How a Machine Cuts a Strip of Carpet into Pieces

Cutting carpet into precise pieces can feel like a daunting task, but modern machines make it surprisingly simple. A machine cuts a strip of carpet with unmatched efficiency and accuracy, saving you time and effort. These machines often come equipped with advanced features like intelligent edge-finding and automatic error correction. Some models even boost material utilization by up to 30%, reducing waste and maximizing output. With cutting speeds up to five times faster than manual methods, these tools transform what used to be a labor-intensive job into a seamless process.

Key Takeaways

- Choose the right carpet cutting machine based on your project size and material for optimal results.

- Properly prepare your machine and carpet by ensuring everything is clean, sharp, and correctly set up to avoid mistakes.

- Always measure and mark your carpet accurately to achieve precise cuts and minimize waste.

- Prioritize safety by wearing protective gear and maintaining a clutter-free workspace during cutting.

- Regular maintenance, including cleaning and inspecting your machine, extends its lifespan and ensures consistent performance.

- Invest in high-quality carpet materials to facilitate easier cutting and achieve cleaner edges.

- Practice proper cutting techniques and start with scrap pieces to refine your skills before tackling valuable materials.

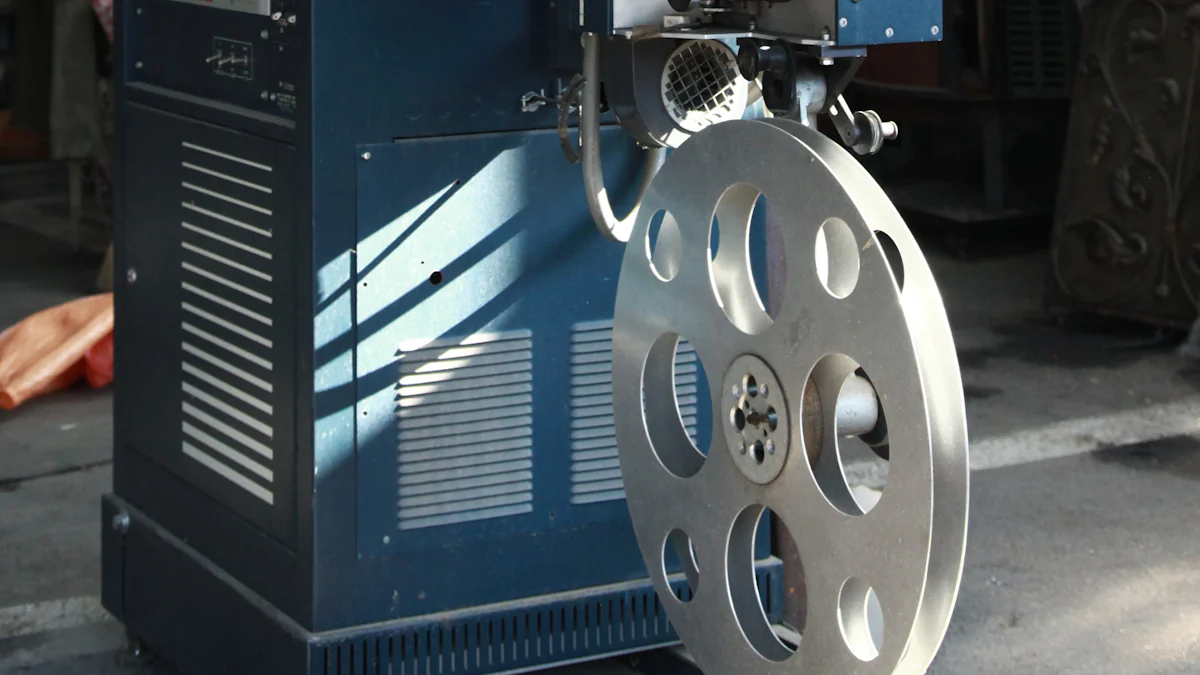

Types of Machines Used for Cutting Carpet

When it comes to cutting carpet, choosing the right machine can make all the difference. Each type of machine offers unique benefits, depending on your project size, material, and precision needs. Let’s explore the most common options available.

Manual Carpet Cutters

Manual carpet cutters are simple yet effective tools. They’re perfect for smaller projects or when you need to make quick adjustments on-site. These cutters often include tools like standard razor knives, carpet knives, and carpet cutting scissors. Their lightweight design makes them easy to handle, and they don’t require electricity, which is great for portability.

However, manual cutters demand more effort and skill. You’ll need to measure and cut carefully to ensure straight lines. While they’re budget-friendly, they may not be ideal for large-scale projects or thick carpets. If you’re working on a small DIY project, though, these tools can get the job done efficiently.

