Tips for Maintaining Your CNC Laser Cutting Machine

Proper maintenance is the backbone of keeping your CNC laser cutting machine in top condition. Regular care ensures smooth operations, minimizes downtime, and prevents costly repairs. Neglecting maintenance can lead to residue buildup, overheating, and even system failures. Cleaning your machine and inspecting its components daily can help you spot early signs that your fiber laser machine needs maintenance. These efforts not only extend the life of your laser cutting machine but also improve its precision and reliability. If you're wondering where to buy CNC laser cutting machines with reliable servicing options, choosing trusted vendors is key.

Daily Maintenance Practices to Extend the Life of Your Laser Cutting Machine

Proper daily maintenance is essential to keep your CNC laser cutting machine running efficiently and to avoid unnecessary downtime. By following these daily maintenance tips, you can extend the lifespan of your machine, ensure precision, and reduce the risk of costly repairs.

Regular Cleaning

Regular cleaning is the foundation of effective fiber laser machine maintenance. Dust and debris can accumulate on the cutting bed and surrounding areas, impacting the machine's performance.

- Remove dust and debris from the cutting bed after every use. This prevents particles from interfering with the cutting process and ensures smooth operations.

- Focus on cleaning the fiber laser machine's lens and laser head. Residue buildup on these components can reduce cutting precision and power. Use a soft, lint-free cloth and specialized cleaning solutions to maintain their clarity.

A clean machine not only operates more efficiently but also produces consistent, high-quality results.

Inspecting for Wear and Tear

Daily inspection helps you identify potential issues before they escalate into significant problems. Make it a habit to inspect the machine thoroughly.

- Check for loose screws, belts, or other components. Tighten any loose parts immediately to prevent operational disruptions.

- Inspect the condition of cables and connections. Look for signs of wear, fraying, or damage. Damaged cables can lead to electrical issues or even machine failure.

By taking a few minutes each day to inspect the machine, you can avoid unexpected breakdowns and maintain optimal performance.

