How to Work a Laser Cutting Machine Easily

Mastering how to work a laser cutting machine can revolutionize your crafting or manufacturing endeavors. This comprehensive guide will walk you through the process of operating a laser cutting machine effortlessly. Start by familiarizing yourself with the machine's components and choosing the appropriate materials. Proper alignment and calibration are essential for achieving optimal performance. Tutorials frequently highlight the significance of conducting test cuts to ensure precision. By adhering to these steps, you can attain high-quality results while reducing errors. Always prioritize safety by following the recommended guidelines when using a laser cutter.

Understanding Laser Cutting Machines

To effectively operate a laser cutting machine, you must first understand its components and types. This knowledge will help you make informed decisions and achieve precise results.

Components of a Laser Cutting Machine

A laser cutting machine consists of several key components that work together to cut and engrave materials with precision.

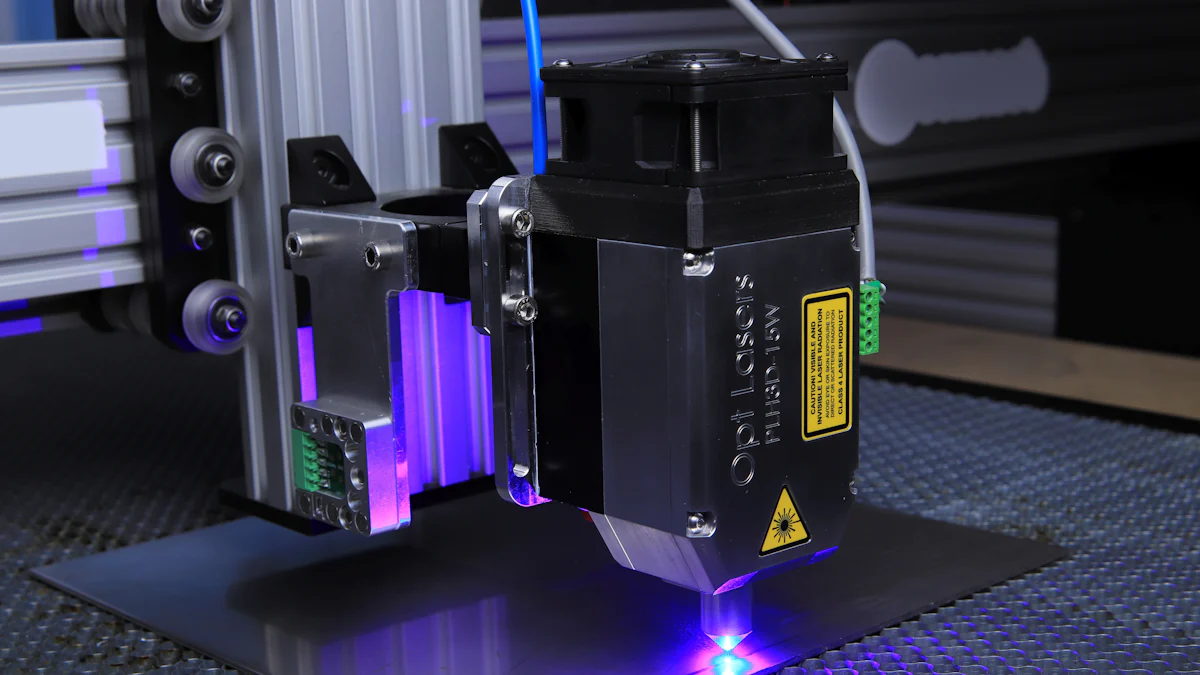

Laser Source

The laser source is the heart of the laser cutter. It generates the high-power laser beam used for cutting and engraving. Different types of laser sources offer varying levels of power and efficiency, making them suitable for different applications.