Electric Carpet Cutting Machines

Electric carpet cutting machines bring speed and precision to the table. These machines are equipped with motors that power the blades, allowing you to cut through carpets effortlessly. They’re especially useful for medium-sized projects where manual cutting would take too long or lack accuracy.

Some electric models come with advanced features like oscillating knives or adjustable cutting speeds. These features help you handle various carpet materials, from soft silk loops to tougher, brushed carpets. Electric cutters are a great choice if you want to save time and reduce physical strain while achieving clean, professional cuts.

Industrial Carpet Cutting Machines

For large-scale projects, industrial carpet cutting machines are the ultimate solution. These machines are designed to handle heavy-duty tasks, such as cutting large rolls of carpet in factories or construction sites. They often include CNC cutting technology, which ensures precise cuts for complex shapes and patterns.

Industrial machines can cut through a wide range of materials, including fur, leather, and asphalt carpets. Features like intelligent edge-finding and automatic error compensation make them incredibly efficient. With these machines, you can achieve consistent results even on challenging projects. While they require a higher investment, their efficiency and versatility make them indispensable for professionals.

“A machine cuts a strip of carpet into pieces with unmatched precision, especially when using advanced industrial models.”

Whether you’re tackling a small DIY project or managing a large commercial job, there’s a carpet cutting machine suited to your needs. Understanding the strengths of each type will help you make the best choice for your project.

Preparing the Machine and Carpet for Cutting

Before you start cutting, proper preparation ensures smooth and precise results. Taking the time to set up your machine and carpet correctly can save you from unnecessary mistakes and wasted material. Let’s break it down step by step.

Setting Up the Machine

Setting up your carpet cutting machine is the first and most important step. Begin by placing the machine on a stable, flat surface. This prevents any wobbling or uneven cuts during operation. If your machine has adjustable settings, such as cutting speed or blade depth, configure them based on the type of carpet you’re working with. For instance, thicker carpets may require slower speeds and deeper blade adjustments.

Check the blade for sharpness before you proceed. A dull blade can cause frayed edges or uneven cuts. If needed, replace the blade to ensure clean results. Some machines, especially industrial ones, come with features like intelligent edge-finding or automatic error compensation. These tools can help you achieve precise cuts, so make sure they’re activated if available.

Finally, plug in the machine (if it’s electric) and test it on a small piece of scrap carpet. This helps you confirm that everything is functioning properly before you begin the actual cutting process.

Measuring and Marking the Carpet

Accurate measurements are key to achieving the perfect cut. Start by laying the carpet flat on a clean, spacious surface. Smooth out any wrinkles or folds to avoid uneven cuts. Use a measuring tape to determine the exact dimensions you need. Mark these measurements clearly using chalk or a washable marker. For straight lines, a long ruler or straightedge can help you draw precise guides.

If you’re cutting a large roll of carpet, consider dividing it into smaller, more manageable sections. Strips that are 2 to 3 feet wide are easier to handle and feed into the machine. This approach not only simplifies the cutting process but also reduces the risk of errors.

“Maneuvering the material becomes much easier when you cut manageable sections from the carpet roll.”

Double-check your measurements before proceeding. Even a small mistake can lead to wasted material or mismatched pieces.

Safety Precautions

Safety should always come first when working with carpet cutting machines. Wear protective gloves to shield your hands from sharp blades. If your machine is electric, ensure the power cord is in good condition and positioned away from the cutting area to prevent accidents.

Keep the workspace well-lit and free of clutter. A clear environment allows you to focus on the task without distractions. If you’re using an industrial machine, follow the manufacturer’s safety guidelines closely. These machines often operate at high speeds and require extra caution.

Lastly, never rush the process. Take your time to feed the carpet into the machine steadily and avoid forcing it through. This not only ensures a cleaner cut but also minimizes the risk of injury.

By preparing both the machine and the carpet properly, you set yourself up for success. Whether you’re using a manual cutter or an advanced industrial model, these steps will help you achieve precise and professional results every time.

Step-by-Step Guide: How a Machine Cuts a Strip of Carpet

Feeding the Carpet into the Machine

Start by positioning the carpet correctly. Lay it flat on a clean surface and ensure there are no wrinkles or folds. Smooth out the material to prevent uneven cuts. If you’re working with a large roll, unroll only the section you plan to cut. This keeps the workspace manageable and reduces the chance of errors.

Next, align the edge of the carpet with the machine’s feeding mechanism. Most machines have guides or markers to help you position the material accurately. Use these to ensure the carpet feeds straight into the machine. Hold the carpet firmly but avoid pulling or forcing it. Let the machine’s feeding system do the work. This step is crucial because a machine cuts a strip of carpet most effectively when the material is fed smoothly and evenly.

