Tips for Using Laser Cutting Machines for Creative Projects

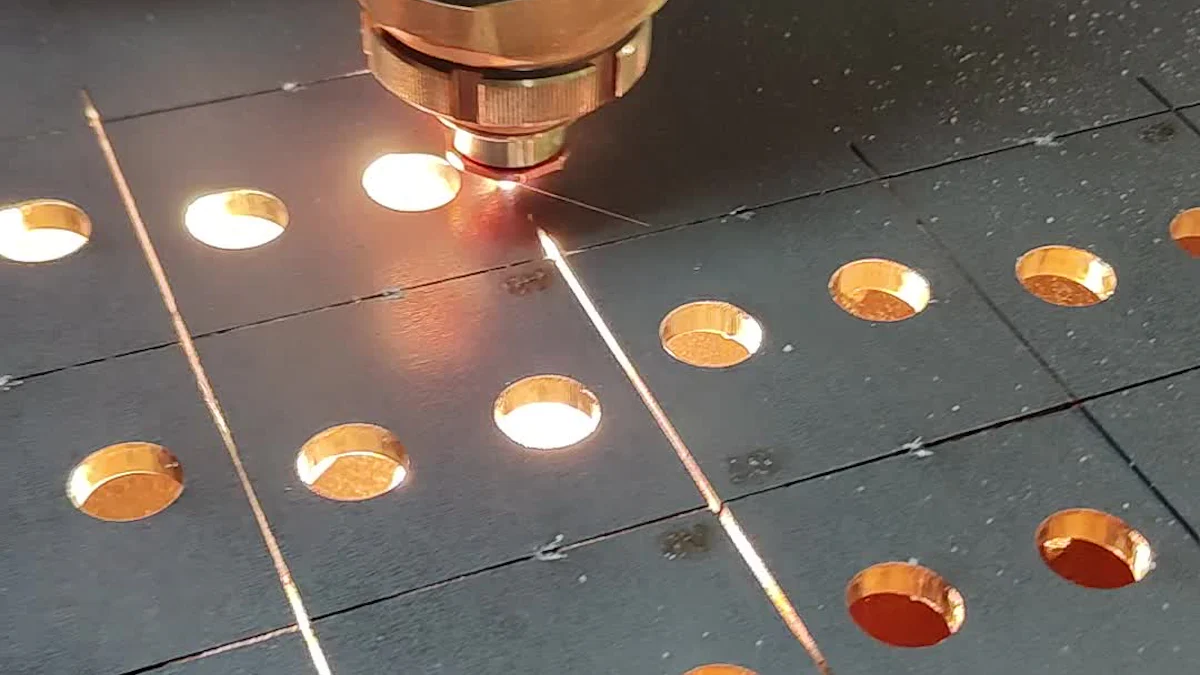

Laser cutting machines unlock endless possibilities for your creative endeavors. With their unparalleled precision, they allow you to craft intricate designs that would be nearly impossible to achieve by hand. From personalized jewelry and custom greeting cards to one-of-a-kind home décor, these machines transform your ideas into stunning, tangible works of art. For example, laser engraved paper can elevate simple cardstock into delicate, lace-like creations. So, what are laser cutting machines used for? They serve as a powerful tool and source of inspiration, enabling you to push the boundaries of your creativity and explore limitless artistic expression.

What Are Laser Cutting Machines Used For in Creative Projects?

Laser cutting machines have revolutionized the way you can approach creative projects. Their precision and versatility make them a go-to tool for artists, designers, and hobbyists alike. Let’s dive into how these machines elevate your creative process.

Applications in Art and Design

The art of laser cutting opens up endless possibilities in art and design. You can use it to create intricate patterns, detailed engravings, and custom shapes that would be nearly impossible to achieve by hand. Whether you’re designing jewelry, crafting home décor, or producing unique sculptures, laser cutting technology ensures every detail is sharp and precise.

For example, in graphic design, you can transform digital illustrations into physical pieces by cutting or engraving materials like wood, acrylic, or paper. In fashion, laser cutting allows you to experiment with fabric, creating bold patterns and textures for clothing or accessories. Even in architecture, you can use it to produce detailed scale models that bring your concepts to life.

