How Laser Die Cutting Machines Transform Paper Crafting

Imagine transforming your paper crafting projects with precision and efficiency. This is how laser die cutting machines revolutionize paper crafting by changing the way you work with paper. These machines offer unmatched accuracy, allowing you to create intricate designs that were once unimaginable. With their versatility, you can explore endless creative possibilities, from delicate greeting cards to elaborate scrapbooking elements. The global market for laser die cutting services is booming, projected to grow from USD 3.5 billion in 2022 to USD 5.8 billion by 2030. This growth highlights the increasing demand for customization and efficiency in crafting.

Benefits of Laser Die Cutting in Paper Crafting

Laser die cutting machines have transformed the world of paper crafting, offering numerous benefits that enhance your creative projects. Let's explore how these machines can elevate your crafting experience.

Cost-Effectiveness

Laser die cutting machines provide significant cost savings over time.

Long-term savings on materials and tools

You save money on materials and tools with laser cutting paper. Traditional methods often require multiple tools and dies for different designs. Laser cutters eliminate this need by allowing you to create various designs with a single machine. This versatility reduces the need for purchasing additional tools, leading to long-term savings.

Reduced waste due to precision cutting

Precision cutting minimizes material waste. Laser cutting paper ensures that each cut is exact, reducing the amount of scrap material. This efficiency not only saves money but also contributes to a more sustainable crafting process.

Precision and Accuracy

The precision and accuracy of laser die cutting machines are unmatched.

Ability to create intricate designs with ease

You can easily create intricate designs that were once challenging with traditional methods. The laser's precision allows for detailed cuts, enabling you to bring complex patterns to life effortlessly.

Consistent results across multiple projects

Consistency is key in crafting. Laser cutting paper ensures that each project maintains the same level of quality. Whether you're making one item or a hundred, the results remain consistent, saving you time and effort.

Creative Possibilities

Laser die cutting opens up a world of creative possibilities.

Customization of designs and patterns

Customization becomes a breeze with laser cutting paper. You can design and cut unique patterns tailored to your specific needs. This flexibility allows you to personalize your projects, making them truly one-of-a-kind.

Ability to work with various materials beyond paper

While paper is a primary focus, laser die cutting machines can handle a variety of materials. You can experiment with fabrics, leather, and even thin wood, expanding your creative horizons beyond paper crafting.

Incorporating laser die cutting into your paper crafting projects not only enhances efficiency and precision but also unlocks endless creative potential. Embrace the possibilities and watch your crafting skills soar.

How to Use Laser Die Cutting Machines

Getting started with a laser die cutting machine might seem daunting, but with a little guidance, you'll be crafting like a pro in no time. Let's walk through the process step-by-step.

Step-by-Step Guide

Setting up the machine

First things first, you need to set up your Laser Die Cutting Machine. Place it on a stable surface to ensure smooth operation. Connect it to a power source and your computer. Most machines come with software that controls the laser. Install this software and follow the instructions to sync it with your machine. Make sure the laser tube is properly installed. The machine uses a 400W or 600W laser tube, which allows it to cut materials up to 18mm thick. This setup ensures that your machine is ready to handle a variety of projects.

Choosing the right materials

Next, select the materials you want to work with. While paper is a popular choice, these machines can cut through various materials. Consider using fabrics, leather, or even thin wood to expand your crafting possibilities. Always check the material's thickness and compatibility with your machine's specifications. This ensures optimal cutting performance and prevents damage to both the material and the machine.

Designing and uploading patterns

Now comes the fun part—designing your patterns! Use graphic design software to create your designs. Many laser cutting machines support a range of file formats, so check your machine's manual for specifics. Once your design is ready, upload it to the machine's software. This step allows you to preview how the design will look once cut. Adjust the settings as needed to ensure precision and accuracy.

