How to Operate CNC Laser Cutting Machine Safely

Learning how to operate a CNC laser cutting machine involves strict adherence to safety protocols. Prioritizing safety is crucial to prevent accidents and injuries. When used correctly, CNC laser cutting machines are typically low-risk, Class 1 lasers, but they can still pose hazards if safety features are bypassed. Personal Protective Equipment (PPE), such as coveralls, head covers, and face shields, is essential to protect against contaminants. Always ensure that the machine's safety features remain intact and functional. By following these guidelines, you can safely harness the power of CNC laser cutting technology.

Safety Precautions for Laser Cutter

Ensuring safety while operating a laser cutter is paramount. You must adhere to specific precautions to protect yourself and maintain a safe working environment. This section will guide you through essential protective gear and necessary safety checks.

Essential Protective Gear

When using a laser cutter, wearing the right protective gear is crucial. This gear shields you from potential hazards associated with laser cutting.

Eye Protection

Your eyes are particularly vulnerable when operating a laser cutter. Always wear safety goggles designed for laser protection. These goggles prevent harmful laser radiation from damaging your eyes. Never compromise on eye protection, as it is a vital component of your safety gear.

Protective Clothing

In addition to eye protection, you should wear appropriate clothing. Personal Protective Equipment (PPE) includes coveralls and head covers. These items protect your skin from laser exposure and potential debris. Ensure that your clothing is non-flammable to reduce fire risks.

Conducting Safety Checks

Before starting any cutting operation, conducting thorough safety checks is essential. These checks ensure that the laser cutter operates safely and efficiently.

Machine Inspection

Regularly inspect the laser cutter to ensure it is in good working condition. Check for any signs of wear or damage. Make sure all safety features are intact and functional. A well-maintained machine reduces the risk of accidents during the cutting process.

Ventilation and Fire Safety

Proper ventilation is crucial when using a laser cutter. Ensure that the workspace is well-ventilated to prevent the buildup of fumes and smoke. Keep a fire extinguisher nearby and ensure the area around the cutter is free of flammable materials. Following these precautions minimizes fire risks and maintains a safe environment.

By following these safety precautions, you can operate a laser cutter confidently and safely. Always prioritize safety to prevent accidents and ensure a smooth cutting process.