“Laser cutting provides significant advantages over conventional methods in terms of precision tolerances and material efficiency.”

This means you can focus on your artwork without worrying about imperfections or wasted materials.

Benefits of Laser Cutting for Creativity

Why should you consider laser cutting for your projects? The benefits are hard to ignore. First, it offers unmatched precision. You can cut or engrave even the most intricate designs with ease. Second, it’s incredibly versatile. From soft materials like paper to harder ones like metal, laser cutting technology works across a wide range of mediums.

Another advantage is its speed. Unlike traditional cutting methods, laser cutting completes tasks quickly and with minimal mess. This efficiency lets you spend more time on the fun part—designing and experimenting. Plus, the clean edges and professional finish it provides can elevate your projects to a whole new level.

Finally, laser cutting encourages innovation. It allows you to push boundaries and explore ideas that might seem too complex or time-consuming with other tools. This makes it an invaluable resource for anyone looking to expand their creativity.

Examples of Popular Creative Uses

If you’re wondering, “What are laser cutting machines used for?” here are some inspiring examples:

- Custom Jewelry: Create personalized necklaces, earrings, or bracelets with intricate designs.

- Home Décor: Design unique wall art, lampshades, or coasters that reflect your style.

- Paper Crafts: Craft delicate wedding invitations, greeting cards, or scrapbook embellishments.

- Prototyping: Build detailed prototypes for products or architectural models.

- Engraved Gifts: Personalize items like wooden cutting boards, leather wallets, or glassware.

These examples highlight how laser cutting can transform ordinary materials into extraordinary creations. Whether you’re a beginner or an experienced maker, the possibilities are endless.

Choosing the Right Machine and Materials

When starting your laser cutting journey, selecting the right machine and materials can make or break your project. The choices you make here will directly impact the quality, precision, and overall success of your creative endeavors. Let’s break it down step by step.

