What Kind of Machine Can Laser Cut 5 Inch Wood

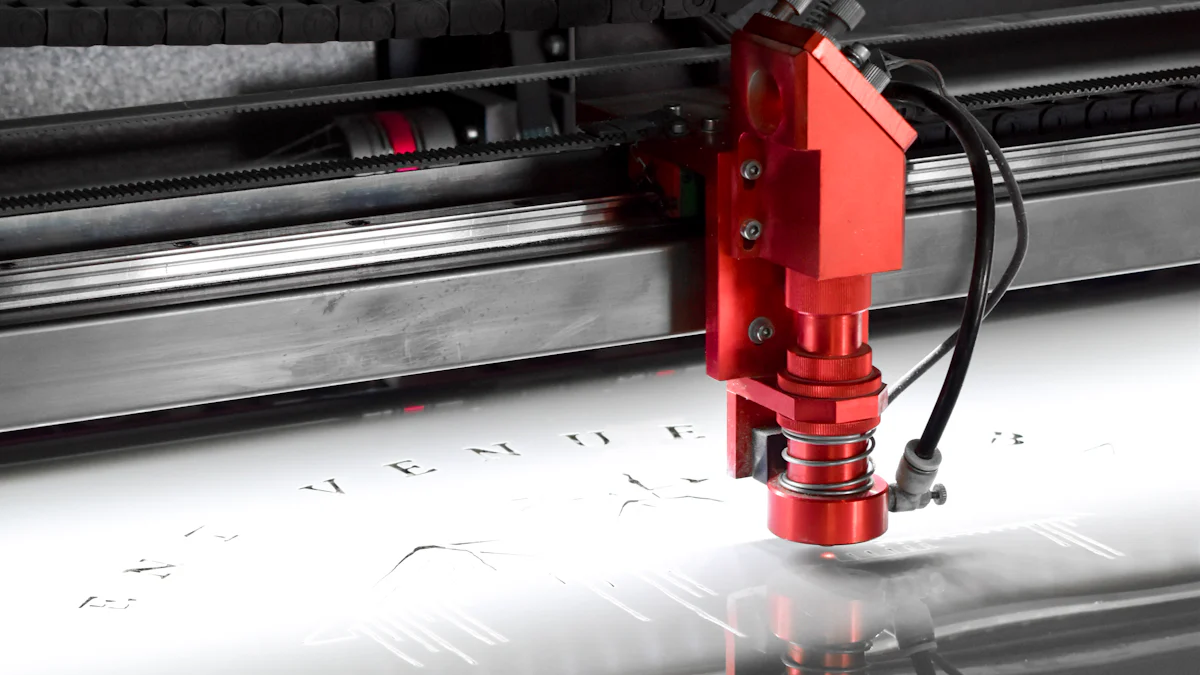

Can a laser cutting machine handle 5-inch thick wood? The answer lies in the power and precision of specialized industrial-grade laser cutters. When considering what kind of machine can laser cut 5 inch wood, it is important to note that cutting wood of this thickness presents significant challenges. This requires machines with exceptional wattage and advanced cooling systems to manage heat effectively. High-power CO2 laser cutters stand out as the best laser cutter option for such demanding tasks. These machines excel in laser cutting and engraving, offering the capability to cut through dense materials like hardwood with remarkable accuracy. However, achieving this level of performance often demands a substantial investment in equipment.

Understanding the Technical Requirements for Cutting 5-Inch Wood

When it comes to cutting thick materials like 5-inch wood, understanding the technical requirements is essential. The right combination of laser power, technology, and other factors can make all the difference in achieving precise and efficient results. Let’s break it down step by step.

Laser Power and Wattage

Minimum wattage required for cutting thick wood

The power of a laser cutter determines how effectively it can handle thick wood. For cutting wood up to 5 inches thick, you’ll need a high-power laser cutter with at least 100 watts or more. Machines with lower wattage may struggle to penetrate such dense material, leading to incomplete cuts or excessive burning. High-power CO2 lasers are often the best laser engravers for this task because they deliver the energy needed to cut through thick wood efficiently.

