What is a Laser Cutting Machine Used For?

You might wonder, what is a laser cutting machine used for? These machines have revolutionized various industries with their precision and efficiency. In manufacturing, they excel in cutting metals and composites, especially in the automotive and aerospace sectors. Artists and designers use them to create intricate sculptures and custom art pieces. The fashion industry benefits from their ability to craft unique fabric patterns and personalized accessories. Laser cutting machines have become indispensable tools across these fields, offering unmatched versatility and accuracy.

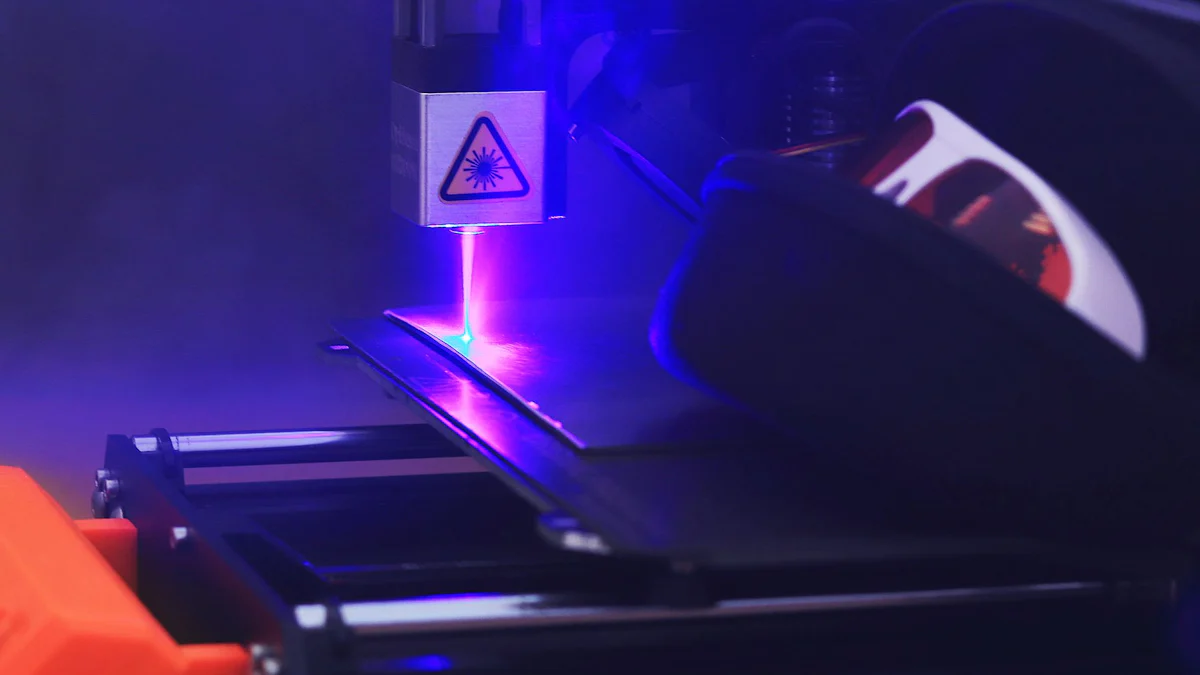

Industrial Applications of Laser Cutting

Laser cutting machines have become indispensable in various industrial sectors due to their precision and efficiency. You will find these machines playing a crucial role in the manufacturing, automotive, and aerospace industries.

Manufacturing Industry

Precision in Metal Cutting

In the manufacturing industry, laser cutting machines offer unparalleled precision in metal cutting. You can achieve cuts with high precision, which is essential for producing intricate components. This precision ensures that each piece meets exact specifications, reducing errors and waste.

Efficiency in Mass Production

When it comes to mass production, laser cutting machines excel by increasing efficiency. You can produce large quantities of parts quickly, thanks to the speed of laser cutting. This efficiency helps manufacturers meet tight deadlines and reduce production costs.

Automotive Industry

Customization of Auto Parts

In the automotive industry, laser cutting allows for the customization of auto parts. You can create unique designs and modifications with ease. This capability is vital for producing custom vehicles and aftermarket parts that meet specific customer needs.

Enhanced Safety Features

Laser cutting also contributes to enhanced safety features in vehicles. You can fabricate precise components that improve the overall safety and performance of automobiles. This precision ensures that safety features function as intended, providing peace of mind to drivers and passengers.

Aerospace Industry

Lightweight Component Fabrication

The aerospace industry benefits from laser cutting through the fabrication of lightweight components. You can produce parts that are both strong and light, which is crucial for aircraft and spacecraft. This capability helps improve fuel efficiency and performance.