Selecting the Best Laser Cutting Machine for Your Needs

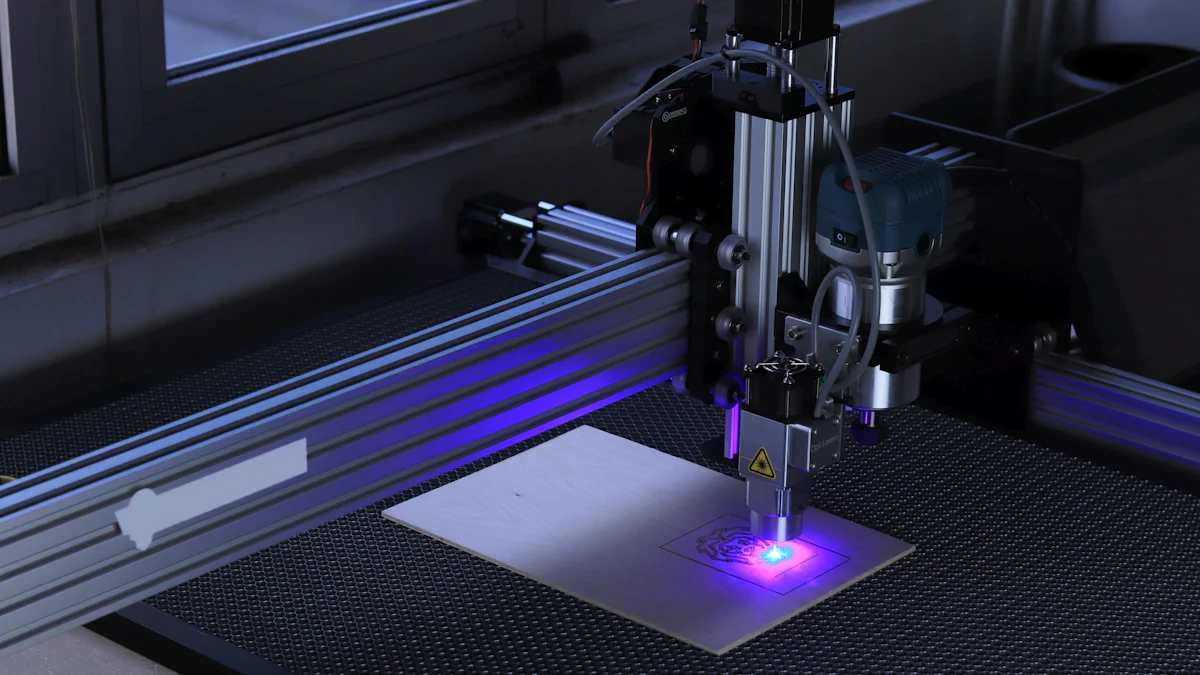

Not all laser cutting machines are created equal. Your choice depends on what you plan to create and the materials you want to work with. For beginners or hobbyists, entry-level machines offer affordability and ease of use. These machines are perfect for smaller projects like paper crafts or lightweight materials. If you’re aiming for more advanced designs or working with tougher materials like wood or acrylic, consider investing in a mid-range or professional-grade machine.

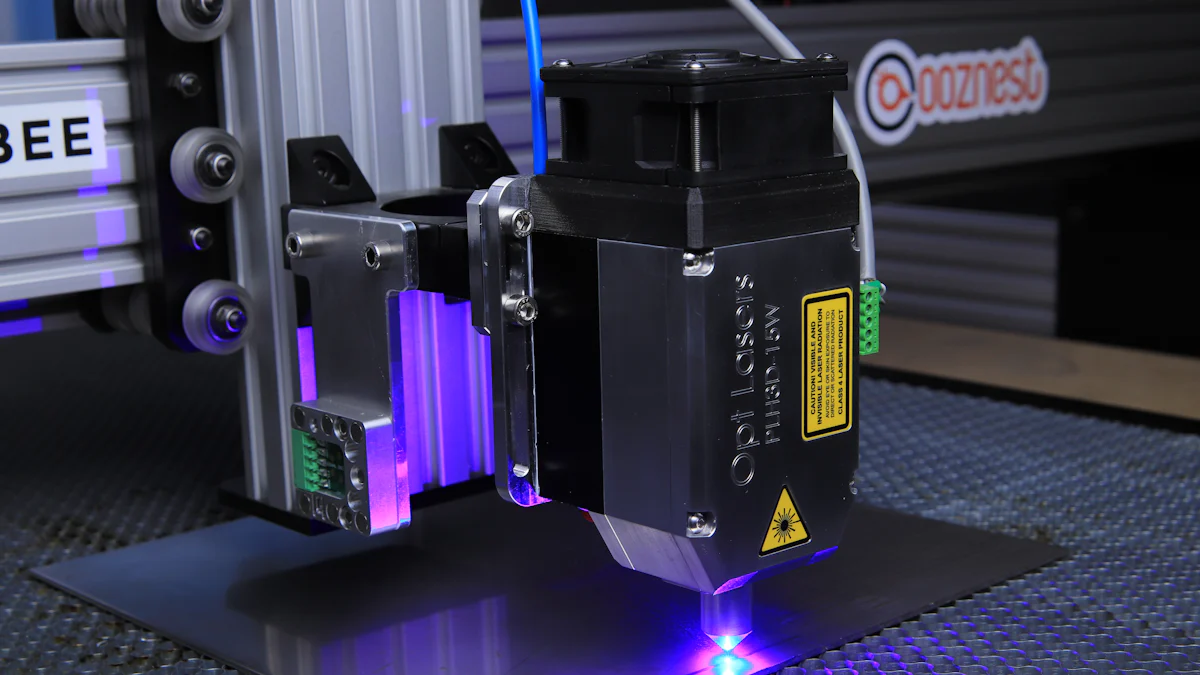

Pay attention to the machine’s power and features. Higher wattage allows you to cut thicker materials, while advanced features like 3D cutting capabilities or built-in design software can expand your creative possibilities. For example, a 3D fiber laser cutting machine is ideal for intricate designs and precise cuts on materials like steel or acrylic. Think about your long-term goals and choose a machine that grows with your skills.

“A good laser cutting machine is an investment in your creativity. Choose one that aligns with your vision and needs.”

Understanding Material Compatibility

Laser cutting machines work with a wide range of materials, but not every material is suitable for every machine. Understanding material compatibility is crucial for achieving the best results. Common materials like wood and acrylic are popular choices because they are versatile and easy to work with. Wood offers a natural, warm finish, making it ideal for home décor or custom gifts. Acrylic, on the other hand, provides a sleek, modern look and is perfect for jewelry or signage.