How laser power impacts cutting depth and speed

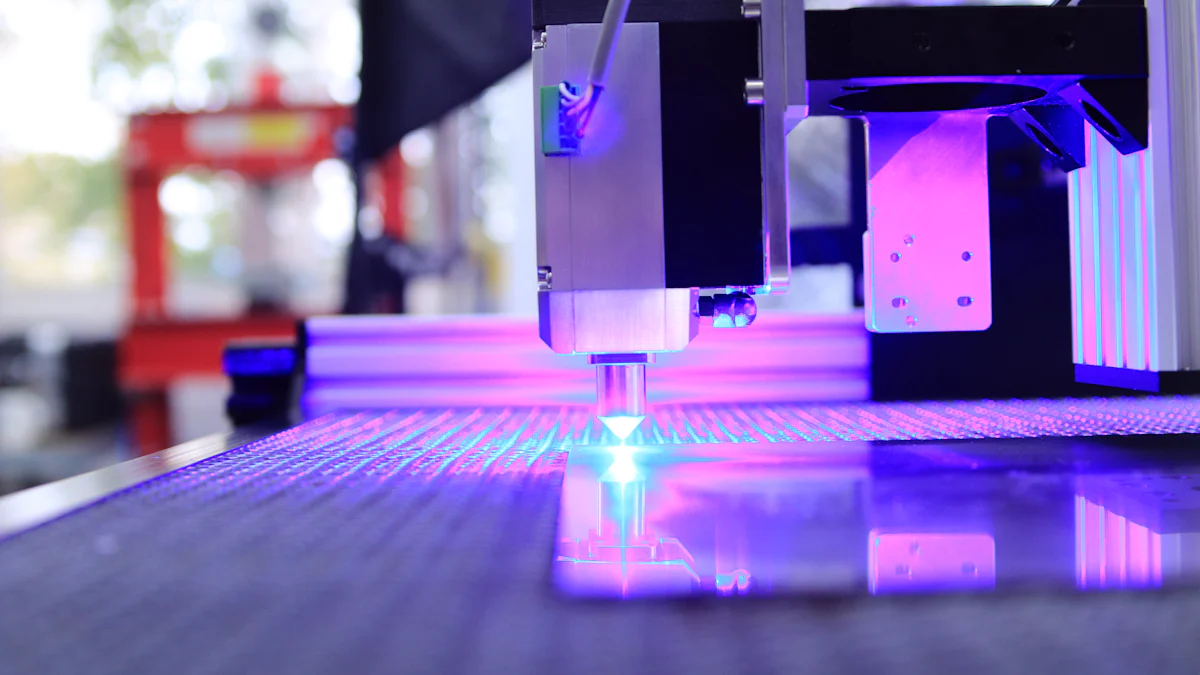

Laser power directly affects both the depth and speed of cutting. Higher wattage allows the laser to cut deeper into the material in a single pass, reducing the time required for the job. However, increasing power also generates more heat, which can scorch the wood if not managed properly. To optimize cutting performance for thick materials, you should balance power and speed settings. For instance, slowing down the cutting speed while using higher power ensures cleaner cuts without compromising the material’s integrity.

Type of Laser Technology

CO2 lasers and their suitability for thick wood

CO2 lasers are widely regarded as the best laser engravers for cutting thick wood. These machines excel in laser engraving and cutting due to their high power output and ability to handle organic materials like wood. They produce a focused beam that can cut through dense hardwoods such as oak or maple with precision. Additionally, CO2 lasers are versatile, making them ideal for both cutting and engraving tasks.

