How to Use Cut Off Machine Safely

Learning how to use a cut-off machine safely is essential, as these powerful tools can cause severe injuries if not handled properly. Improper use often results in accidents, including injuries to the hands, thumbs, or even the face. For example, studies reveal that 86% of adults injured by cutting tools experience hand-related harm. Understanding the risks and taking necessary precautions is crucial to prevent such incidents. By adhering to safety guidelines, you can protect yourself and others from unnecessary danger. Always treat the machine with respect and prioritize safe practices to ensure every task is completed without incident.

Key Takeaways

Always read the user manual before operating a cut-off machine to understand its features and safety guidelines.

- Inspect the machine for any damage or wear before each use to prevent accidents and ensure optimal performance.

- Set up a clutter-free and well-lit workspace to minimize hazards and enhance visibility during cutting tasks.

- Wear essential personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection to safeguard against injuries.

- Follow proper handling techniques, including maintaining a firm grip and standing to the side of the blade to avoid kickback.

- Regularly clean and maintain your cut-off machine to extend its lifespan and ensure safe operation. Always use the correct blade for the material being cut to prevent overheating and potential equipment failure.

Pre-Use Preparation

Before operating a cut-off machine, taking the right steps to prepare ensures both safety and efficiency. Proper preparation minimizes risks and sets the foundation for a smooth cutting process.

Read the User Manual

Start by thoroughly reading the user manual provided by the manufacturer. This document contains essential information about the machine's features, limitations, and safety guidelines. Familiarize yourself with the controls, safety mechanisms, and emergency procedures. Each cut-off machine may have unique specifications, so understanding your specific model is crucial. Never skip this step, as it equips you with the knowledge to handle the machine confidently and safely.

Tip: Always follow the manufacturer's instructions to avoid accidents and ensure optimal performance.

Inspect the Machine

Inspecting the machine before every use is a critical safety measure. Check for visible signs of wear or damage, such as cracks in the blade, loose components, or malfunctioning safety guards. Ensure that the blade is in optimal condition and securely attached. If you notice any issues, address them immediately or consult a professional for repairs. Operating a damaged machine can lead to severe accidents or equipment failure.

Checklist for Inspection:

- Examine the blade for wear and tear.

- Confirm that all safety guards are intact and functional.

- Look for loose or damaged components.

- Test the machine for unusual noises or vibrations.

Never use a machine that appears faulty. Safety should always come first.

Set Up a Safe Workspace

Creating a safe workspace is just as important as inspecting the machine. Choose a stable, level surface to operate the cut-off machine. Remove any obstacles or debris from the area to prevent tripping or interference during operation. Ensure proper lighting so you can see the cutting line clearly. If you are working indoors or in a confined space, ensure adequate ventilation to avoid inhaling harmful fumes or dust.

Safety Tips for Your Workspace:

- Keep the area free of clutter and hazards.

- Maintain a stable stance while operating the machine.

- Avoid working in poorly lit or poorly ventilated spaces.

By preparing your workspace and equipment properly, you reduce the likelihood of accidents and ensure a safer cutting experience.

Personal Protective Equipment (PPE)

Wearing the right personal protective equipment (PPE) is essential when operating a cut-off machine. PPE acts as your first line of defense against potential hazards, ensuring you stay safe while working. By equipping yourself with the proper gear, you reduce the risk of injuries and create a safer working environment.

Essential Safety Gear

Certain safety gear is non-negotiable when using a cut-off machine. These items protect critical areas of your body from harm caused by flying debris, sparks, or accidental contact with the blade. Always ensure you have the following:

- Safety Glasses or Goggles: Protect your eyes from dust, sparks, and fragments that may fly during operation.

- Hearing Protection: Use earplugs or earmuffs to shield your ears from the loud noise generated by the machine.

- Cut-Resistant Gloves: Wear gloves designed to resist cuts and abrasions, providing a secure grip on the machine.

- Steel-Toed Boots: Protect your feet from falling objects or accidental contact with the machine.

- Dust Mask or Respirator: Prevent inhalation of harmful particles, especially when cutting materials that produce fine dust.

Tip: Always inspect your safety gear for damage before use. Replace any worn-out equipment to maintain maximum protection.