Before starting your project, check your machine’s specifications to ensure it supports your chosen material. Some machines handle soft materials like paper or fabric effortlessly, while others excel with harder surfaces like metal or glass. Proper material preparation is also key. Clean and smooth materials produce cleaner cuts and reduce the risk of errors during the process.

Tips for Sourcing High-Quality Materials

The quality of your materials can significantly impact the outcome of your project. Low-quality materials may lead to uneven cuts, burns, or even damage to your machine. To avoid these issues, always source high-quality materials from trusted suppliers. Look for materials specifically labeled as laser-compatible, as these are designed to work seamlessly with laser cutting machines.

For wood, choose varieties like birch plywood or MDF for consistent results. When working with acrylic, opt for cast acrylic instead of extruded acrylic. Cast acrylic cuts more cleanly and produces a polished edge. If you’re unsure where to start, many suppliers offer sample packs of recommended materials, allowing you to test different options before committing to larger quantities.

Online communities and forums can also be valuable resources. Experienced users often share tips on where to find the best materials and how to prepare them for laser cutting. Don’t hesitate to ask questions and learn from others’ experiences.

Tips and Techniques for Your First Laser Cutting Project

Embarking on your first laser cutting project can feel both exciting and a bit daunting. But don't worry! With the right tips and techniques, you'll be crafting amazing designs in no time. Let's dive into the essential steps to get you started.

Preparing Your Design

Before you even touch the laser cutter, focus on crafting the perfect design. This step is crucial for ensuring your project turns out just as you envision. Start by sketching your ideas on paper or using design software. Many tutorials online can guide you through this process, offering tips on how to create clean and precise designs.

When preparing your design, remember to convert all text and fonts into outlines or paths. This ensures that the laser cutter reads them correctly. Also, keep in mind the limitations and capabilities of your machine. Simple shapes and clear lines often work best for beginners. As you gain confidence, you can experiment with more intricate patterns.

"The tips and techniques outlined in this article provide valuable insight into gaining proficiency in laser cutting for beginners." - Experienced laser cutting users

Setting Up Your Laser Cutter

Once your design is ready, it's time to set up your laser cutter. This step involves configuring the laser cutter settings to match your material and design requirements. Begin by selecting the appropriate material and ensuring it's compatible with your machine. Check the manufacturer's guidelines for recommended settings.

Position your material securely on the cutting bed. Make sure it's flat and free from any debris. Adjust the focus of the laser to ensure precision. Many tutorials suggest running a quick test cut on scrap material to verify the settings. This helps prevent mistakes and ensures your project runs smoothly.

Testing and Executing Your Project

With everything set up, you're ready to bring your design to life. Start by conducting a small test run. This allows you to see how the laser interacts with your material and make any necessary adjustments. Pay attention to the speed and power settings, as they can significantly impact the outcome.

Once satisfied with the test, proceed with executing your project. Keep an eye on the process, especially if it's your first time. This helps you catch any issues early and make real-time adjustments. After completion, carefully remove your project from the machine and inspect it for any imperfections.

Remember, practice makes perfect. Each project you complete will enhance your skills and boost your confidence. So, embrace the learning process and enjoy the creative journey!

Avoiding Common Mistakes in Laser Cutting

Mistakes happen, especially when you're starting out with laser cutting. But the good news? Most of these errors are easy to avoid once you know what to look for. Let’s break down the common pitfalls and how you can steer clear of them.

Design Errors to Watch Out For

Your design is the foundation of your project, so even small mistakes here can cause big problems later. One common issue is forgetting to account for the kerf—the width of the material removed by the laser during the cutting process. If you don’t adjust for this, your pieces might not fit together as planned. For example, one user shared how a tiny error in kerf measurement (0.07 instead of 0.007) led to oversized cuts, making their project unusable. Always double-check your measurements and test your design on scrap material first.

Another frequent mistake is using overly complex designs, especially if you're new to laser cutting. Intricate patterns with too many tiny details can overwhelm the machine or lead to uneven cuts. Start with simpler shapes and gradually work your way up to more detailed designs as you gain confidence.

