How to Operate a Laser Cutting Machine: Step-by-Step

Ever wondered how to operate a laser cutting machine with precision and ease? You're in the right place! Learning how to operate a laser cutting machine is crucial as these machines have become essential in various industries due to their high accuracy, speed, and versatility. Whether you're a beginner or looking to refine your skills, following a step-by-step guide on how to operate a laser cutting machine ensures you achieve the best results. These machines offer unmatched precision, making them a preferred choice over traditional methods. By understanding how to operate a laser cutting machine and the associated procedures, you can harness the full potential of this technology and enhance your projects significantly.

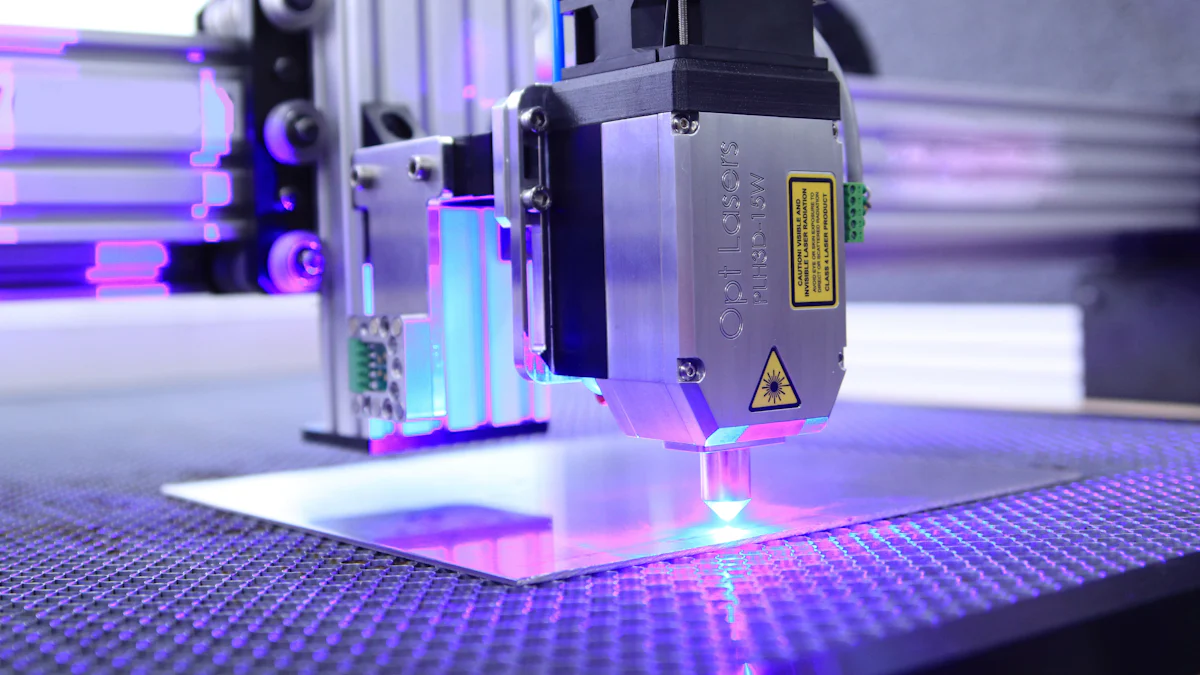

Understanding Laser Cutting Machines

When you dive into the world of laser cutting, understanding the different types of machines and their components is crucial. This knowledge forms the foundation of your journey in mastering the art of laser cutting.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each designed for specific tasks and materials. The most common types include:

-

CO2 Laser Cutting Machines: These machines use CO2 gas to cut through materials like metal and non-metal. They are widely used in industrial fabrication due to their ability to cut carbon steel, stainless steel, and aluminum alloy with precision. CO2 lasers are known for their versatility and are a staple in many workshops.

-

Fiber Laser Cutting Machines: Fiber lasers are ideal for cutting metals. They offer high-speed cutting and are energy-efficient. These machines excel in cutting thin materials and are often used in industries where speed and precision are paramount.

-

Nd:YAG Laser Cutting Machines: These are solid-state lasers used for high-power applications. They are suitable for cutting and engraving metals and ceramics. Nd:YAG lasers are often found in industries requiring deep penetration and high-quality cuts.

Understanding these types helps you choose the right machine for your specific needs, ensuring optimal cutting quality and efficiency.

