Tips for How to Cut Leather in Laser Machine

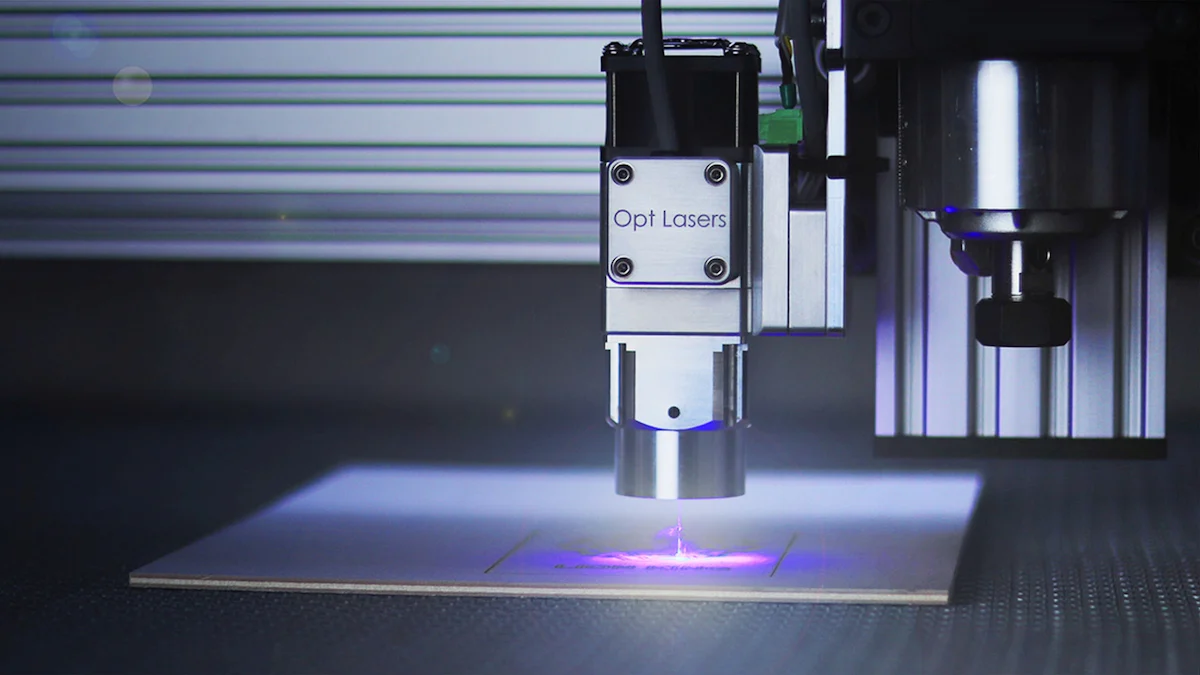

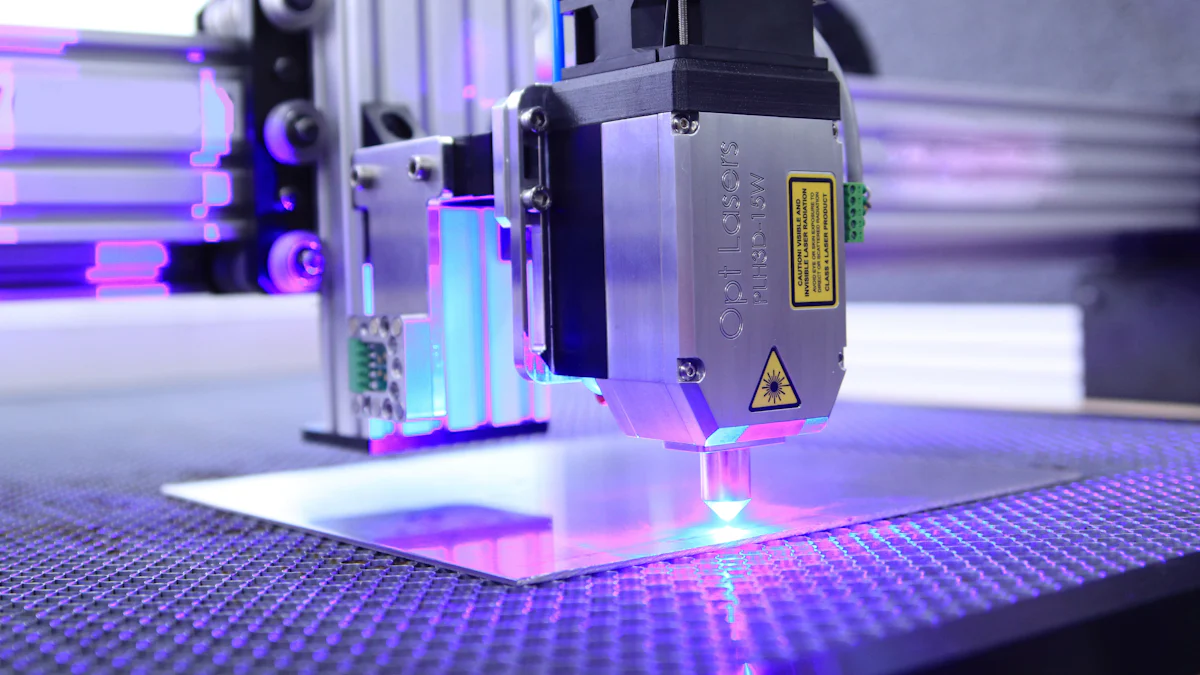

Cutting leather with a laser machine offers precision and efficiency. Understanding how to cut leather in a laser machine effectively is essential to achieve the best results. Selecting the right type of leather is crucial, as natural leather often provides better outcomes than synthetic options. Properly setting up your laser machine is equally important. A CO2 laser with a power rating of over 40W is recommended for cutting leather, as it ensures clean cuts with minimal edge burns. By mastering these aspects of how to cut leather in a laser machine, you can significantly enhance your leather cutting projects.

Selecting the Right Type of Leather

Natural vs. Synthetic Leather

Benefits of Natural Leather

When you choose natural leather for laser cutting, you gain several advantages. Natural leathers, such as full-grain, nubuck, and suede, respond well to laser cutting. They allow for intricate cuts and smooth edges. This type of leather, derived from animal hides, offers high-quality outcomes. Vegetable-tanned leather stands out due to its durability and responsiveness to detailed engravings. Its strength and flexibility make it ideal for creative laser engraving projects. You can achieve exceptional precision and intricate detailing, creating complex shapes with high accuracy.

Challenges with Synthetic Leather

Synthetic leather presents its own set of challenges. Unlike natural leather, synthetic options may not respond as well to laser cutting. They often lack the same level of durability and flexibility. This can lead to less precise cuts and potential issues with edge quality. Additionally, synthetic leather might produce more fumes and require different laser settings. You need to carefully test and adjust your laser machine to accommodate these differences. Understanding these challenges helps you make informed decisions when selecting leather for your projects.

Thickness and Quality Considerations

Choosing the Right Thickness

Selecting the right thickness of leather is crucial for successful laser cutting. Thicker leathers may require higher power settings, while thinner leathers benefit from lower power to prevent charring. You should consider the specific requirements of your project. For intricate designs, thinner leather allows for more detailed cuts. However, thicker leather provides added durability for items like belts or bags. By choosing the appropriate thickness, you ensure that your laser cutting results meet your expectations.

Assessing Leather Quality