High-Precision Engineering

High-precision engineering is another advantage of laser cutting in aerospace. You can achieve the exact specifications required for critical components. This precision ensures that each part fits perfectly, contributing to the overall reliability and safety of aerospace vehicles.

Artistic and Creative Uses of Laser Cutting

Laser cutting has transformed the world of art and design, offering artists and designers a tool that combines precision with creativity. You can explore new dimensions in your work, whether you're crafting intricate sculptures or designing unique fashion pieces.

Art and Design

Intricate Detailing in Sculptures

In the realm of sculpture, laser cutting allows you to achieve levels of detail that were once unimaginable. Artists like Gabriel Schama have harnessed this technology to create mesmerizing 3D artworks from wood. Schama's process begins with intricate drawings that are then transformed into stunning 3D pieces using a laser cutter. This method not only speeds up the creation process but also enhances the artist's ability to realize complex designs. The precision of laser cutting ensures that every detail is captured, allowing for the creation of both abstract forms and realistic portraiture.

Custom Art Pieces

Laser cutting also opens up possibilities for creating custom art pieces. You can experiment with various materials, from paper to metal, to produce unique works that reflect your artistic vision. The versatility of laser cutting means you can push the boundaries of creativity, crafting pieces that are both innovative and precise. This technology has revolutionized the art world, enabling artists to explore new techniques and expand their creative horizons.

Fashion Industry

Unique Fabric Patterns

In the fashion industry, laser cutting offers the ability to create unique fabric patterns that stand out. You can design intricate lace-like patterns or bold geometric shapes with ease. This technology allows for precise cuts that enhance the texture and appearance of fabrics, giving designers the freedom to experiment with new styles and trends. The precision of laser cutting ensures that each pattern is consistent, providing a high-quality finish that elevates the overall design.

Personalized Accessories

Laser cutting also plays a significant role in the creation of personalized accessories. You can design custom jewelry, bags, and other fashion items that cater to individual tastes. This capability allows for a high degree of customization, enabling you to offer products that are truly unique. The precision and versatility of laser cutting make it an invaluable tool for fashion designers looking to create standout pieces that capture the attention of consumers.

Advantages of Laser Cutting Over Traditional Methods

Laser cutting offers numerous advantages over traditional cutting methods, making it a preferred choice in various industries. You will find that its speed, precision, and versatility set it apart.

Speed and Efficiency

Faster Production Times

With laser cutting, you can achieve faster production times compared to traditional methods. The technology allows for rapid processing, which is especially beneficial when dealing with complex designs. This speed not only boosts productivity but also helps you meet tight deadlines with ease.

Reduced Labor Costs

Laser cutting technology reduces labor costs significantly. The automation involved means fewer manual interventions are required, allowing you to allocate your workforce more efficiently. This reduction in labor not only saves money but also minimizes the risk of human error.

Accuracy and Precision

Minimal Material Waste

One of the standout advantages of laser cutting is its high precision. You can achieve cuts with incredible accuracy, which leads to minimal material waste. This precision ensures that each piece is cut to exact specifications, reducing the need for rework and saving resources.

Consistent Quality

Laser cutting provides consistent quality across all cuts. You can rely on this technology to deliver uniform results, ensuring that every piece meets the same high standards. This consistency is crucial for maintaining quality control in production processes.