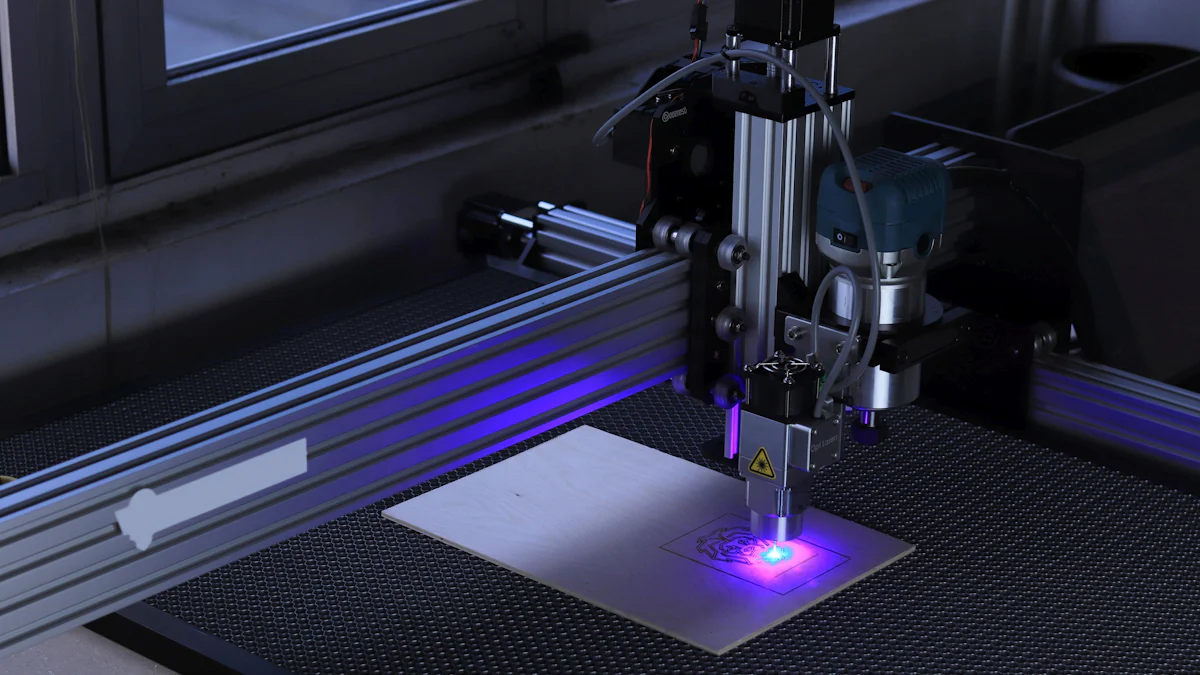

Machine Setup for Laser Cutting

Setting up your CNC laser cutting machine correctly is crucial for achieving precise cuts and ensuring safety. This section will guide you through the necessary steps to prepare both the machine and the material for a successful cutting operation.

Preparing the CNC Laser Cutting Machine

Before you start cutting, you need to ensure that the CNC laser cutter is ready for operation. Proper preparation involves checking the power supply and connections, as well as configuring the software.

Power Supply and Connections

- Check the Power Supply: Ensure that the laser cutter is connected to a stable power source. Unstable power can lead to malfunctions or damage to the machine.

- Inspect Connections: Verify that all cables and connections are secure. Loose connections can cause interruptions during the cutting process.

Software Configuration

- Install Necessary Software: Make sure that the required software for operating the laser cutter is installed on your computer. This includes any drivers and control software specific to your machine.

- Configure Settings: Open the software and configure the settings according to the material you plan to cut. This step is crucial for choosing print settings that match the material's properties.

- Load the Design: Use vector graphics software to create an image file of your design. Import this file into the laser cutter's software, ensuring it is compatible and ready for cutting.

Material Preparation for Laser Cutting

Proper material preparation is essential for achieving clean and accurate cuts. This involves selecting the right material and securing it on the laser cutter's bed.

Material Selection

- Choose the Right Material: Different materials react differently to laser cutting. Select a material that is suitable for your project and compatible with your laser cutter's capabilities.

- Consider Material Thickness: The thickness of the material affects the cutting speed and power settings. Ensure that your machine can handle the thickness of the material you choose.

Securing the Material

- Position the Material: Place the material flat on the laser cutter's bed. Ensure it is aligned properly with the cutting area.

- Secure the Material: Use clamps or weights to hold the material in place. This prevents movement during the cutting process, ensuring precision and safety.

By following these steps, you can effectively prepare your CNC laser cutting machine and material for operation. Proper setup minimizes risks and enhances the quality of your cuts, allowing you to focus on mastering cutting techniques and achieving the desired results.