Assessing the quality of leather is essential for achieving the best results. High-quality leather offers strength and flexibility, making it ideal for laser engraving. You should look for leather that is free from defects and has a consistent texture. This ensures that your cuts are clean and precise. Testing different types of leather on your laser machine can help you determine which quality works best for your needs. By prioritizing quality, you enhance the overall outcome of your laser cutting projects.

Setting Up the Laser Machine

Setting up your laser machine correctly is crucial for achieving precise cuts and minimizing damage to the leather. Understanding how to cut leather in a laser machine involves careful preparation and testing.

Testing Laser Settings

Importance of Test Cuts

Before you start your main project, conducting test cuts is essential. Test cuts help you determine the optimal settings for your specific type of leather. By experimenting with different power levels and speeds, you can find the perfect balance that allows for clean cuts without excessive charring. This step is particularly important when working with new or unfamiliar leather types. Testing ensures that you achieve the desired results and avoid wasting valuable materials.

Adjusting Power and Speed

Adjusting the power and speed settings on your laser machine is vital for effective leather cutting. A machine with adjustable power settings allows you to tailor the laser's intensity to the thickness and type of leather you are using. For thinner leathers, lower power settings prevent charring and maintain intricate details. Conversely, thicker leathers may require higher power to cut through effectively. By fine-tuning these settings, you can master how to cut leather in a laser machine with precision and efficiency.

Using a Cutting Mat

Benefits of a Cutting Mat

A cutting mat offers several advantages when laser cutting leather. It provides a stable surface that helps prevent the leather from shifting during the cutting process. This stability ensures that your cuts remain accurate and consistent. Additionally, a cutting mat protects the laser bed from potential damage caused by the laser beam. By using a cutting mat, you enhance the overall quality of your cuts and extend the lifespan of your laser machine.

Selecting the Right Mat

Choosing the right cutting mat is important for optimal results. Look for mats specifically designed for laser cutting, as they can withstand the heat generated by the laser. These mats often feature a grid pattern that aids in aligning your leather pieces accurately. Selecting a mat that matches the size of your laser bed ensures full coverage and protection. With the right cutting mat, you can improve your technique and achieve cleaner cuts.

Techniques to Prevent Damage

Avoiding Scorching and Burn Marks

When cutting leather with a laser machine, scorching and burn marks can be a common issue. However, you can take several steps to minimize these unwanted effects.