Additional Protective Measures

Beyond the essential gear, consider additional measures to enhance your safety. These precautions address specific risks and provide an extra layer of security:

- Face Shield: Use a face shield in combination with safety glasses for full-face protection against sparks and debris.

- Protective Clothing: Wear snug-fitting clothing made of durable material to prevent loose fabric from getting caught in the machine.

- Non-Slip Mat or Footwear: Ensure stability by using non-slip mats or wearing shoes with excellent traction.

- High-Visibility Vest: If working in a shared or busy area, wear a high-visibility vest to make yourself easily noticeable to others.

Reminder: Avoid wearing jewelry, scarves, or any accessories that could get entangled in the machine. Keep long hair tied back securely.

By prioritizing PPE, you significantly lower the chances of accidents and injuries. Understanding how to use cut off machine safely involves not only mastering its operation but also protecting yourself with the right equipment. Always remember that safety starts with preparation.

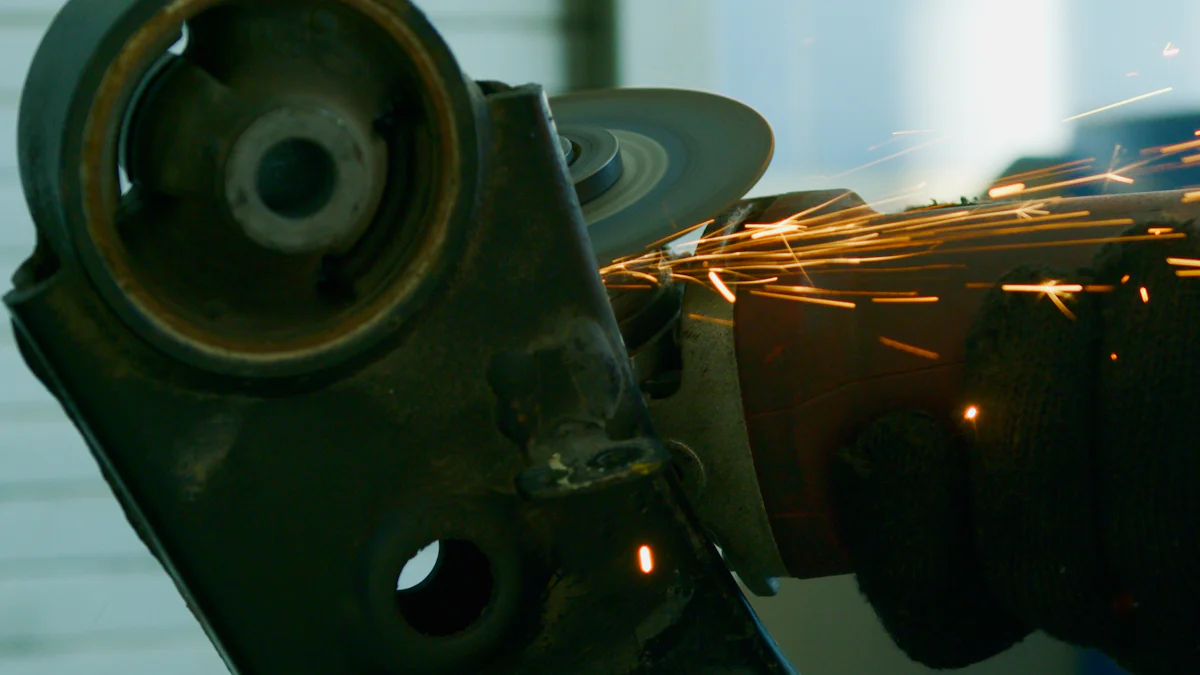

How to Use Cut Off Machine Safely: Operating Guidelines

Operating a cut-off machine requires precision and adherence to safety protocols. By following proper techniques, you can minimize risks and ensure effective performance. This section outlines essential guidelines to help you understand how to use a cut-off machine safely.

Proper Handling Techniques

Handling the cut-off machine correctly is vital for maintaining control and preventing accidents. Always maintain a firm grip on the machine with both hands. Keep your dominant hand on the rear handle and your other hand on the front handle for stability. Stand in a balanced position with your feet shoulder-width apart to ensure a steady stance.

Avoid overreaching or leaning too close to the machine while cutting. Position yourself slightly to the side of the blade, not directly behind it. This reduces the risk of injury if the blade kicks back or breaks. Let the machine reach full speed before making contact with the material, and apply consistent pressure without forcing the blade through the cut.