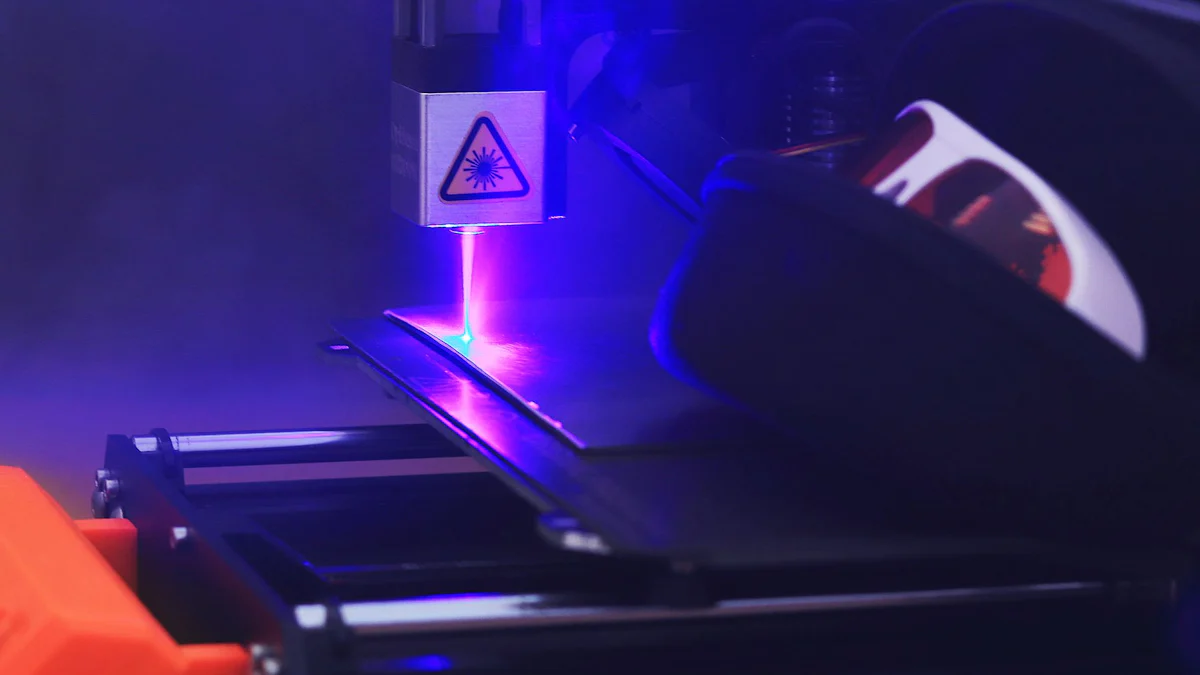

Operating the machine safely

Safety first! Before you start cutting, ensure that all safety measures are in place. Most machines come with protective shields and cooling systems. These features help prevent accidents and keep the machine from overheating. Always wear safety goggles and keep your hands clear of the cutting area. Follow the manufacturer's guidelines for safe operation. Once everything is set, hit the start button and watch your design come to life!

By following these steps, you'll master the art of laser die cutting in no time. Enjoy the process and let your creativity shine!

Common Mistakes and How to Avoid Them

When you're diving into the world of laser die cutting, it's easy to stumble upon a few common pitfalls. But don't worry! With a bit of guidance, you can sidestep these issues and make your crafting journey smoother.

Incorrect Material Settings

One of the first hurdles you might face is setting the machine for different materials. Each material requires specific settings to achieve the best results.

Ensuring proper settings for different materials

To avoid mishaps, always check the manufacturer's guidelines for the best setting for laser cutting paper or any other material you're using. These settings ensure that the laser cuts cleanly without damaging the material. If you're unsure, start with a test cut on a scrap piece. This practice helps you fine-tune the settings before working on your main project. Remember, the right settings can make a world of difference in the quality of your cuts.

Design Errors

Designing is a fun part of the process, but it can also be tricky. Errors in your design can lead to wasted materials and time.

Tips for creating error-free designs

To create flawless designs, double-check your work before uploading it to the machine. Use design software that allows you to preview your patterns. This step helps you spot any potential issues early on. Keep your designs simple at first, gradually increasing complexity as you gain confidence. Also, ensure that your design files are compatible with your machine's software to prevent any hiccups during the cutting process.

