How to Use Laser Cutting Machine Effectively

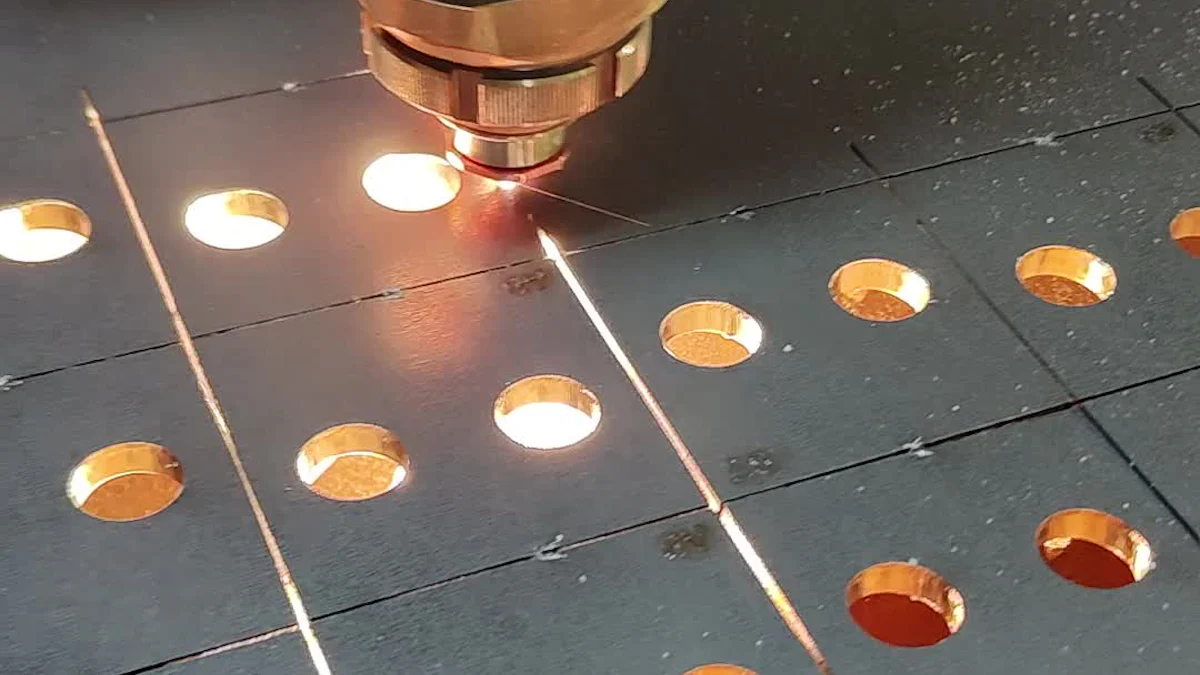

Learning how to use a laser cutting machine effectively requires attention to detail and a strong focus on safety. By understanding the proper steps, you can protect yourself while achieving precise and efficient results. Although laser cutters are generally low risk when operated correctly, neglecting safety features can lead to serious harm. Knowing how to use a laser cutting machine properly not only improves the quality of your work but also helps maintain the machine in excellent condition for a longer time. By mastering the process, you’ll fully unlock the potential of this powerful tool while minimizing unnecessary risks.

Key Takeaways

- Prioritize safety by wearing protective gear, ensuring proper ventilation, and understanding the machine's safety features to minimize risks.

- Prepare your laser cutting machine by positioning it on a stable surface, connecting all necessary systems, and securing materials properly for precise cuts.

- Follow a systematic approach during operation: power up the machine, load design files, adjust settings, and run test cuts to ensure accuracy.

- Maintain your machine regularly by cleaning optics, lubricating moving parts, and updating software to extend its lifespan and performance.

- Troubleshoot common issues by checking settings, ensuring material compatibility, and inspecting for loose connections to maintain cutting quality.

- Optimize your workflow by using vector files, batch processing, and experimenting with settings to enhance efficiency and reduce material waste.

Safety Precautions

When working with a laser cutting machine, safety should always come first. By following essential precautions and understanding the machine's built-in safety features, you can minimize risks and focus on achieving great results.

Essential Safety Measures

Wearing protective gear such as goggles and gloves.