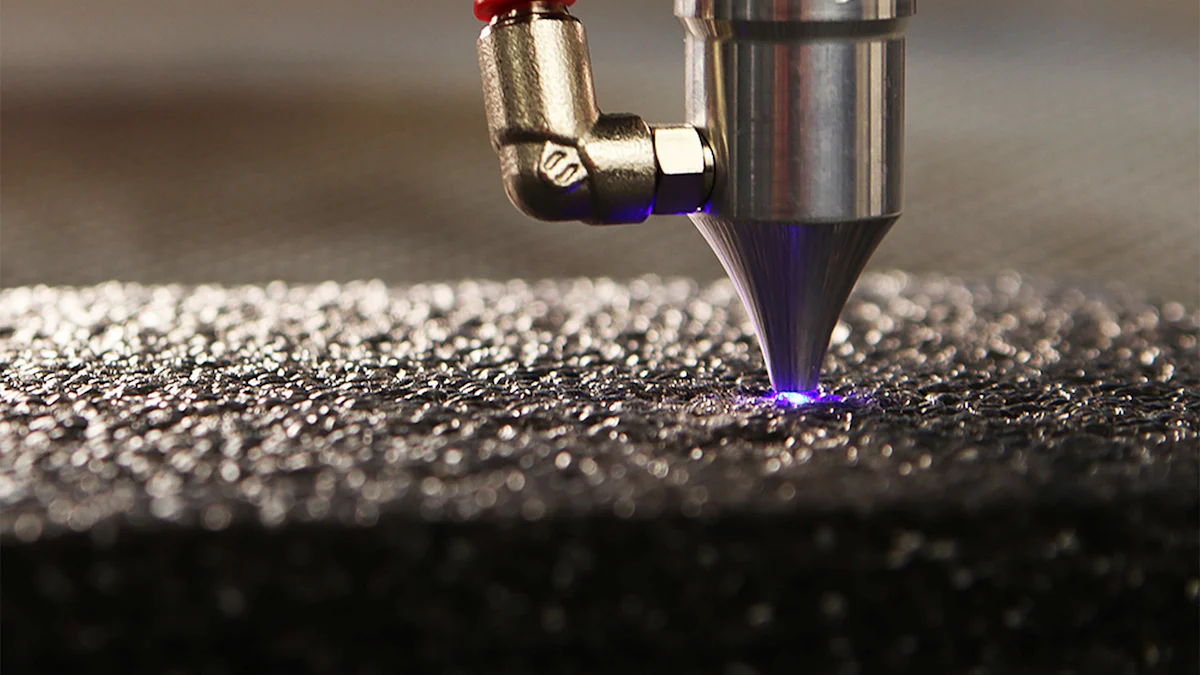

How to Operate CNC Laser Cutting Machine

Operating a CNC laser cutting machine requires careful attention to detail and adherence to safety protocols. This step-by-step guide will help you understand how to operate CNC laser cutting machine effectively, ensuring both safety and precision in your work.

Step-by-Step Operating Guide

Starting the Machine

- Power On: Begin by powering on the CNC laser cutting machine. Ensure that all safety features are active and functioning. This step is crucial for maintaining a safe work environment.

- Warm-Up: Allow the machine to warm up. This process ensures that the laser reaches optimal operating conditions, which is essential for precise cuts.

Loading the Design File

- Prepare Your Design: Use design software to create or select the graphic you wish to cut or engrave. Tutorials can be helpful if you're new to design software.

- Transfer the File: Load the design file into the machine's software. Ensure compatibility to avoid errors during the cutting process.

- Preview the Design: Before proceeding, preview the design on the machine's interface. This step helps confirm that the layout matches your expectations.

Adjusting Settings

- Select Material Settings: Choose the appropriate settings based on the material you are using. Different materials require specific power and speed settings for optimal results.

- Focus the Laser: Adjust the laser focus to match the thickness of the material. Proper focus is vital for achieving clean cuts and engravings.

- Test Cut: Perform a test cut on a scrap piece of material. This practice helps verify that the settings are correct and that the machine is ready for the actual cutting task.

Monitoring the Cutting Process

- Supervise the Operation: Stay attentive while the machine operates. Monitoring the process helps prevent accidents and ensures that the cut is proceeding as planned.

- Watch for Issues: Be alert for any signs of malfunction or irregularities. If you notice anything unusual, pause the operation and troubleshoot the issue.

- Complete the Cut: Once the cutting process is finished, carefully remove the material. Inspect the final product to ensure it meets your quality standards.

By following these steps, you can confidently operate a CNC laser cutting machine. Remember, understanding how to operate CNC laser cutting machine safely and effectively is crucial for achieving high-quality results and maintaining a secure work environment.

Post-Operation Procedures for Laser Cutter

After completing your laser cutting tasks, it's crucial to follow proper post-operation procedures. These steps ensure the safety and longevity of your laser cutter, as well as maintain a clean and efficient workspace.

Safe Shutdown Process

Powering Down the Machine

- Turn Off the Laser Cutter: Begin by switching off the laser cutter. This step prevents any accidental activation and ensures the machine is safe to handle.

- Disconnect Power Supply: Unplug the machine from the power source. This action eliminates any risk of electrical hazards during maintenance or cleaning.

Cleaning the Work Area

- Remove Residual Material: Clear away any leftover material from the cutting bed. This practice prevents debris from interfering with future cuts and maintains a tidy workspace.

- Wipe Down Surfaces: Use a damp cloth to clean the machine's surfaces. Removing dust and particles helps keep the laser cutter in optimal condition.

- Check Ventilation System: Ensure that the ventilation system is free of obstructions. Proper ventilation is crucial to prevent the buildup of fumes and maintain a safe environment.

Maintenance Tips for Laser Cutting Machine

Regular maintenance is essential for the safe and efficient operation of your laser cutter. By following a maintenance schedule, you can prevent malfunctions and extend the machine's lifespan.

Regular Maintenance Schedule

- Weekly Inspections: Conduct weekly checks of the laser cutter. Look for signs of wear or damage, especially in the laser lens and mirrors. Clean these components to ensure clear laser paths.