Finally, ensure all text in your design is converted to outlines or paths. If you skip this step, your laser cutter might not recognize the fonts, leading to unexpected results. A little extra preparation here can save you a lot of frustration later.

Machine Operation Mistakes

Operating a laser cutter requires precision and attention to detail. One common mistake is skipping the calibration step. If your machine isn’t properly calibrated, the laser might not focus correctly, resulting in uneven cuts or engravings. Take the time to adjust the focus and run a quick test cut before starting your main project.

Another issue is using incorrect speed and power settings. These settings vary depending on the material, so always refer to your machine’s guidelines. For instance, using too much power on thin materials like paper can cause burns, while too little power on thicker materials like wood might not cut through completely. Experiment with test pieces to find the perfect balance.

Also, don’t forget to secure your material on the cutting bed. If it shifts during the cutting process, your design could end up misaligned. Use clamps or adhesive mats to keep everything in place.

Pro Tip: Regularly clean your machine’s lens and mirrors. Dust and debris can affect the laser’s performance, leading to inconsistent results.

Material-Related Issues

Choosing the wrong material or failing to prepare it properly can derail your project. Not all materials are suitable for laser cutting, so always check compatibility. For example, some plastics release toxic fumes when cut, while others might melt instead of cutting cleanly. Stick to laser-compatible materials like wood, acrylic, or paper for the best results.

Material thickness is another factor to consider. If your material is too thick for your machine’s power level, the laser might struggle to cut through it, leaving rough edges or incomplete cuts. On the flip side, using very thin materials without adjusting the settings can lead to burns or warping.

Lastly, inspect your materials before starting. Dirty or uneven surfaces can interfere with the cutting process, leading to poor-quality results. Clean and smooth your materials to ensure a flawless finish.

By staying mindful of these common mistakes, you’ll set yourself up for success. Each project is an opportunity to learn and improve, so don’t be afraid to experiment and refine your techniques.

Safety Tips for Using Laser Cutting Machines

Operating a laser cutting machine can be incredibly rewarding, but safety should always come first. By following essential safety guidelines, you can protect yourself, your workspace, and your machine. Let’s explore how to create a safe environment and maintain proper practices.

Setting Up a Safe Workspace

Your workspace plays a critical role in ensuring safety while using a laser cutter. Start by choosing a well-ventilated area. Laser cutting generates fumes and combustion byproducts that can be hazardous if inhaled. Proper ventilation, such as an exhaust system or air purifier, helps remove these harmful substances from the air.

Keep your workspace organized and free of clutter. Flammable materials like paper, fabric, or wood scraps should be stored away from the laser cutter. A clean area reduces the risk of accidental fires and makes it easier to focus on your project.

Pro Tip: Display clear warning signs around your workspace to alert others about the potential hazards of laser cutting. This ensures that only trained individuals enter the area.

Control access to the laser cutter by restricting it to authorized users. This minimizes the chances of untrained individuals operating the machine unsafely. Additionally, always have a fire extinguisher nearby. Fires are rare but can occur if the laser interacts with flammable materials.

Personal Safety Guidelines

Protecting yourself is just as important as safeguarding your workspace. Always wear appropriate safety gear when operating a laser cutter. Safety goggles designed for laser use shield your eyes from harmful laser beams and bright flashes. Avoid regular sunglasses, as they don’t provide adequate protection.

Wear non-flammable clothing to reduce the risk of burns. Avoid loose-fitting garments or accessories that could accidentally come into contact with the laser. Closed-toe shoes are also a must to protect your feet from falling objects or debris.

Never leave the laser cutter unattended while it’s running. Even a small issue, like a material shift, can escalate quickly. Stay close to the machine and monitor the process to catch any problems early.

“Training is key to safe laser cutting. Make sure you understand the machine’s operating procedures and potential hazards before starting your first project.”

Maintaining Your Machine for Safety

Regular maintenance keeps your laser cutter running smoothly and safely. Start by cleaning the machine’s lens and mirrors. Dust and debris can interfere with the laser’s performance, leading to uneven cuts or potential malfunctions.

Inspect the machine’s ventilation system frequently. A clogged or damaged exhaust system can allow harmful fumes to accumulate, posing health risks. Replace filters as needed and ensure the system operates efficiently.