Maintenance Oversights

Regular maintenance is crucial for keeping your laser die cutting machine in top shape. Neglecting this can lead to performance issues and even damage.

Regular cleaning and maintenance tips

Make it a habit to clean your machine after each use. Dust and debris can accumulate, affecting the laser's precision. Use a soft brush or cloth to wipe down the machine's components. Check the laser lens regularly and clean it with a lens cleaner to maintain clarity. Additionally, follow the manufacturer's maintenance schedule for more in-depth servicing. Keeping your machine well-maintained ensures it runs smoothly and extends its lifespan.

By being mindful of these common mistakes and taking proactive steps to avoid them, you'll enhance your laser die cutting experience. Happy crafting!

Examples of Projects Enhanced by Laser Die Cutting

Laser die cutting machines open up a world of creativity in paper crafting. You can transform ordinary paper into extraordinary works of art. Let's explore some exciting projects that benefit from this technology.

Personalized Greeting Cards

Creating personalized greeting cards becomes a breeze with laser cutting paper. You can design unique cards that stand out with intricate cutouts and detailed patterns. Imagine sending a card with delicate lace-like edges or a beautifully cut silhouette. These designs capture attention and convey thoughtfulness. The precision of laser cutting ensures each card looks professional and polished, making your greetings truly memorable.

Unique designs and intricate cutouts

With laser cutting, you can achieve designs that were once impossible by hand. The machine's accuracy allows for complex patterns and fine details. You can experiment with different themes and styles, from elegant floral motifs to modern geometric shapes. Each card becomes a canvas for your creativity, offering endless possibilities to express your sentiments.

Custom Scrapbooking Elements

Scrapbooking enthusiasts will love the versatility of laser cutting paper. You can create custom embellishments and decorations that add a personal touch to your scrapbook pages. Whether it's a special photo frame or a themed border, laser cutting lets you tailor each element to fit your vision.

Tailored embellishments and decorations

Laser die cutting machines allow you to craft embellishments that perfectly match your scrapbook's theme. You can cut out letters, shapes, and intricate designs with ease. This customization enhances your storytelling, making each page a unique reflection of your memories. The precision of laser cutting ensures that every detail is crisp and clear, adding a professional finish to your scrapbook.

Decorative Home Décor

Laser cutting paper isn't just for cards and scrapbooks. You can also create stunning home décor pieces. From creative wall art to intricate paper sculptures, the possibilities are endless. These projects add a touch of elegance and personality to your living space.

Creative wall art and paper sculptures

Imagine crafting a beautiful paper sculpture that becomes the centerpiece of your room. Laser cutting allows you to design intricate patterns and assemble them into three-dimensional art. You can also create wall hangings with delicate cutouts that cast interesting shadows. These projects showcase the versatility of laser cutting and highlight your artistic flair.

Incorporating laser die cutting into your crafting projects not only enhances the quality but also expands your creative horizons. Whether you're making personalized cards, custom scrapbook elements, or decorative home décor, laser cutting paper offers precision and versatility. Dive into these examples of paper laser cutting projects and let your imagination soar.

How Laser Die Cutting Machines Revolutionize Paper Crafting

Laser die cutting machines have truly transformed the world of paper crafting. They bring a new level of efficiency, safety, and creativity to your projects. Let's dive into how these machines make such a big difference.

Increased Productivity

Laser die cutting machines significantly boost productivity in paper crafting. You can cut through materials much faster than with manual methods. This speed means you can complete more projects in less time. Imagine finishing a batch of intricate greeting cards in a fraction of the time it would take by hand. This efficiency not only saves time but also allows you to take on more ambitious projects without feeling overwhelmed.

Safety Features

Safety is a top priority when working with any cutting machine. Laser die cutting machines come equipped with protective shields and cooling systems. These features ensure safe operation, reducing the risk of accidents. You can focus on your creative process without worrying about potential hazards. The cooling systems prevent the machine from overheating, which keeps both you and your projects safe. This peace of mind lets you enjoy crafting without unnecessary stress.

