What Machine Can Cut Metal? Discover Laser Benefits

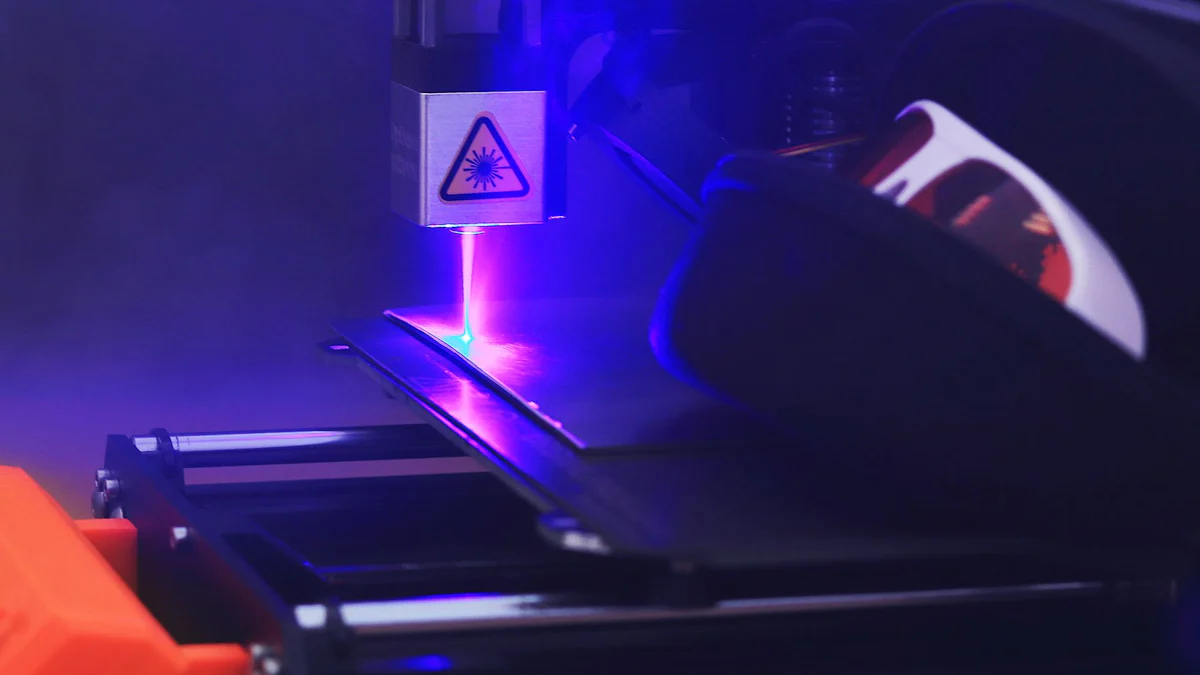

When you need to know what machine can cut metal with precision and efficiency, laser cutting machines stand out as the ideal choice. These machines offer unparalleled accuracy, making them the most precise method for cutting various materials, including metals. You benefit from their speed, which significantly reduces production time compared to traditional methods. Laser cutting also minimizes material waste, enhancing cost-effectiveness and environmental sustainability. Additionally, these machines require minimal maintenance, ensuring long-term reliability. Whether you're working on intricate designs or large-scale projects, laser cutting provides a versatile solution that meets diverse needs.

Key Takeaways

- Laser cutting machines provide unmatched precision, allowing for intricate designs and complex cuts with tight tolerances, essential for industries like medical and aerospace.

- The speed of laser cutting significantly enhances productivity, enabling faster project completion compared to traditional cutting methods, making it ideal for time-sensitive tasks.

- Laser cutting minimizes material waste, leading to cost savings and environmentally friendly practices, which is beneficial for businesses looking to optimize operations.

- These machines are versatile, capable of cutting various metals, including stainless steel and aluminum, making them suitable for a wide range of applications across different industries.

- With low maintenance requirements, laser cutting machines ensure long-term reliability, reducing downtime and allowing businesses to focus on production without frequent interruptions.

- The automation capabilities of laser cutting reduce labor costs and the need for skilled operators, enhancing overall efficiency in manufacturing processes.

- Choosing laser cutting technology not only meets diverse cutting needs but also offers significant advantages over traditional methods, including lower production costs and improved quality.

Precision in Laser Cutting

Laser cutting machines excel in precision, making them the top choice when you wonder what machine can cut metal with the highest accuracy. These machines use a focused laser beam to melt, burn, or vaporize materials, ensuring that the cuts are clean and precise. This method is non-contact, which means the laser beam does not physically touch the material, reducing tool wear and maintaining the integrity of the surrounding area. This precision is unmatched by traditional cutting methods like saw cutting.