Tip: Never carry the machine while it is running. Turn it off completely before moving it to another location.

Avoiding Kickback

To avoid kickback, always use a sharp blade that is appropriate for the material you are cutting.

Maintain proper cutting speed and pressure as recommended by the manufacturer. Avoid twisting or tilting the machine during operation, as this can cause the blade to bind. Inspect the material for any embedded objects, such as nails or screws, that could interfere with the blade's movement.

Safety Reminder: Never stand directly in line with the blade while cutting. Position yourself to the side to reduce the risk of injury from sudden movements.

Correct Blade Usage

Select a blade specifically designed for the material you are cutting, whether it is metal, concrete, or wood.

Ensure the blade is securely attached and properly aligned before starting the machine. Keep the blade clean, sharp, and free of debris to maintain optimal performance. Regularly inspect the blade for signs of wear or damage, such as cracks or uneven edges. Replace it immediately if you notice any issues.

Pro Tip: Apply cutting fluids when working with metal to prevent the blade from overheating and to extend its lifespan.

By following these operating guidelines, you can enhance your understanding of how to use a cut-off machine safely. Proper handling, awareness of kickback risks, and correct blade usage are key to achieving safe and efficient results.

Maintenance and Post-Use Safety

Proper maintenance and post-use safety practices are essential to keep your cut-off machine in excellent condition and ensure safe operation. By dedicating time to clean and store the machine correctly, you can extend its lifespan and reduce the risk of accidents during future use.

Cleaning the Machine

Cleaning your cut-off machine after each use is a critical step in maintaining its performance. Dust, debris, and residue from cutting materials can accumulate on the machine, potentially causing damage or reducing efficiency. Follow these steps to clean your machine effectively:

- Turn Off and Unplug: Always ensure the machine is powered off and unplugged before cleaning. This eliminates the risk of accidental activation.

- Remove Debris: Use a soft brush or compressed air to remove dust and debris from the blade, vents, and other components. Pay close attention to areas where particles tend to accumulate.

- Wipe Surfaces: Use a damp cloth to wipe down the exterior surfaces of the machine. Avoid using excessive water, as moisture can damage internal components.

- Inspect the Blade: Check the blade for any residue or buildup. Clean it with a suitable cleaning agent if necessary, and ensure it remains sharp and free of damage.

Pro Tip: Regular cleaning prevents wear and tear caused by debris and ensures the machine operates smoothly during every use.

Storing the Machine Safely

Storing your cut-off machine properly is just as important as cleaning it. Incorrect storage can lead to moisture damage, rust, or accidental injuries. Follow these guidelines to store your machine safely:

- Choose a Dry Location: Store the machine in a dry, well-ventilated area to prevent moisture from causing rust or corrosion. Avoid damp basements or outdoor sheds without proper insulation.

- Use a Protective Cover: Cover the machine with a dust-resistant cover to shield it from dirt and debris while in storage.

- Secure the Blade: Ensure the blade is securely attached or removed and stored separately if recommended by the manufacturer. This reduces the risk of accidental cuts or damage.

- Keep Out of Reach: Store the machine in a location that is out of reach of children or unauthorized users. Use a locked cabinet or designated tool storage area for added safety.

Reminder: Always follow the manufacturer’s instructions for storage to maintain the machine’s condition and ensure it is ready for use when needed.

By incorporating these maintenance and storage practices into your routine, you can enhance the longevity of your cut-off machine and ensure it remains safe to operate. Understanding how to use cut off machine safely includes not only proper operation but also diligent care after each use.

Safety should always be your top priority when using a cut-off machine. By preparing thoroughly, wearing proper personal protective equipment (PPE), following correct operating techniques, and maintaining the machine after use, you can significantly reduce the risk of accidents. These steps not only protect you but also ensure the machine operates efficiently. Always remember that understanding how to use cut off machine safely is a responsibility that requires consistent effort. Stay vigilant, follow these guidelines, and make safety an integral part of every task.

FAQ

What are some safety tips for using a cut-off machine?

To ensure your safety while using a cut-off machine, follow these essential tips:

- Always wear proper personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Inspect the machine and blade for any damage or wear before use.

- Set up a stable and clutter-free workspace with adequate lighting and ventilation.