Protective gear is your first line of defense when operating a laser cutting machine. Always wear safety goggles designed to shield your eyes from harmful laser radiation. Regular sunglasses or clear glasses won’t provide adequate protection. Gloves are equally important, especially when handling materials that may have sharp edges or high temperatures after cutting. These simple steps can prevent injuries and ensure a safer working environment.

Ensuring proper ventilation and having a fire extinguisher nearby.

Laser cutting generates fumes and smoke, which can be harmful if inhaled. Make sure your workspace has proper ventilation or a fume extraction system to remove these byproducts effectively. This not only protects your health but also keeps the air clean for others in the area. Additionally, always keep a fire extinguisher within reach. Laser cutters can produce heat that might ignite certain materials, so being prepared for emergencies is crucial.

"By being mindful of the possible hazards associated with each type of laser cutter, you can work securely and effectively whenever using one." – Laser Cutting Machine Safety Expert

Machine Safety Features

Understanding emergency stop buttons and safety interlocks.

Modern laser cutting machines come equipped with safety features to protect you during operation. Familiarize yourself with the emergency stop button, which allows you to halt the machine instantly in case of an issue. Safety interlocks are another critical feature. These mechanisms prevent the machine from operating if certain conditions, like an open cover, are detected. Knowing how these features work can help you respond quickly to unexpected situations.

Avoiding direct exposure to the laser beam.

Direct exposure to the laser beam can cause severe injuries to your eyes or skin. Never look directly at the laser while it’s in operation, and avoid placing your hands or any part of your body near the cutting area. The laser’s intensity is powerful enough to cause permanent damage in seconds. Always stay alert and maintain a safe distance from the beam.

"It should be noted that when operating a laser cutting machine, you must strictly abide by relevant safety operating procedures, wear personal protective equipment, and avoid direct exposure of the laser beam to your eyes or skin to avoid causing damage." – Laser Cutting Machine Safety Expert

By following these safety measures and understanding the machine’s built-in features, you can confidently operate a laser cutting machine while minimizing risks. Safety isn’t just about protecting yourself; it’s also about ensuring the longevity and reliability of your equipment.

Machine Preparation

Preparing your laser cutting machine properly is the foundation for achieving precise and efficient results. By following these steps, you’ll ensure smooth operation and avoid unnecessary issues during the cutting process.

Setting Up the Machine

Positioning the machine on a stable, level surface.

Start by placing your laser cutting machine on a sturdy and flat surface. A stable base prevents vibrations that could affect the accuracy of your cuts. Uneven surfaces can also strain the machine’s components over time, leading to potential malfunctions. Take a moment to double-check the levelness of the surface before proceeding.

Connecting the power supply, PC, and exhaust system.

Once the machine is positioned, connect it to a reliable power source. Ensure all cables are securely plugged in, including the connection to your PC or control system. The exhaust system is equally important. It removes fumes and smoke generated during cutting, keeping the workspace safe and clean. A properly functioning exhaust system also protects the machine’s internal components from contamination.

"A well-connected and ventilated setup not only ensures safety but also enhances the machine's performance." – Laser Cutting Expert

Material Positioning

Securing the material on the cutting bed and ensuring it is flat.

Before starting, place your material firmly on the cutting bed. Make sure it lies completely flat to avoid uneven cuts. Use clamps or other securing tools if necessary. A stable material position ensures the laser beam interacts with the surface consistently, resulting in clean and precise cuts.

Aligning the material with the cutting area for precision.

Take time to align the material with the designated cutting area. Use the machine’s alignment tools or guides to position it accurately. Proper alignment minimizes errors and reduces material waste. This step is especially crucial when working on intricate designs or expensive materials.

Focal Adjustments

Adjusting the laser focus based on material thickness.

The laser’s focus determines the quality of your cuts. Adjust the focus according to the thickness of the material you’re working with. Most machines have a focus adjustment knob or an automatic focusing feature. Proper focus ensures the laser beam penetrates the material effectively without causing burns or incomplete cuts.

Testing the focus with a small trial cut.

Before starting your main project, perform a small trial cut. This test helps you verify the focus and other settings. If the trial cut isn’t satisfactory, make the necessary adjustments and test again. A quick trial saves you from ruining the entire material and ensures the final output meets your expectations.

