How to Use a Laser Cutting Machine: Beginner's Guide

A laser cutting machine is a fascinating tool that uses a highly focused laser beam to cut or engrave materials with precision. This machine consists of several key components, including a laser source, mirrors, and a cutting head. You can think of it as a computer-controlled device that directs the laser to burn, melt, or vaporize materials like wood, acrylic, or metal. If you're wondering how to use a laser cutting machine, the appeal of laser cutting lies in its versatility and precision. Whether you're a hobbyist or a beginner, you can create intricate designs and bring your creative ideas to life with ease.

Understanding Laser Cutting Machines

When you dive into the world of laser cutting, you'll find that not all machines are created equal. Different types of laser cutters cater to various needs and materials. Let's explore the main types of laser cutting machines and their applications.

Types of Laser Cutting Machines

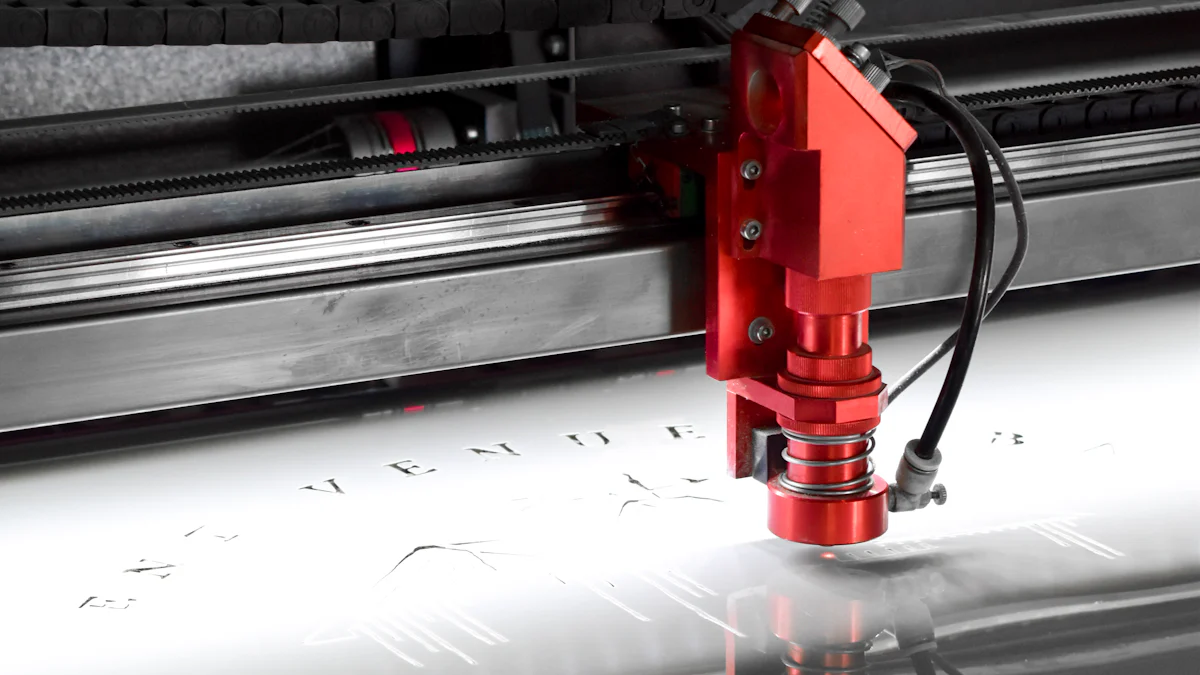

CO2 Laser Cutters

CO2 laser cutters are popular among hobbyists and professionals alike. They excel at cutting and engraving a wide range of non-metallic materials. You can use them on wood, acrylic, leather, and even some fabrics. These machines use a gas mixture to produce a laser beam, which makes them versatile for many projects. However, they do have higher operating and maintenance costs compared to other types.