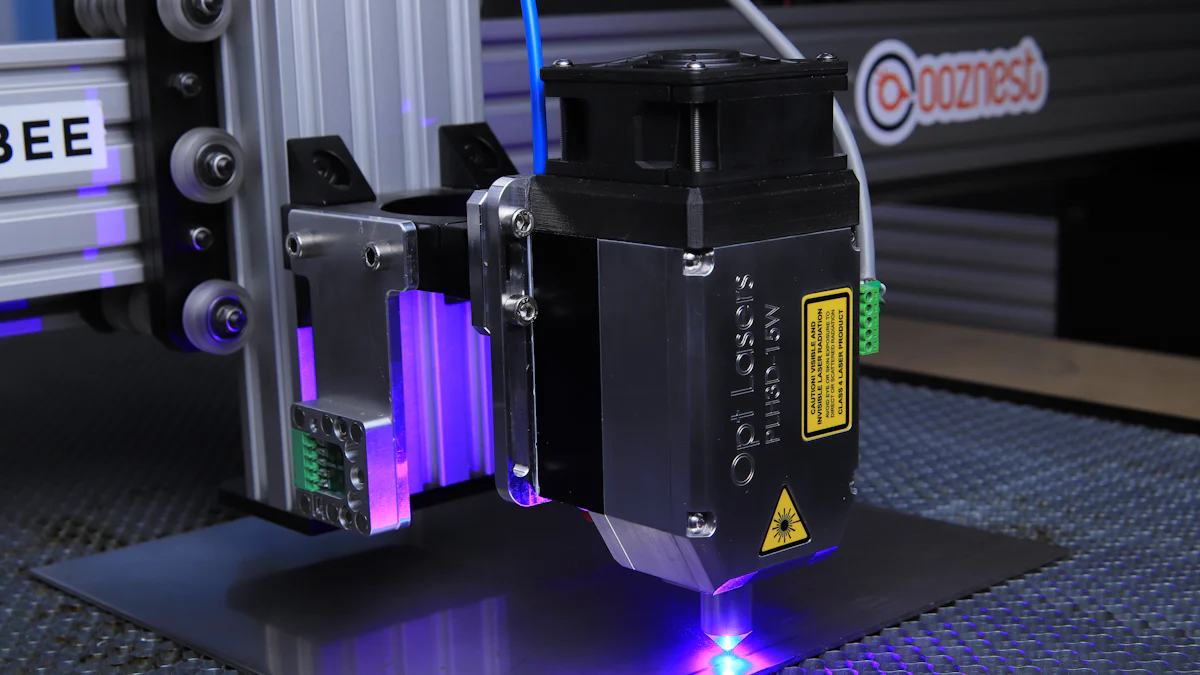

Monitoring Operational Parameters

Monitoring the machine's operational parameters is another critical aspect of fiber laser machine maintenance. This ensures that the machine operates at its best capacity.

- Verify the laser power and alignment daily. Misaligned lasers can compromise cutting precision and lead to material waste.

- Ensure proper airflow and ventilation during operation. A clean air assist system prevents material ignition and supports clean, precise cuts.

Consistently monitoring these parameters helps you maintain cutting accuracy and reduces the risk of overheating or other operational issues.

By incorporating these daily maintenance tips into your routine, you can protect your investment, ensure precision, and keep your CNC laser cutting machine in peak condition.

Optimizing the Machine's Environment for Longevity

Creating the right environment for your CNC laser cutting machine is essential to ensure its durability and consistent performance. Environmental factors such as placement, temperature, and cleanliness directly impact the machine's efficiency and lifespan. By optimizing these conditions, you can reduce wear and tear, prevent malfunctions, and optimize performance.

Ideal Placement

The placement of your CNC laser cutting machine plays a significant role in its stability and functionality. Improper positioning can lead to vibrations, misalignment, and even damage over time.

- Position the machine in a stable, vibration-free area. Vibrations can disrupt the cutting process and affect precision. Use a sturdy surface or anti-vibration pads to keep the machine steady during operation.

- Keep the machine away from direct sunlight or heat sources. Excessive heat can cause components to expand, leading to alignment issues. Place the machine in a shaded area to maintain its structural integrity.

Proper placement not only enhances cutting accuracy but also minimizes the risk of mechanical failures.

Temperature and Humidity Control

Maintaining the right temperature and humidity levels is critical for the longevity of your CNC laser cutting machine. Extreme conditions can strain the machine and increase energy consumption.

- Maintain a consistent temperature to prevent overheating. Sudden temperature fluctuations can damage sensitive components. Studies highlight that cold temperatures may also hinder the machine's operation, so aim for a balanced room temperature.

- Avoid excessive humidity to reduce the risk of corrosion. High humidity can lead to rust on metal parts, compromising the machine's performance. Use a dehumidifier if necessary to control moisture levels.

By regulating these environmental factors, you can protect your machine from unnecessary stress and ensure smooth operations.

Dust and Particle Prevention

Dust and airborne particles are common culprits behind reduced machine efficiency. They can settle on critical components, leading to blockages and reduced cutting precision.

- Use air filtration systems to minimize airborne particles. Filters help trap dust before it reaches the machine, keeping internal components clean and functional.

- Regularly clean the workspace to reduce contamination. A clean environment prevents debris from accumulating on the cutting bed and optical components. This simple practice ensures consistent cutting quality.

Keeping the workspace clean and free of contaminants not only improves the machine's performance but also extends its lifespan.

By optimizing the environment around your CNC laser cutting machine, you create conditions that support its durability and reliability. These steps help you avoid unnecessary repairs and ensure the machine operates at peak efficiency for years to come.

Component-Specific Maintenance Tips

Proper maintenance of individual components in your CNC laser cutting machine ensures optimal performance and extends its lifespan. Each part plays a critical role in the machine's functionality, so giving them the attention they deserve is essential.