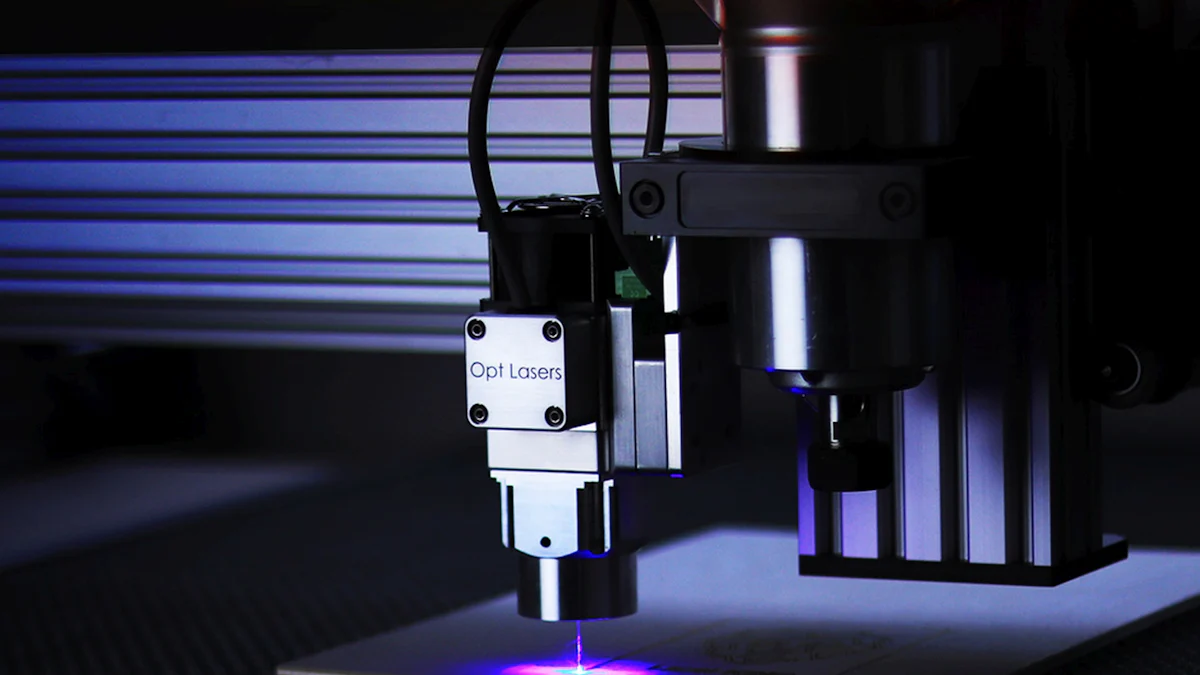

Key Components and Functions

A laser cutter relies on several key components to function effectively. Knowing these components helps you operate the machine with confidence:

-

Laser Source: This is the heart of the laser cutter. It generates the laser beam that cuts through materials. The type of laser source determines the machine's capabilities and the materials it can handle.

-

Laser Head: The laser head directs the laser beam onto the material. It contains lenses and mirrors that focus the beam to a precise point, ensuring accurate cuts.

-

Optics: These include lenses and mirrors that guide and focus the laser beam. Proper maintenance of optics is essential for maintaining cutting quality.

-

Control System: This system allows you to program and control the laser cutter. It ensures the machine follows the desired path and executes the design accurately.

-

Motion System: This component moves the laser head and the work table. It ensures precise positioning and smooth movement during the cutting process.

-

Work Table: The surface where you place the material to be cut. A stable and flat work table is crucial for achieving consistent results.

-

Cooling System: This system prevents the laser cutter from overheating. It ensures the machine operates efficiently and prolongs its lifespan.

-

Exhaust System: It removes fumes and debris generated during the cutting process. A good exhaust system is vital for maintaining a clean and safe working environment.

-

Assist Gas System: This system uses gases like oxygen or nitrogen to enhance the cutting process. It helps remove molten material and improves the quality of the cut.

By familiarizing yourself with these components, you can better understand how a laser cutting machine operates and how to maintain it for optimal performance. This knowledge is a key part of the step-by-step process to becoming proficient in laser cutting basics.

Preparing the Machine and Materials

Before you start using a laser cutting machine, it's crucial to prepare both the machine and the materials properly. This preparation ensures a smooth and efficient laser cutting process, minimizing errors and maximizing safety.