"Testing your settings with a trial cut is a simple yet effective way to avoid costly mistakes." – Laser Cutting Specialist

By carefully setting up the machine, positioning the material, and adjusting the focus, you’ll be well-prepared to operate your laser cutting machine effectively. These preparation steps not only improve the quality of your work but also help maintain the machine’s longevity.

Operating Steps

Operating a laser cutting machine effectively requires a clear understanding of the steps involved. By following these steps, you’ll ensure smooth operation and achieve precise results every time.

Powering Up the Machine

Turning on the machine and initializing the system.

Start by powering up the laser cutting machine. Locate the power switch and turn it on. Once the machine is on, allow it to initialize. This process prepares the system for operation by calibrating its components. Pay attention to any error messages or alerts during initialization, as they may indicate issues that need addressing before proceeding.

Loading the G-code or design file into the software.

After initialization, load your design file into the machine’s software. The file, often in G-code format, contains the instructions the machine will follow to cut or engrave the material. Use the software interface to upload the file and verify that it displays correctly. Double-check the design’s dimensions and placement to ensure it aligns with your material. This step is crucial for avoiding errors during the cutting process.

"The G-code acts as the brain of your laser cutter, guiding every movement with precision." – Professional Laser Equipment Services

Setting Parameters

Adjusting laser power, speed, and frequency for the material.

Before starting the cutting process, adjust the machine’s settings based on the material you’re using. Set the laser power to a level that matches the material’s thickness and type. Adjust the speed to control how quickly the laser moves across the surface. Modify the frequency if needed, especially for materials like acrylic or wood. These settings directly impact the quality of your cuts, so take your time to get them right.

Selecting the appropriate cutting or engraving mode.

Choose the correct mode for your project. Most laser cutting machines offer options for cutting, engraving, or both. Cutting mode is ideal for slicing through materials, while engraving mode works best for creating detailed designs on the surface. Select the mode that aligns with your design file and material. This ensures the machine performs the task accurately without damaging the material.

Executing the Cutting Process

Running a test cut to verify settings.

Before starting the main job, run a small test cut. This trial helps confirm that your settings are correct. Use a scrap piece of the same material to avoid wasting valuable resources. Check the test cut for clean edges and proper depth. If the results aren’t satisfactory, tweak the settings and test again. A few minutes spent on testing can save you from costly mistakes later.

Monitoring the cutting process for accuracy and safety.

Once you’re satisfied with the test cut, begin the actual cutting process. Stay close to the machine and monitor its progress. Watch for any signs of irregularities, such as uneven cuts or excessive smoke. Keep an eye on the material to ensure it doesn’t shift during cutting. If you notice any issues, pause the machine and make adjustments. Your vigilance ensures both the quality of the work and the safety of the operation.

"Constant monitoring during the cutting process is key to achieving flawless results and preventing accidents." – Professional Laser Equipment Services

By following these steps, you’ll master how to use a laser cutting machine effectively. From powering up the machine to executing the cutting process, each step plays a vital role in ensuring success. With practice and attention to detail, you’ll produce high-quality results while keeping your equipment in excellent condition.

Maintenance Tips

Proper maintenance is essential to keep your laser cutting machine running smoothly and delivering consistent results. By dedicating time to routine care, you can extend the machine’s lifespan and avoid costly repairs. Let’s dive into the key maintenance practices you should follow.

Routine Cleaning

Cleaning the laser lens, mirrors, and cutting bed regularly.

Dust and debris can accumulate on the laser lens and mirrors, reducing the machine’s cutting precision. Use a lint-free cloth or microfiber towel to gently clean these components after each use. Avoid using abrasive materials that could scratch the surfaces. The cutting bed also requires regular attention. Remove any leftover material or residue to maintain a clean workspace. A well-maintained cutting bed ensures the laser power is distributed evenly, resulting in precise cuts.

"Regular cleaning of the optics and cutting bed not only improves performance but also prevents long-term damage." – Laser Cutting Expert

Removing debris after each use to maintain performance.

After every cutting session, inspect the machine for debris. Empty slag drawers and bins to prevent buildup. Scraps left on the work surface can interfere with the laser’s operation and even cause overheating. Keeping the machine free of debris ensures it operates efficiently and reduces the risk of malfunctions.