- Monthly Servicing: Perform a more thorough inspection each month. Check the alignment of the laser beam and ensure all mechanical parts are functioning smoothly. Lubricate moving parts as needed.

Troubleshooting Common Issues

- Identify Problems Early: Stay alert for any irregularities during operation. Unusual noises or inconsistent cuts may indicate underlying issues.

- Consult the Manual: Refer to the manufacturer's manual for troubleshooting guidance. This resource provides specific solutions for common problems.

- Seek Professional Help: If you encounter persistent issues, contact a professional technician. Expert assistance ensures that repairs are done correctly and safely.

By adhering to these post-operation procedures, you can maintain a safe and efficient laser cutting environment. Regular maintenance not only enhances the performance of your laser cutter but also safeguards against potential hazards.

Operating a CNC laser cutting machine safely requires your full attention to safety protocols. Always wear the appropriate protective gear, such as safety goggles and non-flammable clothing, to shield yourself from potential hazards. Conduct regular inspections and ensure proper ventilation to maintain a safe environment. Follow the outlined procedures for machine setup, operation, and post-operation maintenance. By adhering to these guidelines, you can ensure both safety and efficiency in your cutting tasks. Remember, your commitment to safety not only protects you but also enhances the quality of your laser cutting projects.

FAQ

What is laser cutting and engraving?

Laser cutting and engraving involve using a CNC laser to move in the X-Y plane, allowing you to cut or engrave materials. This process does not involve Z movement, meaning the laser cannot create blind holes or slots. Instead, it can engrave just the surface or cut entirely through the material. This technique is ideal for creating intricate designs and patterns with precision.

What are the advantages of laser cutting?

Laser cutting offers several benefits. It uses a focused laser beam to produce clean, accurate edges, making it perfect for creating shapes, parts, and custom designs. The process allows you to craft complex shapes with high precision, resulting in minimal waste and reducing the need for post-processing. This efficiency makes laser cutting a preferred choice in various industries.

How frequently is laser cutting used?

Laser cutting is a widely used process today, thanks to its high accuracy, speed, and versatility. It is suitable for cutting a variety of materials, making it a popular choice in manufacturing and design. The ability to produce precise cuts quickly has made laser cutting an essential tool in many fields.

What materials can be cut with a laser cutter?

Laser cutters can handle a wide range of materials, including wood, acrylic, plastic, fabric, and metal. However, the type of material you choose will affect the laser's settings, such as power and speed. Always ensure that the material is compatible with your laser cutter to achieve the best results.

Are there any safety concerns with laser cutting?

Yes, safety is a critical concern when operating a laser cutter. You must wear appropriate protective gear, such as safety goggles and non-flammable clothing, to protect yourself from potential hazards. Regularly inspect the machine and ensure proper ventilation to maintain a safe environment.

What are the things you'll need to operate a laser cutter safely?

To operate a laser cutter safely, you'll need several things. These include personal protective equipment (PPE) like safety goggles and protective clothing, a well-ventilated workspace, and a fire extinguisher nearby. Additionally, ensure that the laser cutter is in good working condition and that you follow all safety protocols.

How do I maintain a laser cutter?

Regular maintenance is crucial for the efficient operation of your laser cutter. Conduct weekly inspections to check for wear or damage, especially in the laser lens and mirrors. Clean these components regularly to ensure clear laser paths. Monthly servicing should include checking the alignment of the laser beam and lubricating moving parts as needed.

Can laser cutting be used for engraving?

Yes, laser cutting can also be used for engraving. By adjusting the laser's power and speed settings, you can engrave intricate designs onto the surface of various materials. This versatility makes laser cutting a valuable tool for both cutting and engraving applications.

What should I do if I encounter issues with my laser cutter?

If you experience problems with your laser cutter, first consult the manufacturer's manual for troubleshooting guidance. This resource provides specific solutions for common issues. If the problem persists, seek professional help to ensure that repairs are done correctly and safely.

Is laser cutting environmentally friendly?

Laser cutting is considered more environmentally friendly compared to traditional cutting methods. It produces minimal waste due to its precision and efficiency. However, the environmental impact also depends on the materials used and the energy consumption of the laser cutter.

See Also

Understanding The Functionality Of CNC Laser Cutters

Maximizing Efficiency With Your Laser Cutting Machine

Guidelines For Effective Use Of Plasma Cutters