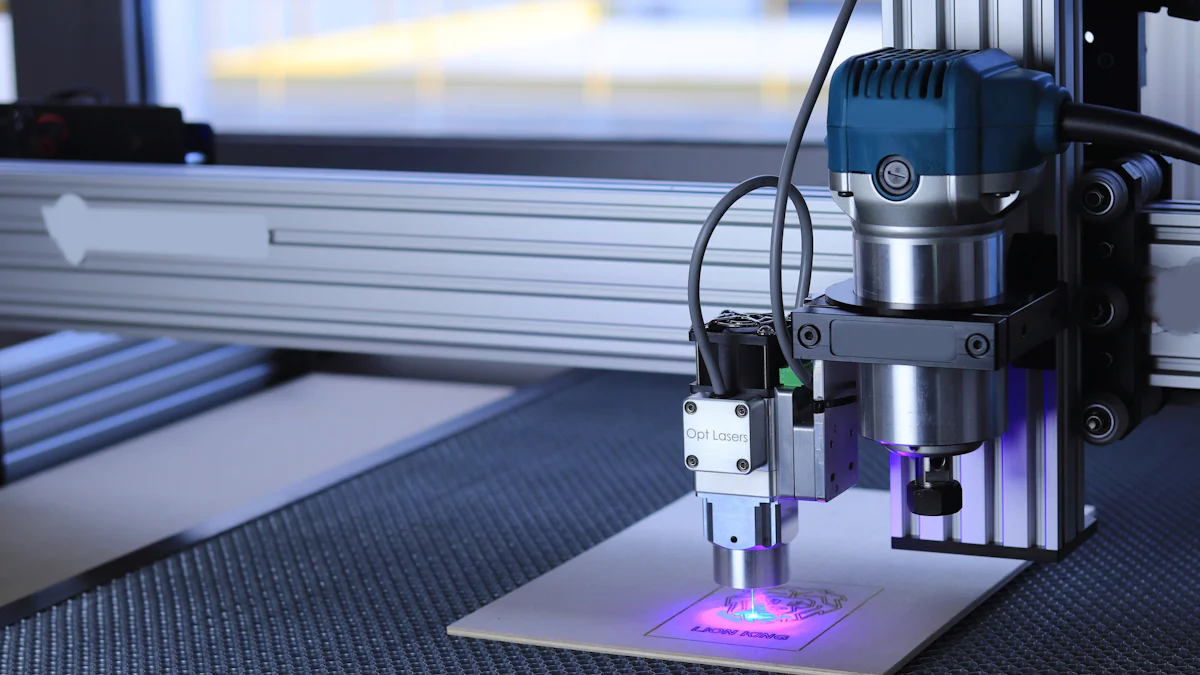

Exploring How Works a Laser Cutting Machine

Laser cutting machines bring unmatched precision and control to modern manufacturing, showcasing how works a laser cutting machine. These machines use a high-powered laser beam to melt, vaporize, or burn materials, creating intricate designs with remarkable accuracy. The laser cutting process relies on CNC laser cutting systems to guide the laser beam along precise paths, ensuring consistent results every time. Assist gases, such as oxygen or nitrogen, enhance the efficiency of the process by improving cut quality and reducing waste. This combination of advanced technology and automation makes laser cutting an essential tool for industries requiring speed and precision.

The Science Behind Laser Cutting Technology

Understanding the science behind laser cutting helps you appreciate the precision and versatility of this advanced process. By exploring how lasers are generated, focused, and interact with materials, you can gain deeper insights into how works a laser cutting machine.

How Lasers Are Generated

Lasers rely on a fascinating principle called stimulated emission. This process creates a coherent light source, meaning all the light waves move in the same direction and phase. This coherence is what gives the laser beam its incredible focus and power.

To generate a laser, three key components work together:

- Gain Medium: This material amplifies light energy. It can be a gas (like CO₂), a solid (like crystals), or a fiber doped with rare-earth elements.

- Energy Source: Often called the pump, this supplies energy to the gain medium. It can come from electrical currents, flash lamps, or diodes.

- Optical Resonator: Mirrors inside the laser device reflect light back and forth through the gain medium, amplifying it until it forms a powerful beam.