If your machine has an automatic feeder, activate it and monitor the process. For manual feeding, maintain a steady pace to avoid jamming or misalignment. Always keep your hands clear of the blades while feeding the carpet.

Adjusting Machine Settings

Before making the cut, adjust the machine settings to match your project’s requirements. Start by selecting the appropriate blade depth. Thicker carpets need deeper blade settings, while thinner materials require less depth. Refer to the machine’s manual if you’re unsure about the correct settings.

Next, set the cutting speed. Slower speeds work better for intricate cuts or thicker carpets, while faster speeds are ideal for straight, simple cuts. Some machines also allow you to adjust the pressure applied during cutting. Use this feature to fine-tune the process based on the carpet’s texture and thickness.

Double-check all settings before proceeding. Test the adjustments on a small scrap piece of carpet. This ensures the machine is ready and helps you avoid mistakes during the actual cut. Remember, precision is key when a machine cuts a strip of carpet, so take your time to get the settings right.

Executing the Cut

Now it’s time to make the cut. Begin by starting the machine and guiding the carpet through the cutting area. Keep a steady hand and focus on maintaining alignment with the guides. If your machine has a laser or marker for straight cuts, use it to stay on track.

As the machine cuts the strip of carpet, watch for any signs of uneven feeding or blade resistance. Pause immediately if you notice an issue. Fix the problem before continuing to avoid damaging the carpet or the machine. For long cuts, take breaks to check the progress and ensure everything is going smoothly.

Once the cut is complete, turn off the machine and carefully remove the carpet. Inspect the edges to confirm they’re clean and even. If adjustments are needed, make them before proceeding with additional cuts. With practice, you’ll find that a machine cuts a strip of carpet quickly and with professional-level precision.

“Taking your time during each step ensures a flawless result and minimizes wasted material.”

By following these steps, you can achieve clean, accurate cuts every time. Whether you’re working on a DIY project or a professional installation, this guide will help you make the most of your carpet cutting machine.

Troubleshooting Common Issues During Carpet Cutting

Even with the best preparation, challenges can arise when cutting carpet. Knowing how to address these issues ensures smooth progress and saves you from wasting time or materials. Let’s dive into some common problems and how you can fix them.

Uneven Cuts

Uneven cuts can ruin the look of your project. This issue often happens when the carpet shifts during cutting or when the blade isn’t sharp enough. To prevent this, always secure the carpet before starting. Use clamps or weights to hold it in place. If your machine has alignment guides, double-check that the carpet is feeding straight into the cutting area.

Another tip is to inspect the blade. A dull blade struggles to cut cleanly, leading to jagged edges. Replace it if necessary. Also, take your time while feeding the carpet. Rushing can cause misalignment, which results in uneven cuts. Remember, cutting carpet may seem straightforward, but there’s an art to getting it right.

If you’ve already made an uneven cut, don’t panic. Trim the edges carefully using a manual cutter or scissors. This can help salvage the piece and maintain a professional appearance.

“Knowing the finer points of cutting carpet can save valuable time and expense.”

Machine Jams

A jammed machine can bring your project to a halt. This problem usually occurs when the carpet is too thick, improperly fed, or contains hidden debris like tacks or staples. Before cutting, inspect the carpet thoroughly. Remove any fasteners or foreign objects that could obstruct the machine.

If a jam happens, turn off the machine immediately. Forcing it to continue can damage both the carpet and the machine. Carefully remove the jammed material, following the manufacturer’s instructions. Once cleared, test the machine on a scrap piece of carpet to ensure it’s functioning properly.

To avoid future jams, feed the carpet slowly and steadily. If your machine has adjustable settings, lower the cutting speed for thicker materials. Regular maintenance, such as cleaning the feeding mechanism, also helps prevent jams.

Dull or Damaged Blades

A dull or damaged blade can lead to frayed edges, uneven cuts, or even machine jams. Over time, even a perfect cut can develop frayed edges if the blade isn’t sharp enough. Inspect the blade before each use. Look for signs of wear, such as nicks or a loss of sharpness.

Replace the blade if it’s no longer cutting cleanly. Most machines make this process simple, but always follow the manufacturer’s guidelines. Using a high-quality replacement blade ensures better results and extends the life of your machine.

To keep blades in good condition, clean them after each use. Carpet fibers and adhesive residues can build up, dulling the blade faster. Store spare blades in a dry, safe place to prevent rust or damage.

“Here are ways to prevent frayed edges on a perfect cut.”