Check all electrical components for wear or damage. Loose wires or faulty connections can create safety hazards. Address any issues immediately to prevent accidents.

Finally, schedule routine professional inspections. A qualified technician can identify and fix problems you might overlook. Regular checkups extend the life of your machine and ensure it operates safely.

By following these safety guidelines, you can enjoy the creative possibilities of laser cutting without compromising your well-being. A little preparation goes a long way in creating a safe and productive environment.

Inspiring DIY Laser Cut Paper Projects and More

Laser cutting opens up a world of creativity, especially when working with paper. Whether you're a beginner or an experienced maker, paper-based projects offer endless possibilities to express your artistic vision. Let’s explore some exciting ideas to get you started.

Beginner-Friendly Paper Projects

Starting simple is the best way to build confidence with laser cutting. Paper is an excellent material for beginners because it’s affordable, easy to work with, and forgiving of small mistakes. Here are a few beginner-friendly ideas to try:

- Custom Greeting Cards: Design intricate patterns or personalized messages to create one-of-a-kind cards for birthdays, weddings, or holidays. Laser cutting allows you to achieve delicate, lace-like details that elevate your designs.

- Bookmarks: Craft unique bookmarks with fun shapes or inspirational quotes. These make great gifts and are quick to produce.

- Papercut Lanterns: Create stunning lanterns by cutting patterns into cardstock and assembling them into 3D shapes. Add a battery-operated LED light inside for a magical glow. These lanterns can even become a profitable venture if marketed as customizable gifts for special occasions.

“Laser cutters don’t exert mechanical force on the material, making it possible to create extremely delicate designs without damage.”

These projects are perfect for practicing precision and experimenting with different settings on your machine.

Intermediate and Advanced Project Ideas

Once you’ve mastered the basics, it’s time to challenge yourself with more complex designs. Intermediate and advanced projects let you push the boundaries of what’s possible with laser cutting.

- Layered Artwork: Combine multiple layers of laser-cut paper to create depth and dimension in your designs. This technique works beautifully for landscapes, portraits, or abstract art.

- Pop-Up Cards: Take your greeting cards to the next level by incorporating pop-up elements. Laser cutting ensures precise folds and cuts, making assembly easier.

- Paper Sculptures: Build intricate 3D sculptures by cutting and assembling individual pieces. From animals to architectural models, the possibilities are endless.

- Wedding Invitations: Design elegant, laser-cut invitations that leave a lasting impression. Use fine details and premium paper to create a luxurious feel.

These projects require more planning and attention to detail, but the results are worth the effort. They also allow you to experiment with combining engraving and cutting techniques for added complexity.

Exploring Multi-Material Creations

Paper isn’t the only material you can use in your projects. Mixing materials adds texture, contrast, and a unique touch to your creations. Here are some ideas to inspire you:

- Paper and Wood: Combine laser-cut paper with wooden frames or bases to create wall art or decorative pieces. The natural warmth of wood complements the delicate look of paper beautifully.

- Paper and Acrylic: Use clear or colored acrylic as a backing for your paper designs. This pairing works well for modern home décor or signage.

- Paper and Fabric: Incorporate fabric elements into your paper projects for a soft, tactile finish. For example, you could add fabric accents to a papercut lantern or greeting card.

Experimenting with multi-material creations not only enhances your designs but also helps you understand how different materials interact with the laser cutter. This knowledge will expand your creative potential and inspire new ideas.

By exploring these DIY laser cut paper projects and beyond, you’ll discover just how versatile and rewarding laser cutting can be. Whether you stick to paper or branch out into mixed materials, the only limit is your imagination.

Laser cutting empowers you to bring your creative visions to life with unmatched precision and versatility. It transforms simple materials into intricate designs, offering endless possibilities for artistic expression. Whether you're crafting delicate paper projects or experimenting with multi-material creations, this technology encourages innovation and efficiency. By exploring different techniques and materials, you can unlock new levels of creativity and refine your skills. Now’s the perfect time to dive in, start your first project, and let your imagination guide you toward exciting new ideas. The only limit is what you dream up!

FAQ

What are the safety requirements for laser cutters?