High Accuracy

The high accuracy of laser cutting machines is a significant advantage. You can achieve intricate designs and complex cuts with tight tolerances. This level of precision is crucial in industries where accuracy is paramount. For instance, in the medical industry, laser cutting is essential for creating intricate devices and implants. These components often play critical roles in life-saving procedures, so precision is non-negotiable. The ability to replicate results consistently makes laser cutting a valuable tool in manufacturing, ensuring that each product meets the highest quality standards.

Applications

Laser cutting's precision opens up a wide range of applications across various industries. In the automotive and aerospace sectors, you can use laser cutting to create complex parts and components with exact specifications. The furniture and fixtures industry benefits from the ability to produce detailed designs and patterns. In construction, laser cutting provides precise cuts for structural components, enhancing the overall quality and safety of buildings. Additionally, artists and designers leverage laser cutting to bring intricate and creative visions to life, showcasing the versatility of this technology.

The precision and accuracy of laser cutting not only improve efficiency but also reduce material waste. This cost-effectiveness makes it an attractive option for companies of all sizes. By integrating laser cutting with automated CNC technology, you can achieve high productivity levels even for small quantities, ensuring a competitive edge in the market.

Speed of Laser Cutting

When considering what machine can cut metal quickly and efficiently, laser cutting machines are the answer. They excel in speed, making them a preferred choice for many industries. The rapid processing capabilities of laser cutting machines significantly enhance productivity, allowing you to complete projects faster than traditional methods.

Rapid Processing

Laser cutting machines operate at high speeds, especially when dealing with complex shapes or multiple pieces. This speed advantage becomes evident when compared to traditional mechanical cutting methods. For instance, laser cutting can handle intricate designs much faster than saw cutting. The non-contact nature of laser cutting also reduces the risk of tool wear, ensuring consistent performance over time. This rapid processing not only saves time but also boosts overall efficiency in manufacturing processes.

Time-Sensitive Projects

In industries where deadlines are crucial, laser cutting machines provide a reliable solution. Their ability to deliver fast and precise cuts makes them ideal for time-sensitive projects. Whether you're working on a small-scale operation or a large production run, laser cutting ensures timely completion without compromising quality. The technology's capability to maintain low tolerances and exact cuts further enhances its suitability for urgent tasks. By choosing laser cutting, you can meet tight deadlines while maintaining high standards of accuracy and detail.

Versatility of Laser Cutting

Laser cutting machines offer remarkable versatility, making them a top choice for various industries. When you consider what machine can cut metal with precision and adaptability, laser cutting stands out. This technology handles a wide range of materials, providing solutions for diverse applications.

Handling Various Metals

Laser cutting machines excel in processing different types of metals. You can use them to cut stainless steel, aluminum, titanium, and more. The high-powered laser beams ensure clean and precise cuts, regardless of the metal's thickness or hardness. This capability allows you to work with both ferrous and non-ferrous metals, expanding your project possibilities. The flexibility of laser cutting machines means you can adjust settings to meet specific requirements, ensuring optimal results for each material type.

Diverse Applications

The versatility of laser cutting extends beyond handling various metals. You can apply this technology across multiple industries, from automotive to aerospace, and even in creative fields like art and design. In manufacturing, laser cutting machines enable the production of intricate components and prototypes with high accuracy. This precision reduces the need for additional finishing processes, saving you time and resources.

In the construction industry, laser cutting provides precise cuts for structural elements, enhancing the quality and safety of buildings. Artists and designers leverage laser cutting to create detailed and innovative works, showcasing the technology's creative potential. The ability to produce complex geometries and patterns makes laser cutting an invaluable tool for any project requiring precision and creativity.

By choosing laser cutting, you gain access to a versatile and efficient method for cutting metal and other materials. This technology not only meets diverse needs but also offers significant advantages over traditional cutting methods.

Cost-effectiveness of Laser Cutting

Laser cutting machines offer significant cost-saving advantages, making them an attractive option for businesses looking to optimize their operations. By investing in this technology, you can achieve substantial reductions in both material waste and labor costs, ultimately improving your bottom line.

Reduced Waste

One of the primary benefits of laser cutting is its ability to minimize material waste. The precision and accuracy of laser cutters ensure that each cut is exact, reducing the need for secondary operations and excess material usage. This efficiency not only conserves resources but also lowers production costs. By using a laser cutter, you can achieve faster production times, which translates to higher output and shorter lead times for your customers. The reduced waste contributes to a more sustainable manufacturing process, aligning with environmentally conscious business practices.

