How to Operate a Key Cutting Machine Effectively

Operating a key cutting machine with precision ensures accurate duplicates and extends the machine’s lifespan. You must understand its functions to avoid errors and maintain safety. Improper use can lead to misaligned cuts or damaged equipment. Regular maintenance, such as cleaning and lubrication, keeps the machine efficient. Experts emphasize that proper training is essential for safe operation. Knowing how to use a key cutting machine effectively not only enhances your skills but also ensures consistent results. Mastering this process builds confidence and guarantees the best performance from your equipment.

Key Takeaways

- Understanding the different types of key cutting machines—manual, electric, and laser—helps you choose the right one for your needs.

- Regular maintenance, including cleaning and lubrication, is essential for ensuring the longevity and efficiency of your key cutting machine.

- Always prioritize safety by wearing protective gear and inspecting the machine before use to prevent accidents.

- Proper training is crucial for operating key cutting machines effectively, especially for complex models like laser machines.

- Follow a step-by-step guide for each type of machine to achieve accurate key duplication and avoid common issues like misalignment.

- Regular inspections and prompt addressing of any wear or damage can prevent major problems and ensure consistent performance.

Types of Key Cutting Machines

Understanding the different types of key cutting machines helps you choose the right one for your needs. Each type has unique features, advantages, and limitations. Below is an overview of the three main types.

Manual Key Cutting Machines

Manual key cutting machines are the simplest and most commonly used. These machines rely on a vice to hold both the original key and the key blank securely. You operate a lever or handle to guide the cutting wheel along the keys.

-

Advantages:

- Easy to use, even for beginners.

- Affordable and portable, making them ideal for small-scale operations.

-

Limitations:

- Slower than other types.

- Require physical effort, which can be tiring over time.

- Tend to be noisy during operation.

Manual machines are a great choice if you need a budget-friendly option or work in environments where portability is essential.

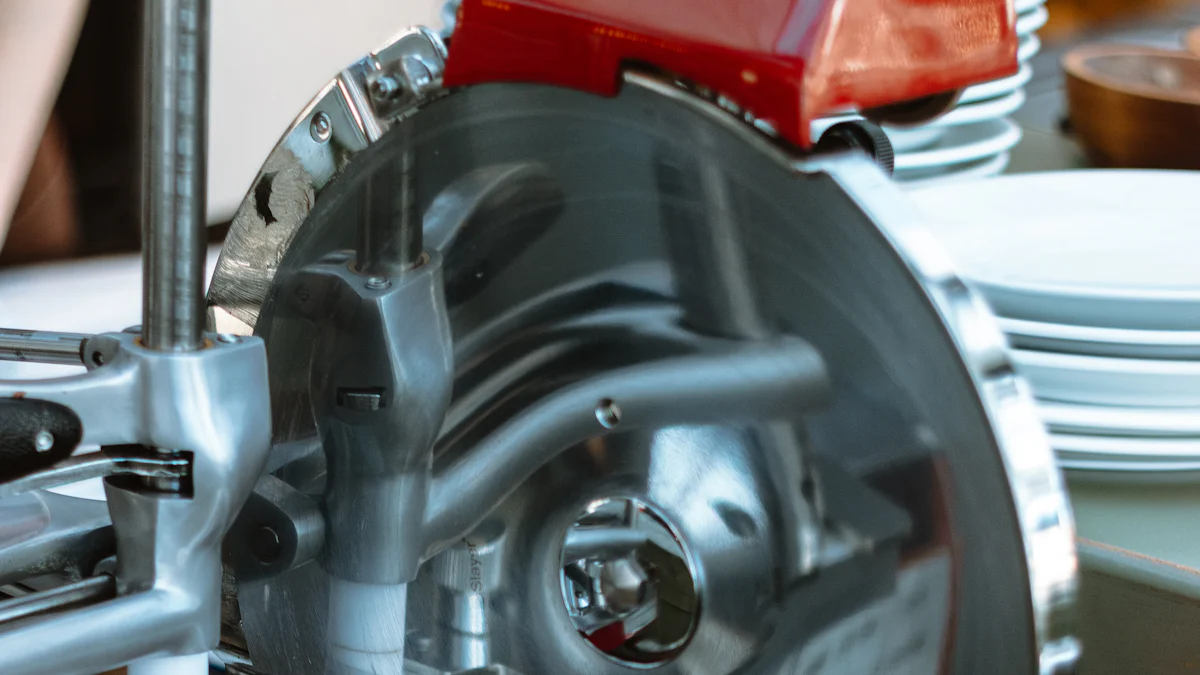

Electric Key Cutting Machines

Electric key cutting machines offer a faster and more efficient alternative to manual ones. These machines also use a vice to hold the keys, but instead of manual effort, a motor powers the cutting wheel.