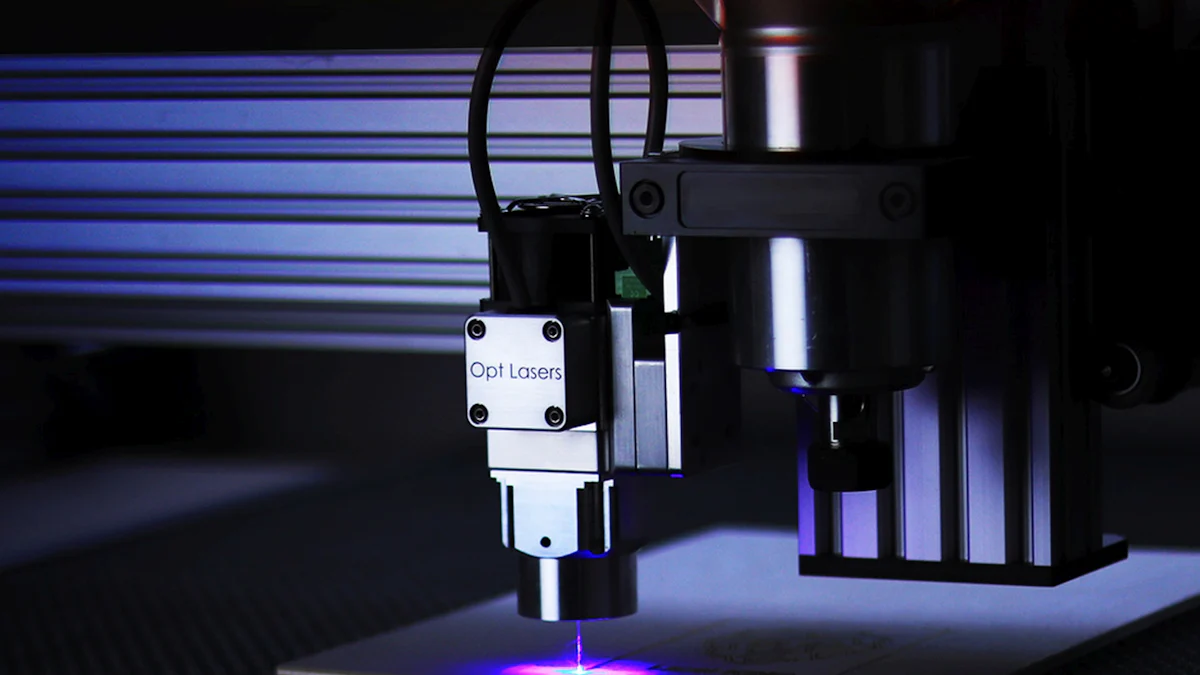

Fiber Laser Cutters

Fiber laser cutters are the go-to choice for cutting metals. They offer greater precision and speed, making them ideal for industrial applications. If you're working with metals like steel or aluminum, a fiber laser cutter will get the job done efficiently. These machines have a longer lifespan and require less maintenance, which can be a big plus if you're planning to use them frequently.

