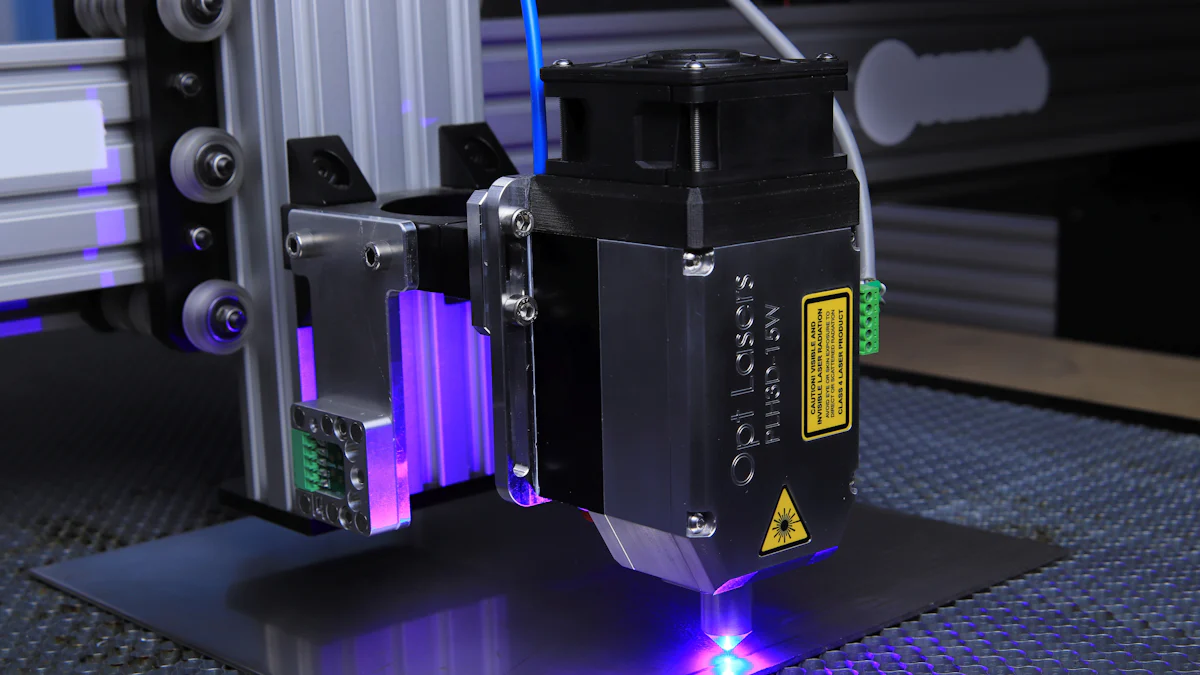

Latest Trends in Laser-Cutting Machine Technology

In today's fast-paced industrial landscape, laser cutting technology stands at the forefront of innovation. You witness its transformative impact across various sectors, driving efficiency and precision. The global market for laser-cutting machines, valued at $5.7 billion in 2023, is projected to soar to $13.3 billion by 2032. This growth underscores the technology's pivotal role in maintaining a competitive edge. As you explore these advancements, consider how adopting a laser-cutting machine can revolutionize your operations, offering unparalleled speed and accuracy.

Current Advancements in Laser Cutting

Faster Cutting Speeds

In the realm of laser cutting technology, speed is a game-changer. Recent innovations in laser power and efficiency have propelled fiber laser cutting to the forefront. These machines operate at unprecedented speeds, significantly outpacing traditional methods. The increased power of ultrafast lasers allows you to cut through thicker materials swiftly, making them suitable for a broader range of applications. This leap in speed directly impacts production timelines, enabling you to meet tight deadlines and enhance overall productivity.

Enhanced Precision

Precision remains a hallmark of laser cutting technology. Developments in laser beam control have refined the accuracy of cuts, allowing you to achieve intricate designs with ease. Ultrafast lasers, known for their rapid pulse rates, ensure smooth edges and minimal material distortion. This precision is invaluable when working with delicate patterns or complex geometries. By leveraging these advancements, you can produce high-quality components that meet stringent industry standards.

Automation Integration

Automation and AI are revolutionizing the laser cutting landscape. The integration of AI-powered optimization tools streamlines operations, reducing the likelihood of human error. These systems analyze data in real-time, adjusting parameters to optimize cutting processes. As a result, you experience enhanced efficiency and consistency in production. Automation also frees up your workforce to focus on more strategic tasks, further boosting operational effectiveness.