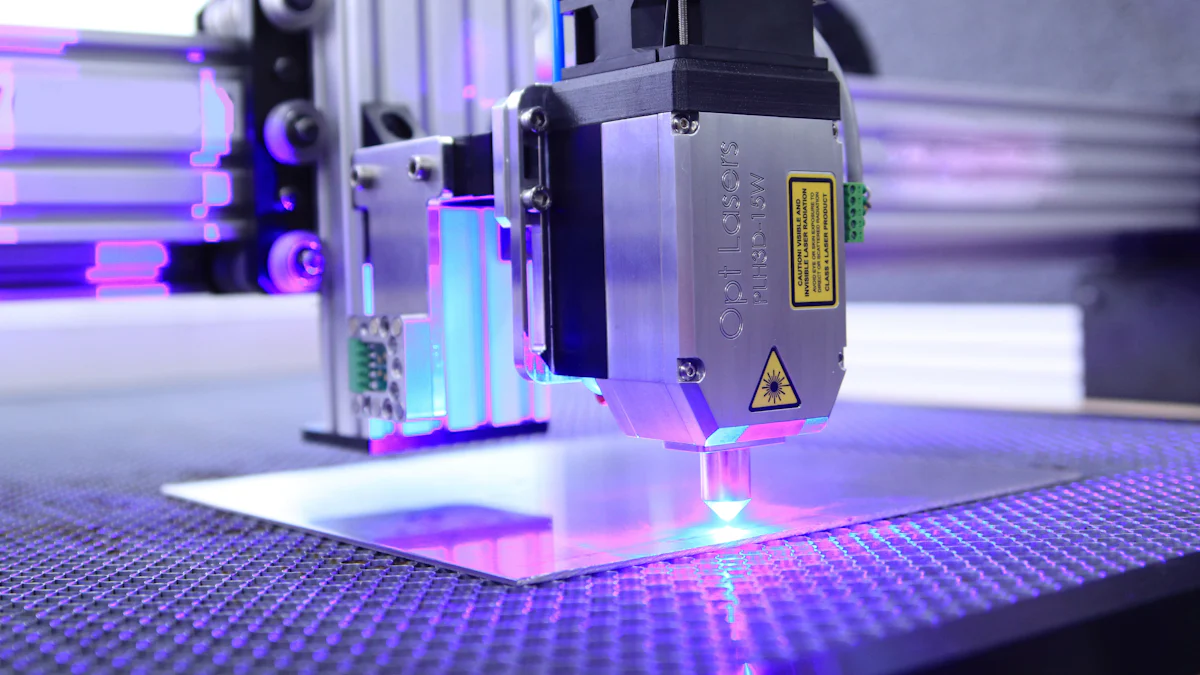

Fiber lasers and their limitations for wood cutting

Fiber lasers, on the other hand, are less suitable for cutting wood, especially thick pieces. While they are excellent for cutting metals and other non-organic materials, their wavelength doesn’t interact well with wood. This limitation makes them less effective for achieving the desired cutting performance for thick materials. If your primary focus is wood, a CO2 laser cutter for wood is the better choice.

Other Factors Influencing Cutting Capability

Material density and wood type

Not all wood is created equal. The density and type of wood significantly impact the cutting process. Hardwoods like cherry or walnut require more power compared to softer woods like pine. Denser woods absorb more energy, which means you’ll need to adjust the laser settings accordingly. Conducting test cuts on scrap wood can help you fine-tune the settings for optimal results.

Cooling systems and heat management

Cutting thick wood generates a lot of heat, which can damage both the material and the machine. Advanced cooling systems are crucial for maintaining consistent laser cutting performance. These systems prevent overheating and ensure the laser operates efficiently during prolonged use. Proper heat management also reduces the risk of burns or warping, resulting in cleaner cuts and better overall quality.

By understanding these technical requirements, you can choose the right laser cutter for wood and achieve exceptional results. Whether you’re working with CO2 lasers or exploring other options, knowing how to optimize power, speed, and cooling will set you up for success.

Examples of the Best Laser Cutters for Thick Wood

When it comes to cutting thick wood, not all laser cutters are created equal. Some machines stand out for their power, precision, and ability to handle demanding tasks. Let’s dive into the top options available and what makes them the best laser cutters for thick wood.

Industrial CO2 Laser Machines

Features and specifications of high-power CO2 lasers

Industrial CO2 laser machines are the go-to choice for cutting thick wood. These machines deliver exceptional power and versatility, making them ideal for both cutting and engraving tasks. With wattage often exceeding 100 watts, they can cut through dense materials like hardwood with ease. Their ability to handle a wide range of non-metallic materials, including wood, acrylic, leather, and glass, makes them a favorite among professionals.

Key features of high-power CO2 lasers include:

- High wattage: Ensures deep cuts and faster processing times.

- Large work area: Accommodates bigger projects, perfect for furniture or large-scale designs.

- Advanced cooling systems: Prevents overheating during prolonged use, ensuring consistent performance.

- Laser engraving capabilities: Allows for intricate designs and detailed finishes on wood.

These machines are built for durability and precision, making them a reliable choice for industrial applications. If you’re looking for a machine that combines power with versatility, a CO2 laser cutter is hard to beat.