-

Advantages:

- Faster and quieter than manual machines.

- Provide more accurate cuts, reducing the chances of errors.

-

Limitations:

- More expensive than manual machines.

- Heavier and less portable.

- Depend on electricity, which may limit their use in certain locations.

If you prioritize speed and precision, an electric key cutting machine is a reliable option for professional use.

Laser Key Cutting Machines

Laser key cutting machines represent the most advanced technology in key duplication. These machines use a laser scanner to create a digital image of the original key. The image appears on a computer screen, allowing you to make adjustments before cutting.

-

Advantages:

- Unmatched accuracy and precision.

- Versatile enough to handle complex key designs.

- Enhanced security features, making them suitable for high-security keys.

-

Limitations:

- The most expensive type of key cutting machine.

- Complex to operate, requiring specialized training.

- Not as portable due to their size and weight.

Laser machines are ideal for professionals who handle high-security or intricate key designs and need the highest level of precision.

Pro Tip: When selecting a key cutting machine, consider factors like your budget, the volume of keys you plan to cut, and the level of precision required.

How to Use a Key Cutting Machine: Step-by-Step Guide

Learning how to use a key cutting machine effectively ensures accurate results and prevents unnecessary wear on the equipment. Follow these step-by-step instructions for each type of machine to achieve the best outcomes.

Operating a Manual Key Cutting Machine

-

Prepare the Machine

Clean the machine to remove any debris from previous use. Ensure the cutting wheel is sharp and properly aligned. -

Select the Key Blank

Choose a key blank that matches the original key. Verify the size and shape to avoid errors during cutting. -

Secure the Keys

Place the original key in one vice and the key blank in the other. Tighten both vices to hold the keys firmly in place. -

Align the Keys

Align the original key and the blank so their grooves match perfectly. This step is crucial for accurate duplication. -

Cut the Key

Use the lever to guide the cutting wheel along the grooves of the original key. Apply steady pressure to ensure smooth cuts. -

Finish and Test

Remove the newly cut key and smooth any rough edges with a file. Test the key in the lock to confirm it works correctly.

Tip: Always double-check the alignment before cutting to avoid wasting key blanks.

Operating an Electric Key Cutting Machine

-

Inspect the Machine

Check the motor, cutting wheel, and vices for any signs of damage. Clean the machine to maintain precision. -

Choose the Key Blank

Select a key blank that matches the original key. Ensure it fits securely in the vice. -

Secure and Align the Keys

Place the original key and the blank in their respective vices. Align them carefully to ensure the cuts match. -

Power On the Machine

Turn on the machine and let the motor reach full speed. This ensures smooth and precise cutting. -

Cut the Key

Gently guide the cutting wheel along the grooves of the original key. Avoid applying excessive force to prevent damage. -

Smooth and Test

Remove the key and file down any rough edges. Test the key in the lock to ensure it functions properly.

Pro Tip: Keep the cutting wheel sharp and replace it when it shows signs of wear for consistent results.

Operating a Laser Key Cutting Machine

-

Set Up the Machine

Power on the machine and connect it to the computer. Ensure the laser scanner and cutting components are clean and functional. -

Scan the Original Key

Place the original key in the scanner. The machine will create a digital image of the key’s grooves and profile. -

Insert the Key Blank

Place the key blank in the cutting area. Secure it tightly to prevent movement during the cutting process. -

Adjust the Settings

Use the computer interface to adjust the cutting settings. Confirm the digital image matches the original key. -

Cut the Key

Start the cutting process. The laser will precisely replicate the grooves of the original key onto the blank. -

Inspect and Test

Remove the key and inspect it for accuracy. Test it in the lock to ensure it operates smoothly.