Material Versatility

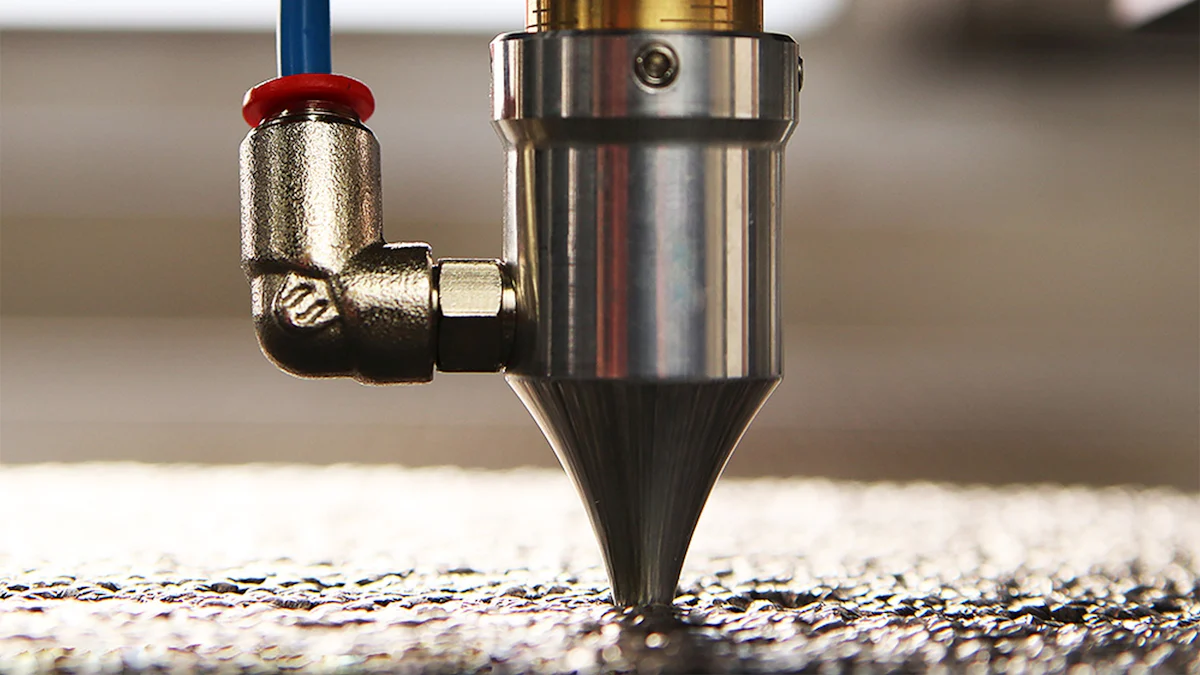

Cutting Various Materials

Laser cutting is versatile, capable of cutting a wide range of materials. Whether you're working with metals, plastics, or non-ferrous materials, you can rely on laser cutting to handle the task. This versatility makes it an invaluable tool for diverse projects.

Adaptability to Different Projects

The adaptability of laser cutting technology allows you to tackle different projects with ease. You can switch between materials and designs without the need for extensive retooling. This flexibility enhances your ability to meet varied customer demands and explore new creative possibilities.

While laser cutting offers many advantages, it's important to be aware of the disadvantages of laser cutting as well. These include limitations on material thickness and the potential release of harmful gases. However, the benefits, such as higher sheet utilization and high precision, often outweigh these drawbacks, making laser cutting a superior choice for many applications.

Technological Benefits of Laser Cutting

Laser cutting technology offers numerous technological benefits that enhance its appeal across various industries. You will find that its automation, cost-effectiveness, and environmental impact make it a superior choice for many applications.

Automation and Integration

Seamless Workflow Integration

Laser cutting machines integrate seamlessly into existing workflows. You can connect them with computer-aided design (CAD) software, allowing for precise and automated cutting processes. This integration streamlines production, reducing the time and effort required to transition from design to finished product. By automating these steps, you can maintain a consistent workflow, minimizing disruptions and enhancing overall productivity.

Reduced Human Error

Automation in laser cutting significantly reduces human error. You can rely on the machine's precision to execute complex cuts accurately, eliminating the inconsistencies that often arise from manual operations. This reduction in error not only improves the quality of the final product but also decreases the need for rework, saving both time and resources.

Cost-Effectiveness

Lower Operational Costs

Laser cutting provides a low-cost solution for material processing. You can achieve high precision without the need for expensive tooling or frequent maintenance. The contactless nature of laser cutting means less wear and tear on equipment, further reducing operational expenses. This efficiency translates into lower costs for businesses, making laser cutting an economically viable option.

Long-Term Savings

Investing in laser cutting technology offers long-term savings. Although the initial setup may require a substantial investment, the benefits outweigh the costs over time. You will experience reduced labor expenses, minimal material waste, and consistent product quality. These factors contribute to significant savings, enhancing your company's profitability in the long run.

Environmental Impact

Reduced Waste Production

Laser cutting is an eco-friendly method that minimizes waste production. You can achieve precise cuts that maximize material utilization, reducing scrap and excess. This efficiency not only conserves resources but also aligns with sustainable practices, making laser cutting an environmentally responsible choice.

Energy Efficiency

The energy efficiency of laser cutting technology is another notable advantage. You can convert electricity into light with minimal energy waste, making the process more sustainable compared to traditional methods. This efficiency reduces the carbon footprint of manufacturing operations, contributing to a greener environment.

Safety and Maintenance Considerations

Ensuring the safety and proper maintenance of your laser cutting machine is essential for optimal performance and longevity. By following recommended safety measures and maintenance practices, you can enhance the efficiency and reliability of your equipment.