Examples of specific models or brands, such as OMTech 60W and Atomstack A70 Pro

Several models stand out when reviewing the top laser cutters for wood. The OMTech 60W CO2 Laser Engraver is a popular choice for its balance of power and affordability. It offers a robust 60-watt laser, capable of cutting through thick wood while maintaining precision. Its user-friendly interface and reliable performance make it a great option for both professionals and serious hobbyists.

Another excellent option is the Atomstack A70 Pro, which boasts impressive cutting capabilities. This machine is designed to handle various materials, including thick wood, with remarkable efficiency. Its high wattage and advanced features make it one of the best laser cutters for demanding projects. Both models also offer a large work area, giving you the flexibility to tackle bigger designs without limitations.

Hybrid or Custom-Built Laser Systems

How custom systems are designed for extreme cutting tasks

For those who need even more power and flexibility, hybrid or custom-built laser systems provide a tailored solution. These systems combine the strengths of different laser technologies to achieve unparalleled cutting performance. Engineers design these machines to handle extreme tasks, such as cutting through exceptionally thick wood or working on unique materials.

Custom systems often include:

- Enhanced power sources: To deliver higher wattage for deeper cuts.

- Specialized cooling mechanisms: To manage heat during extended operations.

- Adjustable work areas: To accommodate projects of varying sizes.

These setups are ideal for industrial environments where standard machines may fall short. While they require a significant investment, their ability to handle specialized tasks makes them invaluable for businesses with unique cutting needs.

Examples of hybrid setups used in industrial applications

In industrial settings, hybrid laser systems are often used to push the boundaries of what’s possible. For example, some manufacturers combine CO2 and fiber laser technologies to create machines capable of cutting both organic and non-organic materials. These systems excel in versatility, allowing businesses to switch between tasks without compromising quality.

One notable example is a hybrid system designed for woodworking factories. These machines feature a high-power CO2 laser for cutting thick wood and a secondary laser for engraving intricate details. This combination ensures efficiency and precision, even for the most complex projects. While these setups are less common, they represent the cutting edge of laser technology.

By exploring these options, you can find the best laser cutter to meet your needs. Whether you choose an industrial CO2 laser or a custom-built system, investing in the right machine will ensure you achieve outstanding results every time.

Comparing the Best Laser Cutters for Thick Wood

When choosing the right laser cutter for thick wood, understanding the strengths and weaknesses of different machines is essential. Let’s break down the pros and cons of industrial CO2 lasers and fiber lasers, along with the costs and availability of these machines.

Pros and Cons of Industrial CO2 Lasers

Advantages such as power and efficiency

Industrial CO2 lasers are a powerhouse when it comes to cutting thick wood. These machines excel in delivering high power, which allows them to cut through dense materials like hardwood with ease. Their versatility makes them suitable for both cutting and engraving tasks, offering excellent results for a variety of projects. CO2 lasers also provide better cut-edge quality on thicker surfaces compared to other laser types. If you’re looking for a machine that combines power and precision, CO2 lasers are a top choice.

Drawbacks such as cost and size

Despite their impressive capabilities, CO2 lasers come with some challenges. These machines consume significantly more power, leading to higher operational costs. Their size can also be an issue, as they require ample space for installation and operation. Additionally, while they are less expensive upfront than fiber lasers, the long-term maintenance and energy costs can add up. If you’re working on a tight budget or have limited space, these factors might make CO2 lasers less appealing.

Pros and Cons of Fiber Lasers

Advantages such as precision and energy efficiency

Fiber lasers stand out for their precision and energy efficiency. These machines consume less power, making them more cost-effective to operate over time. They also require minimal maintenance, which reduces downtime and keeps your workflow smooth. Fiber lasers have a longer service life, ensuring consistent performance for years. If you prioritize precision and lower operating costs, fiber lasers are worth considering.

Limitations for cutting thick wood

However, fiber lasers have limitations when it comes to cutting thick wood. Their wavelength doesn’t interact well with organic materials like wood, making them less effective for this purpose. While they excel at cutting metals and other hard materials, they struggle with non-metallic surfaces. If your primary focus is wood cutting, fiber lasers may not deliver the quality or depth you need.