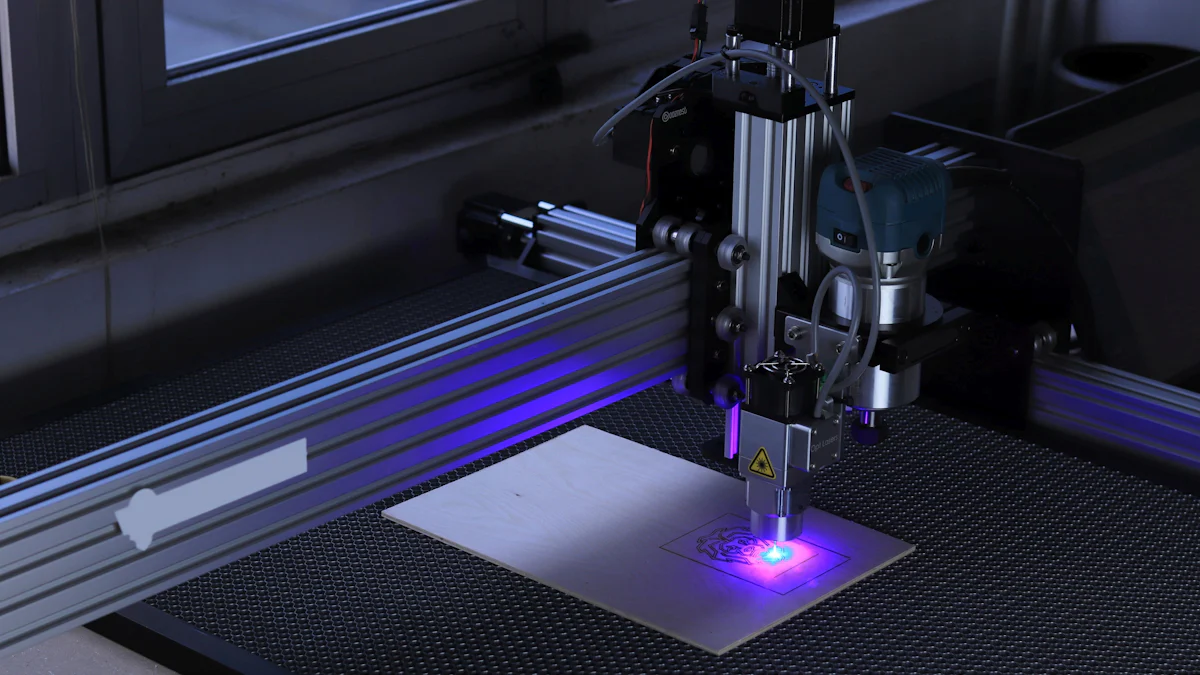

Diode Laser Cutters

Diode laser cutters are the most affordable option. They are great for beginners who want to experiment with laser cutting without a significant investment. While they may not match the power of CO2 or fiber lasers, they are perfect for small-scale projects and simple engravings. Diode lasers are easy to use and maintain, making them a good starting point for anyone new to laser cutting.

Applications of Laser Cutting

Industrial Uses

In the industrial sector, laser cutting plays a crucial role. Manufacturers use laser cutters to create precise components for machinery, electronics, and automotive parts. The ability to cut complex shapes with high accuracy makes laser cutting indispensable in these fields. Fiber laser cutters, in particular, are favored for their efficiency in handling metal materials.

Hobbyist and DIY Projects

For hobbyists and DIY enthusiasts, laser cutting opens up a world of creativity. You can craft intricate designs, personalized gifts, and custom decorations with ease. CO2 laser cutting is especially popular in this community due to its versatility with various materials. Whether you're making jewelry, model kits, or home decor, a laser cutter can bring your ideas to life.

Laser cutting machines offer endless possibilities, whether you're in an industrial setting or working on personal projects. Understanding the different types of laser cutters and their applications will help you choose the right tool for your needs.

How to Use a Laser Cutting Machine

Learning how to use a laser cutting machine can be an exciting journey. This step-by-step guide will walk you through the process, ensuring you have the basic knowledge needed to get started. Let's dive into the details of material preparation, machine setup, and executing a cut.

Material Preparation

Before you start operating the laser cutter, you need to prepare your materials properly. This ensures a smooth cutting process and high-quality results.

Selecting the Right Material

Choosing the right material is crucial in laser cutting. Different materials react differently to the laser. For beginners, wood and acrylic are excellent choices. They are easy to work with and provide good results. Avoid materials like PVC, as they release harmful gases when cut. Always check the compatibility of your material with your laser cutter.

Preparing the Material for Cutting

Once you've selected your material, make sure it fits within the work area of the laser cutter. Trim it to size if necessary. Clean the surface to remove any dust or debris. This helps in achieving a clean cut. Proper preparation sets the stage for successful laser cutting.

Machine Setup

Setting up the laser cutter is a critical step in the process. It involves installing software and calibrating the machine to ensure precision.

Installing the Software

Most laser cutters come with specific software. Install it on your computer and familiarize yourself with its features. This software allows you to design and control the cutting process. Tutorials can be helpful in understanding the software's capabilities and functions.

Calibrating the Machine

Calibration ensures that your laser cutter operates accurately. Follow the manufacturer's instructions to calibrate the machine. This usually involves adjusting the focus and aligning the laser beam. Proper calibration is essential for precise cuts and engravings.

Executing a Cut

With your material ready and machine set up, it's time to execute a cut. This involves loading your design and starting the cutting process.

Loading the Design

Load your design into the laser cutter's software. Ensure that the design fits within the material's dimensions. Preview the cutting trajectory to avoid any mistakes. This step is crucial in how to use a laser cutting machine effectively.

Starting the Cutting Process

Once everything is set, start the cutting process. Monitor the laser cutter closely to ensure safety and accuracy. Beginners should start with simple designs to gain confidence. As you gain experience, you can explore advanced tips and tricks to enhance your projects.

Operating the laser cutter can be a rewarding experience. With this step-by-step guide, you now have the basic knowledge to start your laser cutting journey. Remember, practice makes perfect, and soon you'll be creating intricate designs with ease.