Safety Measures

When operating a laser cutting machine, prioritizing safety is crucial. Implementing appropriate safety measures protects both the operator and the equipment.

Protective Equipment

You should always wear protective equipment when using a laser cutting machine. This includes safety goggles to shield your eyes from harmful laser beams and gloves to protect your hands from sharp edges and hot surfaces. Wearing the right gear minimizes the risk of injury and ensures a safer working environment.

Safe Operating Procedures

Adhering to safe operating procedures is vital for preventing accidents. You must familiarize yourself with the machine's user manual and follow all instructions carefully. Ensure that the work area is clean and free of obstructions. Regularly check that all safety features, such as emergency stop buttons and interlocks, are functioning correctly. By maintaining a disciplined approach to safety, you can reduce the likelihood of mishaps.

Maintenance Requirements

Proper maintenance is key to keeping your laser cutting machine in top condition. Regular upkeep not only extends the machine's lifespan but also ensures consistent performance.

Regular Inspections

Conducting regular inspections is an important aspect of maintenance. You should routinely check for signs of wear and tear, such as damaged cables or worn-out components. Inspect the machine's optics and lenses for cleanliness and alignment. Identifying and addressing issues early prevents more significant problems down the line.

Preventive Maintenance

Implementing a preventive maintenance schedule helps maintain the machine's optimal performance. This includes cleaning the machine regularly, lubricating moving parts, and replacing worn components as needed. By performing these tasks consistently, you can minimize downtime and avoid costly repairs. Regular maintenance not only enhances safety but also contributes to cost savings and improved efficiency.

Key Takeaway: Proper maintenance and safety measures are essential for the effective operation of laser cutting machines. By prioritizing these aspects, you ensure the machine's longevity and maintain high-quality output.

Laser cutting machines have transformed industries with their versatility and efficiency. You can see their impact across sectors like manufacturing, art, and fashion. These machines offer unmatched precision, speed, and material versatility, making them superior to traditional cutting methods. They reduce waste and enhance productivity, providing significant advantages in both cost and environmental impact. By adopting laser cutting technology, you embrace a future of innovation and excellence in various applications.

FAQ

What industries benefit from laser cutting machines?

Laser cutting machines serve a wide range of industries. You will find them in manufacturing, automotive, aerospace, art, design, and fashion. Each industry benefits from the precision, speed, and versatility that laser cutting offers.

How does laser cutting compare to traditional cutting methods?

Laser cutting provides several advantages over traditional methods. You can achieve higher precision, faster speeds, and less material waste. This makes laser cutting a more efficient and cost-effective option for many applications.

Can laser cutting machines handle different materials?

Yes, laser cutting machines are versatile. You can use them to cut various materials, including metals, plastics, and non-ferrous materials. This adaptability makes them suitable for diverse projects.

What are the safety measures when using a laser cutting machine?

Safety is crucial when operating a laser cutting machine. You should wear protective equipment like safety goggles and gloves. Following safe operating procedures and ensuring the work area is clear of obstructions is also important.

How do laser cutting machines integrate into existing workflows?

Laser cutting machines integrate seamlessly into workflows. You can connect them with computer-aided design (CAD) software for precise and automated cutting. This integration streamlines production and reduces the time from design to finished product.

Are there environmental benefits to using laser cutting machines?

Yes, laser cutting machines offer environmental benefits. They produce minimal waste and are energy-efficient. You can achieve precise cuts that maximize material utilization, aligning with sustainable practices.

What maintenance is required for laser cutting machines?

Regular maintenance is essential for optimal performance. You should conduct routine inspections for wear and tear, clean the machine, and replace worn components. Preventive maintenance helps minimize downtime and avoid costly repairs.

How do laser cutting machines reduce labor costs?

Laser cutting machines reduce labor costs through automation. You need fewer manual interventions, allowing you to allocate your workforce more efficiently. This reduction in labor minimizes the risk of human error and saves money.

What are the cost benefits of investing in laser cutting technology?

Investing in laser cutting technology offers long-term savings. You will experience reduced labor expenses, minimal material waste, and consistent product quality. These factors contribute to significant savings and enhance profitability.

Can laser cutting machines be used for custom designs?

Absolutely, laser cutting machines excel in creating custom designs. You can produce unique art pieces, personalized accessories, and custom auto parts. This capability allows for a high degree of customization, catering to individual tastes and needs.

See Also

Understanding Laser Cutting Machines And Their Various Types

The Functionality Of Laser Cutting Machines In Industry

Tips For Efficient Use Of Laser Cutting Machines