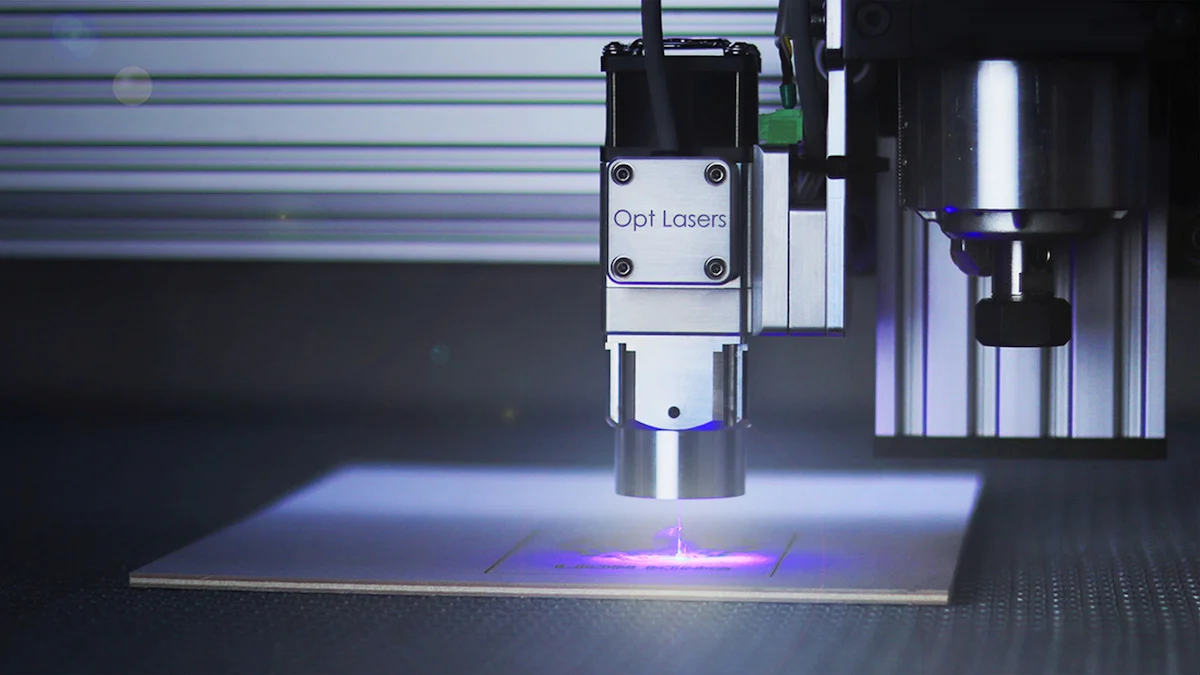

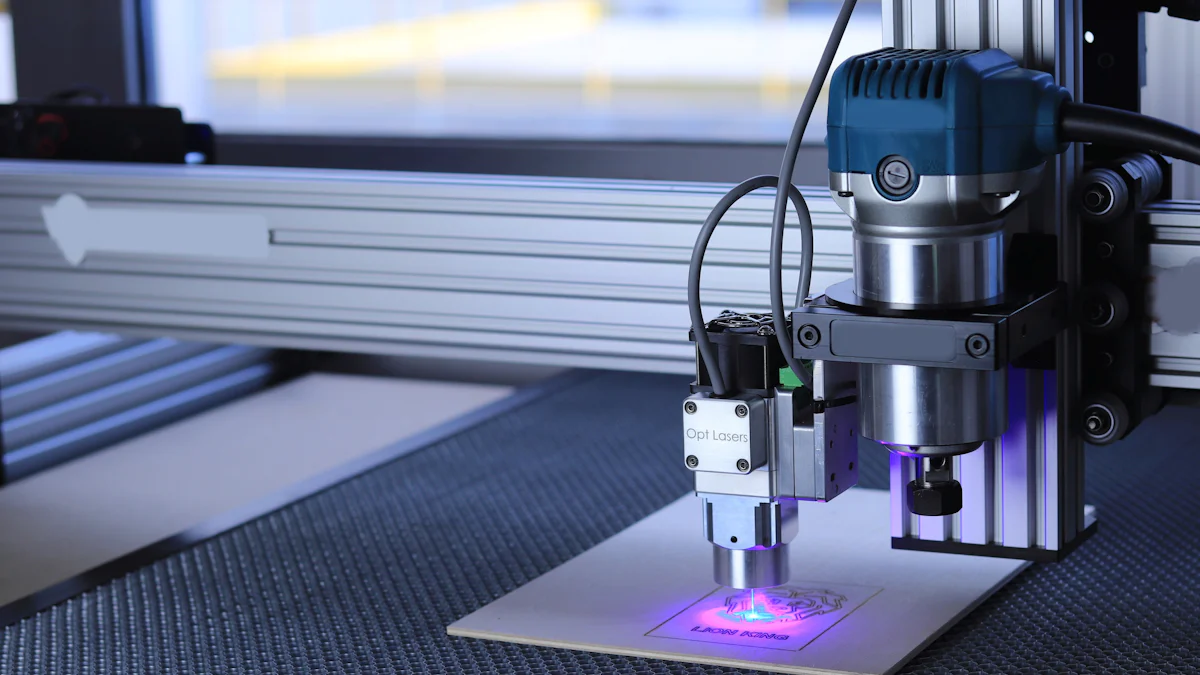

Cutting Bed

The cutting bed is where you place the material to be cut or engraved. It provides a stable surface for the laser to work on. The size and type of the cutting bed can vary depending on the machine's design and intended use.

Control Panel

The control panel allows you to operate the laser cutting machine. It includes controls for adjusting settings such as power, speed, and focus. Familiarizing yourself with the control panel is crucial for achieving the desired results.

Types of Laser Cutting Machines

Different types of laser cutting machines are available, each with unique characteristics and applications.

CO2 Lasers

CO2 lasers are widely used in laser cutting machines. They are ideal for cutting non-metal materials like wood, acrylic, and plastic. These lasers offer excellent precision and are commonly used for laser engraving as well.

Fiber Lasers

Fiber lasers are known for their efficiency and ability to cut metals. They are suitable for high-speed cutting and are often used in industrial applications. Fiber lasers provide clean cuts with minimal burrs, making them a popular choice for metalworking.

Nd:YAG Lasers

Nd:YAG lasers are versatile and can cut both metals and non-metals. They are often used in applications requiring high precision and tight tolerances. These lasers are also effective for engraving intricate designs on various materials.

Understanding these components and types will help you choose the right laser cutting machine for your needs. Whether you're cutting metal or non-metal materials, selecting the appropriate machine ensures optimal performance and quality results.

Selecting and Preparing Materials

Choosing the right material is crucial when working with a laser cutting machine. The material you select will determine the quality and safety of your project. Understanding material compatibility and thickness considerations will help you make informed decisions.

Choosing the Right Material

