How Much is a Laser Metal Cutting Machine Today

When considering how much is a laser metal cutting machine, you will find a wide range of prices. These machines can start as low as $2,000 for hobbyists and soar beyond $200,000 for industrial-grade equipment. The price varies based on the machine's capabilities and intended use. For instance, entry-level models typically fall under $4,000, while more advanced options range from $4,000 to $10,000. Mid-range machines might cost between $10,000 and $35,000, and high-end models often exceed $35,000. This broad spectrum ensures that there is a metal laser cutting machine suitable for every budget and need.

Understanding the Pricing of Laser Metal Cutting Machines

When you explore the world of laser cutting machines, understanding the pricing structure becomes essential. The cost of laser cutting machines varies significantly based on several factors, including the type of machine, its capabilities, and the additional features it offers. Let's delve into the different price ranges and what you can expect within each category.

Price Range Overview

Entry-Level Models

Entry-level metal laser cutting machines are perfect for hobbyists or small businesses. These machines typically range from $2,000 to $4,000. They offer basic functionality and are suitable for light-duty tasks. You might find these machines equipped with CO2 lasers, which are ideal for cutting non-metal materials like wood and acrylic. However, they can handle thin metals with limited precision.

Mid-Range Models

Mid-range models cater to more demanding applications. Priced between $10,000 and $35,000, these machines provide enhanced power and versatility. They often feature larger working areas and higher power outputs, allowing you to cut thicker metals with greater accuracy. Mid-range machines might include fiber lasers, which are known for their efficiency in cutting metals.

High-End Models

High-end metal laser cutting machines exceed $35,000 and are designed for industrial use. These machines boast advanced features, such as high-speed cutting, superior precision, and the ability to handle a wide range of materials. High-end models often incorporate the latest technology, ensuring optimal performance for large-scale production.

What is Included in the Price?

When you consider how much is a laser metal cutting machine, it's crucial to understand what the price includes. Beyond the machine itself, several components and services contribute to the overall cost.

Software Packages

Most laser cutting machines come with software packages that facilitate design and operation. These packages are essential for creating precise cuts and optimizing the machine's performance. The software's complexity and capabilities can influence the machine's price.

Technical Support and Training

Purchasing a metal laser cutting machine often includes access to technical support and training. Manufacturers provide these services to ensure you can operate the machine efficiently and troubleshoot any issues. The level of support and training can vary, impacting the overall cost.

Additional Equipment and Accessories

Additional equipment and accessories, such as air compressors, dust extractors, and safety features, may be included in the price. These components enhance the machine's functionality and ensure safe operation. Depending on your needs, you might choose to invest in extra features, which can increase the cost.

Understanding the pricing of laser cutting machines involves considering various factors, from the type of machine to the included features. By evaluating your specific needs and budget, you can select a machine that offers the best value for your investment.

Comparing Different Models of Laser Metal Cutting Machines

When choosing a laser cutting machine, understanding the features and costs of different models is crucial. This section will explore some popular models, highlighting their key features and evaluating their pros and cons.

Key Features of Popular Models

OMTech 60W CO2 Laser Engraver Cutting Machine Features and Cost

The OMTech 60W CO2 Laser Engraver is a versatile option for both beginners and small businesses. It offers a working area suitable for various materials, including wood, acrylic, and thin metals. The machine's CO2 laser technology ensures precise cuts and engravings. Priced around $3,199.99, it provides a balance between affordability and functionality. The included software package enhances its usability, making it a popular choice for those new to laser cutting.

FSL Muse Core Desktop CO2 Laser Cutting and Engraving Machine Features and Cost

The FSL Muse Core Desktop CO2 Laser Cutting and Engraving Machine stands out with its compact design and user-friendly interface. It is ideal for hobbyists and small-scale projects. With a price tag of approximately $2,999.00, it offers excellent value for its features. The machine supports a variety of materials, providing flexibility in creative projects. Its intuitive software and robust build make it a reliable option for personal use.