Lubrication and Calibration

Lubricating moving parts to prevent wear and tear.

The moving parts of your laser cutting machine, such as rails and gears, require lubrication to function smoothly. Apply a manufacturer-recommended lubricant to these areas at regular intervals. This reduces friction, prevents wear, and ensures the machine operates without unnecessary strain. Neglecting lubrication can lead to mechanical issues over time.

Calibrating the laser for consistent and precise cuts.

Calibration is crucial for maintaining the accuracy of your cuts. Over time, the alignment of the laser may shift, affecting its precision. Follow the manufacturer’s guidelines to recalibrate the laser periodically. Test the alignment by performing a small trial cut and adjust as needed. Regular calibration ensures your machine delivers consistent results, even after extended use.

"Planned calibration and lubrication routines minimize the risk of breakdowns and keep your machine running like new." – Professional Laser Equipment Services

Software and Firmware Updates

Updating the machine's software and firmware regularly.

Manufacturers often release software and firmware updates to improve machine performance and fix bugs. Check for updates regularly and install them as soon as they become available. Updated software enhances compatibility with design files and optimizes the machine’s functionality. Staying current with updates ensures you’re using the machine at its full potential.

Checking for updates from the manufacturer.

Visit the manufacturer’s website or contact their support team to stay informed about the latest updates. Some manufacturers also provide notifications through their software interface. Keeping the machine’s software and firmware up to date not only improves performance but also ensures compliance with safety standards.

"Following the manufacturer’s recommendations for updates and maintenance keeps your laser cutting machine operating at peak efficiency." – Boss Laser

By incorporating these maintenance tips into your routine, you’ll ensure your laser cutting machine remains reliable and efficient. Regular cleaning, lubrication, calibration, and software updates are simple yet effective ways to protect your investment and achieve high-quality results.

Troubleshooting Common Issues

Even with proper preparation and operation, laser cutting machines can sometimes encounter problems. Knowing how to identify and resolve these issues ensures your projects stay on track and your machine remains in top condition. Let’s explore some common challenges and how you can address them effectively.

Poor Cutting Quality

When your cuts appear rough, uneven, or incomplete, it’s time to take a closer look at your machine settings and materials.

Adjusting the laser focus and power settings.

The laser’s focus and power settings play a critical role in achieving clean cuts. If the edges of your material look jagged or burnt, check the focus first. Adjust the laser to match the thickness of your material. A properly focused laser ensures the beam penetrates the material evenly. Next, review the power settings. Too much power can scorch the material, while too little may leave incomplete cuts. Fine-tune these settings until you achieve smooth, precise edges.

"Laser cutting precision depends heavily on the right focus and power balance. Small adjustments can make a big difference." – Laser Cutting Specialist

Ensuring the material is suitable for laser cutting.

Not all materials respond well to laser cutting. Some may burn, melt, or produce excessive smoke. Always confirm that your material is compatible with your machine. For example, acrylic and wood often cut cleanly, while certain metals or plastics may require specialized settings. Using unsuitable materials can lead to poor results and even damage your equipment.

Tip: Keep a list of materials that work best with your machine to save time and avoid trial-and-error during future projects.

Machine Malfunctions

Occasional malfunctions can disrupt your workflow, but most issues are easy to diagnose and fix.

Checking for loose connections or damaged components.

Loose cables or damaged parts can cause your machine to malfunction. Inspect all connections, including the power supply, PC, and exhaust system. Ensure everything is securely plugged in and free from wear or damage. Pay special attention to the laser lens and mirrors, as misaligned or dirty components can affect performance. Regular inspections help you catch these issues early.

Restarting the machine and reloading the design file.

Sometimes, a simple restart can resolve unexpected errors. Turn off the machine, wait a few moments, and power it back on. Reload your design file into the software and verify its accuracy. Corrupted files or software glitches can also cause problems, so reloading ensures the machine receives clear instructions.

"A quick restart often clears up minor glitches, saving you time and frustration." – Professional Laser Equipment Services

Overheating or Smoke Issues

Excessive heat or smoke can compromise both the quality of your cuts and the safety of your workspace.

Ensuring proper ventilation and cooling systems are functioning.