Material Compatibility

When selecting materials for laser cutting, you must consider their compatibility with the laser. Not all materials are suitable for laser cutting. For instance, acrylic and wood are popular choices due to their excellent cutting properties. However, some materials, like PVC, should be avoided. Cutting PVC releases harmful gases, such as hydrochloric gas, which can pose health risks. Always research the materials you plan to use to ensure they are safe and compatible with your laser cutter.

Thickness Considerations

The thickness of the material also plays a significant role in laser cutting. Thicker materials require more power and slower cutting speeds. Acrylic and wood come in various thicknesses, and each thickness may require different settings on your laser cutter. For precise cuts, you should test different settings to find the optimal balance between power and speed. This ensures clean edges and reduces the risk of burning or charring the material.

Preparing Materials for Cutting

Proper preparation of materials is essential for achieving high-quality results. Cleaning and securing the material on the cutting bed are two critical steps in this process.

Cleaning the Material

Before cutting, you should clean the material to remove any dust, dirt, or residues. These contaminants can affect the quality of the cut and may cause the laser to reflect or scatter. Use a soft cloth or a mild cleaning solution to wipe down the surface of the acrylic or wood. Ensuring a clean surface will help the laser cutter perform optimally and produce precise cuts.

Securing the Material on the Cutting Bed

Once the material is clean, you need to secure it on the cutting bed. Properly securing the material prevents movement during the cutting process, which can lead to misaligned cuts. Use clamps or adhesive mats to hold the acrylic or wood in place. Make sure the material lies flat on the cutting bed to avoid any uneven cuts. By securing the material properly, you can achieve consistent and accurate results.

