Guide to Machines for Cutting Acrylic Sheets

Using machines to cut acrylic sheets offers numerous advantages. You gain precision and efficiency that manual methods simply can't match. Machines like laser cutters provide smooth, shiny edges without the need for additional polishing. This not only saves time but also enhances product quality. Modern machines come with advanced automation features, allowing you to program settings for consistent results. They integrate seamlessly with other production systems, reducing labor costs and boosting productivity. So, what machine do you use to cut acrylic? Choosing the right one can transform your manufacturing process.

Key Takeaways

- Using machines like laser cutters and CNC machines enhances precision and efficiency in cutting acrylic sheets, resulting in high-quality finishes.

- CNC machines are ideal for intricate designs and batch processing, while laser cutters excel in producing smooth edges without additional polishing.

- When selecting a cutting machine, consider factors such as precision, material compatibility, project scale, and budget to ensure the best fit for your needs.

- Proper setup and maintenance of your acrylic cutting machine are crucial for achieving optimal performance and longevity.

- Always prioritize safety by wearing appropriate protective gear and ensuring proper ventilation when operating cutting machines.

- Regularly clean and inspect your machine to prevent issues and maintain consistent cutting quality.

Types of Machines for Acrylic Cutting

When deciding what machine do you use to cut acrylic, understanding the different types available is crucial. Each machine offers unique features and capabilities that cater to various applications.

CNC Machines

CNC machines are renowned for their precision and versatility. They use cutting-edge technology to create accurate components from acrylic. These machines operate with a computer numerical control system, allowing you to program intricate designs and execute them with high precision.

Features and capabilities

- Precision: CNC machines provide incredible accuracy, making them ideal for detailed work.

- Versatility: They can handle a variety of materials, including acrylic, wood, and metals.

- Automation: The CNC system automates the cutting process, reducing manual labor and increasing efficiency.

Suitable applications

CNC machines excel in applications requiring detailed and complex designs. They are perfect for batch processing and creating intricate patterns. Industries such as automotive, aerospace, and electronics often rely on CNC machines for their precision and reliability.