Impact on Efficiency, Precision, and Cost-Effectiveness

Improved Operational Efficiency

Laser cutting technology significantly enhances operational efficiency. You can achieve a substantial reduction in material waste due to the precision of laser cuts. Unlike traditional methods, laser cutting minimizes excess material, ensuring that you use resources optimally. This efficiency not only conserves materials but also contributes to environmental sustainability.

Moreover, laser cutting machines increase throughput. The speed and accuracy of these machines allow you to complete projects faster than ever before. By reducing the time required for each cut, you can handle more projects in a shorter period. This capability is crucial for meeting high demand and maintaining a competitive edge in the market.

Cost-Effectiveness

Investing in a laser-cutting machine offers significant cost advantages. You will notice lower operational costs as laser cutting requires less energy compared to traditional methods. The technology's energy efficiency translates into reduced electricity bills, making it a cost-effective choice for your business.

Additionally, the return on investment for businesses adopting laser cutting technology is impressive. The initial investment may seem substantial, but the long-term savings in labor and material costs quickly offset this expense. By streamlining production processes and reducing the need for manual labor, you can allocate resources more effectively and improve your bottom line.

Cutting-Edge Applications Across Industries

Laser cutting technology has revolutionized various industries, offering precision and efficiency that were once unimaginable. As you explore its applications, you'll find that a laser-cutting machine is indispensable in sectors like automotive, aerospace, and medical.

Automotive Industry

Precision Parts Manufacturing

In the automotive industry, precision is paramount. Laser cutting technology allows you to manufacture parts with exceptional accuracy. This precision ensures that components fit perfectly, reducing the need for adjustments and enhancing vehicle performance. The ability to cut intricate shapes and designs means you can produce complex parts that meet stringent industry standards.

Customization and Prototyping

Customization is a growing trend in the automotive sector. With laser cutting, you can easily create custom parts and prototypes. This flexibility enables you to meet specific customer demands and stay ahead of the competition. Whether it's a unique design or a prototype for testing, laser cutting provides the tools you need to innovate.

Aerospace Industry

Lightweight Material Processing

The aerospace industry demands lightweight materials to improve fuel efficiency and performance. Laser cutting excels in processing these materials, allowing you to create components that are both strong and light. This capability is crucial for developing advanced aircraft that meet modern efficiency standards.

Enhanced Safety and Reliability

Safety and reliability are non-negotiable in aerospace. Laser cutting technology ensures that every component meets the highest safety standards. By producing parts with precise dimensions and minimal defects, you can enhance the overall reliability of aircraft, contributing to safer skies.

Medical Industry

Production of Medical Devices

In the medical field, precision is critical. Laser cutting technology enables you to produce medical devices with exact specifications. From surgical instruments to diagnostic tools, the accuracy of laser cutting ensures that each device performs its intended function flawlessly.

Custom Implants and Prosthetics

The demand for custom implants and prosthetics is rising. Laser cutting allows you to create personalized solutions tailored to individual patients. This customization improves patient outcomes and enhances the quality of life for those requiring medical interventions. By leveraging laser cutting, you can offer innovative solutions that meet the unique needs of each patient.

Sustainability in Laser Cutting Technology

In the evolving landscape of manufacturing, sustainability has become a crucial focus. Laser cutting technology plays a pivotal role in this shift, offering solutions that prioritize energy efficiency and the use of sustainable materials.

Energy Efficiency

Advancements in eco-friendly laser systems have significantly reduced the environmental impact of laser cutting. Modern laser machines, particularly those utilizing fiber lasers, consume less energy compared to traditional CO2 lasers. This reduction in power usage not only lowers operational costs but also minimizes the carbon footprint of manufacturing processes. By adopting energy-efficient laser sources, you can achieve high precision and speed while conserving energy.

To further enhance energy efficiency, regular maintenance of laser cutting equipment is essential. Ensuring that all components function optimally reduces energy waste. Additionally, integrating automated systems allows for real-time monitoring and adjustment of energy usage, ensuring that the process remains as efficient as possible. These practices contribute to both environmental and economic benefits, making laser cutting a sustainable choice for your business.