These components combine to produce the high-energy light that powers laser cutting technology. The ability to control this light with precision makes lasers ideal for cutting tasks.

Focusing the Laser Beam

Once generated, the laser beam must be concentrated to achieve the energy density needed for cutting. Lenses and mirrors play a crucial role in this step. They focus the beam onto a tiny spot, increasing its intensity.

This focused beam delivers immense heat to a specific area, enabling precise cuts. The high energy density ensures that even intricate designs can be executed with remarkable accuracy. This level of control is why cnc laser cutting systems are so effective in industrial and creative applications.

Material Interaction

When the laser beam meets the material, it generates intense heat that melts, vaporizes, or burns the surface. This thermal process allows the laser to cut through a wide range of materials, including metals, plastics, and wood.

Assist gases, such as oxygen and nitrogen, enhance this interaction. Oxygen reacts with the material, increasing the cutting speed. Nitrogen, on the other hand, prevents oxidation, resulting in cleaner edges. These gases improve the quality of the cut and reduce the need for post-processing.

According to a study published in Applied Sciences, optimizing laser parameters enables precise cutting of both flat and complex shapes across various materials, from thick steel to delicate fabrics.

The combination of advanced laser technology and assist gases ensures that laser cutting delivers consistent results, whether you're working on industrial projects or artistic creations.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each designed to meet specific needs. Understanding these types helps you choose the right machine for your projects. Below, we explore the three main categories of laser cutting machines and their unique features.

CO2 Laser Cutting Machines

Mechanism: Using carbon dioxide gas as the gain medium

CO2 laser cutting machines rely on a vacuum-sealed tube filled with carbon dioxide gas. When electrified, the gas molecules generate a powerful laser beam. This mechanism has been a cornerstone of laser technology for decades due to its reliability and efficiency.

The laser beam produced by CO2 machines is highly effective for cutting and engraving non-metal materials. The process ensures smooth and precise results, making it a popular choice for various industries.

Best suited for non-metal materials like wood, acrylic, and plastics

CO2 laser cutting machines excel at working with materials such as wood, acrylic, and plastics. These machines are ideal for applications requiring intricate designs or detailed engravings. For example:

- Woodworking: Creating custom furniture or decorative pieces.

- Acrylic fabrication: Producing signage or display items.

- Plastic cutting: Shaping components for packaging or consumer goods.

Their versatility and precision make CO2 machines indispensable for creative and industrial tasks.

Fiber Laser Cutting Machines

Mechanism: Using optical fibers doped with rare-earth elements

Fiber laser cutting machines utilize optical fibers infused with rare-earth elements to amplify light energy. This advanced mechanism generates a laser beam with exceptional power and focus. Fiber laser technology stands out for its efficiency and ability to handle demanding tasks.

The laser beam from fiber machines is highly concentrated, allowing it to cut through tough materials with ease. This makes it a go-to option for industries requiring high precision and durability.

Ideal for cutting metals and high-precision applications

Fiber laser cutting machines are best suited for cutting metals, including steel, aluminum, and brass. Their precision also makes them ideal for intricate designs in industrial manufacturing. Common applications include:

- Metal fabrication: Shaping parts for automotive and aerospace industries.

- Electronics: Producing components for circuit boards and devices.

- Jewelry making: Crafting detailed and delicate designs.

These machines deliver consistent results, ensuring high-quality output for every project.

Crystal Laser Cutting Machines

Mechanism: Using crystals like Nd:YAG or Nd:YVO4 as the gain medium

Crystal laser cutting machines use specialized crystals, such as Nd:YAG (neodymium-doped yttrium aluminum garnet) or Nd:YVO4 (neodymium-doped yttrium orthovanadate), to generate their laser beam. This mechanism produces a highly focused and powerful beam, making it suitable for heavy-duty tasks.

Crystal-based laser technology is known for its precision and ability to handle high-power applications. These machines are often used in industries where accuracy and strength are critical.

Applications in high-power cutting and engraving tasks

Crystal laser cutting machines excel in high-power tasks, including cutting thick materials and engraving intricate patterns. They are widely used in industries such as:

- Automotive and aerospace: Cutting durable components for vehicles and aircraft.

- Metal engraving: Adding detailed designs to tools or machinery.