Cost and Availability of Suitable Machines

Price range for industrial-grade laser cutters

The cost of industrial-grade laser cutters varies widely based on their power and features. CO2 lasers tend to be more affordable upfront, with prices starting around $5,000 for entry-level models and going up to $20,000 or more for high-power machines. Fiber lasers, on the other hand, are more expensive, often starting at $10,000 and exceeding $50,000 for advanced models. While CO2 lasers offer a lower initial investment, fiber lasers can save you money in the long run due to their lower operational costs.

Availability for personal versus industrial use

When it comes to availability, CO2 lasers are more accessible for personal and small business use. Many manufacturers offer compact models designed for hobbyists or small workshops. Fiber lasers, however, are typically geared toward industrial applications, making them harder to find in smaller, budget-friendly sizes. If you’re a hobbyist or a small business owner, CO2 lasers might be the better fit for your needs. For large-scale industrial operations, fiber lasers could provide the precision and efficiency required.

By weighing the pros and cons of each type of laser cutter, you can make an informed decision that aligns with your cutting needs and budget. Whether you choose a CO2 laser for its power or a fiber laser for its efficiency, understanding these factors will help you achieve the best results.

Practical Considerations for Using Laser Cutters on Thick Wood

When working with laser cutters for thick wood, you need to weigh several practical factors. These considerations can help you decide if investing in such equipment aligns with your goals and resources.

Cost of Ownership

Initial investment and operational costs

Laser cutters capable of cutting and engraving thick wood come with a hefty price tag. High-power industrial machines often start at $40,000 and can exceed $1,000,000, depending on their wattage and features. Even budget laser machines designed for smaller projects may not meet the demands of cutting 5-inch wood. Beyond the initial purchase, operational costs like electricity and consumables add up quickly. Machines with higher power outputs consume more energy, which increases monthly expenses. If you're planning to use these machines regularly, you should factor in these ongoing costs to avoid surprises.

Maintenance and repair expenses

Maintaining a high-performance laser cutter requires consistent effort and investment. Over time, components like lenses, mirrors, and cooling systems wear out and need replacement. Repairs for industrial-grade machines can be expensive, especially for custom-built systems. Regular maintenance ensures optimal performance, but it also adds to the overall cost of ownership. Neglecting upkeep can lead to reduced cutting efficiency or even machine failure, which disrupts your workflow and increases expenses.

Safety Concerns

Risks associated with high-power lasers

Operating high-power laser cutters involves significant risks. The intense laser beam can cause severe burns or eye injuries if mishandled. Additionally, cutting wood generates fumes that may contain harmful particles. Without proper ventilation, these fumes can pose health hazards. You must also consider the fire risk, as the heat from the laser can ignite wood dust or debris. These dangers highlight the importance of prioritizing safety when using such powerful equipment.

Safety measures and equipment required

To minimize risks, you should implement robust safety features and protocols. Equip your workspace with proper ventilation systems to manage fumes effectively. Use protective gear like safety goggles and gloves to shield yourself from potential harm. Install fire extinguishers and smoke detectors near the cutting area to address emergencies promptly. Many modern laser cutters include built-in safety features, such as automatic shut-off mechanisms, to enhance ease of use and reduce accidents. Always follow the manufacturer's guidelines to ensure safe operation.

Feasibility for Personal Use

Space and power requirements

Laser cutters designed for cutting and engraving thick wood demand significant space and power. Industrial machines are large and require dedicated areas for installation. You’ll also need a stable power supply to support their high wattage. If your workspace is limited or lacks sufficient electrical capacity, accommodating such equipment becomes challenging. Before purchasing, evaluate whether your setup can handle the machine's requirements.

Alternatives for hobbyists or small businesses

If you're a hobbyist or run a small business, investing in an industrial-grade laser cutter may not be practical. Instead, consider alternatives like outsourcing your cutting needs to professional services. This approach eliminates the need for a large upfront investment while still delivering high-quality results. For smaller projects, budget laser machines with lower wattage might suffice, though they won’t handle 5-inch wood. Exploring these options can help you achieve your goals without overextending your resources.

By addressing these practical considerations, you can make an informed decision about using laser cutters for thick wood. Whether you prioritize safety, cost, or ease of use, understanding these factors ensures a smoother experience and better outcomes.

