How Much is Laser Metal Cutting Machine Price Guide

When considering the purchase of a laser cutting machine, understanding the price range is crucial. These machines can vary significantly in cost, with prices ranging from $3,000 to over $1 million. Factors such as the type of laser, power, and additional features influence the buying price. For instance, CO2 laser cutters typically range from $8,000 to $50,000, while fiber laser cutters can cost between $20,000 and $500,000. Knowing how much is laser metal cutting machine price helps you make informed decisions, ensuring that the laser cutting process aligns with your budget and needs.

Types of Lasers and Their Costs

When exploring laser cutting machines, understanding the types of lasers and their associated costs is essential. Each type of laser offers unique advantages and price points, which can significantly impact your purchasing decision.

CO2 Lasers

CO2 lasers are a popular choice for cutting non-metal materials. They typically range in price from $8,000 to $50,000. These machines operate with power outputs between 100W and 500W, making them suitable for applications like engraving and cutting wood, acrylic, and other non-metallic materials. While CO2 lasers are generally more affordable than other types, they come with higher operational costs due to maintenance and energy consumption. If you prioritize versatility in non-metal applications, CO2 lasers might be the right fit for you.

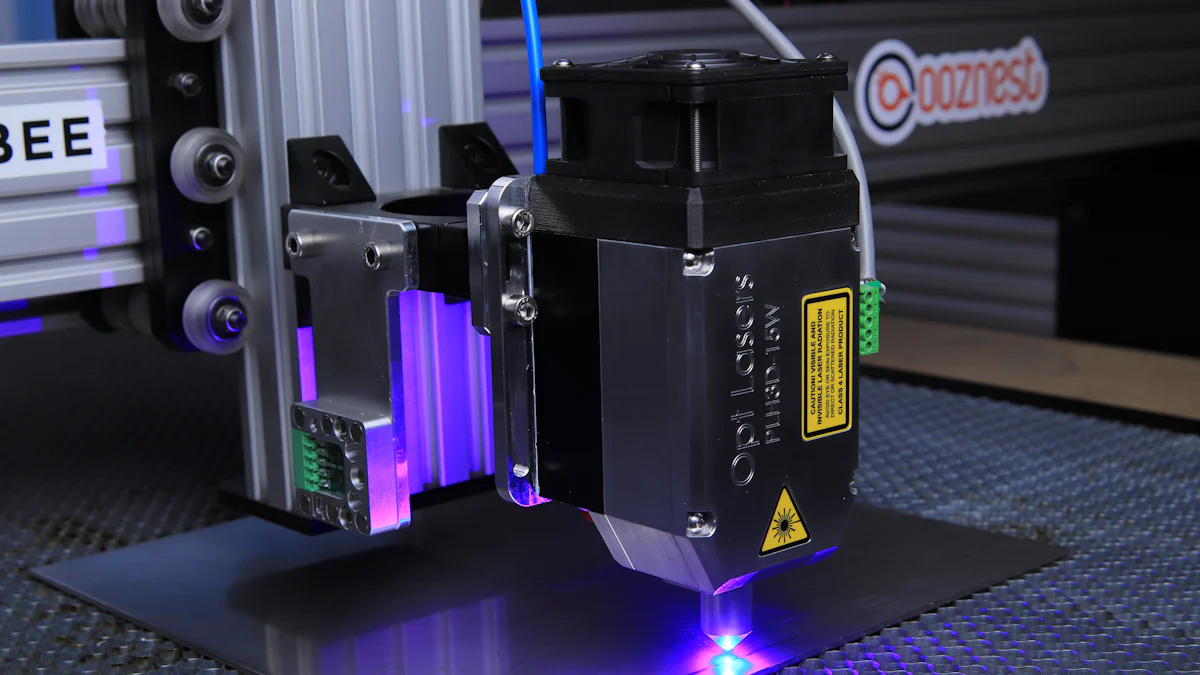

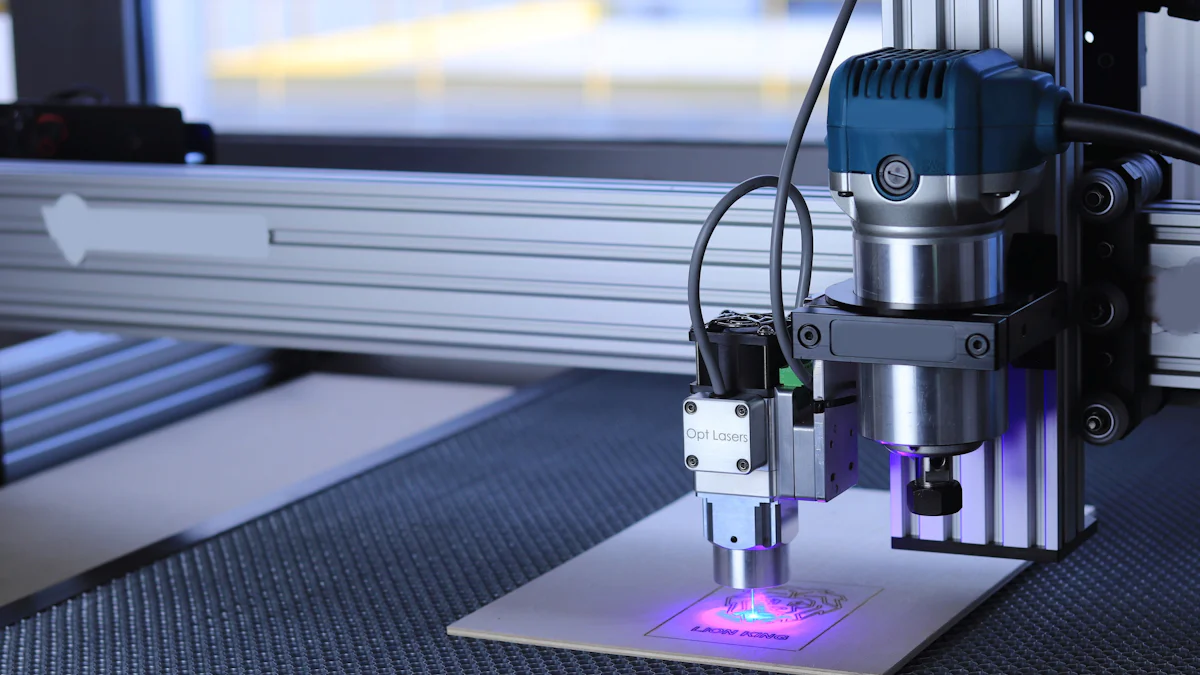

Fiber Lasers

Fiber lasers represent a more advanced option, especially for metal cutting. These machines can cost anywhere from $20,000 to $600,000, depending on their power and precision capabilities. Fiber lasers excel in cutting metals such as aluminum, brass, and stainless steel. They offer faster cutting speeds and lower operational costs compared to CO2 lasers. The initial investment might be higher, but the efficiency and reduced maintenance make fiber lasers a cost-effective choice for industrial applications. If your focus is on metal cutting, investing in a fiber laser could enhance your laser cutting process.

Other Laser Types

Beyond CO2 and fiber lasers, other laser types like YAG lasers exist, though they are less common in standard laser cutting machines. YAG lasers are typically used for specialized applications and can start at prices around $200,000. These lasers are known for their precision and ability to cut through thicker materials. However, their high cost makes them less accessible for small businesses or hobbyists. Understanding how much is laser metal cutting machine price for these specialized lasers can help you determine if they align with your specific needs.