- Scientific research: Creating microstructures for advanced studies.

Their ability to handle challenging materials makes crystal laser cutting machines a valuable asset in manufacturing and research.

"The versatility of laser cutting machines allows them to cater to diverse industries, from creative arts to heavy manufacturing."

By understanding the mechanisms and applications of these laser cutting machines, you can select the one that best suits your needs. Whether you work with wood, metals, or specialized materials, laser technology offers a solution tailored to your requirements.

Practical Applications of Laser Cutting Machines

Laser cutting machines have revolutionized various industries by offering high-quality cutting solutions for a broad spectrum of applications. Their ability to deliver precision, speed, and versatility makes them indispensable in both industrial and creative fields. Below, we explore the real-world applications of laser cutting technology and how it continues to shape modern manufacturing and design.

Industrial Manufacturing

Cutting and shaping metals for automotive and aerospace industries

In industrial manufacturing, laser cutting machines play a pivotal role in producing components with unmatched accuracy. The automotive and aerospace industries rely heavily on this technology for precision sheet metal cutting. For example, manufacturers use laser beams to shape metals like steel and aluminum into intricate cuts required for vehicle frames, aircraft panels, and engine components.

The demand for automobiles has surged due to urbanization and rising income levels, driving the need for advanced manufacturing techniques. Laser technology meets this demand by enabling faster production cycles and reducing material waste. Since the late 1960s, companies like Boeing began using laser-drilled dies, showcasing the early adoption of laser cutting in aerospace manufacturing. Today, this technology ensures that even the most complex shapes meet stringent industry standards.

Creating intricate designs for electronics and machinery

Electronics and machinery industries also benefit from the precision of laser cutting machines. The ability to cut a wide range of materials, including metals and plastics, allows manufacturers to create detailed designs for circuit boards, gears, and machine parts. Laser beams provide the control needed to achieve consistent results, even for small-scale components. This level of precision ensures that every piece fits perfectly, enhancing the overall performance of the final product.

Creative and Artistic Fields

Engraving designs on wood, glass, and leather

Laser cutting machines have opened new possibilities for artists and designers. The focused laser beam can engrave intricate patterns on materials like wood, glass, and leather. Whether you’re creating custom furniture, decorative glassware, or personalized leather goods, laser technology offers unparalleled accuracy and detail.

For example, artisans use laser cutting to craft unique designs on wooden surfaces, adding a touch of elegance to home décor. Similarly, glass engraving with lasers produces clean, precise lines that elevate the aesthetic appeal of products. This versatility makes laser cutting a favorite tool for creative professionals.

Producing custom jewelry and decorative items

Jewelry makers and crafters also leverage laser cutting machines to produce custom pieces. The ability to handle complex shapes and fine details allows designers to create intricate patterns in metals, acrylics, and other materials. From delicate necklaces to ornate decorative items, laser technology ensures that every piece stands out with precision and quality. This application highlights the benefits of laser cutting in delivering high-quality, personalized solutions for artistic endeavors.

Medical and Scientific Applications

Precision cutting for medical devices and implants

In the medical field, laser cutting machines provide advanced manufacturing solutions for creating devices and implants. The precision of laser beams ensures that surgical tools, stents, and prosthetics meet exact specifications. This level of accuracy is critical for ensuring the safety and effectiveness of medical equipment.

For instance, laser technology enables the production of micro-sized components used in minimally invasive surgeries. These components require intricate cuts and smooth edges, which only laser cutting can achieve. By delivering consistent results, this technology supports the development of innovative medical solutions.

Use in research for creating microstructures

Scientific research also benefits from the applications of laser cutting technology. Researchers use laser beams to create microstructures for experiments and prototypes. These structures often involve complex shapes and require extreme precision, making laser cutting an ideal choice.

For example, scientists working on advanced materials or nanotechnology rely on laser cutting machines to fabricate tiny, detailed components. This capability accelerates innovation and expands the possibilities for scientific discovery.

"The versatility of laser cutting machines allows them to cater to diverse industries, from heavy manufacturing to creative arts and medical advancements."

By understanding the real-world applications of laser cutting, you can see how works a laser cutting machine to transform industries and improve processes. Whether you’re in industrial manufacturing, artistic design, or scientific research, laser technology offers solutions tailored to your needs.