Lower Labor Costs

Laser cutting machines also help in reducing labor costs. The advanced technology of these machines allows for automation and minimal manual intervention. You can program the laser cutter to handle complex designs and switch between different tasks quickly, which reduces the need for skilled labor. This automation leads to increased efficiency and productivity, allowing your workforce to focus on other critical tasks. Additionally, the energy efficiency of laser cutters means they consume less power compared to traditional cutting methods, further contributing to cost savings. By lowering labor and energy expenses, laser cutting enhances profitability and strengthens your business's financial position.

Minimal Maintenance Requirements

Low Upkeep

Laser cutting machines offer the advantage of low upkeep, making them a practical choice for businesses. Regular maintenance ensures that these machines operate at peak efficiency. You should focus on routine tasks such as cleaning optics, checking laser beam alignment, and servicing components like the cooling unit and exhaust system. These steps help maintain the machine's performance and prevent unexpected downtime.

By following a recommended maintenance schedule, you can extend the lifespan of your laser cutting machine. This approach reduces the likelihood of costly repairs and replacements. Regular checks and cleaning of parts like lenses and mirrors are essential. They ensure consistent cutting quality and prevent issues that could lead to deviations in tolerances. Proper maintenance not only enhances the machine's reliability but also contributes to energy efficiency, ultimately saving on operational costs.

Long-term Reliability

Investing in a laser cutting machine means you prioritize long-term reliability. These machines are designed to withstand high usage environments, provided they receive proper care. By adhering to maintenance guidelines, you ensure that your laser cutter remains a dependable asset for your production needs.

The stability and efficiency of a well-maintained laser cutting machine minimize the risk of production interruptions. This reliability is crucial for meeting customer demands and maintaining a competitive edge. With less downtime, you can maximize production capacity and deliver projects on time.

Comparison with Other Cutting Methods

Traditional Methods

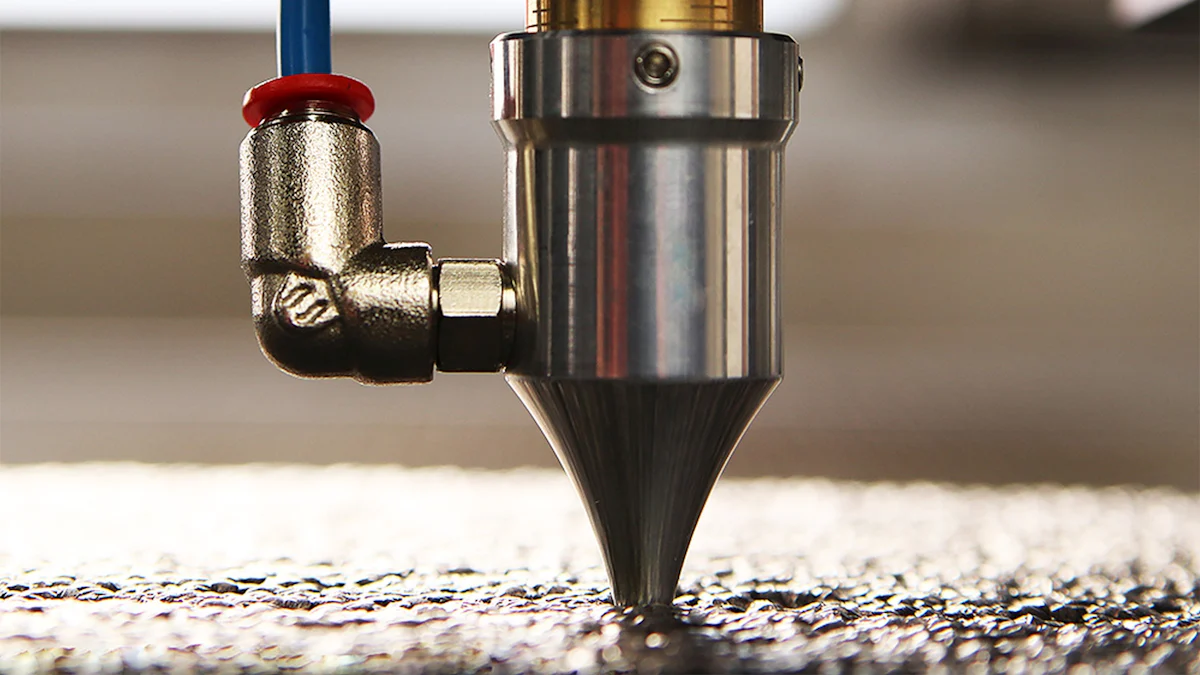

When you explore traditional metal cutting methods, you encounter techniques like sawing, milling, and waterjet cutting. These methods have served industries for decades, but they come with limitations. Traditional cutting often involves physical contact with the material, which can lead to tool wear and potential contamination. This contact may also compromise the precision of the cut, especially when dealing with intricate designs or complex shapes.