Power and Capability

Understanding the power and capability of laser cutting machines is crucial when evaluating their suitability for your needs. The power of a laser cutting machine directly impacts its ability to cut through various materials and its overall performance. Let's explore the differences between low power and high power machines.

Low Power Machines

Low power machines typically offer a more affordable entry point into laser cutting. These machines usually have lower startup costs and do not require specialized plugs, making them more universally available. They are ideal for intricate designs and delicate materials, providing excellent accuracy for detailed work. If your projects involve thin materials or require high precision, a low power machine might be the right choice. However, keep in mind that these machines may have limitations in terms of production capabilities and the thickness of materials they can handle.

High Power Machines

High power machines, on the other hand, come with a higher price tag but offer significant advantages in terms of cutting speed and material thickness. These sophisticated devices utilize unique technologies to deliver superior accuracy and efficiency. High power machines excel in heavy-duty projects, allowing you to cut through thicker materials at faster rates. While the initial investment and operational expenses are higher, the enhanced performance and expanded production capabilities can justify the cost for industrial applications. If your focus is on maximizing efficiency and handling a wide range of materials, investing in a high power machine could be beneficial.

Machine Size and Configuration

When selecting a laser cutting machine, the size and configuration play a crucial role in determining its cost and suitability for your projects. Understanding the differences between small and large format machines will help you make an informed decision.

Small Format Machines

Small format machines are compact and ideal for hobbyists or small businesses. These machines typically have a smaller cutting area, making them perfect for intricate designs and smaller projects. You can find entry-level models at a lower price point, often starting at a few hundred dollars. These machines are easy to set up and operate, making them accessible for beginners. They are suitable for cutting thin materials like paper, fabric, and acrylic. If your workspace is limited or your projects are small-scale, a small format machine might be the best choice for you.