Laser cutting generates heat and fumes, which need to be managed effectively. Check that your ventilation system is working properly. A clogged or malfunctioning exhaust system can lead to overheating and smoky conditions. If your workspace lacks ventilation, consider adding a fume extractor to keep the air clean and protect your health.

Reducing laser power for sensitive materials.

Some materials, like thin plastics or fabrics, are more prone to burning. Lower the laser power when working with these materials to prevent overheating. You can also use a heat sink or cooling system to control the material’s temperature during cutting. These adjustments ensure your cuts remain clean and your materials stay intact.

"Proper cooling and ventilation not only improve safety but also enhance the overall cutting quality." – Laser Cutting Expert

By addressing these common issues, you’ll maintain consistent results and extend the life of your laser cutting machine. Troubleshooting may seem daunting at first, but with practice, you’ll quickly learn to identify and resolve problems with confidence.

Pro Tips for Efficiency

Maximizing efficiency when using a laser cutting machine can save you time, reduce material waste, and improve the quality of your projects. By refining your workflow and experimenting with different techniques, you can achieve professional results with minimal effort. Let’s explore some practical tips to enhance your laser cutting process.

Optimizing Design Files

Using vector files for precise cutting paths.

Vector files are essential for achieving clean and accurate cuts. Unlike raster images, which rely on pixels, vector files use mathematical paths to define shapes. This ensures that your laser cutter follows precise cutting paths without unnecessary deviations. Programs like Adobe Illustrator or CorelDRAW allow you to create and edit vector files easily. By using these files, you’ll notice smoother edges and better overall results.

"Laser cutting technology offers dimensional accuracy of roughly 0.0005 inches, making it ideal for intricate designs." – Laser Cutting Specialist

Minimizing unnecessary movements in the design.

Unnecessary movements in your design can slow down the cutting process and waste valuable time. Simplify your design by removing redundant lines or overlapping paths. Group similar elements together to streamline the laser’s movements. This not only speeds up the process but also reduces wear on the machine’s components. A well-optimized design ensures that every second of operation is productive.

Batch Processing

Cutting multiple pieces in one session to save time.

Batch processing is a game-changer when working on large projects. Instead of cutting one piece at a time, arrange multiple designs on the cutting bed. This allows the laser cutter to work continuously, reducing downtime between cuts. For example, industries like automotive manufacturing use fiber laser machines to cut multiple components simultaneously, enhancing both speed and efficiency.

"The flexible manufacturing process of laser cutting provides high-speed, high-quality results for various applications." – Industrial Expert

Grouping similar materials for consistent results.

When cutting different materials, group similar ones together to maintain consistency. Each material requires specific settings for power, speed, and frequency. By processing similar materials in one session, you avoid constant adjustments and ensure uniform results. This approach is particularly useful for batch production, where consistency is key to maintaining quality.

Experimenting with Settings

Testing different parameters to find the best combination.

Every material reacts differently to laser cutting. Experiment with various settings, such as power, speed, and frequency, to determine what works best for your project. Start with small test cuts to evaluate the results. Adjust the settings incrementally until you achieve the desired outcome. This trial-and-error process helps you understand how to use laser cutting machines effectively for different applications.

"Testing parameters is crucial for achieving precise and accurate cuts, especially when working with complex shapes." – Laser Cutting Specialist

Keeping a log of successful settings for future reference.

Documenting your successful settings saves time and effort in future projects. Create a logbook or digital file where you record the parameters used for each material and design. Include details like laser power, speed, and focus adjustments. This reference guide becomes invaluable when working on similar projects, ensuring consistent results without repeated experimentation.

"Keeping a record of effective settings streamlines your workflow and enhances productivity over time." – Professional Laser Equipment Services

By applying these pro tips, you’ll not only improve your efficiency but also elevate the quality of your work. Optimizing design files, leveraging batch processing, and experimenting with settings are simple yet powerful strategies to get the most out of your laser cutting machine. With practice, you’ll master these techniques and enjoy smoother, faster, and more precise cutting processes.

Mastering how to use laser cutting machine effectively involves focusing on five key areas: safety, preparation, operation, maintenance, and troubleshooting. By prioritizing safety measures, you protect yourself and ensure smooth operations. Proper preparation and setup lead to precise results, while regular maintenance keeps your machine in top condition. Troubleshooting common issues helps you avoid delays and maintain efficiency. Experimenting with settings and techniques allows you to continuously improve your skills. Apply these tips to achieve high-quality results, extend your machine’s lifespan, and unlock its full potential.