Laser cutting machines empower you to achieve precision and versatility in cutting and engraving tasks. By understanding how works a laser cutting machine, you can see how laser technology combines laser generation, beam focusing, and material interaction to deliver exceptional results. Each type of machine caters to specific needs, ensuring flexibility across industries. From shaping metals in automotive manufacturing to crafting intricate designs in creative arts, laser cutting has transformed modern production. Explore this advanced technology further or consult experts to discover how it can elevate your projects and streamline your processes.

FAQ

What is laser cutting, and how does it work?

Laser cutting uses a high-powered laser beam to cut, melt, or vaporize materials. The process involves focusing the laser beam onto a specific area, generating intense heat to create precise cuts. A CNC system controls the movement of the laser, ensuring accuracy and repeatability. Assist gases like oxygen or nitrogen improve the quality of the cut by removing debris and preventing oxidation.

What materials can a laser cutting machine handle?

Laser cutting machines work with a wide range of materials. These include metals like steel, aluminum, and brass, as well as non-metals such as wood, acrylic, plastics, leather, and glass. The type of material you can cut depends on the machine you use. For example, CO₂ lasers excel at cutting non-metals, while fiber lasers are ideal for metals.

How do I choose the right laser cutting machine for my needs?

To choose the right machine, consider the materials you plan to work with and the level of precision required. CO₂ lasers are best for non-metals like wood and acrylic. Fiber lasers are better suited for metals and high-precision tasks. Crystal lasers handle heavy-duty applications, such as cutting thick materials or engraving intricate patterns. Evaluate your project requirements to make an informed decision.

What are the advantages of using assist gases in laser cutting?

Assist gases enhance the cutting process in several ways. Oxygen increases cutting speed by reacting with the material, while nitrogen prevents oxidation, resulting in cleaner edges. These gases also help remove molten material from the cut area, improving overall efficiency and reducing the need for post-processing.

Is laser cutting safe to use?

Yes, laser cutting is safe when proper precautions are followed. Machines come equipped with safety features like enclosed cutting areas and emergency stop buttons. Always wear protective eyewear and ensure the workspace is well-ventilated. Following the manufacturer’s guidelines minimizes risks and ensures safe operation.

Can laser cutting machines engrave as well as cut?

Yes, laser cutting machines can engrave materials in addition to cutting them. By adjusting the laser’s power and speed settings, you can create detailed engravings on surfaces like wood, glass, leather, and metals. This versatility makes laser machines valuable for both industrial and artistic applications.

How precise are laser cutting machines?

Laser cutting machines offer exceptional precision, often achieving tolerances as tight as ±0.1 mm. The focused laser beam allows for intricate designs and detailed cuts, making these machines ideal for industries like electronics, jewelry, and aerospace. The use of CNC systems ensures consistent results across multiple projects.

What maintenance does a laser cutting machine require?

Regular maintenance keeps your machine running efficiently. Clean the lenses and mirrors to ensure optimal beam focus. Check and replace worn parts, such as nozzles and filters. Keep the machine’s software updated and inspect the cooling system to prevent overheating. Following a maintenance schedule extends the machine’s lifespan and ensures consistent performance.

How does laser cutting compare to other cutting methods?

Laser cutting offers several advantages over traditional methods like mechanical cutting or waterjet cutting. It provides higher precision, faster speeds, and cleaner edges. Unlike mechanical cutting, laser cutting doesn’t cause tool wear, and it requires minimal post-processing. While waterjet cutting works well for thicker materials, laser cutting excels in speed and detail.

Can laser cutting machines help my business grow?

Absolutely. Laser cutting machines bring precision, speed, and versatility to your operations. Whether you’re in manufacturing, design, or research, these machines streamline production and open new possibilities. They allow you to create high-quality products, reduce waste, and meet customer demands efficiently. Investing in laser technology can give your business a competitive edge.

"Laser machines have the power to transform your business with their precision and adaptability. Whether you're starting out or upgrading, understanding their capabilities helps you make the most of this technology."

See Also

Understanding The Basics Of Laser Cutting Machines

The Functionality Of CNC Laser Cutting Machines

Exploring The Advantages And Disadvantages Of Laser Cutting