Selecting and preparing the right material is a vital step in laser cutting. By understanding material compatibility and thickness considerations, you can choose the best materials for your projects. Proper cleaning and securing of the material ensure that your laser cutting machine operates efficiently, resulting in high-quality cuts.

Setting Up the Laser Cutting Machine

Setting up a laser cutting machine correctly is essential for achieving precise cuts and maintaining safety. This process involves configuring power and speed settings, as well as focusing the laser accurately. By understanding these steps, you can optimize the performance of your laser cutter and ensure high-quality results.

Configuring Power and Speed Settings

Proper configuration of power and speed settings is crucial for effective laser cutting. These settings determine how the laser interacts with the material, affecting the quality and efficiency of the cut.

Adjusting Power Levels

Adjusting the power levels of your laser cutter is the first step in setting up the machine. The power level determines the intensity of the laser beam. Higher power levels are suitable for cutting thicker materials, while lower levels work well for thinner materials. You should always start with the manufacturer's recommended settings and make adjustments based on the material's response. This approach helps prevent damage to both the material and the laser cutting machine.

Setting Cutting Speed

Setting the cutting speed is equally important. The speed at which the laser moves across the material affects the precision and quality of the cut. Faster speeds may result in less accurate cuts, while slower speeds can lead to overheating and burning. You should experiment with different speeds to find the optimal setting for your specific material. This trial-and-error method ensures that you achieve clean and precise cuts every time.

Focusing the Laser

Focusing the laser is a critical step in the setup process. Proper focus ensures that the laser beam is concentrated on the material, allowing for precise and efficient cutting.

Manual Focus Adjustment

Manual focus adjustment involves physically adjusting the laser cutter's lens to achieve the correct focus. You should follow the manufacturer's instructions to set the focus manually. This process typically involves adjusting the distance between the lens and the material until the laser beam is sharp and concentrated. Manual focusing requires patience and precision, but it is essential for achieving high-quality cuts.

Automatic Focus Systems

Many modern laser cutting machines come equipped with automatic focus systems. These systems use sensors to automatically adjust the focus based on the material's thickness and type. Automatic focus systems simplify the setup process and reduce the risk of human error. If your laser cutter has this feature, you should familiarize yourself with its operation to take full advantage of its benefits.

By carefully configuring power and speed settings and focusing the laser, you can optimize the performance of your laser cutting machine. These steps are essential for achieving precise cuts and ensuring the longevity of your equipment. Always prioritize safety and follow the manufacturer's guidelines when adjusting the machine.

Running a Test Cut on the Laser Cutter

Running a test cut is a crucial step in the laser cutting process. It helps you verify settings and adjust for optimal results, ensuring high cutting quality. By conducting a test cut, you can prevent errors and achieve the desired outcome.

Importance of Test Cuts

Test cuts play a vital role in the operation procedures of laser cutting. They allow you to fine-tune the machine settings and ensure everything is running smoothly.

Verifying Settings

Before you proceed with your final project, it's essential to verify the settings on a scrap piece of material. This practice helps you confirm that the power, speed, and frequency are correctly configured. By testing different settings, you can understand how they affect the material's appearance and cutting quality. This step is crucial for avoiding mistakes and ensuring a successful cut.

Adjusting for Optimal Results

Once you've verified the settings, you may need to make adjustments to achieve optimal results. Experiment with parameters like power and speed until you find the sweet spot for your material and design. Adjusting these settings ensures that the laser cutter performs efficiently and produces clean cuts. This process helps you attain the best possible cutting quality for your project.

Analyzing Test Cut Results

After running a test cut, analyzing the results is essential for ensuring the cutting quality meets your expectations. This analysis helps you identify any issues and make necessary adjustments.

Checking for Clean Edges

One of the primary indicators of cutting quality is the cleanliness of the edges. Examine the test cut for any rough or uneven edges. Clean edges indicate that the laser cutter is operating correctly and that the settings are appropriate for the material. If you notice any imperfections, consider adjusting the power or speed to improve the cut.