Note: Laser machines require specialized training. Familiarize yourself with the software and machine features before use.

By following these steps, you can master how to use a key cutting machine for any type. Each machine has unique features, but the principles of precision and care remain the same.

Safety Precautions for Key Cutting Machines

Operating a key cutting machine requires attention to safety. Following proper precautions protects you from injuries and ensures smooth operation. Below are essential guidelines to keep in mind.

General Safety Guidelines

-

Wear Protective Gear

Always wear safety goggles to shield your eyes from flying debris. Use a dust mask to avoid inhaling harmful particles. Gloves protect your hands from sharp edges and metal shavings that may cause irritation or cuts. -

Maintain a Clean Workspace

Keep the area around the machine free of clutter. Remove any loose objects that could interfere with the machine's operation or pose a tripping hazard. -

Inspect the Machine Before Use

Check for any visible damage or loose components. Ensure the cutting wheel is sharp and properly aligned. A quick inspection prevents accidents caused by faulty equipment. -

Avoid Loose Clothing and Accessories

Do not wear loose clothing, jewelry, or anything that could get caught in the machine. Tie back long hair to prevent it from coming into contact with moving parts. -

Stay Focused

Pay full attention while operating the machine. Avoid distractions to reduce the risk of errors or accidents.

Tip: Regularly clean the machine to remove debris and maintain its efficiency. A well-maintained machine is safer to use.

Machine-Specific Safety Tips

-

Manual Key Cutting Machines

- Use steady pressure when guiding the cutting wheel. Avoid forcing the lever, as this can cause the machine to slip or the key to misalign.

- Ensure the vices hold the keys securely to prevent movement during cutting.

-

Electric Key Cutting Machines

- Allow the motor to reach full speed before cutting. This ensures smooth operation and reduces the risk of uneven cuts.

- Keep the cutting wheel sharp. A dull wheel requires more force, increasing the chance of accidents.

-

Laser Key Cutting Machines

- Familiarize yourself with the machine’s software and settings. Incorrect adjustments can lead to errors or damage.

- Avoid looking directly at the laser beam. Even brief exposure can harm your eyes. Use the protective shields provided with the machine.

Pro Tip: Follow the manufacturer’s safety guidelines for your specific machine. These instructions are tailored to the design and features of the equipment.

By adhering to these safety precautions, you can confidently operate any key cutting machine. Prioritizing safety not only protects you but also ensures the machine performs at its best.

Maintenance Tips for Key Cutting Machines

Proper maintenance of your key cutting machine ensures its longevity and optimal performance. Neglecting maintenance can lead to inefficiency, inaccurate cuts, or even machine failure. Follow these essential tips to keep your machine in excellent condition.

Cleaning the Machine

Regular cleaning is vital for maintaining the precision and efficiency of your key cutting machine. Dust, metal shavings, and debris can accumulate over time, affecting the machine's performance.

-

Unplug the Machine

Always disconnect the machine from its power source before cleaning. This step ensures your safety and prevents accidental operation. -

Remove Debris

Use a soft brush or compressed air to clear away metal shavings and dust from the cutting area. Pay special attention to the vices and cutting wheel, as debris buildup can hinder their functionality. -

Wipe Down Surfaces

Dampen a clean cloth with a mild cleaning solution and wipe the machine's exterior. Avoid using harsh chemicals that could damage the machine's components. -

Inspect the Cutting Wheel

Check the cutting wheel for any residue or buildup. Clean it thoroughly to maintain sharpness and precision.

Pro Tip: Clean your machine after every use to prevent debris from accumulating and affecting its performance.

Lubricating Moving Parts

Lubrication reduces friction between moving parts, ensuring smooth operation and preventing wear and tear. Without proper lubrication, your machine may experience increased resistance and reduced efficiency.

