Licensing

Research the licensing requirements in your area. You may need a business license or permit to operate legally. Check local regulations to ensure compliance. Some regions have specific rules for laser cutting businesses, especially regarding safety standards. Meeting these requirements avoids legal issues down the road.

Budgeting and Investment

Plan your budget carefully. Consider the costs of purchasing a fiber laser cutting machine, setting up your workspace, and obtaining licenses. Factor in ongoing expenses like materials, utilities, and maintenance. It's wise to set aside funds for unexpected costs. Evaluate different financing options if needed. A well-thought-out budget helps you manage your finances and ensures your business remains sustainable.

By following these steps, you can establish a solid foundation for your laser cutting business. With the right equipment, a safe workspace, and proper legal and financial planning, you're well on your way to success. Remember, preparation is key to turning your laser cutting passion into a thriving business.

Marketing Strategies for Laser-Cut Products

To make your laser-cut products shine, you need effective marketing strategies. Let's explore how you can build an online presence and leverage networking opportunities to boost your business.

Building an Online Presence

In today's digital age, having a strong online presence is crucial. It helps you reach a wider audience and showcase your unique creations.

E-commerce Platforms

Start by setting up shop on popular e-commerce platforms like Etsy, Amazon Handmade, or Shopify. These platforms provide a ready-made audience interested in handmade and personalized items. Make sure your product listings are detailed and include high-quality photos. Take great pictures and videos of your laser-cut products. Use a well-lit room and consistent backgrounds. Capture multiple angles to highlight the intricacies of your designs. This visual appeal can attract potential buyers and increase sales.

Social Media Marketing

Social media platforms offer a fantastic way to connect with your audience. Instagram, with its image-focused nature, is perfect for showcasing your laser-cut creations. Share engaging visuals and captions to start conversations with potential customers. Use hashtags related to your niche to increase visibility. Facebook and Pinterest are also great platforms to share your work and engage with followers. Regularly post updates, behind-the-scenes content, and customer testimonials to keep your audience engaged.

Networking and Collaborations

Building relationships with other businesses and individuals can open new doors for your laser cutting business.

Partnering with Local Businesses

Consider partnering with local businesses to expand your reach. Collaborate with boutiques, gift shops, or interior designers who might be interested in your products. Offer them exclusive designs or custom orders. This partnership can lead to increased exposure and sales. Additionally, local businesses can help you capitalize on Christmas and the holiday season by featuring your products in their stores or promotions.

Attending Craft Fairs and Markets

Craft fairs and markets provide excellent opportunities to showcase your products in person. Set up an attractive booth with eye-catching displays. Engage with visitors and share the story behind your creations. These events allow you to connect with potential customers and receive immediate feedback. They also offer a chance to network with other artisans and learn from their experiences. During the holiday season, these events can be particularly lucrative as shoppers look for unique gifts.

By implementing these marketing strategies, you can effectively promote your laser-cut products and grow your business. Remember, a strong online presence combined with strategic networking can help you stand out in the competitive market. Keep exploring new avenues and stay open to collaborations to maximize your success.

Pricing Models and Profit Margins

Understanding how to price your laser-cut products is crucial for maximizing profits. Let's dive into the essentials of cost analysis and strategies to enhance your profit margins.

Cost Analysis and Pricing Strategy

To set the right price, you need to consider both material and labor costs. This ensures you cover expenses and make a profit.

Material and Labor Costs

Start by calculating the cost of materials. Whether you're using wood, acrylic, or metal, knowing the price per unit helps you determine the base cost. For instance, if you're using a fiber laser cutting machine, factor in the cost of electricity and maintenance. Labor costs are next. If you're working solo, estimate the time spent on each project. For those with employees, include their wages in your calculations. A common approach is to charge around $20 per hour for labor, plus material costs. This method ensures you cover expenses while maintaining a healthy profit margin.

Competitive Pricing

Once you know your costs, research the market. Look at what competitors charge for similar products. Aim to offer competitive pricing without undercutting your value. Consider the uniqueness of your designs and the quality of your craftsmanship. If your products offer superior personalization, you can justify a higher price. Remember, customers often pay more for unique, personalized items that stand out.

Maximizing Profit Margins

Boosting your profit margins involves more than just setting the right price. Explore strategies like upselling and offering customization options to increase revenue.