Laser Cutters

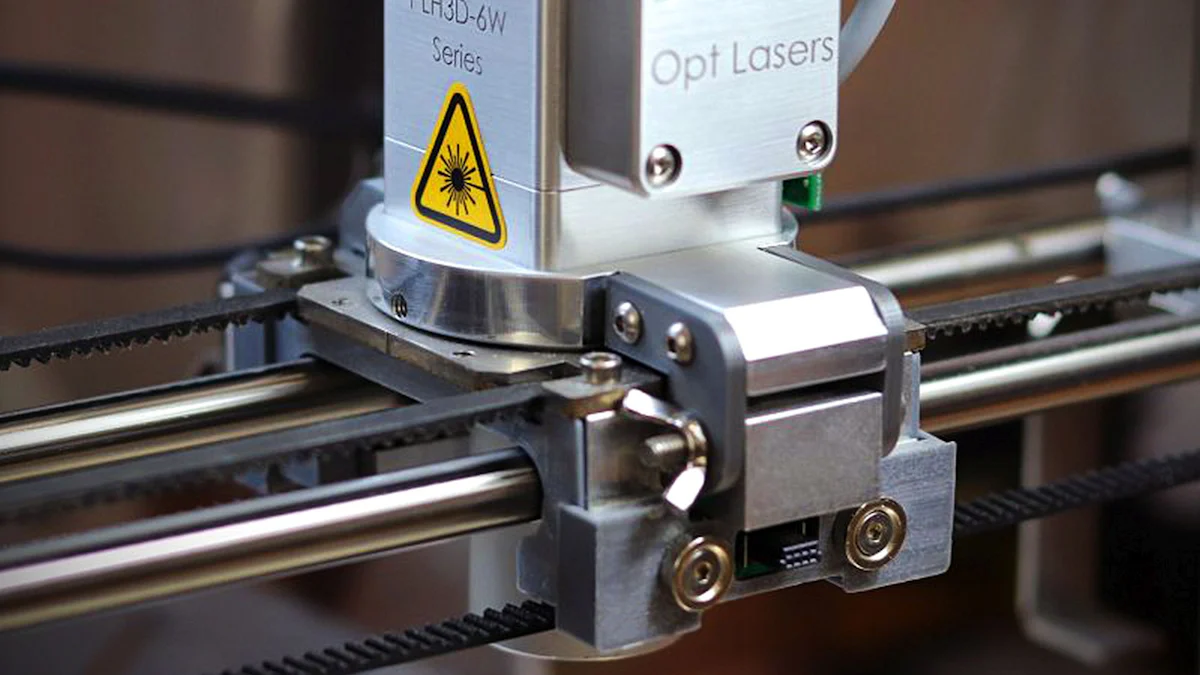

Laser cutters are another popular choice when considering what machine do you use to cut acrylic. They offer superior precision and smooth edges, making them a favorite in many industries.

Features and capabilities

- High Precision: Laser cutters use a concentrated laser beam for pinpoint accuracy.

- Smooth Edges: They produce clean cuts without the need for additional polishing.

- Versatility: These machines can cut a wide range of materials, including metals, plastics, and ceramics.

Suitable applications

Laser cutters are ideal for projects requiring intricate cuts and smooth finishes. They are widely used in industries like construction, oil and gas, and crafts. Their ability to handle varying thicknesses of acrylic makes them versatile for different project needs.

Other Machines

For smaller-scale projects, rotary tools and saws offer a practical solution. While they may not match the precision of CNC machines or laser cutters, they are useful for specific applications.

Features and capabilities of rotary tools and saws

- Affordability: These tools are generally more cost-effective than advanced machines.

- Portability: They are easy to transport and set up, making them suitable for small workshops.

- Ease of Use: Rotary tools and saws are user-friendly, requiring minimal setup and maintenance.

Suitable applications for small-scale projects

Rotary tools and saws are perfect for hobbyists and small businesses. They work well for simple cuts and basic designs, especially when precision is not the primary concern. These tools are excellent for DIY projects and small-scale manufacturing.

How to Use Acrylic Cutting Machines

Mastering the use of acrylic cutting machines can significantly enhance your project outcomes. This section guides you through the essential steps, from setting up your workspace to executing precise cuts.

Machine Setup

Preparing the workspace

Before you start, ensure your workspace is clean and organized. A clutter-free environment minimizes accidents and improves efficiency. Place your machine on a stable surface to prevent vibrations during operation. Adequate lighting is crucial for visibility, allowing you to monitor the cutting process closely. Ensure proper ventilation to manage fumes and debris, especially when using laser cutters.

Setting up the machine

Begin by reading the machine's manual to understand its specific setup requirements. Connect the machine to a power source and ensure all cables are secure. Calibrate the machine according to the material thickness and desired cut depth. Adjust the settings for speed and power based on the type of acrylic sheet you are using. This step is vital for achieving clean and precise cuts.

Design Preparation

Software and file formats

Design preparation involves using software compatible with your machine. Popular options include AutoCAD, Adobe Illustrator, and CorelDRAW. These programs allow you to create intricate designs and save them in formats like DXF or SVG, which are commonly used for machine cutting. Ensure your design file is compatible with your machine's software to avoid errors during the cutting process.

Importing and adjusting designs

Once your design is ready, import it into the machine's software. Check the dimensions and adjust them if necessary to fit the acrylic sheet. Pay attention to the orientation and alignment of the design on the virtual cutting bed. This step ensures that the final product matches your expectations. Make any necessary adjustments to the design before proceeding to the cutting stage.

Cutting Process

Loading the acrylic sheet

Carefully place the acrylic sheet onto the machine's cutting bed. Ensure it is flat and properly aligned with the machine's guides. Secure the sheet to prevent movement during cutting, which can lead to inaccuracies. Double-check the positioning to ensure the design will be cut correctly.

Executing the cut

With everything set, initiate the cutting process. Monitor the machine as it works, ensuring it follows the design accurately. Keep an eye on the machine's performance and be ready to pause or stop it if any issues arise. Once the cut is complete, carefully remove the acrylic piece and inspect it for quality. Proper execution results in smooth edges and precise shapes, enhancing the overall quality of your project.

