What to Look for in a Jewelry Laser Cut Machine

When selecting a jewelry laser cut machine, you must consider several key factors to ensure optimal performance and value. Cutting speed and precision are crucial for producing intricate designs efficiently. Machines with speeds ranging from 50m/min to 100m/min offer excellent productivity. The power of the laser, typically between 60W to 100W, determines its ability to cut through various materials, including metals like gold and silver. Additionally, the size of the machine should fit your workspace and accommodate the jewelry pieces you plan to create. If you're wondering how much is a jewelry laser cut machine, it's important to note that prices can vary widely based on features and capabilities. Ease of use and software compatibility enhance the user experience, while budget considerations help you balance cost with features.

Cutting Speed and Precision

When you choose a laser cutting machine for jewelry, cutting speed and precision become vital factors. These elements directly impact the quality and efficiency of your production process.

Importance of Speed in Jewelry Production

In jewelry production, speed plays a crucial role. A laser cutting machine with a speed range of 50m/min to 100m/min can significantly enhance productivity. Faster machines allow you to complete more pieces in less time, which is essential for meeting customer demands and maximizing profits. However, it's important to balance speed with quality. If the machine operates too quickly, it might leave unfinished cuts. Conversely, a slower speed can result in noticeable marks on the material. Therefore, finding the right speed setting is key to achieving optimal results.

Achieving Precision in Intricate Designs

Precision is equally important when working with intricate jewelry designs. A high-precision laser engraving machine can achieve spot sizes ranging from 0.1mm to 2mm. This level of precision ensures that even the most delicate patterns are accurately reproduced. The thin laser beam and a frequency of around 20Hz contribute to this precision, allowing you to create detailed and complex designs with ease. Precision not only enhances the aesthetic appeal of the jewelry but also ensures that each piece meets the highest standards of craftsmanship.

By understanding the importance of cutting speed and precision, you can select a laser cutting machine that meets your specific needs. This knowledge will help you produce high-quality jewelry efficiently and effectively.