Safety Tips for Laser Cutting

When you're using a laser cutting machine, safety should always be your top priority. These machines are powerful tools that can pose risks if not handled properly. Let's dive into some essential safety guidelines to keep you safe while you work.

Personal Protective Equipment (PPE)

Wearing the right personal protective equipment (PPE) is crucial when operating a laser cutter. You should always wear safety goggles designed to protect your eyes from laser exposure. High-powered lasers can cause permanent eye damage, so never skip this step. Additionally, consider wearing gloves to protect your hands from sharp edges and hot materials. A lab coat or apron can also shield your clothing from sparks or debris.

Safe Operating Procedures

Following safe operating procedures is key to preventing accidents. Before you start, ensure that your workspace is well-ventilated. Proper ventilation helps prevent the buildup of harmful fumes and reduces fire risks. Always check that the material you're cutting is compatible with your machine. Some materials can release toxic gases or dust, which can harm your health and damage the machine.

Make sure to receive proper training from a qualified individual before using the laser cutter. Familiarize yourself with the machine's controls and functions. Always stay alert and focused while the machine is running. Avoid distractions and never leave the machine unattended during operation.

Handling Emergencies

Even with the best safety precautions, emergencies can happen. Knowing how to handle them is vital. In case of a fire, have a fire extinguisher nearby and know how to use it. If you notice any unusual sounds or smells, stop the machine immediately and investigate the issue. Always have an emergency plan in place and make sure everyone in the workspace knows what to do.

By following these safety protocols, you can enjoy the benefits of laser cutting while minimizing risks. Remember, safety is not just a set of rules—it's a mindset that keeps you and those around you protected.

Troubleshooting Common Issues

When you're working with a laser cutting machine, you might encounter some hiccups along the way. Don't worry—it's all part of the learning process. Let's tackle some common issues you might face and how to solve them.

Poor Cutting Quality

If your cuts aren't as clean as you'd like, several factors could be at play. First, check the focus of your laser. An unfocused laser can lead to jagged or incomplete cuts. Adjust the focus according to your machine's manual. Next, examine the material you're using. Some materials might not be suitable for laser cutting, or they might require different settings. Make sure your material is clean and free from dust or debris, as these can affect the quality of the cut.

Another thing to consider is the speed and power settings of your machine. If the speed is too high or the power too low, the laser might not cut through the material effectively. Experiment with different settings to find the sweet spot for your specific project. Remember, practice makes perfect, and each material might need a unique approach.

Machine Not Responding

A non-responsive machine can be frustrating, but it's often a simple fix. Start by checking the power supply. Ensure that all cables are securely connected and that the machine is plugged in. If the machine still doesn't respond, try restarting it. Sometimes, a simple reboot can resolve minor glitches.

If the problem persists, inspect the machine's software. Outdated software can cause communication issues between your computer and the laser cutter. Check for any available updates and install them. If you're still having trouble, consult the machine's manual or reach out to customer support for assistance. They can provide guidance tailored to your specific model.

Software Errors

Software errors can disrupt your workflow, but they're usually easy to fix. Begin by ensuring that your design file is compatible with the laser cutter's software. Some formats might not work well, so double-check the file type. If you're unsure, refer to the software's documentation or look for online tutorials that can guide you through the process.

If the software crashes or freezes, try closing and reopening it. This can clear temporary bugs. Additionally, check your computer's resources. Running too many programs simultaneously can slow down performance and lead to errors. Close unnecessary applications to free up memory and processing power.

By addressing these common issues, you'll become more confident in using your laser cutting machine. As you gain experience, you'll discover advanced tips and tricks to enhance your projects and streamline your workflow.

Maintenance and Care

Taking care of your laser cutting machine is essential for keeping it in top shape. Regular maintenance not only extends the life of your machine but also ensures consistent performance and safety. Let's explore some key maintenance practices you should follow.

Regular Cleaning

Keeping your laser cutter clean is crucial. Dust and debris can accumulate on the machine's components, affecting its performance. Start by cleaning the lens and mirrors regularly. Use a soft cloth and a gentle cleaning solution to remove any residue. This helps maintain the clarity of the laser beam, ensuring precise cuts.

Don't forget to clean the work bed as well. A clean work surface prevents material buildup, which can interfere with the cutting process. Regular cleaning reduces the risk of fire hazards and keeps your machine running smoothly.