8 x 4 ft 1000W CAMFive Laser Fiber Metal Cutter Features and Cost

For industrial applications, the 8 x 4 ft 1000W CAMFive Laser Fiber Metal Cutter is a powerhouse. It excels in cutting thick metals with high precision and speed. The fiber laser technology used in this machine ensures minimal maintenance and high efficiency. Priced at $43,900, it represents a significant investment but delivers exceptional performance for large-scale operations. Its advanced features cater to demanding industrial needs, making it a top choice for professionals.

Pros and Cons of Each Model

OMTech 60W CO2 Laser Engraver Cutting Machine Pros and Cons

- Pros:

- Affordable and versatile

- Suitable for various materials

- User-friendly software

- Cons:

- Limited power for thicker metals

- Smaller working area compared to industrial models

FSL Muse Core Desktop CO2 Laser Cutting and Engraving Machine Pros and Cons

- Pros:

- Compact and easy to use

- Excellent for hobbyists

- Cost-effective

- Cons:

- Not suitable for heavy-duty tasks

- Limited to smaller projects

8 x 4 ft 1000W CAMFive Laser Fiber Metal Cutter Pros and Cons

- Pros:

- High precision and speed

- Ideal for industrial use

- Low maintenance with fiber laser technology

- Cons:

- High initial cost

- Requires significant space

Choosing the right metal laser cutting machine depends on your specific needs and budget. Whether you are a hobbyist or a professional, understanding the features and costs of different models will help you make an informed decision.

Factors Influencing the Price of Laser Metal Cutting Machines

Understanding how much is a laser metal cutting machine involves examining several key factors that influence its cost. These factors include technology and innovation, brand and manufacturer reputation, and market demand and supply dynamics. Each plays a crucial role in determining the price you might pay for a laser cutting machine.

Technology and Innovation

Advancements in technology significantly impact the cost of laser cutting machines. Since the 1970s, when CO2 lasers first achieved outputs exceeding 1,000 watts, the precision and efficiency of these machines have improved dramatically. The 1990s marked a golden age for laser cutting development, introducing high-powered cutters capable of handling larger volumes with increased precision. Today, innovations continue to enhance maximum performance, allowing machines to cut a broader range of materials with greater accuracy. As technology evolves, newer models often come with higher price tags due to their advanced features and capabilities.

Brand and Manufacturer

The brand and manufacturer of a metal laser cutting machine can greatly affect its cost. Well-established brands with a reputation for quality and reliability often command higher prices. These manufacturers invest heavily in research and development to ensure their machines deliver precision and durability. They also provide comprehensive support and training, which adds value to their products. When considering how much is a laser metal cutting machine, you might find that opting for a reputable brand ensures long-term satisfaction and performance, even if it means a higher initial investment.

Market Demand and Supply

Market dynamics, including demand and supply, also influence the price of laser cutting machines. As consumer disposable incomes rise, more individuals and businesses invest in cutting-edge technology, driving market growth. This increased demand can lead to higher prices, especially for models that offer the latest innovations. Conversely, shifts in consumer preferences and technological advancements can alter industry dynamics, affecting supply and cost. For instance, the trend towards automation in tube laser cutting machines has led to cost savings on labor and improved consistency, impacting overall pricing structures.

In your journey to find the right laser metal cutting machine, consider the diverse price ranges and features discussed. From entry-level models for hobbyists to high-end machines for industrial use, each option serves different needs. To make an informed decision:

- Assess Your Needs: Identify your specific requirements and production goals.

- Research Thoroughly: Explore various brands and models to understand their capabilities.

- Consider Technical Features: Focus on power, cutting area, and software compatibility.

- Seek Expert Advice: Consult professionals to ensure the machine aligns with your budget and objectives.

By following these steps, you can select a machine that offers the best value for your investment.

FAQ

What types of lasers do metal fabricators use for cutting steel?

Metal fabricators primarily use three types of lasers for cutting steel: CO2 lasers, fiber lasers, and Nd:YAG lasers. CO2 lasers are versatile and effective for cutting non-metal materials and thin metals. Fiber lasers, known for their efficiency, excel in cutting metals with high precision. Nd:YAG lasers, although less common, are used for specific applications requiring high peak power.