Cooling System Care

The cooling system is vital for preventing overheating and maintaining consistent cutting precision. Neglecting this component can lead to severe damage and reduced efficiency.

- Check coolant levels regularly and refill them as needed. Low coolant levels can compromise the cooling system's ability to regulate temperature, leading to overheating.

- Clean the cooling system periodically to remove contaminants and prevent blockages. Dirty or clogged systems reduce cooling efficiency and may cause long-term damage to internal components.

Monitoring and maintaining the cooling system ensures reliable performance and protects your investment from costly repairs.

Lubrication of Moving Parts

Lubrication is crucial for reducing friction and wear on moving parts. Without regular lubrication, components like rails, bearings, and gears can degrade quickly, affecting the machine's precision.

- Apply lubricant regularly to all moving parts, including rails, bearings, and gears. Use the manufacturer-recommended lubricants to ensure compatibility and effectiveness.

- Avoid over-lubrication, as excess lubricant can attract dust and debris, leading to residue buildup. This can hinder the smooth movement of parts and reduce efficiency.

By prioritizing the lubrication of moving parts, you can enhance the machine's performance and extend its operational life.

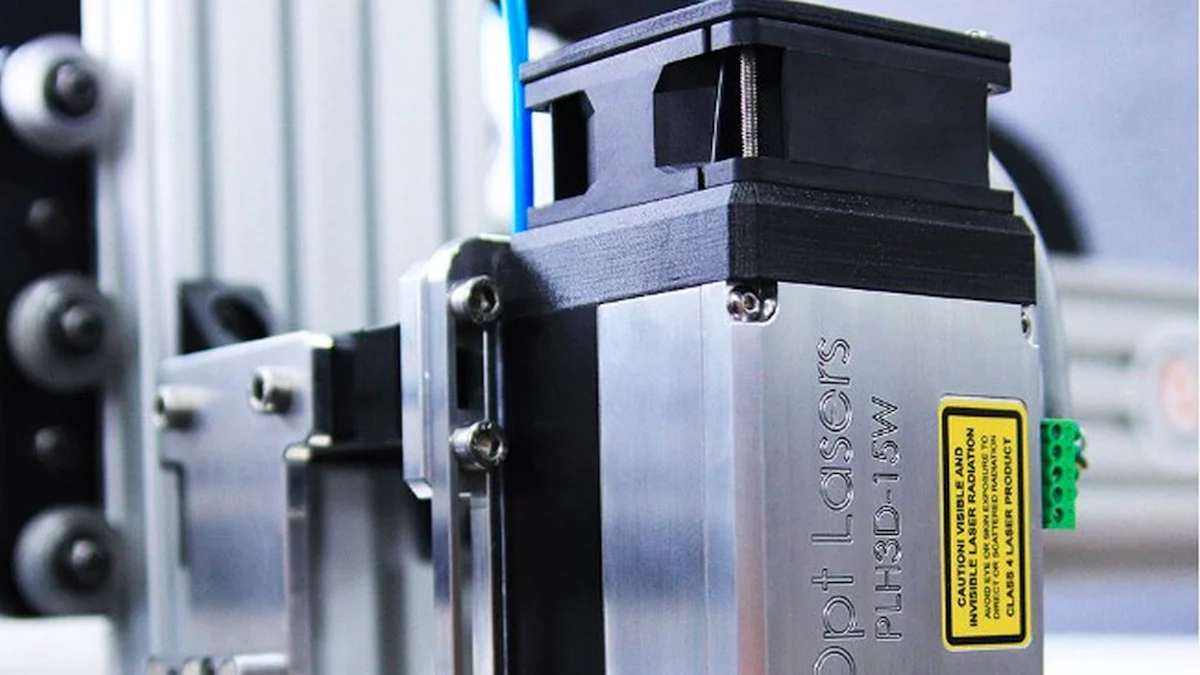

Cleaning Optical Components

Optical components, such as lenses and mirrors, directly impact the quality of your laser cuts. Keeping these parts clean ensures consistent cutting precision and prevents damage.