Power and Wattage

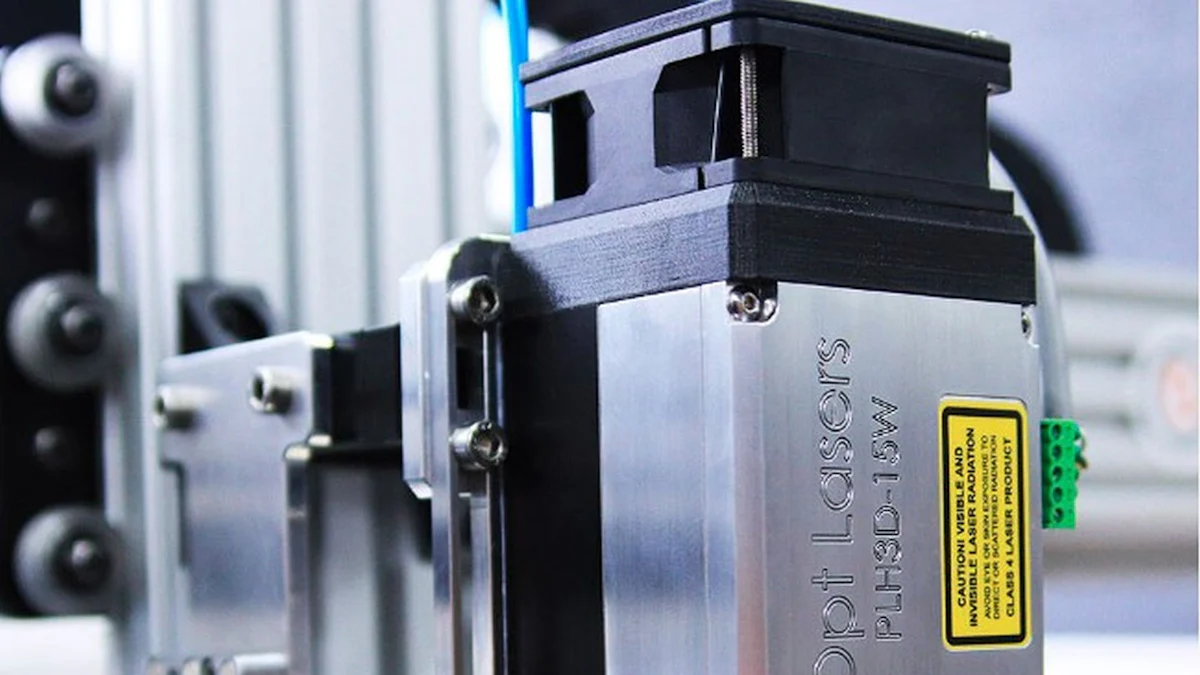

When selecting a jewelry laser cutting machine, understanding power and wattage is crucial. These factors determine the machine's efficiency and capability to handle various materials.

Understanding Wattage and Its Impact

Wattage plays a significant role in the performance of a laser cutting machine. Higher wattage allows the machine to cut through thicker materials with ease. For jewelry applications, a power range between 60W and 100W is often sufficient for intricate designs. However, for more robust tasks, such as cutting thicker metal sheets, you might consider machines with wattage ranging from 1000W to 4000W. This range ensures standardized cutting without compromising the quality of the edges or causing excessive material vaporization.

A laser engraving machine with higher wattage offers greater versatility. It can engrave a wider variety of materials at faster speeds. For instance, a 20W fiber laser engraver is ideal for detailed work on jewelry items, providing precision without sacrificing speed. The power output directly affects the machine's ability to perform efficiently, making it a critical factor in your decision-making process.

Choosing the Right Power for Different Materials

Different materials require different power levels for optimal cutting and engraving. For metals like gold and silver, a laser cutting machine with higher power is necessary to achieve clean cuts. Machines like the Metal Jewelry Laser Cutter are designed to handle these tasks, ensuring that the metal does not warp or suffer damage during the process.

For softer materials or intricate designs, a lower wattage machine with a fine focus lens might be more appropriate. This setup allows for high precision without the risk of overcutting or damaging delicate pieces. When considering the types of laser engraving machines, it's essential to match the machine's power to the specific materials you plan to work with. This ensures both efficiency and quality in your jewelry production.

By understanding the nuances of power and wattage, you can select a laser cutting machine that meets your specific needs. This knowledge will help you produce high-quality jewelry efficiently and effectively.

Size and Capacity

When choosing a jewelry laser cutting machine, you must consider the size and capacity of the machine. These factors determine how well the machine fits into your workspace and its ability to handle various materials.

Assessing Machine Size for Your Workspace

The size of the laser cutting machine is crucial. You need to ensure that it fits comfortably in your workspace. Jewelry laser cutting machines typically have working areas ranging from 400x200mm to 600x600mm. This range allows you to select a machine that suits your specific needs. A larger machine might offer more versatility, but it requires more space. Measure your available area before purchasing to avoid any installation issues.

Consider the layout of your workspace. Ensure that there is enough room for the machine and for you to work comfortably. Adequate space around the machine is essential for safety and ease of operation. A well-organized workspace enhances productivity and reduces the risk of accidents.

Material Capacity and Its Importance

Material capacity refers to the machine's ability to handle different materials and thicknesses. This aspect is vital for producing high-quality jewelry. A laser engraving machine with a higher capacity can cut through various materials like stainless steel, gold, and silver. The ideal power range for these tasks is between 1000W and 4000W. This power ensures standardized cutting and quality edges.

When selecting a laser engraving machine, consider the maximum sheet size it can accommodate. This feature is important if you plan to work on larger projects. A machine with a larger capacity allows you to create intricate designs without compromising on quality. It also provides the flexibility to experiment with different materials and designs.

By understanding the size and capacity of a laser cutting machine, you can make an informed decision. This knowledge helps you choose a machine that fits your workspace and meets your production needs.

Ease of Use and Software Compatibility

When selecting a jewelry laser cutting machine, you should prioritize ease of use and software compatibility. These factors significantly impact your ability to efficiently produce high-quality jewelry pieces.