Upselling and Cross-Selling

Encourage customers to buy more by offering complementary products. If someone buys a laser-cut necklace, suggest matching earrings or a bracelet. This strategy, known as upselling, increases the average order value. Cross-selling works similarly. Recommend related items that enhance the customer's purchase. For example, if a customer buys a laser-cut home decor piece, suggest coasters or wall art that match the theme. These tactics not only boost sales but also enhance customer satisfaction.

Offering Customization Options

Personalization is a powerful tool. Offer customers the chance to customize their purchases. Whether it's engraving a name or choosing a specific design, customization adds value. Customers appreciate the opportunity to create something unique. This approach can lead to higher profit margins, as personalized items often command a premium price. According to a survey, enhancing existing products with laser engraving can lead to profit margins of up to 50% after shipping. This highlights the potential of personalization in boosting your bottom line.

By implementing these pricing models and strategies, you can effectively manage costs and maximize profits. Remember, understanding your expenses and leveraging personalization can set your laser cutting business on the path to success.

Scaling Your Business

As your laser cutting business grows, you'll want to explore ways to scale up. Expanding your product lines and investing in advanced technology can help you reach new heights. Let's dive into how you can achieve this.

Expanding Product Lines

Diversifying your offerings can attract more customers and increase sales. Here's how you can expand your product lines effectively.

Introducing New Designs

Keep your product line fresh by introducing new designs regularly. Customers love variety and unique creations. Experiment with different styles and materials to create something special. For example, if you currently offer laser-cut jewelry, consider adding a line of home decor items. This approach not only keeps your existing customers engaged but also attracts new ones. Stay updated with design trends and incorporate them into your products to maintain relevance in the market.

Exploring New Markets

Venturing into new markets can open up exciting opportunities. Research potential markets that align with your products. For instance, if you specialize in personalized gifts, consider targeting corporate clients for custom branding products. You can also explore international markets by offering shipping options to other countries. This expansion can significantly boost your customer base and revenue. Remember, understanding the needs and preferences of your target market is key to successful expansion.

Investing in Advanced Technology

Upgrading your technology can enhance efficiency and product quality. Let's explore how investing in advanced technology can benefit your business.