Traditional methods typically require post-processing to achieve a smooth finish. This additional step increases production time and costs. For complex cuts, these methods can be slower, leading to longer lead times. The precision of traditional cutting methods often falls short, especially when compared to modern alternatives like laser cutting.

Advantages of Laser Cutting

Laser cutting offers several advantages over traditional methods, making it a superior choice for many applications. Here are some key benefits:

-

High Precision: Laser cutting provides extreme accuracy, allowing you to achieve intricate designs with tight tolerances. This precision reduces the need for post-processing, saving time and resources.

-

Faster Cutting Speeds: The speed of laser cutting machines significantly enhances productivity. You can complete projects faster, even when dealing with complex shapes, compared to traditional methods.

-

Material Flexibility: Laser cutting handles a wide range of materials, including various metals. This flexibility allows you to work with different thicknesses and hardness levels without compromising quality.

-

Non-Contact Process: The non-contact nature of laser cutting minimizes tool wear and reduces the risk of contamination. This feature ensures consistent performance and maintains the integrity of the material.

-

Reduced Waste: Laser cutting's precision minimizes material waste, contributing to cost-effective manufacturing. This efficiency aligns with environmentally conscious practices.

-

Lower Costs: By reducing waste and eliminating the need for extensive post-processing, laser cutting lowers overall production costs. The technology's automation capabilities further decrease labor expenses.

Laser cutting machines provide unmatched benefits when you consider what machine can cut metal with precision and efficiency. They excel in precision, speed, and versatility, making them a superior choice over traditional methods. You gain the advantage of faster production times and reduced material waste, which enhances cost-effectiveness. The minimal maintenance requirements ensure long-term reliability, allowing you to focus on your projects without frequent interruptions. By choosing laser cutting, you embrace a technology that meets diverse needs and offers significant advantages in metal cutting.

FAQ

What types of metals can laser cutting machines handle?

Laser cutting machines can handle a wide range of metals. You can cut stainless steel, aluminum, titanium, and more. The versatility of these machines allows you to work with both ferrous and non-ferrous metals, making them suitable for various applications.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers several advantages over traditional methods. It provides high precision, faster cutting speeds, and reduced material waste. Unlike traditional methods, laser cutting is a non-contact process, which minimizes tool wear and contamination risks. This technology also reduces the need for post-processing, saving time and resources.

Is laser cutting cost-effective?

Yes, laser cutting is cost-effective. It minimizes material waste and lowers labor costs due to its automation capabilities. The precision of laser cutting reduces the need for secondary operations, further decreasing production expenses. This efficiency makes it an attractive option for businesses looking to optimize their operations.

What maintenance do laser cutting machines require?

Laser cutting machines require minimal maintenance. Regular tasks include cleaning optics, checking laser beam alignment, and servicing components like the cooling unit and exhaust system. Following a recommended maintenance schedule ensures optimal performance and extends the machine's lifespan.

Can laser cutting machines handle intricate designs?

Absolutely, laser cutting machines excel in handling intricate designs. They provide high accuracy and tight tolerances, allowing you to achieve complex cuts with ease. This capability makes them ideal for industries where precision is crucial, such as medical device manufacturing and aerospace.

How fast can laser cutting machines process materials?

Laser cutting machines operate at high speeds, especially when dealing with complex shapes or multiple pieces. This rapid processing significantly enhances productivity, allowing you to complete projects faster than traditional methods. The speed advantage is particularly beneficial for time-sensitive projects.

Are laser cutting machines environmentally friendly?

Yes, laser cutting machines contribute to environmentally friendly practices. They minimize material waste through precise cuts, conserving resources and reducing production costs. The energy efficiency of these machines also means they consume less power compared to traditional cutting methods.

What industries benefit from laser cutting technology?

Many industries benefit from laser cutting technology. Automotive, aerospace, construction, and manufacturing sectors use laser cutting for precise and efficient production. Creative fields like art and design also leverage this technology to bring intricate and innovative works to life.

Do laser cutting machines require skilled operators?

Laser cutting machines require minimal manual intervention due to their advanced automation capabilities. You can program these machines to handle complex designs and switch between tasks quickly. This reduces the need for skilled labor, allowing your workforce to focus on other critical tasks.

How reliable are laser cutting machines?

Laser cutting machines offer long-term reliability. With proper maintenance, they remain dependable assets for your production needs. Their stability and efficiency minimize the risk of production interruptions, ensuring you meet customer demands and maintain a competitive edge.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Comparative Analysis of Laser Cutting Machine Costs

Understanding the Advantages and Disadvantages of Laser Cutters