"Operating an acrylic cutting machine involves various factors related to health and safety that should be carefully considered." Always prioritize safety by wearing appropriate protective gear and following the manufacturer's guidelines.

Tips for Selecting the Right Machine and Materials

Choosing the right machine and materials for cutting acrylic sheets can significantly impact your project's success. Understanding the factors involved will help you make informed decisions.

Choosing the Right Machine

Factors to consider

When deciding what machine do you use to cut acrylic, consider several key factors:

- Precision and Accuracy: Machines like laser cutters provide high precision, ensuring smooth and polished edges. CNC machines offer versatility and are ideal for intricate designs.

- Material Compatibility: Ensure the machine can handle the type of acrylic you plan to use. Some machines are better suited for specific materials.

- Project Scale: For large-scale projects, CNC machines and laser cutters are efficient. For smaller tasks, rotary tools and saws may suffice.

- Budget: Consider the cost of the machine and its maintenance. Laser cutters and CNC machines are more expensive but offer superior results.

Comparing machine features

Comparing features helps you select the best machine for your needs:

- Laser Cutters vs. CNC Machines: Laser cutters excel in speed and precision, making them ideal for delicate designs. CNC machines provide versatility and can handle various materials.

- Acrylic Sheet Cutting Machines vs. CNC Milling Machines: Acrylic sheet cutting machines specialize in precision and accuracy, while CNC milling machines offer increased precision with multi-point cutting tools.

- Laser Cutting vs. Water Jetting: Laser cutting is efficient and precise, while water jetting suits thicker materials and complex shapes.

Selecting Acrylic Materials

Types of acrylic sheets

Acrylic sheets come in different types, each with unique properties:

- Cast Acrylic: Offers superior optical clarity and is ideal for laser cutting. It is more expensive but provides better quality.

- Extruded Acrylic: More affordable and suitable for applications where optical clarity is less critical. It is easier to cut but may not offer the same finish as cast acrylic.

Thickness and quality considerations

The thickness and quality of acrylic sheets affect the cutting process:

- Thickness: Thicker sheets require more powerful machines. Laser cutters handle varying thicknesses well, while CNC machines offer versatility for different projects.

- Quality: High-quality acrylic ensures better results. Consider the sheet's clarity, color, and finish when selecting materials.

"Selecting the right machine and materials is crucial for achieving the desired outcome in acrylic cutting projects." By understanding these factors, you can make informed decisions that enhance your project's quality and efficiency.

Safety Precautions and Maintenance Tips

Ensuring safety and maintaining your acrylic cutting machine are crucial for optimal performance and longevity. By following these guidelines, you can protect yourself and keep your equipment in top condition.

Safety Precautions

Personal protective equipment

When operating an acrylic cutting machine, always wear appropriate personal protective equipment (PPE). This includes:

- Safety goggles: Protect your eyes from debris and harmful laser light.

- Gloves: Shield your hands from burns and cuts.

- Respirators or masks: Prevent inhalation of toxic fumes produced during the cutting process.

"The process of cutting acrylic can produce toxic fumes, so it is important to follow safety guidelines, wear protective gear, and work in a well-ventilated area."

Safe machine operation practices

Operating your machine safely involves several key practices:

- Read the manual: Familiarize yourself with the machine's instructions and safety guidelines.

- Ensure proper ventilation: Work in a well-ventilated area to disperse fumes effectively.

- Check machine settings: Verify that the machine settings match the material specifications before starting.

- Stay alert: Monitor the machine during operation to quickly address any issues.

Maintenance Tips

Regular cleaning and inspection

Regular maintenance keeps your machine running smoothly. Follow these steps:

- Clean the machine: Remove dust and debris from the machine's components after each use.

- Inspect parts: Check for wear and tear on belts, blades, and other moving parts.

- Lubricate moving parts: Apply lubricant to reduce friction and prevent damage.

Troubleshooting common issues

Addressing common issues promptly can prevent larger problems:

- Inconsistent cuts: Check the alignment and calibration of the machine.

- Overheating: Ensure proper ventilation and clean cooling fans regularly.

- Software errors: Update software and firmware to the latest versions.

By adhering to these safety precautions and maintenance tips, you can ensure a safe working environment and prolong the life of your acrylic cutting machine.