- Clean optical components using specialized cleaning solutions designed for lenses and mirrors. Avoid using abrasive materials that could scratch the surface.

- Inspect for scratches or damage during each cleaning session. Replace any damaged components promptly to maintain cutting accuracy and prevent further issues.

Regular care for optical components not only improves the quality of your work but also reduces the likelihood of costly replacements.

By focusing on these component-specific maintenance tasks, you can ensure your CNC laser cutting machine operates at peak efficiency. These practices protect your equipment, reduce downtime, and deliver consistent results.

Material Considerations for CNC Laser Cutting Machines

Understanding the materials you work with is essential for maintaining your CNC laser cutting machine and achieving optimal cutting quality. Each material interacts differently with the laser, which can impact performance and longevity. By following proper guidelines, you can ensure efficient operations and protect your machine from unnecessary wear.

Understanding Material Impact

The type of material you cut plays a significant role in how your machine performs. Different materials absorb and react to laser energy in unique ways, which affects the power and precision required for cutting.

- Recognizing how materials affect performance: Metals like stainless steel or aluminum demand higher laser power due to their density and reflective properties. In contrast, materials such as wood or acrylic require less power, making them easier to cut. Adjusting the laser settings based on the material ensures precise results and reduces strain on the machine.

- Avoiding harmful materials: Some materials produce excessive residue or release toxic fumes when cut. For example, cutting PVC can release harmful chlorine gas, which can damage the machine and pose health risks. Always follow manufacturer guidelines to determine which materials are safe to use.

Understanding how materials interact with your machine helps you optimize its performance and avoid potential hazards.

Proper Material Handling

Handling materials correctly is just as important as understanding their impact. Proper handling ensures consistent cutting quality and prevents damage to both the machine and the materials.

- Using appropriate settings: Adjust the machine's settings, such as laser power, speed, and focus, to match the material type and thickness. Thicker materials require more energy to penetrate deeper layers, while thinner materials need less power to avoid burns or warping. Following these guidelines ensures clean cuts and minimizes waste.

- Cleaning the cutting bed: After processing, remove leftover debris from the cutting bed. Residue from previous cuts can contaminate new materials, affecting the cutting quality and causing uneven results. A clean cutting bed also prevents buildup that could interfere with the machine's operation.

By handling materials with care and precision, you can maintain the efficiency of your CNC laser cutting machine and achieve high-quality results.

Where to Buy CNC Laser Cutting Machine and Professional Servicing

Finding the right CNC laser cutting machine and ensuring its proper upkeep can significantly impact your productivity and the machine's lifespan. Knowing where to buy CNC laser cutting machines and how to schedule professional servicing is essential for maintaining efficiency and preventing costly downtime.

Choosing a Reliable Vendor

Selecting a trustworthy vendor is the first step in acquiring a high-quality CNC laser cutting machine. A reliable supplier ensures you receive not only a durable product but also the support you need for long-term success.

- Research trusted suppliers: Look for vendors with a proven track record of delivering high-quality CNC laser cutting machines. Customer reviews and testimonials can provide valuable insights into their reliability. For example, companies like STYLECNC emphasize transparency by sharing genuine customer feedback. This helps you understand the real-world performance of their machines and services.

- Ensure after-sales support: A good vendor offers more than just the machine. They provide comprehensive after-sales support, including technical assistance and maintenance services. Vendors like STYLECNC stand out by offering 24/7 customer service and a 30-day return policy, ensuring you feel confident in your purchase.

Choosing the right vendor not only guarantees a quality machine but also gives you access to resources that help you maintain it effectively.

Scheduling Professional Maintenance

Establishing a regular maintenance schedule is crucial for keeping your CNC laser cutting machine in top condition. Professional servicing ensures that potential issues are addressed before they escalate, helping you prevent downtime and costly repairs.

- Set up a preventive maintenance schedule: Work with certified technicians to create a maintenance plan tailored to your machine's needs. Regular inspections and tune-ups help identify wear and tear early, ensuring your machine operates smoothly. A well-planned schedule minimizes disruptions and extends the machine's lifespan.