Large Format Machines

Large format machines cater to industrial needs and larger projects. They come with a greater cutting area, allowing you to handle bigger pieces or batch process smaller items efficiently. These machines are built with robust structures to accommodate thicker and denser materials such as steel or titanium. Due to their enhanced capacity and sturdier build, large format machines naturally cost more. Prices can range from thousands to tens of thousands of dollars, depending on the features and capabilities. If you require high-volume production or need to cut large materials, investing in a large format machine will provide the necessary power and efficiency.

Brand and Reputation

When choosing a laser cutting machine, the brand's reputation plays a significant role in your decision-making process. Established brands often provide reliability and quality, while emerging brands might offer innovative features at competitive prices.

Established Brands

Established brands in the laser cutting industry have built their reputation over years of delivering high-quality products and excellent customer service. Companies like Prima Power and TANAKA are well-known for their reliable and efficient machines. Prima Power specializes in both CO₂ and fiber laser cutting machines, offering high performance and flexibility for various production needs. TANAKA, a pioneer in the laser industry, provides a range of cutting machines, including laser, plasma, and gas options. These brands often come with a higher price tag due to their proven track record and robust after-sales support. However, investing in an established brand can ensure you receive a machine that meets your expectations and provides long-term value.

Emerging Brands

Emerging brands, such as Focused Laser Systems and Accurl, bring fresh perspectives and innovative solutions to the market. Focused Laser Systems, a leading supplier in the UK, emphasizes affordability and reliability, making their machines an attractive option for those on a budget. Accurl offers precision and versatility in their laser cutting machines, catering to a wide range of industries. These brands may offer lower costs compared to established names, providing an opportunity to access advanced technology without breaking the bank. While emerging brands might not have the same level of recognition, they often focus on customer satisfaction and competitive pricing, making them worth considering for your next purchase.

Choosing between established and emerging brands depends on your specific needs and budget. Established brands offer peace of mind with their proven reliability, while emerging brands provide innovative features at a more accessible price point. By evaluating the reputation and offerings of each brand, you can make an informed decision that aligns with your requirements.

Additional Features and Automation

Incorporating additional features and automation into laser cutting machines can significantly enhance their functionality and efficiency. These enhancements often come with a higher price tag, but they can offer substantial benefits in terms of productivity and precision.

Automation Options

Automation in laser cutting machines can transform your production process. Features like automatic loading and unloading systems streamline operations, reducing manual labor and increasing throughput. This degree of automation allows you to handle larger volumes of work with minimal human intervention. While the initial investment might be higher, the long-term savings in labor costs and increased production efficiency can justify the expense. Automation options also include real-time monitoring systems that provide insights into machine performance, helping you maintain optimal operation and reduce downtime.

Software and Control Systems

Advanced software and control systems play a crucial role in enhancing the accuracy and efficiency of laser cutting machines. Modern machines often come equipped with intuitive user interfaces and built-in design software, allowing you to create and modify designs directly on the machine. These systems improve the accuracy of cuts by providing precise control over the laser power and cutting parameters. Additionally, features like auto-focus and material recognition ensure consistent results across different materials and thicknesses. Investing in machines with sophisticated software capabilities can lead to better quality outputs and reduced waste, ultimately impacting the charge per minute of laser cutting positively.

When evaluating laser cutting machines, consider how these additional features align with your production needs and budget. The right combination of automation and software can enhance your machine's performance, offering greater accuracy and efficiency in your operations.

Material Type and Thickness

When selecting a laser cutting machine, you must consider the material type and thickness you plan to work with. These factors significantly influence both the machine's cost and its operational efficiency.

Thin Materials

Thin materials, such as paper, fabric, and thin plastics, require less power to cut. Machines designed for these materials often come at a lower price point. You can achieve precise cuts with minimal kerf width, which is the width of the cut made by the laser. This precision makes low-power machines ideal for intricate designs and delicate projects. The cost of materials like thin plastics or fabrics is generally lower, which can reduce overall production expenses. If your projects primarily involve thin materials, investing in a machine tailored for these applications can be both cost-effective and efficient.

Thick Materials

Thick materials, such as metals and dense plastics, demand more powerful lasers. Machines capable of cutting through these materials often come with a higher price tag due to the need for advanced technology and increased power output. The material type and thickness directly affect the machine's capabilities and the cost of materials used in production. For instance, cutting high-grade aluminum requires more power than cutting steel, impacting both the machine's price and operational costs. Thicker materials also result in larger kerfs, which can influence the precision and quality of the cut. If your focus is on heavy-duty projects, investing in a high-power machine designed for thick materials will ensure optimal performance and efficiency.

Understanding the relationship between material type, thickness, and machine capabilities is crucial. By aligning your machine choice with your specific material needs, you can optimize both cost and performance.