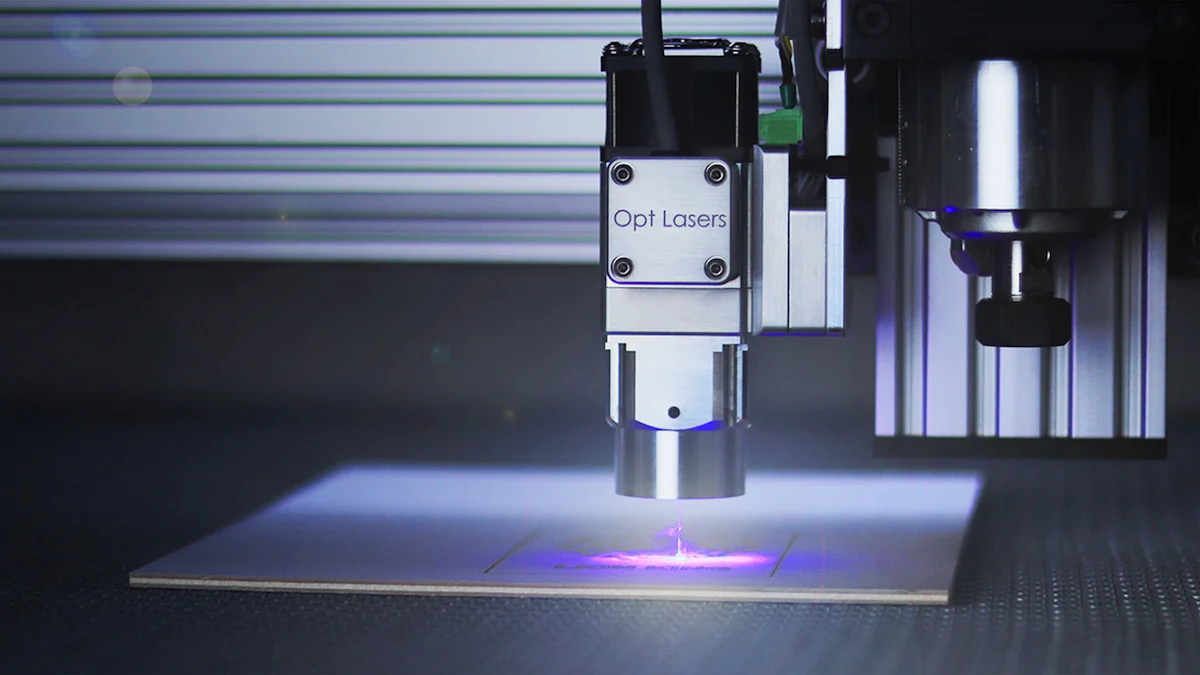

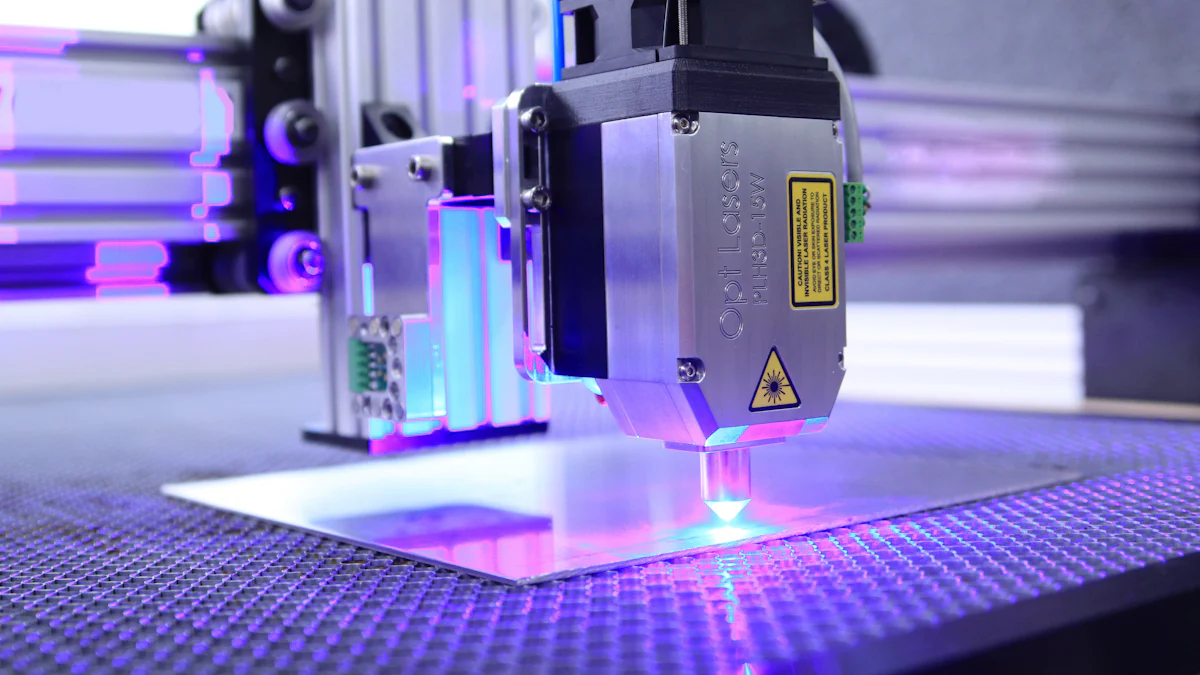

How does laser cutting work?

Laser cutting works by directing a high-powered laser beam onto the material's surface. The laser melts, burns, or vaporizes the material, creating a precise cut. The process involves focusing the laser beam through a lens, which intensifies the energy at a specific point. This concentrated energy allows for clean and accurate cuts, making laser cutting a preferred method in various industries.

What are the benefits of laser cutting?

Laser cutting offers several benefits:

- Precision: Achieves highly accurate cuts with minimal material waste.

- Versatility: Suitable for a wide range of materials, including metals, plastics, and wood.

- Speed: Faster than traditional cutting methods, increasing productivity.

- Quality: Produces smooth edges, reducing the need for additional finishing processes.

Can you cut thick metals with a laser cutting machine?

Yes, you can cut thick metals with a laser cutting machine, especially when using high-power fiber lasers. These machines can handle materials like stainless steel and aluminum with thicknesses exceeding 20mm. However, the machine's power and the type of laser technology used will determine the maximum thickness it can cut effectively.

Is laser cutting environmentally friendly?

Laser cutting is considered environmentally friendly compared to traditional cutting methods. It produces less waste and requires fewer resources. The precision of laser cutting minimizes material waste, and the process generates fewer emissions. Additionally, many laser cutting machines use energy-efficient technologies, further reducing their environmental impact.

How do you maintain a laser cutting machine?