Ensuring Proper Depth

Another critical aspect of analyzing test cut results is ensuring the proper depth of the cut. The depth should match your project's requirements without overcutting or undercutting the material. Check the test cut to confirm that the laser has penetrated the material to the desired depth. If the depth is incorrect, adjust the settings accordingly to achieve the perfect cut.

By running a test cut and analyzing the results, you can optimize the laser cutting process and ensure high cutting quality. This step is essential for achieving precise cuts and maintaining the efficiency of your laser cutting machine. Always prioritize this part of the operation procedures to enhance your project's success.

Executing the Final Cut with the Laser Cutting Machine

When executing the final cut with a laser cutting machine, you must pay close attention to the entire process. This ensures that the final product meets your expectations and maintains high quality.

Monitoring the Cutting Process

Monitoring the cutting process is crucial for achieving precise results. By keeping an eye on the laser cutter, you can quickly identify and address any issues that arise.

Observing the Cut

You should always observe the cut as it progresses. Watching the laser cutter in action allows you to spot any irregularities, such as scorching or deviations in the cut path. If you notice any problems, you can pause the machine and make necessary adjustments. This proactive approach helps prevent material wastage and ensures a clean, accurate cut.

Making Real-time Adjustments

During the cutting process, you may need to make real-time adjustments. If you detect anomalies like material movement or cutting deviations, promptly pause the laser cutter. Adjust the settings or reposition the material to correct the issue. This hands-on approach ensures that the final cut aligns with your design specifications and maintains the quality of the finished product.

Post-Cut Procedures

After completing the cut, you must follow specific post-cut procedures to ensure the final product's quality and safety.

Removing the Material

Carefully remove the material from the laser cutting machine once the cut is complete. Handle the material gently to avoid damaging the edges or surfaces. Use appropriate tools or gloves to protect yourself from sharp edges or residual heat. Proper removal ensures that the final product remains intact and ready for further processing or use.

Inspecting the Final Product

Inspect the final product thoroughly after removing it from the laser cutter. Check for clean edges and ensure that the cut depth matches your requirements. Look for any burrs or rough surfaces that may need additional processing. If necessary, perform post-cut processing, such as cleaning or deburring, to enhance the product's quality. This careful inspection guarantees that the final product meets your standards and is ready for its intended application.

By diligently monitoring the cutting process and following post-cut procedures, you can achieve high-quality results with your laser cutting machine. These steps are essential for ensuring precision and maintaining the integrity of your projects.

Maintenance Tips and Safety Precautions for Laser Cutting

Maintaining your laser cutter and adhering to safety precautions are essential for ensuring its longevity and safe operation. Regular maintenance keeps the machine in optimal condition, while safety measures protect you from potential hazards.

Regular Maintenance Practices

Regular maintenance is crucial for the efficient operation of your laser cutter. By following these practices, you can prevent unexpected breakdowns and extend the machine's lifespan.

Cleaning the Machine

You should clean your laser cutter regularly to remove dust, debris, and residue from previous cuts. These contaminants can affect the machine's performance and the quality of your cuts. Use a soft cloth or brush to clean the cutting bed and other accessible parts. Pay special attention to the laser lens, as dirt can scatter the laser beam and reduce cutting precision.

Checking for Wear and Tear

Inspect your laser cutter for signs of wear and tear. Look for any loose or damaged components, such as belts, pulleys, and screws. Regularly check the alignment of the laser beam to ensure it remains accurate. If you notice any issues, address them promptly to prevent further damage. Keeping a maintenance log can help you track when each part was last checked or replaced.

Essential Safety Measures

Safety should always be your top priority when operating a laser cutter. Implementing these safety measures will help you avoid accidents and protect yourself from harm.

Wearing Protective Gear

Always wear protective gear when using a laser cutter. Safety glasses protect your eyes from the intense laser beam, while gloves shield your hands from sharp edges and hot surfaces. Never bypass safety interlocks or remove protective covers, as they are designed to prevent accidental exposure to the laser.

Ensuring Proper Ventilation

Proper ventilation is vital when operating a laser cutter. The cutting process produces smoke, fumes, and particulates that can be harmful if inhaled. Ensure your workspace has adequate ventilation to remove these byproducts. Use an air extraction system to vent the air outside, reducing the risk of respiratory issues and maintaining a safe environment.