Market Trends and Economic Factors

Understanding market trends and economic factors is crucial when considering the purchase of a laser cutting machine. These elements can significantly influence the selling price and overall costs associated with these machines.

Technological Advancements

Technological advancements play a pivotal role in shaping the laser cutting industry. As technology evolves, manufacturers introduce new features and capabilities that enhance machine performance. These innovations often lead to changes in the selling price. For instance, machines with faster cutting speeds or advanced automation options typically come with higher costs. The investment in high-quality components and research and development contributes to this increase. However, these advancements also improve efficiency and precision, which can reduce the laser cutting service cost over time. Staying informed about the latest technological trends helps you make informed decisions and choose a machine that aligns with your needs.

Economic Conditions

Economic conditions also impact the selling price of laser cutting machines. Factors such as market demand and supply, global economic events, and consumer disposable income levels can influence pricing. In periods of high demand, prices may rise, especially if supply is limited. Conversely, during times of low demand or when new technologies emerge, prices might decrease as manufacturers aim to clear inventory or capture market share. Additionally, global events like the ongoing conflict between Russia and Ukraine can affect the availability of certain parts, influencing costs. Rising disposable incomes, particularly in the United States, encourage consumers to invest in cutting-edge technology, impacting the laser cutting service cost. By understanding these economic factors, you can better anticipate price fluctuations and plan your purchase accordingly.

In your journey to find the right laser cutting machine, understanding how much is laser metal cutting machine price is crucial. By evaluating the types of laser cutting machines, their power, and additional features, you can align your choice with your specific needs and budget. Remember, the buying price and selling price of these machines vary based on factors like brand reputation and technological advancements. Investing in a machine that suits your requirements will enhance your laser cutting process and ensure a sound investment. Always consider the laser cutting service cost and potential future needs to make an informed decision.

FAQ

What materials can laser cutter machines be used on?

Laser cutter machines work on a wide variety of materials. You can use them on wood, acrylic, fabric, leather, metal, paper, and cardboard. This versatility makes laser cutter machines ideal for enhancing products in any business. Whether you create or sell, there's likely a way a laser machine can help improve your offerings.

How do I choose the right laser cutting machine for my needs?

To choose the right laser cutting machine, consider the materials you plan to cut and the thickness of those materials. Evaluate the machine's power and size, and think about your budget. Also, consider the brand reputation and any additional features you might need, such as automation or advanced software.

Are laser cutting machines safe to use?

Yes, laser cutting machines are safe when you follow proper safety guidelines. Always wear protective eyewear and ensure the machine has proper ventilation. Regular maintenance and following the manufacturer's instructions also enhance safety.

How much maintenance do laser cutting machines require?

Laser cutting machines require regular maintenance to function optimally. You should clean the lenses and mirrors regularly, check the alignment, and replace worn parts as needed. Following a maintenance schedule helps extend the machine's lifespan and ensures consistent performance.

Can I use a laser cutting machine for engraving?

Yes, you can use laser cutting machines for engraving. They offer precision and detail, making them suitable for engraving intricate designs on various materials like wood, acrylic, and metal. Adjusting the laser's power settings allows you to achieve different engraving depths.

What is the difference between CO2 and fiber lasers?

CO2 lasers are ideal for cutting non-metal materials like wood and acrylic. They are generally more affordable but have higher operational costs. Fiber lasers excel in cutting metals such as aluminum and stainless steel. They offer faster speeds and lower maintenance costs, making them suitable for industrial applications.

How does the power of a laser cutting machine affect its performance?

The power of a laser cutting machine directly impacts its cutting speed and the thickness of materials it can handle. Higher power machines cut thicker materials more efficiently and at faster speeds. However, they also come with higher initial and operational costs.

What should I consider when buying a laser cutting machine for a small business?

For a small business, consider the machine's size, power, and cost. Small format machines are often more affordable and suitable for limited space. Evaluate the types of materials you will work with and ensure the machine meets those needs. Also, consider the brand's reputation and after-sales support.

How do technological advancements impact laser cutting machines?

Technological advancements introduce new features and capabilities in laser cutting machines. These improvements enhance performance, efficiency, and precision. While they may increase the initial cost, they often reduce long-term operational expenses and improve the quality of outputs.

What economic factors influence the price of laser cutting machines?

Economic factors such as market demand, supply, and global events can influence the price of laser cutting machines. High demand or limited supply can drive prices up, while new technologies or economic downturns might lead to price reductions. Understanding these factors helps you anticipate price changes and plan your purchase effectively.

See Also

Comparative Guide To Laser Cutting Machine Prices

Cost Analysis For Water Jet Cutting Machines

Exploring Prices And Types Of Cutting Machines