- Use the correct blade for the material you are cutting to prevent overheating or blade failure.

- Maintain a firm grip on the machine and stand slightly to the side of the blade to avoid potential kickbacks.

Remember: Safety starts with preparation. Never skip these steps to protect yourself and others.

What should you do before starting any cutting task?

Before beginning any cutting task, take the following precautions:

- Inspect the machine for signs of damage, such as worn-out blades or loose components.

- Ensure all safety guards are securely in place and functioning properly.

- Familiarize yourself with the machine’s controls and emergency procedures.

- Clear the workspace of obstacles and hazards. Confirm that you are using the appropriate blade for the material.

Tip: Never operate a machine that appears faulty. Address any issues immediately to avoid accidents.

Why is safety important when operating a cut-off machine?

Safety is crucial when operating a cut-off machine because improper use can lead to severe injuries. These machines are powerful tools that require careful handling. Following safety guidelines reduces risks, ensures a productive work environment, and protects you from harm. Proper precautions, such as wearing PPE and inspecting the machine, help prevent accidents and equipment failure.

Key Takeaway: Prioritizing safety not only protects you but also ensures the machine operates efficiently.

What personal protective equipment (PPE) should you wear?

When using a cut-off machine, always wear the following PPE:

- Safety Glasses or Goggles: Protect your eyes from flying debris and sparks.

- Hearing Protection: Shield your ears from the loud noise of the machine.

- Cut-Resistant Gloves: Provide a secure grip and protect your hands from cuts.

- Steel-Toed Boots: Safeguard your feet from falling objects or accidental contact.

- Dust Mask or Respirator: Prevent inhalation of harmful particles.

Additional Tip: Consider wearing a face shield and snug-fitting clothing for extra protection.

How can you avoid kickback while cutting?

Kickback occurs when the blade binds or gets pinched, causing the machine to jerk backward. To avoid this hazard:

- Use a sharp blade suitable for the material you are cutting.

- Maintain consistent cutting speed and pressure.

- Avoid twisting or tilting the machine during operation.

- Inspect the material for embedded objects like nails or screws.

- Stand slightly to the side of the blade, not directly behind it.

Safety Reminder: Always let the machine reach full speed before making contact with the material.

What should you do after using a cut-off machine?

After using a cut-off machine, follow these steps to ensure safety and maintain the equipment:

- Turn off and unplug the machine before cleaning.

- Remove dust and debris using a soft brush or compressed air.

- Wipe down the exterior with a damp cloth, avoiding excessive moisture.

- Inspect the blade for residue or damage and clean it if necessary.

- Store the machine in a dry, secure location, away from children or unauthorized users.

Pro Tip: Regular maintenance extends the lifespan of your machine and ensures it remains safe to use.

Can you use any blade with a cut-off machine?

No, you should only use blades specifically designed for your cut-off machine and the material you are cutting. Using an inappropriate blade can lead to overheating, warping, or catastrophic failure. Always check the manufacturer’s recommendations and inspect the blade for damage before use.

Important Note: A well-maintained, appropriate blade ensures both safety and efficiency.

What should you avoid wearing while operating a cut-off machine?

Avoid wearing loose clothing, jewelry, or accessories that could get caught in the machine. Keep long hair tied back securely. These precautions prevent entanglement, which can lead to serious injuries.

Reminder: Snug-fitting, durable clothing is the safest choice when working with power tools.

How do you prepare your workspace for cutting?

To prepare your workspace:

- Choose a stable, level surface for the machine.

- Remove clutter, debris, and obstacles from the area.

- Ensure proper lighting to see the cutting line clearly.

- Provide adequate ventilation, especially when working indoors or with materials that produce dust.

Tip: A well-organized workspace minimizes distractions and reduces the risk of accidents.

Is training necessary before using a cut-off machine?

Yes, proper training is essential before operating a cut-off machine. Training helps you understand the machine’s controls, safety features, and emergency procedures. It also ensures you are aware of industry best practices and safety guidelines.

Key Advice: Never operate a cut-off machine without adequate training. It’s a critical step in preventing accidents and ensuring safe operation.

See Also

Essential Advice for Operating a Meat Cutter

Maximizing Efficiency with Your Laser Cutting Tool

Comprehensive Instructions for Hair Clipper Usage