Dampening Leather

Dampening the leather before cutting can significantly reduce burn marks. By lightly moistening the surface, you create a barrier that absorbs some of the heat from the laser. This technique is particularly effective for vegetable-tanned leather, which responds well to moisture. You should ensure the leather is not too wet, as excessive moisture can affect the cutting process. A damp cloth or spray bottle can help achieve the right level of moisture.

Using Masking Techniques

Masking techniques offer another way to protect leather from scorching. Applying masking tape to the surface of the leather can shield it from direct laser exposure. The tape acts as a protective layer, absorbing some of the heat and preventing burn marks on the leather. You should choose a tape that is easy to remove and does not leave residue. This method works well for intricate designs where precision is crucial.

Maintaining Clean Cuts

Achieving clean cuts is essential for high-quality leather projects. Proper focus and alignment, along with regular maintenance of your laser machine, play a vital role in maintaining cut quality.

Proper Focus and Alignment

Proper focus and alignment of the laser beam are crucial for clean cuts. You need to ensure that the laser is focused correctly on the leather surface. Misalignment can lead to uneven cuts and poor edge quality. Adjust the focus according to the thickness of the leather you are using. Regularly check and calibrate your machine to maintain optimal performance. This attention to detail ensures that your cuts are precise and consistent.

Regular Maintenance of the Laser Machine

Regular maintenance of your laser machine is essential for preventing damage and ensuring clean cuts. Dust and debris can accumulate on the laser lens and mirrors, affecting the quality of the cut. You should clean these components regularly to maintain the machine's efficiency. Additionally, check for any signs of wear or damage and address them promptly. Keeping your machine in good condition enhances its performance and prolongs its lifespan.

By implementing these techniques, you can prevent damage and achieve high-quality results when cutting leather with a laser machine.

To master how to cut leather in a laser machine, focus on three key areas: selecting the right leather, setting up your machine, and preventing damage. Choose high-quality leather and clean its surface to ensure precise cuts. Adjust power and speed settings, perform test cuts, and maintain proper focus and alignment for optimal results. Experiment with different techniques and refine your approach to achieve high-quality outcomes. By following these steps, you can enhance your leather cutting projects and maintain the integrity of the material.

FAQ

What Kind of Laser Cutter is Needed to Cut Leather?

To cut leather effectively, you need a CO2 laser cutter. These machines are ideal for leather due to their ability to produce clean and precise cuts. A power rating of over 40W is recommended to ensure minimal edge burns and high-quality results.

How Do I Prevent Burn Marks on Leather?

To avoid burn marks, you can dampen the leather slightly before cutting. This technique helps absorb some of the heat from the laser. Additionally, using masking tape on the leather surface can protect it from direct laser exposure, reducing the risk of scorching.

Can I Cut Synthetic Leather with a Laser Machine?

Yes, you can cut synthetic leather with a laser machine. However, synthetic leather may not respond as well as natural leather. It often requires different settings and may produce more fumes. Testing and adjusting your laser settings can help achieve better results.

What Thickness of Leather Works Best for Laser Cutting?

The best thickness depends on your project. Thinner leathers allow for intricate designs and require lower power settings to prevent charring. Thicker leathers provide durability and may need higher power to cut through effectively. Choose the thickness based on your specific needs.

How Important Are Test Cuts?

Test cuts are crucial for determining the optimal settings for your leather type. By experimenting with different power levels and speeds, you can find the perfect balance for clean cuts without excessive charring. This step helps avoid wasting materials and ensures desired results.

Why Should I Use a Cutting Mat?

A cutting mat provides a stable surface, preventing the leather from shifting during the cutting process. It also protects the laser bed from potential damage. Using a cutting mat enhances cut quality and extends the lifespan of your laser machine.

How Do I Maintain Clean Cuts?

To maintain clean cuts, ensure proper focus and alignment of the laser beam. Regularly check and calibrate your machine to maintain optimal performance. Clean the laser lens and mirrors to prevent dust and debris from affecting cut quality.

Is Regular Maintenance of the Laser Machine Necessary?

Yes, regular maintenance is essential. It prevents damage and ensures clean cuts. Clean the laser components regularly and check for signs of wear or damage. Proper maintenance enhances machine performance and prolongs its lifespan.

Can I Use Any Type of Leather for Laser Cutting?

Not all leathers are suitable for laser cutting. Natural leathers like full-grain and vegetable-tanned leather respond well to laser cutting. They offer high-quality outcomes with intricate cuts and smooth edges. Assess the quality and type of leather before starting your project.

What Safety Precautions Should I Take?

Always wear safety glasses when operating a laser cutter. Leather cutting can produce smoke and sparks. Ensure proper ventilation to remove smoke and debris. Follow all safety guidelines provided by the laser machine manufacturer to ensure a safe working environment.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Essential Advice for Operating a Meat Cutting Machine

Effective Techniques for Operating a Key Cutting Machine