Fire safety is another critical aspect to consider. Always keep a fire extinguisher nearby and ensure it is within its use date. Never leave the laser cutter unattended while it is operating, as this increases the risk of a fire starting unnoticed. Regularly check the machine for any signs of overheating or unusual smells, and address them immediately.

By following these maintenance tips and safety precautions, you can ensure the safe and efficient operation of your laser cutter. Regular maintenance keeps the machine in top condition, while safety measures protect you and those around you from potential hazards.

Operating a laser cutting machine becomes straightforward when you follow essential steps. Begin by understanding the machine's components and selecting suitable materials. Proper setup, including power and speed adjustments, ensures precise cuts. Always conduct test cuts to verify settings. Safety remains paramount. Wear protective gear and maintain a clean, ventilated workspace. Regular maintenance extends the machine's lifespan and enhances performance. By adhering to these practices, you achieve high-quality results while minimizing risks. Remember, safety protocols and consistent upkeep are crucial for efficient and safe laser cutting operations.

FAQ

What Materials Can You Cut Using a Laser Cutter?

You can cut a wide range of materials with a laser cutter. Common choices include acrylic, wood, paper, and fabric. Each material reacts differently to the laser, so it's important to adjust the settings accordingly. Avoid materials like PVC, as they release harmful gases when cut.

How Do You Choose the Right Laser Cutting Machine?

Choosing the right laser cutting machine depends on your specific needs. Consider the types of materials you plan to cut and the thickness of those materials. CO2 lasers work well for non-metals, while fiber lasers are better for metals. Evaluate the machine's power, speed, and precision capabilities to ensure it meets your requirements.

How Do You Ensure Safety While Using a Laser Cutter?

Safety is crucial when using a laser cutter. Always wear protective gear, such as safety glasses and gloves. Ensure your workspace has proper ventilation to remove fumes and smoke. Keep a fire extinguisher nearby and never leave the machine unattended during operation.

What Are the Key Steps in Setting Up a Laser Cutter?

Setting up a laser cutter involves several key steps. First, configure the power and speed settings based on the material you're using. Next, focus the laser accurately, either manually or using an automatic system. Finally, run a test cut to verify the settings before proceeding with your final project.

Why Is Running a Test Cut Important?

Running a test cut is essential for verifying your machine's settings. It helps you confirm that the power, speed, and focus are correctly configured. By analyzing the test cut results, you can make necessary adjustments to achieve clean and precise cuts.

How Do You Maintain a Laser Cutting Machine?

Regular maintenance keeps your laser cutter in optimal condition. Clean the machine regularly to remove dust and debris. Inspect components for wear and tear, and replace any damaged parts promptly. Keeping a maintenance log can help track when each part was last checked or replaced.

Can You Cut Metal with a Laser Cutter?

Yes, you can cut metal with a laser cutter, but you need the right type of laser. Fiber lasers are ideal for cutting metals due to their efficiency and precision. Ensure your machine is equipped to handle the specific type and thickness of metal you plan to cut.

What Should You Do If the Laser Cutter Isn't Cutting Properly?

If your laser cutter isn't cutting properly, first check the settings. Ensure the power and speed are appropriate for the material. Verify that the laser is focused correctly. If issues persist, inspect the machine for any signs of wear or damage and perform necessary maintenance.

How Do You Secure Materials on the Cutting Bed?

Securing materials on the cutting bed is crucial for accurate cuts. Use clamps or adhesive mats to hold the material in place. Ensure the material lies flat on the bed to prevent misaligned cuts. Properly securing the material helps achieve consistent and precise results.

What Are the Benefits of Using a Laser Cutter?

Laser cutters offer numerous benefits, including high precision and versatility. They can cut intricate designs with ease and work with a variety of materials. Laser cutting is also efficient, reducing material waste and production time. By following proper procedures, you can achieve high-quality results consistently.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Basics of Laser Cutting Technology

The Functionality of CNC Laser Cutting Machines