User-Friendly Features to Look For

A user-friendly laser engraving machine can make a world of difference in your jewelry-making process. Look for machines that offer intuitive interfaces and straightforward controls. Trotec Speedy series machines, for example, are renowned for their user-friendly design. They provide clear guidance on operation, making them accessible even for beginners.

Consider machines with features like touchscreens, which simplify navigation through settings and options. Automatic focus adjustment is another valuable feature. It ensures precise cuts without manual intervention. Machines that offer easy maintenance and quick setup can save you time and effort, allowing you to focus more on creativity and production.

Compatibility with Popular Design Software

Software compatibility is crucial for a seamless workflow. A laser engraving machine that integrates well with popular design software enhances your creative capabilities. Ensure the machine supports software like Adobe Illustrator or CorelDRAW. This compatibility allows you to import designs directly into the machine, streamlining the engraving process.

Advanced software options provide greater control over the cutting and engraving parameters. They enable you to fine-tune settings for different materials and designs. Machines like the Jewelry Laser Cutting Machines often come with proprietary software that offers additional features tailored for jewelry production. These tools can help you achieve intricate designs with precision and efficiency.

By focusing on ease of use and software compatibility, you can select a laser cutting machine that not only meets your technical needs but also enhances your overall jewelry-making experience.

Budget Considerations

When selecting a laser cutting machine for jewelry, budget plays a crucial role. You must weigh the cost against the features offered to ensure you make a wise investment.

Evaluating Cost vs. Features

The price of the laser engraving machine varies significantly based on its features and capabilities. Machines with advanced features, such as higher wattage or larger working areas, often come with a higher price tag. However, these features can enhance productivity and precision, making them worth the investment for serious jewelry makers.

-

Cost Implications: Consider the initial purchase price and the operational expenses. Machines with higher power may consume more electricity, increasing your operational costs.

-

Operational Expenses: Maintenance requirements also affect the overall cost. Some machines require regular servicing, which can add to your expenses over time.

-

Feature Evaluation: Assess which features are essential for your work. If you primarily work with intricate designs, investing in a machine with high precision might be necessary. Conversely, if you focus on larger pieces, a machine with a bigger working area could be more beneficial.

Long-term Value and Investment

Investing in a laser engraving machine should be viewed as a long-term commitment. The right machine can offer significant returns by enhancing your production capabilities and allowing you to create high-quality jewelry.

-

Durability and Reliability: Choose a machine known for its durability. A reliable machine reduces downtime and maintenance costs, providing better value over time.

-

Versatility: A versatile machine that can handle various materials and designs increases your creative potential. This flexibility can lead to new business opportunities and revenue streams.

-

Resale Value: Consider the machine's resale value. High-quality machines from reputable brands often retain their value better, offering a potential return if you decide to upgrade in the future.

By carefully evaluating the cost versus features and considering the long-term value, you can select a laser cutting machine that aligns with your budget and meets your production needs.