Safety should always come first when using a laser cutter. Proper ventilation is essential because laser cutting produces fumes and particles that can harm your health. You’ll need to set up an exhaust system or air purifier to keep the air clean. Before purchasing a laser cutter, it’s a good idea to consult with Environmental Health and Safety (EHS) professionals. They can guide you on ventilation options and any registration requirements for your machine. Always keep a fire extinguisher nearby and ensure your workspace is free of flammable materials.

What materials work best with laser cutters?

Laser cutters excel at working with thin sheets of materials like acrylic, wood, and paper. These materials are ideal for creating intricate designs and clean cuts. Most accessible laser cutters, such as LED or CO2 models with power levels under 40W, handle these materials well. However, they’re not suitable for cutting metal due to their lower power output. If you’re unsure about material compatibility, check your machine’s specifications or test a small sample before starting your project.

What challenges might I face when using a laser cutter?

Using a laser cutter can be incredibly rewarding, but it comes with its share of challenges. One common issue is configuring the machine correctly. You may need to refine the mirrors, ensure proper beam focusing, and set up active water cooling systems. Ventilation can also be tricky to optimize. While higher-end machines solve many of these problems, their cost might be prohibitive if you only plan to use the cutter occasionally. Starting with smaller projects and gradually learning the machine’s quirks can help you overcome these hurdles.

How do I maintain a laser cutter?

Regular maintenance keeps your laser cutter running smoothly and safely. Clean the lens and mirrors frequently to prevent dust buildup, which can affect the laser’s precision. Check the ventilation system to ensure it’s functioning properly, as poor ventilation can lead to fire hazards or exposure to harmful fumes. Inspect the machine’s electrical components for wear or damage, and replace filters in the exhaust system as needed. Proper care not only extends the life of your machine but also ensures consistent performance.

Can I cut metal with a laser cutter?

Most consumer-grade laser cutters, especially those with power levels under 40W, aren’t designed for cutting metal. These machines work best with softer materials like wood, acrylic, and paper. Cutting metal requires industrial-grade laser cutters with significantly higher power output. If you’re interested in working with metal, consider outsourcing to a professional service or investing in a specialized machine.

How do I choose the right laser cutter for my needs?

Choosing the right laser cutter depends on your project goals and budget. For beginners, entry-level machines are affordable and easy to use, making them perfect for smaller projects. If you plan to work with thicker materials or create more complex designs, a mid-range or professional-grade machine might be a better fit. Look for features like higher wattage for cutting thicker materials and built-in design software for added convenience. Think about your long-term needs and pick a machine that aligns with your creative vision.

Why is ventilation so important for laser cutting?

Ventilation plays a critical role in laser cutting. The process generates fumes, smoke, and particles that can harm your health if inhaled. Proper ventilation removes these byproducts from the air, keeping your workspace safe. Without it, you risk exposure to toxic substances and potential fire hazards. Always use an exhaust system or air purifier, and make sure your workspace is well-ventilated before starting any project.

What should I do if my laser cutter isn’t cutting properly?

If your laser cutter isn’t performing as expected, start by checking the basics. Ensure the lens and mirrors are clean, as dust can interfere with the laser’s focus. Verify that the material is compatible with your machine and that it’s positioned flat on the cutting bed. Adjust the speed and power settings to match the material’s thickness. If the problem persists, consult your machine’s manual or reach out to the manufacturer for support.

Are there any beginner-friendly projects I can try?

Absolutely! Laser cutting is perfect for beginners looking to explore their creativity. Start with simple projects like custom greeting cards, bookmarks, or papercut lanterns. These projects use affordable materials like paper and allow you to practice precision without feeling overwhelmed. As you gain confidence, you can move on to more complex designs and experiment with different materials.

How can I improve my laser cutting skills?

Improving your laser cutting skills takes practice and experimentation. Start by mastering the basics, like preparing clean designs and setting up your machine correctly. Test different materials and settings to understand how they interact with the laser. Join online communities or forums where experienced users share tips and tricks. Over time, you’ll develop a deeper understanding of the process and unlock new creative possibilities.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding Laser Cutting Machines: Benefits and Drawbacks

Essential Advice for Operating a Meat Cutting Machine