Maintaining a laser cutting machine involves regular cleaning and inspection. You should clean the lenses and mirrors to ensure optimal performance. Regularly check the machine's alignment and calibration. Replace worn-out parts promptly to prevent damage. Following the manufacturer's maintenance guidelines will help extend the machine's lifespan and maintain its efficiency.

What safety precautions should you take when using a laser cutting machine?

When using a laser cutting machine, prioritize safety by wearing appropriate protective gear, such as safety goggles and gloves. Ensure the workspace is well-ventilated to avoid inhaling fumes. Keep flammable materials away from the machine. Familiarize yourself with the machine's emergency stop functions and follow all safety protocols provided by the manufacturer.

Can you use a laser cutting machine for engraving?

Yes, you can use a laser cutting machine for engraving. Many laser cutting machines come equipped with engraving capabilities, allowing you to create intricate designs on various materials. The precision of laser engraving makes it ideal for detailed work on metals, wood, acrylic, and more. Adjusting the laser's power and speed settings will help achieve the desired engraving depth and quality.

How do you choose the right laser cutting machine for your needs?

To choose the right laser cutting machine, consider your specific requirements, such as the materials you plan to cut and the desired precision. Evaluate the machine's power, cutting area, and compatibility with software. Research different brands and models to compare features and prices. Consulting with industry professionals can also provide valuable insights to help you make an informed decision.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Understanding the Costs of Water Jet Cutting Machines

Exploring Cutting Machine Prices and Varieties Available