-

Choose the Right Lubricant

Use a lubricant recommended by the manufacturer. Avoid using generic oils that may not be suitable for your machine. -

Apply Sparingly

Apply a small amount of lubricant to the machine's moving parts, such as the cutting wheel shaft and vices. Excessive lubrication can attract dust and debris, leading to clogs. -

Wipe Off Excess

After applying lubricant, wipe off any excess with a clean cloth. This step prevents buildup and keeps the machine clean. -

Test the Movement

Operate the machine manually to ensure all moving parts function smoothly after lubrication.

Tip: Lubricate your machine regularly, especially if you use it frequently. This practice minimizes wear and extends the life of the components.

Regular Inspections

Routine inspections help you identify potential issues before they escalate into major problems. A well-maintained machine operates more efficiently and produces accurate results.

-

Check for Wear and Tear

Inspect the cutting wheel, vices, and other components for signs of wear or damage. Replace worn-out parts promptly to maintain precision. -

Tighten Loose Components

Examine screws, bolts, and other fasteners. Tighten any loose components to ensure the machine remains stable during operation. -

Test the Machine’s Performance

Run a test cut to evaluate the machine's accuracy. If you notice misaligned cuts or irregularities, address the issue immediately. -

Follow Manufacturer Guidelines

Refer to the user manual for specific maintenance recommendations. Adhering to these guidelines ensures your machine stays in optimal condition.

Note: Schedule regular inspections, even if the machine appears to be functioning well. Preventive maintenance saves time and money in the long run.

By incorporating these maintenance practices into your routine, you can ensure your key cutting machine remains reliable and efficient. Understanding how to use a key cutting machine effectively includes taking care of it properly, which guarantees consistent results and extends its lifespan.

Troubleshooting Common Issues with Key Cutting Machines

Even with proper operation, key cutting machines can encounter problems. Identifying and resolving these issues quickly ensures smooth performance and accurate results. Below are common problems you might face and how to address them effectively.

Key Misalignment

Key misalignment often leads to inaccurate cuts, rendering the duplicate unusable. This issue typically arises when the original key and the blank are not properly secured or aligned in the vices.

-

Check the Alignment

Before cutting, ensure the original key and the blank are perfectly aligned. Their grooves should match precisely. Misalignment at this stage guarantees an incorrect cut. -

Secure the Keys Firmly

Tighten the vices to hold both keys securely. Loose keys can shift during the cutting process, causing errors. -

Inspect the Machine’s Components

Examine the vices and cutting wheel for wear or damage. Worn-out parts can affect the machine’s ability to maintain proper alignment.

Tip: Always double-check the alignment before starting the cutting process. This simple step saves time and prevents wasted key blanks.

Machine Jamming

A jammed machine disrupts your workflow and may damage the equipment. The most common cause of jamming is the buildup of metal chips and debris in the cutting area.

-

Clean the Machine Regularly

After every use, remove metal shavings and dust from the cutting area. Use a soft brush or compressed air to clear debris from the vices and cutting wheel. -

Inspect the Cutting Wheel

Check the cutting wheel for obstructions or residue. Clean it thoroughly to ensure smooth operation. -

Lubricate Moving Parts

Apply a small amount of lubricant to the machine’s moving components. Proper lubrication reduces friction and prevents jams.

Pro Tip: Keep your workspace clean and free of clutter. A clean environment minimizes the risk of debris interfering with the machine’s operation.

Inaccurate Key Cuts

Inaccurate cuts result in keys that do not fit or function properly. This problem can stem from dull cutting blades, improper alignment, or user error.

-

Sharpen or Replace the Cutting Wheel

A dull cutting wheel struggles to make precise cuts. Look for signs like longer cutting times or excess metal burrs on the keys. Replace or sharpen the wheel as needed. -

Verify the Key Blank

Ensure the key blank matches the original key in size and shape. Using the wrong blank guarantees an inaccurate cut. -

Test the Key Before Removing It

After cutting, check the accuracy of the grooves while the key is still in the vice. If adjustments are needed, you can repeat the process without wasting another blank. -

Avoid Forcing the Key into the Lock

If the key does not fit, do not force it. Forcing a poorly cut key can damage the lock and the key itself.

Remember: Precision is key. Take your time to align, cut, and inspect each key carefully.

By addressing these common issues, you can maintain the efficiency of your key cutting machine and produce accurate duplicates every time. Regular maintenance and attention to detail are your best tools for troubleshooting and preventing problems.