Using machines for cutting acrylic sheets offers numerous benefits. You gain precision, efficiency, and safety. Machines like laser cutters provide eco-friendly operations with minimal waste. They consume less energy, making them a sustainable choice. When selecting a machine, consider factors like precision and material compatibility. Apply the tips and safety measures discussed to enhance your cutting projects. By doing so, you ensure high-quality results and a safe working environment. Embrace these insights to transform your acrylic cutting process into a more efficient and effective operation.

FAQ

How to choose a suitable acrylic cutting machine?

Selecting the right acrylic cutting machine is crucial for achieving the best results. Consider the type of projects you plan to undertake. If you need to cut thinner acrylic plates or engrave on the surface, a CNC Acrylic Laser Cutter Machine is ideal. For thicker acrylic, reliefs, or three-dimensional engraving, a CNC cutting machine is more suitable. Companies like Blue Elephant offer both types and can provide tailored solutions based on your specific needs.

Why choose an acrylic sheet cutting machine?

Investing in an acrylic sheet cutting machine can greatly improve your project's efficiency and quality. Whether you're a designer, manufacturer, or artist, these machines offer the precision and versatility needed for intricate designs. They are essential tools for applications such as signage, interior design, product packaging, and architecture. Explore options like laser cutting machines for acrylic to find the best fit for your requirements.

What factors should be considered when operating an acrylic cutting machine?

Operating an acrylic cutting machine involves several important considerations. Safety is paramount, so always wear protective gear and ensure proper ventilation. Traditional machines may leave rough edges, requiring additional polishing. However, modern laser cutting technology produces smooth, finished edges without extra steps. This technology is often used for creating signs in public spaces or unique environments. Always follow the manufacturer's guidelines for optimal results.

Can laser cutters handle different materials besides acrylic?

Yes, laser cutters are versatile and can cut a variety of materials. They work well with metals, plastics, and ceramics, making them suitable for diverse projects. This versatility allows you to expand your creative possibilities beyond acrylic, catering to different industry needs.

How do CNC machines differ from laser cutters in terms of applications?

CNC machines and laser cutters serve different purposes. CNC machines excel in creating detailed and complex designs, making them ideal for batch processing and intricate patterns. They are commonly used in industries like automotive and aerospace. Laser cutters, on the other hand, offer superior precision and smooth edges, perfect for projects requiring intricate cuts and polished finishes.

What are the benefits of using laser cutting technology for acrylic?

Laser cutting technology offers several advantages for acrylic projects. It provides high precision and clean cuts, eliminating the need for additional polishing. This results in time savings and enhanced product quality. Laser cutters also consume less energy, making them an eco-friendly choice for sustainable operations.

How do I maintain my acrylic cutting machine for optimal performance?

Regular maintenance is key to keeping your machine in top condition. Clean the machine after each use to remove dust and debris. Inspect parts for wear and tear, and lubricate moving components to reduce friction. Address any issues promptly to prevent larger problems and ensure consistent performance.

What safety precautions should I take when using an acrylic cutting machine?

Always prioritize safety when operating an acrylic cutting machine. Wear safety goggles to protect your eyes from debris and harmful laser light. Use gloves to shield your hands from burns and cuts. Ensure proper ventilation to disperse fumes effectively. Stay alert and monitor the machine during operation to quickly address any issues.

Are there different types of acrylic sheets, and how do they affect the cutting process?

Yes, acrylic sheets come in different types, each with unique properties. Cast acrylic offers superior optical clarity and is ideal for laser cutting. Extruded acrylic is more affordable and suitable for applications where clarity is less critical. The thickness and quality of the sheets also impact the cutting process, with thicker sheets requiring more powerful machines.

How can I ensure the best results when cutting acrylic sheets?

To achieve the best results, choose the right machine and materials for your project. Consider factors like precision, material compatibility, and project scale. Follow the tips and safety measures discussed to enhance your cutting projects. By doing so, you ensure high-quality results and a safe working environment.

See Also

10 Best Acrylic Cutting Machines for Accurate Results

CNC vs. Laser: Which Cuts Acrylic More Effectively?

Complete Tutorial for Cutting Acrylic Using Cricut Maker