Safety Precautions

Safety should always be your top priority when operating a laser cutter. These machines can pose significant risks if not handled correctly. Here are some essential safety precautions to follow:

-

Wear Protective Gear: Always wear safety goggles to protect your eyes from the laser beam. Gloves and protective clothing can also help shield you from potential hazards.

-

Check the Environment: Ensure the workspace is clean and free from flammable materials. A clutter-free environment reduces the risk of accidents.

-

Regular Maintenance: Keep your laser cutting machine in top condition. Regular maintenance helps identify potential issues before they become safety hazards. This practice not only improves safety but also prolongs the machine's lifespan.

-

Stay Alert: Never become complacent. Accidents often happen when operators let their guard down. Always stay focused and aware of your surroundings.

"Accidents happen when people become complacent in their routines. It is important to always think about safety when working near lasers--or any other machinery for that matter." - Laser Cutter Safety Tips

Setting Up the Machine

Setting up the machine correctly is vital for achieving precise cuts. Follow these steps to ensure your laser cutter is ready for action:

-

Power On: Turn on the laser cutting machine and allow it to warm up. This step ensures the laser reaches optimal operating conditions.

-

Check the Optics: Inspect the lenses and mirrors for dust or damage. Clean them if necessary to maintain cutting quality.

-

Calibrate the Laser: Adjust the laser head and focus the beam. Proper calibration ensures accurate cuts and prevents material wastage.

-

Test the Motion System: Run a quick test to ensure the motion system moves smoothly. This step helps avoid any disruptions during the cutting process.

Selecting and Preparing Materials

Choosing the right materials and preparing them correctly is crucial for successful laser cutting. Here's how to do it:

-

Material Selection: Choose materials compatible with your laser cutter. Different machines handle different materials, so ensure your selection matches the machine's capabilities.

-

Material Preparation: Clean the materials to remove dust and debris. This step ensures the laser cuts smoothly without interruptions.

-

Positioning: Place the material on the work table securely. Proper positioning prevents movement during the cutting process, ensuring precise results.

By following these steps, you set the stage for a successful laser cutting session. Proper preparation not only enhances the quality of your cuts but also ensures a safe and efficient operation.

Creating and Importing Design Files

Designing your project is a crucial step in operating a laser cutting machine. You need to create precise and detailed design files to ensure the machine cuts accurately. Let's dive into how you can design with software and import those files to your laser cutter.

Designing with Software

To start, you'll need to use design software to create your project. Several popular programs can help you design vector files suitable for laser cutting. Here are some options:

-

CorelDRAW: Known for its user-friendly interface, CorelDRAW is great for creating detailed vector designs. It offers a range of tools that make it easy to draw and edit shapes.

-

Adobe Illustrator: This software is a favorite among designers for its versatility and precision. It allows you to create intricate designs with ease, making it ideal for complex laser cutting projects.

-

AutoCAD: If you're working on technical or architectural designs, AutoCAD is your go-to. It enables you to create precise 2D or 3D models, ensuring thorough planning before cutting.

-

Inkscape: A free alternative, Inkscape provides robust features for vector design. It's perfect for beginners looking to explore laser cutting without investing in expensive software.

-

DraftSight: This software is another excellent choice for creating detailed designs. It supports various file formats, making it easy to export your work to a laser cutting machine.

Once you've chosen your software, start designing your project. Pay attention to details like line thickness and dimensions, as these will affect the final cut. Remember, the more precise your design, the better the laser cutting machine will perform.

Importing Files to the Machine

After designing your project, the next step is to import the files to your laser cutting machine. Here's how you can do it:

-

Export Your Design: Save your design in a compatible format, such as DXF, SVG, or AI. These formats are widely accepted by most laser cutting machines.

-

Transfer the File: Use a USB drive, network connection, or direct cable to transfer the file to the machine. Ensure the file is correctly formatted and free of errors.

-

Load the File: Access the machine's control system and load your design file. Follow the machine's instructions to ensure the file is ready for cutting.

-

Set Parameters: Adjust the machine's settings based on your material and design. This includes setting the power, speed, and frequency to match your project's requirements.

-

Preview the Design: Before starting the cut, preview the design on the machine's interface. This step helps you verify the alignment and scale, reducing the risk of errors.

By following these steps, you can seamlessly transition from design to cutting. Properly importing your files ensures the laser cutting machine executes your design accurately, resulting in high-quality cuts.

Configuring Laser Settings

Getting the laser settings just right is crucial for achieving precise cuts with your laser cutter. Let's dive into how you can adjust the power and speed, and focus the laser to ensure optimal performance.