By addressing these common issues, you’ll ensure that a machine cuts a strip of carpet efficiently and with precision. Troubleshooting may take a little extra time, but it’s worth it to achieve clean, professional results.

Tips for Maintaining the Machine

Proper maintenance keeps your carpet cutting machine running smoothly and extends its lifespan. By following a few simple steps, you can ensure consistent performance and avoid costly repairs. Let’s dive into the essentials.

Cleaning the Machine

Regular cleaning is crucial for keeping your machine in top shape. Carpet fibers, dust, and adhesive residues can build up over time, affecting the machine’s efficiency. After each use, take a few minutes to clean the blades, feeding mechanism, and surrounding areas. Use a soft brush or cloth to remove debris. For stubborn residue, a damp cloth with mild detergent works well.

Pay special attention to the blades. Residue buildup dulls them quickly, leading to uneven cuts. Wipe them thoroughly and dry them to prevent rust. If your machine has removable parts, disassemble them occasionally for a deeper clean. Always follow the manufacturer’s instructions when doing this.

“The invention of early carpet-cleaning machines revolutionized how we care for carpets. Similarly, maintaining your cutting machine ensures it performs at its best.”

By keeping your machine clean, you’ll not only improve its performance but also make your cutting process smoother and more efficient.

Regular Inspections

Frequent inspections help you catch potential issues before they become major problems. Before each use, check the machine for loose screws, worn-out parts, or any unusual noises during operation. Inspect the blades for nicks or dullness. A sharp blade is essential for clean, precise cuts.

If your machine has adjustable settings, test them to ensure they’re functioning correctly. For electric or industrial models, examine the power cord and connections for wear or damage. Addressing these small issues early prevents bigger headaches later.

Create a habit of inspecting your machine monthly for deeper checks. Look for signs of wear on moving parts, belts, or gears. Replace any damaged components promptly. Regular inspections keep your machine reliable and safe to use.

Storing the Machine

Proper storage protects your machine from damage and extends its life. Always store it in a clean, dry place away from moisture and extreme temperatures. Moisture causes rust, while heat can warp certain components. If possible, use a protective cover to shield the machine from dust and debris.

For manual cutters, retract the blade or cover it to prevent accidents. For electric or industrial machines, unplug them and secure any cords or attachments. Keep spare blades and accessories organized in a designated space. This makes them easy to find when needed and prevents damage.

“Think of your machine as an investment. Proper storage ensures it stays in excellent condition for years to come.”

By following these tips, you’ll keep your carpet cutting machine in peak condition. A well-maintained machine not only delivers better results but also saves you time and money in the long run. Take care of your tools, and they’ll take care of your projects.

Ensuring Consistent Results When Cutting Carpet

Using High-Quality Carpet

The quality of the carpet you choose plays a huge role in achieving consistent results. High-quality carpets are easier to cut and produce cleaner edges. They also hold their shape better, which reduces the risk of fraying or uneven cuts. When selecting a carpet, pay attention to key factors like fiber type, pile construction, and density.

Carpet fibers, such as nylon or wool, tend to offer better durability and precision during cutting. These materials resist wear and tear, making them ideal for projects that demand accuracy. Additionally, the pile type matters. For instance, cut and loop carpets may create challenges because the longer cut fibers can bend over the shorter loops, leading to an uneven appearance. Opting for a uniform pile type ensures smoother cuts.

Density and face weight also impact the cutting process. A denser carpet provides more stability, which helps maintain straight lines. Backing materials should be sturdy but not overly rigid, as this can make feeding the carpet into the machine more difficult. By choosing a high-quality carpet, you set yourself up for success right from the start.

“Investing in a better-quality carpet not only improves the final look but also makes the cutting process much easier.”

Practicing Proper Technique

Even the best machine and carpet won’t guarantee perfect results without proper technique. Your approach to cutting directly affects the outcome. Start by ensuring your workspace is clean and organized. A clutter-free area allows you to focus and reduces the chance of mistakes.

When feeding the carpet into the machine, keep it smooth and steady. Wrinkles or folds can lead to uneven cuts. Use alignment guides on the machine to maintain straight lines. If your machine includes features like laser markers, take advantage of them for added precision.

Pay attention to your hand positioning. Keep your hands firm but relaxed to guide the carpet without forcing it. For intricate cuts, slow down and adjust the machine settings as needed. Rushing through the process often results in errors or wasted material.

Consistency also comes with practice. If you’re new to using a carpet cutting machine, start with scrap pieces. This gives you a chance to refine your technique without worrying about ruining valuable material. Over time, you’ll develop a rhythm that ensures clean, professional cuts every time.