- Address issues proactively: Professional servicing allows you to tackle problems before they become major concerns. Technicians can detect hidden faults, replace worn components, and optimize the machine's performance. This proactive approach saves you time and money in the long run.

By committing to a regular maintenance schedule and relying on professional servicing, you can maximize the efficiency and longevity of your CNC laser cutting machine.

Maintaining your CNC laser cutting machine is essential for its longevity and efficiency. Daily maintenance, such as cleaning and inspecting components, ensures smooth operation and reduces unexpected downtime. Optimizing the machine's environment minimizes wear and tear, while component-specific care, like lubrication and cooling system checks, prevents costly repairs. Understanding material considerations further protects your machine from unnecessary strain. Regular professional servicing identifies potential issues early, keeping your machine reliable and precise. By adopting these practices, you can extend your machine’s lifespan, enhance productivity, and achieve consistent performance.

FAQ

What is the best way to clean the lens and laser head of a CNC laser cutting machine?

To clean the lens and laser head, use a soft, lint-free cloth and a specialized cleaning solution designed for optical components. Avoid using abrasive materials or household cleaners, as they can scratch or damage the surface. Perform this task gently to maintain the clarity and precision of the laser.

How often should I inspect my CNC laser cutting machine for wear and tear?

Daily inspections are ideal for identifying loose screws, worn belts, or damaged cables. Regular checks help you catch potential issues early, preventing costly repairs and ensuring smooth operation. Make this a part of your daily maintenance routine.

What temperature and humidity levels are ideal for a CNC laser cutting machine?

Maintain a consistent room temperature between 68°F and 77°F (20°C to 25°C) to prevent overheating or cold-related malfunctions. Keep humidity levels below 50% to avoid corrosion on metal components. Use air conditioning or a dehumidifier if necessary to control the environment.

Can I use any type of lubricant for the moving parts of my machine?

No, always use the manufacturer-recommended lubricants for your CNC laser cutting machine. These products are specifically formulated to reduce friction and wear without causing residue buildup. Avoid over-lubricating, as excess lubricant can attract dust and debris.

How do I know if my cooling system needs maintenance?

Check the coolant levels regularly and look for signs of contamination, such as discoloration or debris in the coolant. If the system struggles to maintain a stable temperature or you notice overheating, clean the cooling system and replace the coolant immediately.

What materials should I avoid cutting with a CNC laser cutting machine?

Avoid cutting materials like PVC, as it releases toxic chlorine gas when heated. Materials that produce excessive residue, such as certain foams or adhesives, can also damage the machine. Always consult the manufacturer’s guidelines to ensure material compatibility.

How can I ensure consistent cutting precision?

Verify the laser power and alignment daily. Misaligned lasers can compromise precision and waste materials. Additionally, keep the cutting bed clean and free of debris to maintain a smooth surface for accurate cuts.

Is professional servicing necessary if I perform regular maintenance?

Yes, professional servicing is essential even if you follow a strict maintenance routine. Certified technicians can identify hidden issues, optimize performance, and replace worn components. Schedule preventive maintenance at least once or twice a year for optimal results.

What should I look for when choosing a CNC laser cutting machine vendor?

Choose a vendor with a strong reputation for quality and reliability. Look for customer reviews, after-sales support, and warranties. Vendors offering technical assistance and maintenance services, like STYLECNC, provide added value and peace of mind.

How can I extend the lifespan of my CNC laser cutting machine?

Follow a daily maintenance routine that includes cleaning, inspecting, and monitoring operational parameters. Optimize the machine’s environment by controlling temperature, humidity, and dust levels. Schedule regular professional servicing and handle materials properly to minimize wear and tear.

See Also

Essential Tips for Enhancing CNC Metal Cutting Efficiency

Understanding the Functionality of CNC Laser Cutters

Maximizing Efficiency with Your Laser Cutting Machine