Understanding how to use a key cutting machine effectively is essential for achieving precise results and maintaining safety. By following the outlined steps, you ensure accurate key duplication while protecting the machine from unnecessary wear. Regular cleaning and maintenance keep the equipment efficient and extend its lifespan. Prioritizing safety measures, such as wearing protective gear and inspecting the machine before use, minimizes risks. When you combine these practices, you enhance your skills and confidence, ensuring consistent performance and long-term reliability.

FAQ

What is a key cutting machine?

A key cutting machine is a specialized device designed to duplicate keys by cutting grooves and patterns onto blank keys. These machines come in various types, including manual, electric, and laser, each offering different levels of precision and functionality. They are essential tools for locksmiths and professionals who provide key duplication services.

How do key cutting machines work?

Key cutting machines replicate the grooves and patterns of an original key onto a blank key. The process involves securing both keys in the machine’s vices and using a cutting blade, milling cutter, or laser to create precise cuts. The machine’s settings can be adjusted to match the specifications of different key types, ensuring accurate duplication.

What are the main types of key cutting machines?

There are three primary types of key cutting machines:

- Manual Key Cutting Machines: Operated by hand, these are affordable and portable but require physical effort.

- Electric Key Cutting Machines: Powered by a motor, they offer faster and more precise cuts.

- Laser Key Cutting Machines: The most advanced option, using lasers for unmatched accuracy and handling complex key designs.

Each type suits different needs, from basic duplication to high-security key cutting.

How do you use a key cutting machine?

To use a key cutting machine:

- Secure the original key and the blank key in the machine’s vices.

- Align the keys to ensure the grooves match perfectly.

- Select the appropriate cutting pattern or settings.

- Operate the machine to cut the blank key according to the original key’s design.

- Smooth the edges and test the new key in the lock.

Always follow the manufacturer’s instructions and safety guidelines for optimal results.

How do you keep your key cutting machine clean?

Regular cleaning ensures your key cutting machine operates efficiently. Follow these steps:

- Unplug the machine before cleaning.

- Use a soft brush or compressed air to remove metal shavings and debris.

- Wipe the exterior with a damp cloth and mild cleaning solution.

- Inspect and clean the cutting wheel to maintain sharpness.

Cleaning after every use prevents buildup and prolongs the machine’s lifespan.

Why is maintenance important for key cutting machines?

Maintenance keeps your key cutting machine efficient and extends its life. Neglecting maintenance can lead to inaccurate cuts, machine jamming, or even equipment failure. Regular cleaning, lubrication of moving parts, and inspections help prevent these issues and ensure consistent performance.

What safety precautions should you follow when using a key cutting machine?

To operate a key cutting machine safely:

- Wear safety goggles and gloves to protect yourself from debris.

- Keep your workspace clean and free of clutter.

- Inspect the machine for damage or loose components before use.

- Avoid wearing loose clothing or accessories that could get caught in the machine.

- Stay focused and avoid distractions during operation.

Following these precautions minimizes risks and ensures smooth operation.

What should you do if the machine jams?

If your key cutting machine jams:

- Turn off the machine immediately.

- Remove any debris or obstructions from the cutting area.

- Inspect the cutting wheel and vices for damage.

- Lubricate moving parts to reduce friction.

Regular cleaning and maintenance can help prevent jamming in the future.

How can you troubleshoot inaccurate key cuts?

Inaccurate cuts often result from dull blades, misalignment, or user error. To troubleshoot:

- Sharpen or replace the cutting wheel if it shows signs of wear.

- Double-check the alignment of the original key and the blank.

- Ensure the key blank matches the original key in size and shape.

- Test the key in the lock before removing it from the vice.

Taking these steps ensures precise duplication and reduces wasted blanks.

Can anyone use a laser key cutting machine?

Laser key cutting machines require specialized training due to their advanced technology. You need to understand the software and machine settings to operate them effectively. These machines are ideal for professionals handling high-security or intricate key designs. If you’re new to key cutting, start with manual or electric machines before transitioning to laser models.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Essential Tips for Operating a Die Cutting Machine

Beginner's Guide to Operating a Die Cutting Machine