Cutting 5-inch wood with a laser cutter is possible, but it requires industrial-grade machines. These machines deliver the power and precision needed for such demanding tasks. You’ll need to invest in high-performance equipment like CO2 lasers to achieve clean and efficient results. If this isn’t practical, consider alternatives like outsourcing or consulting professionals for custom solutions. This approach can save you time and resources while still meeting your project goals. Always weigh your options carefully to ensure the best outcome for your needs.

FAQ

What factors should you consider when choosing a laser cutter for wood?

When selecting a laser cutter for wood, you need to evaluate several key factors. Start by assessing the machine's power and cutting capabilities. Higher wattage ensures better performance for thicker materials. Look into the quality of the machine, as durable components lead to consistent results over time. Price is another critical aspect—find a balance between your budget and the features you need. Lastly, consider ease of use. A user-friendly interface can save you time and reduce the learning curve, especially if you're new to laser cutting.

What are some tips for laser processing wood?

To maximize efficiency while laser-cutting wood, focus on reducing material waste. Arrange your cuts closely together to make the most of your wood. Using nesting software can help optimize your design layout automatically, ensuring minimal waste. Additionally, clean your laser cutter regularly to maintain precision and avoid residue buildup that could affect the quality of your cuts.

How important is proper focusing of the laser beam in wood cutting?

Properly focusing the laser beam is essential for clean and accurate cuts. Each type of wood and thickness requires specific adjustments to the focus point. Check your laser cutter’s manual for guidance on the correct focal length for your material. Regularly inspect and adjust the focus to maintain consistent cutting performance. Neglecting this step can lead to uneven cuts or excessive burning.

What is the sublimation process involved in laser cutting wood?

Laser cutting wood involves a sublimation process where the laser beam vaporizes the material directly into gas. This process requires precise focusing and the right optics. For engraving, shorter focal lengths, such as 1.5" or 2.0" lenses, work best for detailed designs. For cutting, increase the lens focal length as the wood's thickness grows. For instance, a 2” lens is ideal for 1/8” wood, while a 2.5” lens works better for 1/4" wood.

Can you use a fiber laser for cutting wood?

Fiber lasers are not the best choice for cutting wood. Their wavelength interacts poorly with organic materials like wood, making them less effective. Fiber lasers excel at cutting metals and other non-organic materials. If your primary focus is wood cutting, a CO2 laser cutter will deliver better results in terms of precision and depth.

How do you maintain a laser cutter for optimal performance?

Regular maintenance keeps your laser cutter running smoothly. Clean the lenses and mirrors frequently to prevent residue buildup. Inspect the cooling system to ensure it operates efficiently, as overheating can damage the machine. Replace worn-out components like belts or filters promptly. Following these steps will help you maintain consistent cutting performance and extend the lifespan of your equipment.

What safety precautions should you take when using a laser cutter?

Safety should always be a priority when operating a laser cutter. Wear protective goggles to shield your eyes from the laser beam. Ensure your workspace has proper ventilation to manage fumes generated during cutting. Keep a fire extinguisher nearby, as wood dust and debris can ignite. Always follow the manufacturer’s safety guidelines to minimize risks.

Is it possible to cut 5-inch wood with a budget laser cutter?

Cutting 5-inch wood with a budget laser cutter is unlikely. These machines typically lack the power needed for such thick materials. High-power industrial-grade laser cutters, like CO2 lasers, are required for this task. If purchasing such a machine isn’t feasible, consider outsourcing your project to a professional service.

What are the benefits of using nesting software for wood cutting?

Nesting software helps you optimize your design layout, reducing material waste and saving costs. It arranges your cuts efficiently on the wood, ensuring you use as much of the material as possible. This tool is especially useful for large-scale projects where minimizing waste can significantly impact your budget.

Can laser cutting wood affect the environment?

Laser cutting wood produces fumes that may contain harmful particles. Proper ventilation systems can mitigate this issue by filtering out pollutants. Additionally, using sustainably sourced wood can reduce the environmental impact of your projects. Always dispose of waste materials responsibly to minimize your ecological footprint.

See Also

Is CNC Machinery Effective for Wood Cutting Tasks

Guidelines for Selecting the Best Wood Cutting Machine

Does CNC Cutting Outperform Laser for Acrylic Materials