Adjusting Power and Speed

When it comes to using a laser cutter, adjusting the power and speed settings is like fine-tuning a musical instrument. You want to hit the right notes for your material. Here's how you can do it:

-

Understand Material Requirements: Different materials require different settings. For instance, cutting through thick acrylic needs more power than thin paper. Check your laser cutter's manual for recommended settings or presets for various materials. These presets can save you time and help you avoid trial and error.

-

Set the Power: Power determines how deep the laser cuts. Higher power means deeper cuts, but it can also lead to burning or melting if not set correctly. Start with the recommended power setting and adjust as needed. If you're cutting a new material, test on a small piece first.

-

Adjust the Speed: Speed affects the precision and quality of the cut. Slower speeds allow for more precise cuts, while faster speeds can lead to rough edges. Balance is key. If you notice charring or incomplete cuts, tweak the speed setting.

-

Test and Refine: Always run a test cut before starting your main project. This helps you see how the settings affect the material. Make adjustments based on the test results to achieve the best outcome.

"Presets: Your laser should have some suggested settings for cutting or engraving different materials and different thicknesses." - Instructables

Focusing the Laser

Focusing the laser is like adjusting the lens on a camera. You want the beam to be sharp and precise. Here's how you can focus your laser cutter:

-

Check the Focus Lens: Ensure the focus lens is clean and free from dust. A dirty lens can scatter the laser beam, affecting the cut quality. Regular cleaning keeps your laser cutter in top shape.

-

Adjust the Focus Height: Most laser cutters have a focus gauge or tool. Use it to set the correct distance between the laser head and the material. This distance is crucial for achieving a sharp focus.

-

Perform a Focus Test: Run a focus test by cutting a small line or shape. Examine the edges for sharpness. If the edges are blurry or uneven, adjust the focus height and test again.

-

Lock the Settings: Once you've found the perfect focus, lock the settings in place. This prevents accidental changes during the cutting process.

By mastering these settings, you can ensure your laser cutting machine performs at its best. Proper configuration leads to cleaner cuts, less material waste, and a smoother workflow.

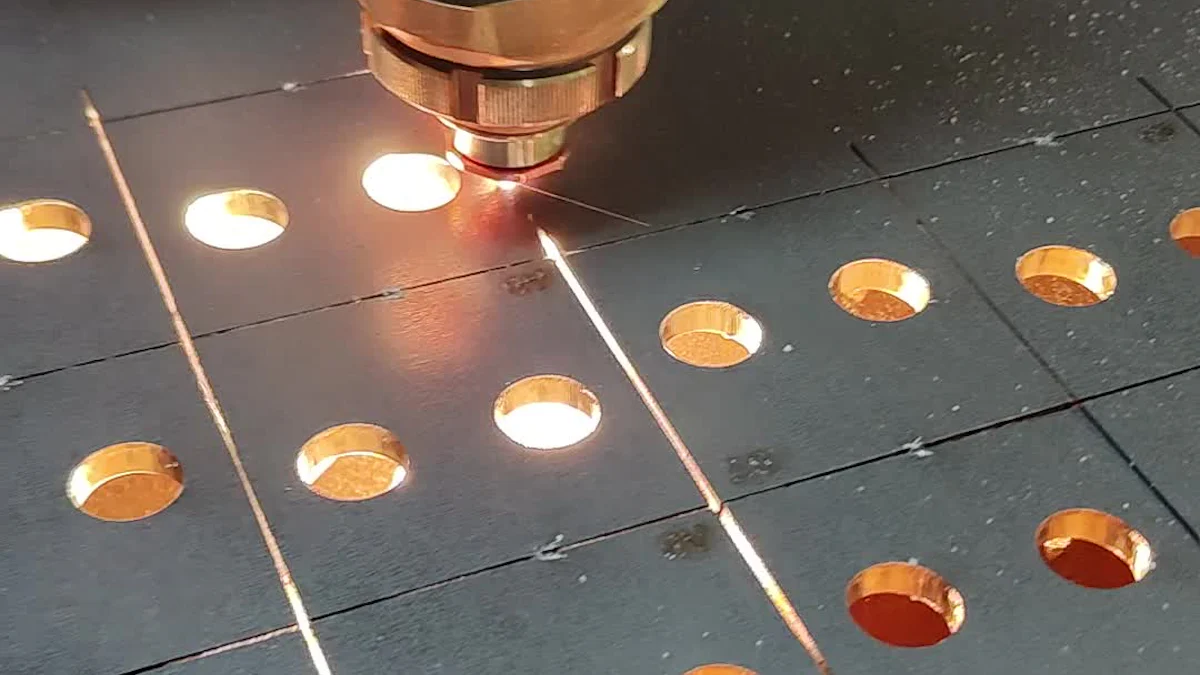

Loading Materials and Securing Them

When you're ready to start cutting, loading your materials onto the laser cutting machine is a crucial step. Proper positioning and securing of materials ensure precision and safety during the cutting process.