“Mastering the technique takes patience, but it’s the key to achieving flawless results.”

By combining high-quality materials with proper cutting methods, you’ll consistently produce excellent results. Whether you’re working on a small DIY project or a large-scale installation, these tips will help you cut carpet like a pro.

Cutting a strip of carpet into pieces becomes a simple task when you use the right machine and follow proper techniques. By preparing your tools, measuring accurately, and maintaining safety, you can achieve clean and precise results every time. Regular maintenance, like cleaning and inspecting your machine, ensures it stays in top condition for years. With practice, you’ll master the process and avoid common issues like uneven cuts or jams. Whether you’re a professional or a DIY enthusiast, a machine cuts a strip of carpet with efficiency and accuracy, making your projects smoother and more enjoyable.

FAQ

What are the popular options for carpet cutting tools?

You have several great options when it comes to carpet cutting tools. The right choice depends on your project size, budget, and comfort level. Here are some popular tools:

- Standard Razor Knife: A simple and affordable option for small tasks.

- Carpet Knife: Designed specifically for cutting carpet with precision.

- Electric Carpet Cutter: Ideal for faster and more accurate cuts.

- Carpet Cutting Scissors: Handy for detailed or curved cuts.

- Stand-Up Carpet Cutter: Perfect for larger projects, allowing you to cut while standing.

Each tool has its strengths, so pick one that matches your needs and skill level.

What are the notable features of a carpet cutting machine?

Modern carpet cutting machines come packed with impressive features. These machines can intelligently find edges, making them perfect for cutting special-shaped or printed carpets. With just one click, you can achieve precise cuts without needing templates. Some standout features include:

- Intelligent Edge-Finding Cutting: Ensures accuracy by detecting the edges of the carpet.

- AI Typesetting: Automatically arranges cutting patterns to maximize material usage.

- Automatic Error Compensation: Adjusts for minor errors to maintain precision.

These features make carpet cutting machines a game-changer for both professionals and DIY enthusiasts.

Can I use a carpet cutting machine for all types of carpets?

Yes, most carpet cutting machines handle a wide range of carpet types. Whether you're working with soft looped carpets, dense pile carpets, or even tougher materials like leather-backed carpets, these machines can adapt. However, always check the machine's specifications to ensure compatibility with your carpet material.

How do I ensure straight cuts when using a carpet cutting machine?

To achieve straight cuts, start by marking your measurements clearly with chalk or a washable marker. Use the machine’s alignment guides or built-in laser markers to keep the carpet steady. Feed the carpet smoothly into the machine without rushing. Practicing on scrap pieces can also help you perfect your technique.

Is it safe to use a carpet cutting machine at home?

Yes, carpet cutting machines are safe to use at home if you follow basic safety precautions. Always wear protective gloves to avoid injuries from sharp blades. Keep your workspace well-lit and free of clutter. For electric machines, ensure the power cord is in good condition and positioned away from the cutting area. Taking your time and staying focused will minimize risks.

How often should I replace the blade on my carpet cutting machine?

Blade replacement depends on how frequently you use the machine and the type of carpet you cut. If you notice frayed edges, uneven cuts, or increased resistance during cutting, it’s time to replace the blade. Regularly inspecting the blade before each use helps you catch dullness early.

Can I cut curved or intricate shapes with a carpet cutting machine?

Yes, many advanced carpet cutting machines allow you to cut curved or intricate shapes. Features like intelligent edge-finding and CNC cutting technology make it easy to handle complex designs. For best results, use a machine designed for precision cutting and practice on scrap material first.

What should I do if my carpet cutting machine jams?

If your machine jams, turn it off immediately to prevent further damage. Carefully remove the jammed material, following the manufacturer’s instructions. Check for hidden debris like tacks or staples in the carpet before restarting. Feeding the carpet slowly and steadily can help prevent future jams.

How do I maintain my carpet cutting machine?

Maintaining your machine is simple. Clean it after each use to remove carpet fibers and adhesive residue. Inspect the blades, screws, and moving parts regularly for wear or damage. Store the machine in a clean, dry place to protect it from moisture and dust. Proper maintenance ensures your machine stays in top condition for years.

Are carpet cutting machines worth the investment?

Absolutely! Carpet cutting machines save you time and effort while delivering professional-quality results. They’re especially valuable for larger projects or frequent use. With features like precision cutting, reduced waste, and faster operation, these machines are a worthwhile investment for both DIYers and professionals.

See Also

Comprehensive Instructions for Operating Hair Cutting Tools

Understanding Cutting Machine Prices and Varieties Available

Essential Techniques for Operating a Die Cutting Machine