Sustainable Materials

The use of recyclable and biodegradable materials in laser cutting processes supports environmental conservation efforts. By selecting materials that can be reused or naturally decompose, you contribute to reducing waste and promoting a circular economy. This approach not only aligns with global sustainability goals but also enhances your brand's reputation as an environmentally responsible entity.

Moreover, the precision of laser cutting technology minimizes material waste during production. This efficiency ensures that resources are used optimally, further supporting sustainable manufacturing practices. By embracing these advancements, you can play a part in conserving the environment while maintaining high-quality production standards.

Strategic Investments and Future Trends

In the rapidly evolving world of laser cutting technology, staying ahead requires strategic investments and a keen eye on future trends. As you navigate this landscape, understanding the potential of emerging technologies can position your business for long-term success.

Emerging Technologies

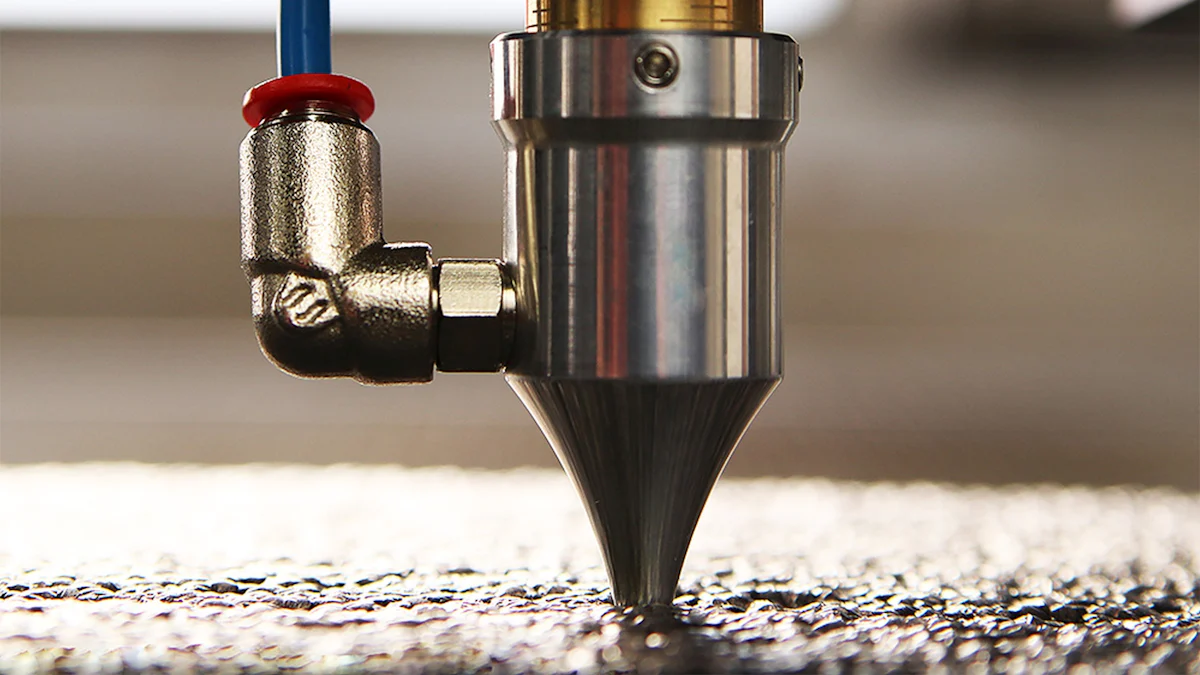

Potential of Hybrid Laser Systems

Hybrid laser cutting systems represent a significant leap forward in laser technology. These systems combine the strengths of different laser types, offering enhanced versatility and efficiency. By integrating multiple laser sources, hybrid systems can handle a wider range of materials and thicknesses. This flexibility allows you to tackle diverse projects with ease, making your operations more adaptable to changing market demands.

The adoption of hybrid systems can also lead to cost savings. By optimizing the cutting process for each material, you reduce waste and improve resource utilization. This efficiency not only lowers operational costs but also enhances your competitive edge in the market.

Integration with IoT and Smart Manufacturing

The integration of laser cutting technology with the Internet of Things (IoT) and smart manufacturing is transforming production processes. IoT-enabled laser machines offer real-time data monitoring and analysis, allowing you to make informed decisions quickly. This connectivity enhances operational efficiency by identifying potential issues before they escalate, reducing downtime and maintenance costs.