Positioning Materials on the Bed

First, you need to position your materials correctly on the machine's bed. This step is essential for achieving accurate cuts. Here's how you can do it:

-

Use Proper Equipment: If you're working with heavy materials like metal sheets, use a forklift or hoisting equipment. This ensures you place the materials flat on the loading platform without straining yourself. Safety first!

-

Align the Material: Make sure the material is aligned with the machine's guides. Proper alignment helps the laser cutter follow the design accurately. Take your time to adjust the material until it's perfectly positioned.

-

Check for Flatness: Ensure the material lies flat on the bed. Any warping or unevenness can affect the cut quality. Use weights or clamps if necessary to keep the material flat.

"Utilize a forklift or hoisting equipment to place the metal sheets flat on the loading platform, ensuring the material is flat and securely fastened." - Material Loading

Securing Materials to Prevent Movement

Once you've positioned the material, securing it is the next step. This prevents any movement during the cutting process, which could lead to errors.

-

Use Clamps or Weights: Secure the material with clamps or weights. This keeps it steady and prevents any shifting. Make sure the clamps don't interfere with the laser path.

-

Double-Check the Setup: Before starting the cut, double-check that everything is secure. Give the material a gentle nudge to ensure it doesn't move. Better safe than sorry!

-

Consider Using Adhesive: For lighter materials, consider using a temporary adhesive to hold them in place. This can be especially useful for intricate designs where precision is key.

By carefully positioning and securing your materials, you set the stage for a successful cutting session. These steps help you achieve clean, precise cuts and minimize the risk of errors.

Running the Cutting Program

Once you've set up your laser cutting machine and prepared your materials, it's time to run the cutting program. This stage is where all your preparation pays off, and you see your design come to life.

Starting the Cutting Process

Starting the cutting process involves a few essential steps to ensure everything runs smoothly:

-

Perform a Trial Cut: Before you dive into the main project, make a trial cut on a piece of scrap material. This step helps you verify that the settings are correct and the laser cutting machine is ready to perform. It’s a small step that can save you from costly mistakes.

-

Load the Design File: Ensure your design file is correctly loaded into the machine's control system. Double-check the alignment and scale to match your material setup.

-

Initiate the Cut: Once everything looks good, initiate the cutting process. Press the start button and watch as the laser cutting machine begins its work. The laser will follow the path outlined in your design file, cutting with precision.

-

Stay Alert: Keep an eye on the machine as it starts cutting. Listen for any unusual sounds or see if there are any unexpected movements. These could indicate a problem that needs immediate attention.

"Before formal cutting, you must make a trial cut on the scrap material to check the cutting effect."

Monitoring the Operation

Monitoring the operation is crucial to ensure the laser cutting process goes as planned:

-

Track the Progress: Use the machine's monitoring system to track the cutting progress. This system provides real-time feedback on how the cut is proceeding. If you notice any anomalies, be ready to pause the operation and make necessary adjustments.

-

Check the Quality: As the machine cuts, periodically check the quality of the cuts. Look for clean edges and consistent depth. If you spot any issues, adjust the parameters like speed or power to improve the results.

-

Be Prepared to Intervene: Sometimes, things don't go as planned. Be prepared to stop the machine if something seems off. It's better to pause and fix an issue than to let it ruin your entire project.

-

Ensure Safety: Always prioritize safety. Keep the workspace clear and avoid distractions. Remember, a focused operator is a safe operator.

By carefully starting and monitoring the cutting process, you ensure that your project turns out just as you envisioned. This attention to detail not only enhances the quality of your work but also helps you become more proficient with your laser cutting machine.

Unloading and Cleaning Up

After completing your cutting project, it's time to safely remove the cut pieces and clean up your workspace. This step ensures your laser cutting machine remains in top condition and ready for future projects.

Safely Removing Cut Pieces

Removing your cut pieces requires care to avoid damage or injury. Follow these steps to ensure a smooth process:

-

Turn Off the Machine: Before you start, make sure the laser cutting machine is powered off. This prevents accidental activation while you're handling the materials.