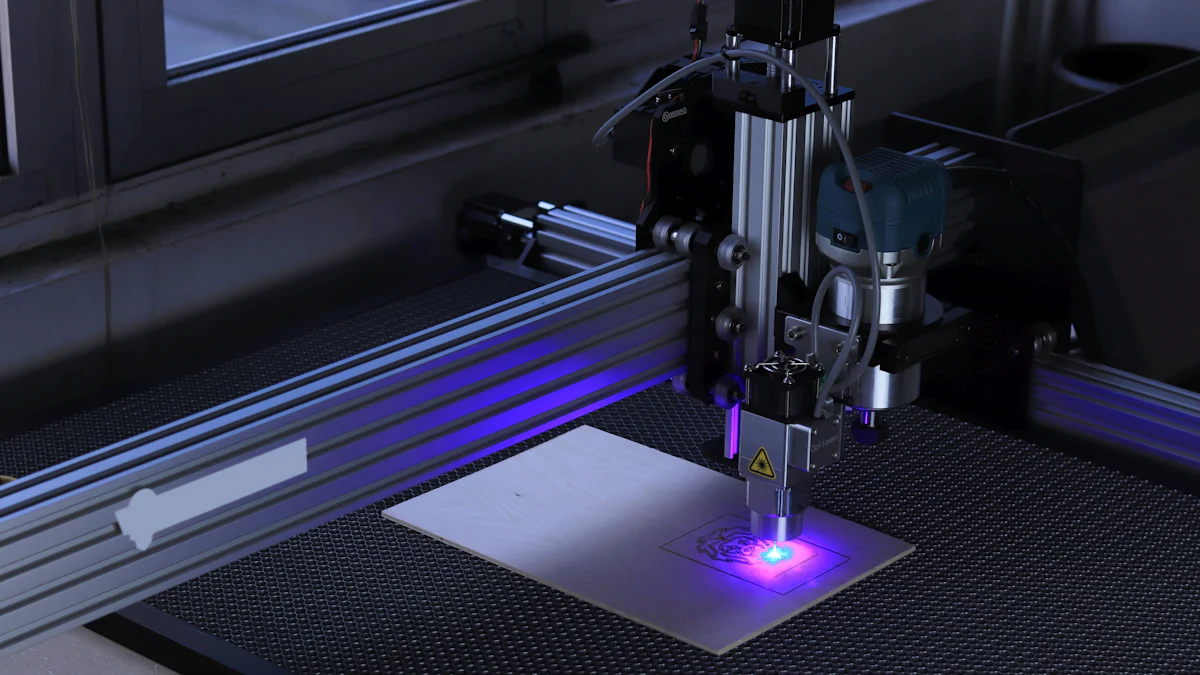

Best Type of Laser Engraving Machine for Jewelry

Choosing the best type of laser engraving machine for jewelry involves understanding the differences between CO2 and Fiber Lasers. Each type offers unique advantages that cater to specific materials and design needs.

CO2 vs. Fiber Lasers

When deciding between CO2 and fiber lasers, consider the materials you plan to work with. CO2 laser engraving machines use a gas mixture to create a laser beam, making them ideal for engraving non-metal materials like plastics and wood. They excel in versatility, allowing you to work on a wide range of non-metallic surfaces. This makes them a great choice if your jewelry designs incorporate diverse materials.

On the other hand, fiber laser engraving machines use a fiber optic cable to generate the laser beam. They are particularly effective for metal engraving due to their power and efficiency. A 30W fiber laser engraver can handle luxury materials such as gold, aluminum, and even marble with precision. If your focus is primarily on metal jewelry, fiber lasers provide the precision and speed necessary for high-quality results.

Rotary Attachments for Versatility

To enhance the versatility of your laser engraving machine, consider adding a rotary attachment. This accessory allows you to engrave cylindrical objects, expanding your creative possibilities. With a rotary attachment, you can easily engrave rings, bracelets, and other round jewelry pieces. This feature is especially beneficial if you aim to offer personalized engravings on curved surfaces.

Rotary attachments work seamlessly with both CO2 and fiber lasers, providing flexibility regardless of the machine type you choose. By incorporating this tool, you can diversify your product offerings and cater to a broader range of customer preferences.

Buying a Laser Engraving Machine

When you're buying a laser engraving machine, thorough research is essential to ensure you make a wise investment. This process involves evaluating the machine's reliability and the level of customer support provided by the manufacturer. Additionally, understanding the safety features and maintenance needs of the machine will help you maintain its longevity and performance.

Researching Reliability and Customer Support

-

Customer Feedback: Start by examining customer reviews and testimonials. Many customers appreciate machines with excellent build quality and performance. They often highlight the importance of receiving the product in perfect condition and having access to excellent support. These insights can guide you in choosing a machine that meets your expectations.

-

Reputable Brands: Consider purchasing from reputable brands known for their reliable products and strong customer support. These brands often offer extended warranties, which can be a worthwhile investment. Although they might charge more, the reliability and support they provide can save you time and money in the long run.