Upgrading Equipment

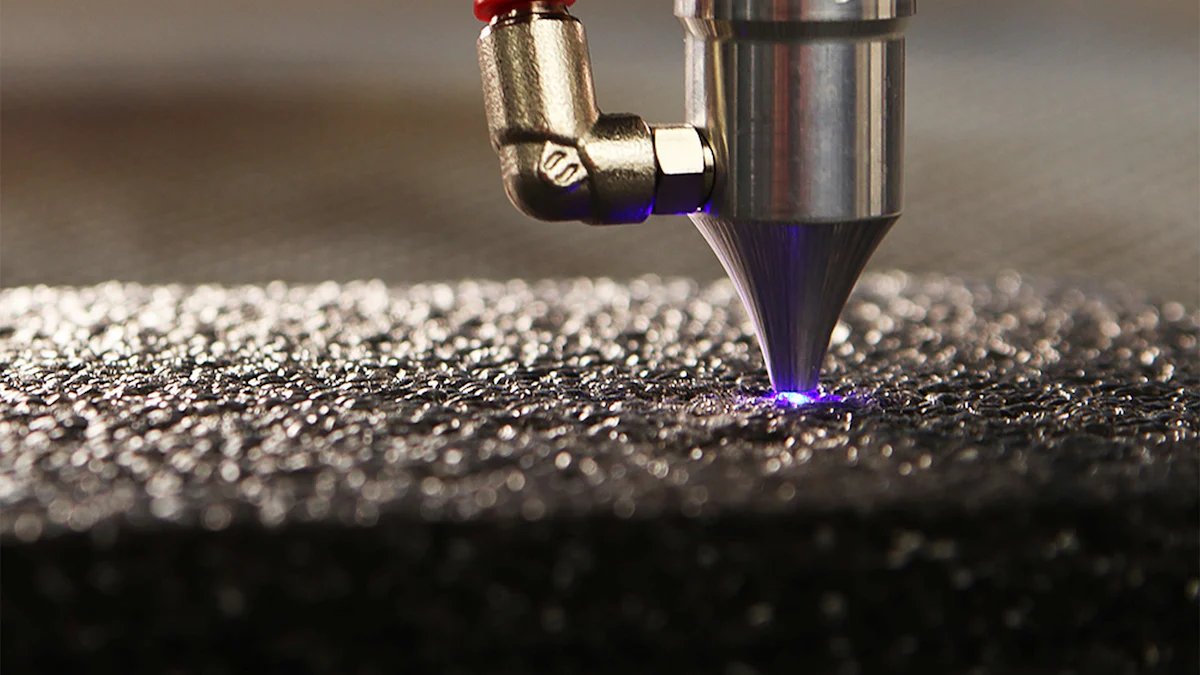

Consider upgrading your equipment to improve precision and speed. Advanced laser cutting machines offer better performance and can handle more complex projects. For example, a manufacturer optimized their laser process to improve quality and throughput. This optimization allowed them to integrate the process into high-volume production. By upgrading your equipment, you can achieve similar results and take on larger orders. This investment can lead to increased productivity and customer satisfaction.

Automation and Efficiency

Automation can streamline your operations and reduce manual labor. Implementing automated systems can help you manage repetitive tasks efficiently. For instance, automated cutting processes can save time and minimize errors. This efficiency allows you to focus on creative aspects and business growth. Additionally, automation can lead to cost savings in the long run. By investing in technology that enhances efficiency, you can scale your business without compromising quality.

Scaling your laser cutting business involves expanding your product lines and investing in advanced technology. By introducing new designs and exploring new markets, you can attract a broader audience. Upgrading equipment and implementing automation can boost efficiency and productivity. These strategies will help you grow your business and achieve long-term success.

You can make money with a laser cutting machine by tapping into its vast potential. This tool offers endless opportunities for creativity and profit. By exploring various business avenues, you can find the perfect niche for making money with a laser cutter. Start by understanding your machine and identifying profitable products. Then, set up your laser cutting business with a focus on quality and innovation. Remember, success comes from delivering unique, high-end services that stand out. Take these actionable steps to grow your business and watch your profits soar.

FAQ

What is laser cutting, and how does it work?

Laser cutting is a process that uses a focused beam of light to cut through materials. The laser melts, burns, or vaporizes the material, creating precise cuts. You can use it on various materials like wood, metal, and acrylic. The high accuracy and speed make it a popular choice for many industries.

How is laser cutting frequently used today?

Laser cutting is widely used for its versatility and precision. Industries like automotive, aerospace, and fashion rely on it for creating intricate designs and components. You can also find laser-cut products in home decor, jewelry, and personalized gifts. Its ability to handle different materials makes it a go-to solution for many applications.

What materials can I cut with a laser cutting machine?

You can cut a wide range of materials with a laser cutter. Common options include wood, acrylic, leather, and metals like stainless steel and aluminum. Each material requires specific settings for optimal results. Always check your machine's compatibility before starting a project.

Is laser cutting safe?

Yes, laser cutting is safe when you follow proper safety guidelines. Ensure your workspace has adequate ventilation to manage fumes. Wear protective eyewear and avoid direct exposure to the laser beam. Regular maintenance of your equipment also helps prevent accidents.

How do I choose the right laser cutting machine for my needs?

Consider the materials you plan to work with and the complexity of your designs. CO2 lasers are great for non-metals, while fiber lasers excel with metals. Diode lasers are suitable for small-scale projects. Evaluate your budget and production needs to make an informed decision.

Can I start a laser cutting business from home?

Absolutely! Starting a laser cutting business from home is possible with the right setup. You'll need a dedicated workspace, a reliable laser cutter, and design software. Ensure you comply with local regulations and safety standards. With creativity and planning, you can turn your home-based business into a success.

How do I price my laser-cut products?

Pricing involves calculating material and labor costs. Research competitors to set competitive prices. Consider the uniqueness and quality of your products. Offering customization can justify higher prices. Aim for a balance between affordability and profitability.

What are some effective marketing strategies for laser-cut products?

Building an online presence is crucial. Use e-commerce platforms like Etsy and social media to showcase your creations. Engage with your audience through captivating visuals and stories. Networking with local businesses and attending craft fairs can also boost your visibility.

How can I expand my laser cutting business?

Expand by introducing new designs and exploring new markets. Keep your product line fresh and diverse. Consider upgrading your equipment for better efficiency. Automation can streamline operations and increase productivity. Stay open to new opportunities and collaborations.

What are the benefits of offering customization options?

Customization adds value to your products. Customers love personalized items that reflect their style. Offering customization can lead to higher profit margins. It also enhances customer satisfaction and loyalty. By providing unique options, you can stand out in the competitive market.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Comparative Guide to Laser Cutting Machine Prices

Understanding the Functionality of CNC Laser Cutters