Flexibility in Design

One of the most exciting aspects of laser die cutting machines is their flexibility in design. You can program them to cut any size or design without needing physical dies. This capability opens up endless possibilities for your paper crafting projects. Whether you're creating a custom scrapbook layout or a unique piece of wall art, the machine adapts to your vision. You can experiment with different patterns and materials, pushing the boundaries of what's possible in paper crafting.

Incorporating laser die cutting machines into your crafting routine revolutionizes the way you work with paper. They offer increased productivity, enhanced safety, and unparalleled design flexibility. Embrace these benefits and watch your paper crafting projects reach new heights.

Laser die cutting machines have truly transformed paper crafting. They offer you unmatched precision, speed, and versatility. You can create intricate designs with ease and efficiency. These machines reduce material waste and labor costs, making them a cost-effective choice. The ability to cut complex shapes with clean edges enhances your projects' quality. By incorporating laser die cutting into your crafting routine, you unlock endless creative possibilities. So, why not explore and experiment with this technology in your next paper project? Let your creativity soar and see where laser die cutting can take you.

FAQ

What is laser die cutting?

Laser die cutting uses a laser to cut materials like paper with precision. This method allows you to create intricate designs that are difficult to achieve with traditional cutting tools. The laser's accuracy ensures clean edges and detailed patterns, making it ideal for paper crafting projects.

How does laser die cutting differ from traditional die cutting?

Traditional die cutting uses physical dies to cut shapes, while laser die cutting uses a laser beam. With laser cutting, you don't need to create or store physical dies, which saves space and cost. You can also achieve more complex designs with laser cutting, as it offers greater flexibility and precision.

Can I use laser die cutting machines for materials other than paper?

Yes, you can use laser die cutting machines on various materials beyond paper. These machines can cut fabrics, leather, thin wood, and more. Always check your machine's specifications to ensure compatibility with the material you choose.

Is laser die cutting cost-effective?

Laser die cutting can be cost-effective in the long run. You save on materials and tools since you don't need multiple dies for different designs. The precision of laser cutting also reduces waste, contributing to cost savings and a more sustainable crafting process.

How do I maintain my laser die cutting machine?

Regular maintenance keeps your laser die cutting machine in top shape. Clean the machine after each use to remove dust and debris. Check the laser lens regularly and clean it with a lens cleaner. Follow the manufacturer's maintenance schedule for more detailed servicing to ensure optimal performance.

What safety features do laser die cutting machines have?

Laser die cutting machines come with safety features like protective shields and cooling systems. These features help prevent accidents and keep the machine from overheating. Always follow the manufacturer's guidelines for safe operation and wear safety goggles during use.

Can I create custom designs with a laser die cutting machine?

Absolutely! You can design and cut unique patterns tailored to your specific needs. Use graphic design software to create your designs and upload them to the machine. This flexibility allows you to personalize your projects, making them truly one-of-a-kind.

What are some common mistakes to avoid when using a laser die cutting machine?

Common mistakes include incorrect material settings, design errors, and neglecting maintenance. Always check the manufacturer's guidelines for material settings and test on scrap pieces first. Double-check your designs before uploading them to the machine. Regularly clean and maintain your machine to ensure it runs smoothly.

How can laser die cutting enhance my paper crafting projects?

Laser die cutting enhances your paper crafting projects by offering precision, speed, and versatility. You can create intricate designs with ease and efficiency. The ability to cut complex shapes with clean edges improves the quality of your projects, unlocking endless creative possibilities.

Where can I find more information about laser die cutting services and equipment?

For more information about laser die cutting services and equipment, you can explore online resources, visit crafting forums, or contact manufacturers directly. Many companies offer detailed guides and customer support to help you get started with laser die cutting.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

A Guide to Operating Your Die Cutting Machine

Understanding How Machines Slice Metal Like Paper