Component Checks

Regularly inspect the components of your laser cutter. Check the alignment of the laser beam to ensure it hits the target accurately. Misalignment can lead to poor cutting quality and increased wear on the machine. Adjust the alignment as needed, following the manufacturer's instructions.

Lubricate the moving parts to keep them functioning smoothly. Proper lubrication reduces friction and prevents wear and tear. This simple step can significantly extend the lifespan of your machine.

Software Updates

Keeping your software up to date is just as important as maintaining the hardware. Software updates often include bug fixes and new features that enhance the machine's performance. Check for updates regularly and install them promptly.

Many manufacturers provide tutorials to help you navigate software updates. These resources can guide you through the process, ensuring you don't miss any critical steps. Updated software contributes to a seamless cutting experience and helps you stay on top of safety guidelines.

By following these maintenance practices, you ensure your laser cutting machine remains in excellent condition. Regular cleaning, component checks, and software updates are simple yet effective ways to keep your machine performing at its best.

You've now explored the essentials of using a laser cutting machine. From understanding different types of machines to mastering safety tips, you're well-equipped to embark on your first laser cutting project. Remember, practice is key. Start with simple designs and gradually challenge yourself with more complex projects. This guide aims to simplify the learning curve, making it easier for you to dive into the world of laser cutting. So, gather your materials, set up your machine, and let your creativity shine. Your first laser cutting project awaits!

FAQ

What will be explored in this blog post about laser cutting?

In this blog post, you'll dive into the fascinating world of laser cutting. You'll learn how it works, the types of materials it can cut, and its various applications. Plus, you'll discover some handy tips to get you started on your laser cutting journey.

What is covered in the beginner's guide to laser cutting?

This beginner's guide will walk you through the basics of how a laser cutter works. You'll see examples of what you can create and learn how to design for laser cutting or engraving. You'll also find out which materials are suitable and how to access a laser cutter.

Why is understanding the fundamentals of CO2 laser cutting important for beginners?

Understanding the fundamentals of CO2 laser cutting is crucial because it opens up a world of creative possibilities. By grasping how the laser works, the materials it can cut, and the settings that yield the best results, you can quickly get up to speed. Always prioritize safety, experiment with different projects, and maintain your equipment for optimal performance. As you gain experience, you'll be able to tackle more complex designs and fully explore your CO2 laser cutter's potential.

What can a beginner learn from the step-by-step guide for laser cutters’ users?

The step-by-step guide for laser cutters’ users is a valuable resource for both beginners and seasoned operators. It provides insights into improving the efficiency and safety of using a laser cutting machine. You'll embark on a journey of exploring laser cutting technology, gaining knowledge that enhances your skills and confidence.

How does a laser cutter work?

A laser cutter works by directing a high-powered laser beam onto a material to cut or engrave it. The laser's precision allows for intricate designs and detailed cuts. The process involves focusing the laser on the material, which either melts, burns, or vaporizes it, depending on the material type and laser settings.

What materials can I use with a laser cutter?

You can use a variety of materials with a laser cutter, including wood, acrylic, leather, and some fabrics. Metals like steel and aluminum are best cut with fiber lasers. However, avoid materials like PVC, as they release harmful gases when cut. Always check your laser cutter's compatibility with the material you plan to use.

What are the safety precautions for using a laser cutting machine?

Safety is paramount when using a laser cutting machine. Always wear safety goggles to protect your eyes from laser exposure. Ensure your workspace is well-ventilated to prevent the buildup of harmful fumes. Familiarize yourself with the machine's controls and never leave it unattended during operation. Have a fire extinguisher nearby and know how to use it in case of emergencies.

How do I maintain my laser cutting machine?

Maintaining your laser cutting machine involves regular cleaning, component checks, and software updates. Clean the lens and mirrors to ensure a clear laser beam. Inspect the alignment of the laser beam and lubricate moving parts to prevent wear and tear. Keep your software up to date to benefit from bug fixes and new features.

Can laser cutting be profitable?

Yes, laser cutting can be a profitable venture. It allows you to transform low-cost materials into valuable products quickly and accurately. Whether you're creating custom designs, personalized gifts, or intricate components, laser cutting offers endless possibilities for both hobbyists and businesses.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

A Comprehensive Manual for Hair Cutting Machines

Beginner's Guide to Operating a Die Cutting Machine

Understanding Laser Cutting Machines: Benefits and Drawbacks