Smart manufacturing further streamlines production by automating routine tasks and optimizing workflows. By leveraging these technologies, you can achieve higher productivity levels and maintain consistent quality standards. This integration positions your business at the forefront of innovation, ready to meet the demands of a digital-first world.

Importance for Businesses

Staying Competitive in a Rapidly Evolving Market

In today's fast-paced market, staying competitive requires embracing emerging trends. Future laser cutting trends, such as hybrid systems and IoT integration, offer opportunities to enhance your capabilities and deliver superior products. By adopting these advancements, you ensure that your business remains relevant and responsive to customer needs.

Investing in cutting-edge technology also signals your commitment to innovation. This reputation can attract new clients and partnerships, expanding your market reach. As competitors strive to keep up, your proactive approach sets you apart as a leader in the industry.

Long-Term Benefits of Adopting New Technologies

The long-term benefits of investing in new technologies extend beyond immediate gains. By incorporating advanced laser cutting solutions, you future-proof your operations against technological obsolescence. This foresight reduces the need for frequent upgrades, saving you time and resources in the long run.

Moreover, the efficiency and precision offered by modern laser systems translate into higher-quality products. This quality assurance builds trust with your clients, fostering loyalty and repeat business. As you continue to innovate, your business not only thrives but also contributes to shaping the future of the industry.

Laser cutting technology has revolutionized manufacturing with its precision, speed, and cost-effectiveness. These advancements offer you a competitive edge, enabling efficient production and sustainable practices. By adopting these technologies, you position your business for future growth and environmental responsibility. Investing in the latest laser-cutting innovations ensures you remain at the forefront of industry trends, meeting the demands of a rapidly evolving market. Embrace this transformative technology to enhance your operations and secure long-term success.

FAQ

What is laser cutting?

Laser cutting is a technology that uses a laser to slice materials. It offers high precision and accuracy, making it ideal for intricate designs and complex shapes. The process involves directing a high-powered laser beam onto the material, which melts, burns, or vaporizes the material away, leaving a clean edge.

How does laser cutting work?

Laser cutting works by focusing a laser beam onto a material's surface. The intense energy from the laser heats and melts the material, allowing it to be cut with precision. This method reduces material waste and often eliminates the need for secondary finishing processes.

What are the benefits of laser cutting?

Laser cutting provides several advantages:

- Precision and Accuracy: Achieve detailed and complex cuts with minimal error.

- Material Efficiency: Reduce waste due to precise cutting capabilities.

- Versatility: Handle a wide range of materials and thicknesses.

- Minimal Finishing: Often eliminates the need for additional finishing processes.

What materials can a laser cut?

Laser cutting can handle a variety of materials, including metals, plastics, wood, glass, and textiles. The type of laser and its power determine the range of materials it can effectively cut.

Is laser cutting cost-effective?

Yes, laser cutting is cost-effective. It reduces material waste and energy consumption, leading to lower operational costs. The precision of laser cutting also minimizes the need for rework, saving time and resources.

How does laser cutting improve production timelines?

Laser cutting enhances production timelines by increasing cutting speed and accuracy. This efficiency allows you to complete projects faster, meeting tight deadlines and boosting overall productivity.

Can laser cutting be automated?

Yes, laser cutting can be automated. Modern laser cutting machines often integrate with AI and machine learning systems, streamlining operations and reducing human error. Automation enhances consistency and frees up your workforce for more strategic tasks.

What industries benefit from laser cutting technology?

Several industries benefit from laser cutting, including:

- Automotive: For precision parts manufacturing and customization.

- Aerospace: For lightweight material processing and safety enhancements.

- Medical: For producing medical devices and custom implants.

How does laser cutting contribute to sustainability?

Laser cutting contributes to sustainability by using energy-efficient systems and minimizing material waste. The use of recyclable and biodegradable materials further supports environmental conservation efforts.

What future trends should businesses watch in laser cutting technology?

Businesses should watch for emerging trends like hybrid laser systems and IoT integration. These advancements offer enhanced versatility, efficiency, and connectivity, positioning your business at the forefront of innovation.

See Also

Exploring Various Laser Cutting Technology Types Available Today

Tips for Maximizing Efficiency with Laser Cutting Machines

Understanding Laser Cutting Machines and Their Different Types

The Functionality of Laser Cutting Machines in Industrial Settings

Advantages and Disadvantages of Laser Cutting Machine Operations