-

Use Proper Tools: Gently lift the cut pieces using appropriate tools like tweezers or a spatula. This helps prevent any bending or breaking, especially with delicate materials.

-

Inspect the Cuts: As you remove each piece, inspect it for quality. Look for clean edges and ensure the cuts match your design specifications. If you notice any issues, adjust your settings for future projects.

-

Organize the Pieces: Place the cut pieces in a designated area to keep them organized. This makes it easier to assemble or use them in your next steps.

Cleaning the Machine and Work Area

A clean machine and workspace are crucial for maintaining performance and safety. Here's how you can keep everything tidy:

-

Remove Scrap Material: Clear out any leftover scrap from the catch-bin. Leaving scraps can pose a fire hazard, as they might ignite and cause explosions. Regularly emptying the bin keeps your workspace safe.

-

Clean the Inside: Dust and debris can accumulate inside the laser cutter. Use a vacuum or soft brush to clean the cutting deck and other areas where dust gathers. This prevents dust from igniting and ensures smooth operation.

-

Wipe Down Lenses and Mirrors: Clean the lenses and mirrors to prevent power loss and damage from dust buildup. Use a soft, lint-free cloth and a suitable cleaning solution to gently wipe these components.

-

Check the Exhaust System: Ensure the exhaust system is free from blockages. A clear exhaust system helps remove fumes and debris, maintaining a clean environment.

-

Regular Maintenance: Schedule regular maintenance checks to keep your laser cutting machine running smoothly. This reduces the likelihood of breakdowns and extends the machine's lifespan.

By following these steps, you ensure your laser cutting machine stays in excellent condition, ready for your next creative endeavor. Regular cleaning and maintenance not only enhance performance but also contribute to a safer and more efficient workspace.

You've now got a comprehensive guide to operating a laser cutting machine. By following these steps, you ensure precision and efficiency in your projects. Remember, safety is paramount. Always wear protective gear and keep your workspace tidy. If you're ever unsure about a material or procedure, reach out to technical support. Having an emergency plan is wise too. Precision and safety go hand in hand for optimal results. Keep practicing, and you'll master the art of laser cutting in no time!

FAQ

What are the most frequently asked questions about laser cutting basics?

When you're diving into the world of laser cutting, you might have a bunch of questions. Here are some of the most common ones we hear:

-

What materials can I cut with a laser cutter?

You can cut a variety of materials, including wood, acrylic, leather, fabric, and certain metals. Always check your machine's specifications to ensure compatibility.

-

How do I choose the right laser cutter for my needs?

Consider the types of materials you'll be working with, the thickness of those materials, and the precision required. Also, think about your budget and the space available in your workshop.

-

Yes, laser cutting is safe when you follow proper safety precautions. Always wear protective gear, keep your workspace clean, and regularly maintain your machine.

-

How do I maintain my laser cutting machine?

Regularly clean the lenses and mirrors, check the exhaust system, and perform routine maintenance checks. This keeps your machine running smoothly and extends its lifespan.

-

Can I engrave with a laser cutter?

Absolutely! Many laser cutters can both cut and engrave. You can create intricate designs on various materials, adding a personal touch to your projects.

-

What software should I use for designing laser cutting projects?

Popular options include CorelDRAW, Adobe Illustrator, AutoCAD, and Inkscape. Choose software that suits your design needs and skill level.

-

How do I ensure precise cuts with my laser cutter?

Properly configure your laser settings, focus the laser accurately, and secure your materials on the bed. Running a test cut can also help you fine-tune your settings.

-

What should I do if my laser cutter isn't cutting properly?

Check the power and speed settings, clean the optics, and ensure the material is flat and secure. If problems persist, consult your machine's manual or reach out to technical support.

-

How long does it take to learn laser cutting?

The learning curve varies depending on your experience and the complexity of your projects. With practice and patience, you'll become proficient in no time.

-

Where can I find more resources on laser cutting?

Online forums, tutorials, and manufacturer websites are great places to start. Joining a community of laser cutting enthusiasts can also provide valuable insights and support.

These FAQs cover the basics and should help you get started on your laser cutting journey. If you have more questions, don't hesitate to reach out to experts or explore online resources. Happy cutting!

See Also

Maximizing Efficiency with Your Laser Cutting Machine

A Comprehensive Guide to Operating Hair Cutting Machines

Understanding the Functionality of CNC Laser Cutters