FAQ

How does laser cutting work?

Laser cutting uses a high-powered laser beam to cut or engrave materials with precision. The laser focuses intense energy on a small area, heating and vaporizing the material to create clean cuts. The process depends on factors like material type, thickness, and laser intensity. For example, improper settings can burn materials or discolor metals. While plasma cutting handles thicker sheets, advancements in laser technology are narrowing this gap. Laser cutting offers unmatched accuracy, though the machinery can be costly.

What materials can you cut with a laser cutting machine?

You can cut a wide range of materials with a laser cutting machine. Common options include wood, acrylic, leather, fabric, and certain plastics. Metals like stainless steel and aluminum are also compatible, but they may require higher-powered lasers. However, avoid cutting materials like PVC or polycarbonate, as they release harmful fumes. Always check your machine’s specifications to ensure compatibility with your chosen material.

Is laser cutting safe?

Yes, laser cutting is safe when you follow proper precautions. Always wear protective goggles to shield your eyes from laser radiation. Ensure your workspace has good ventilation to remove fumes and smoke. Keep a fire extinguisher nearby in case of emergencies. Modern machines also include safety features like emergency stop buttons and interlocks to prevent accidents. Staying alert and following guidelines minimizes risks.

How do you maintain a laser cutting machine?

Maintaining your laser cutting machine involves regular cleaning, lubrication, and updates. Clean the laser lens, mirrors, and cutting bed after each use to prevent debris buildup. Lubricate moving parts to reduce wear and tear. Calibrate the laser periodically to ensure precise cuts. Don’t forget to update the machine’s software and firmware to improve performance and fix bugs. Routine maintenance keeps your machine running smoothly and extends its lifespan.

Can you engrave with a laser cutting machine?

Yes, most laser cutting machines can engrave as well. Engraving involves etching designs onto the surface of a material without cutting through it. You can use this feature to create intricate patterns, logos, or text on wood, acrylic, glass, and more. Adjust the laser’s power and speed settings to achieve the desired depth and detail. Engraving adds versatility to your projects and enhances creativity.

What are the benefits of laser cutting?

Laser cutting offers several advantages. It provides high precision, allowing you to create intricate designs with clean edges. The process is fast and efficient, especially for batch production. Laser cutting works on various materials, making it versatile for different industries. Additionally, it minimizes material waste due to its accuracy. While the initial cost of the machine may be high, the long-term benefits make it a worthwhile investment.

Why is proper ventilation important during laser cutting?

Proper ventilation is crucial because laser cutting generates fumes and smoke. These byproducts can harm your health if inhaled and may contaminate your workspace. A well-functioning exhaust system or fume extractor removes these pollutants, ensuring a safe environment. Ventilation also prevents overheating and protects the machine’s internal components from damage. Always prioritize ventilation to maintain safety and performance.

How do you choose the right laser cutting machine?

Choosing the right laser cutting machine depends on your needs. Consider factors like the materials you’ll work with, the machine’s power, and your budget. For example, CO2 lasers are ideal for non-metal materials, while fiber lasers handle metals better. Look for features like adjustable settings, safety mechanisms, and software compatibility. Research different models and read reviews to find a machine that suits your projects.

What should you do if the laser cutting quality is poor?

If the cutting quality is poor, start by checking the laser’s focus and power settings. Adjust the focus to match the material’s thickness and ensure the power level is appropriate. Inspect the material to confirm it’s suitable for laser cutting. Clean the laser lens and mirrors to remove any dirt or debris affecting performance. Running a test cut can help you identify and fix issues before starting your main project.

Can beginners use a laser cutting machine?

Absolutely! Beginners can use a laser cutting machine with some practice and guidance. Start by reading the user manual and familiarizing yourself with the machine’s features. Begin with simple projects and gradually explore more complex designs. Follow safety protocols and experiment with settings to learn how different materials respond. With time and patience, you’ll gain confidence and master the art of laser cutting.

See Also

Understanding The Functionality Of Laser Cutting Machines

Exploring Laser Cutting Machines And Their Various Types

A Guide To Operating A Die Cutting Machine