-

Online Channels and Specialized Retailers: Explore online channels and specialized retailers. These platforms offer a wide range of cutting machines and related equipment, catering to the specific needs of jewelry manufacturers and designers. The increasing adoption of e-commerce makes it easier to compare different models and find the best deals.

Safety Features and Maintenance Needs

-

Safety Features: Prioritize machines with robust safety features. Look for models with proper ventilation systems and safety interlocks to protect you during operation. These features are crucial for ensuring a safe working environment, especially when dealing with high-powered lasers.

-

Maintenance Requirements: Understand the maintenance needs of the machine. Regular servicing can prevent breakdowns and extend the machine's lifespan. Some machines require more frequent maintenance, which can add to your operational costs. Choose a model that balances performance with manageable maintenance demands.

By focusing on these aspects, you can confidently navigate the process of buying a laser engraving machine. This approach ensures that you select a machine that not only meets your technical needs but also provides long-term value and support.

When choosing a jewelry laser cut machine, focus on several key factors to ensure you make an informed decision. Consider the machine's cutting speed, precision, power, size, and ease of use. Balancing these features with your budget is crucial. You might wonder how much is a jewelry laser cut machine. Prices vary widely based on capabilities and features. Set a budget and explore options that meet your needs while staying within your price range. Remember, the right machine should enhance your production capacity and offer long-term value.

FAQ

How are jewelry laser cutting machines different from traditional cutting methods?

Jewelry laser cutting machines excel in creating fine and intricate designs that traditional cutting methods cannot achieve. These machines use precise laser technology to cut with high accuracy, allowing you to produce detailed patterns and complex shapes effortlessly.

What types of materials can you use with jewelry laser cutting machines?

You can use a variety of materials with jewelry laser cutting machines, including gold, silver, stainless steel, rubber, plastic, acrylic, and aluminum. This versatility makes them ideal for crafting diverse jewelry pieces.

What industries benefit from using jewelry laser cutting machines?

Industries such as machine manufacturing, hardware, aerospace, and jewelry benefit significantly from the high-quality cutting provided by jewelry laser cutting machines. These machines enhance production efficiency and precision across various applications.

What factors should you consider when buying a laser cutting machine for jewelry?

When purchasing a laser cutting machine for jewelry, consider factors like cutting speed, precision, and your specific jewelry-making needs. These elements ensure that the machine aligns with your production goals and delivers optimal results.

Are jewelry laser cutting machines easy to use?

Yes, many jewelry laser cutting machines come with user-friendly interfaces and features. These machines often include intuitive controls and software compatibility, making them accessible even for beginners in the jewelry-making industry.

How does the power of a laser cutting machine affect its performance?

The power of a laser cutting machine, measured in wattage, directly impacts its ability to cut through various materials. Higher wattage allows for cutting thicker materials with ease, while lower wattage is suitable for delicate and intricate designs.

Can you use a jewelry laser cutting machine for engraving?

Yes, jewelry laser cutting machines can also engrave designs onto materials. This dual functionality allows you to create both cuts and engravings, expanding your creative possibilities in jewelry design.

What safety features should you look for in a jewelry laser cutting machine?

When selecting a jewelry laser cutting machine, prioritize models with robust safety features. Look for proper ventilation systems and safety interlocks to ensure a safe working environment during operation.

How do you maintain a jewelry laser cutting machine?

Regular maintenance is crucial for keeping your jewelry laser cutting machine in optimal condition. Follow the manufacturer's guidelines for cleaning and servicing the machine to prevent breakdowns and extend its lifespan.

Is investing in a jewelry laser cutting machine worth it?

Investing in a jewelry laser cutting machine can offer significant returns by enhancing your production capabilities and allowing you to create high-quality jewelry. Consider the long-term value and potential for increased revenue when making your decision.

See Also

Comparative Guide To Understanding Laser Cutting Machines

Maximizing Efficiency With Your Laser Cutting Machine

Guidelines For Selecting The Ideal Water Jet Cutter